ASTM D1066-18e1

(Practice)Standard Practice for Sampling Steam

Standard Practice for Sampling Steam

SIGNIFICANCE AND USE

5.1 It is essential to extract and transport steam in a manner that provides the most representative sample of the process steam in order to accurately determine the amount of all impurities (dissolved chemicals, solid particles, chemicals absorbed on solid particles, water droplets) in it (1).3 An accurate measure of the purity of steam provides information that may be used to determine whether the purity of the steam is within necessary limits to prevent damage or deterioration (corrosion, solid particle erosion, flow-accelerated corrosion, and deposit buildup) of downstream equipment, such as turbines and process heat exchangers. The sources of impurities in the steam can include boiler water carryover, inefficient steam separators, natural salt solubility in the steam and other factors. The most commonly specified and analyzed parameters are sodium, silica, iron, copper, and cation conductivity.

SCOPE

1.1 This practice covers the sampling of saturated and superheated steam. It is applicable to steam produced in fossil fired and nuclear boilers or by any other process means that is at a pressure sufficiently above atmospheric to establish the flow of a representative sample. It is also applicable to steam at lower and subatmospheric pressures for which means must be provided to establish representative flow.

1.2 For information on specialized sampling equipment, tests or methods of analysis, reference should be made to the Annual Book of ASTM Standards, Vols 11.01 and 11.02, relating to water.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D1066 − 18

Standard Practice for

1

Sampling Steam

This standard is issued under the fixed designation D1066; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—3.2.1.1 was editorially corrected in December 2018.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice covers the sampling of saturated and

A269 Specification for Seamless and Welded Austenitic

superheated steam. It is applicable to steam produced in fossil

Stainless Steel Tubing for General Service

fired and nuclear boilers or by any other process means that is

A335/A335M Specification for Seamless Ferritic Alloy-

at a pressure sufficiently above atmospheric to establish the

Steel Pipe for High-Temperature Service

flowofarepresentativesample.Itisalsoapplicabletosteamat

D1129 Terminology Relating to Water

lower and subatmospheric pressures for which means must be

D3370 Practices for Sampling Water from Closed Conduits

provided to establish representative flow.

D5540 Practice for Flow Control and Temperature Control

1.2 For information on specialized sampling equipment, for On-Line Water Sampling and Analysis

tests or methods of analysis, reference should be made to the

3. Terminology

Annual Book of ASTM Standards, Vols 11.01 and 11.02,

3.1 Definitions:

relating to water.

3.1.1 For definitions of terms used in this standard, refer to

1.3 The values stated in SI units are to be regarded as

Terminology D1129.

standard. The values given in parentheses are mathematical

3.2 Definitions of Terms Specific to This Standard:

conversions to inch-pound units that are provided for informa-

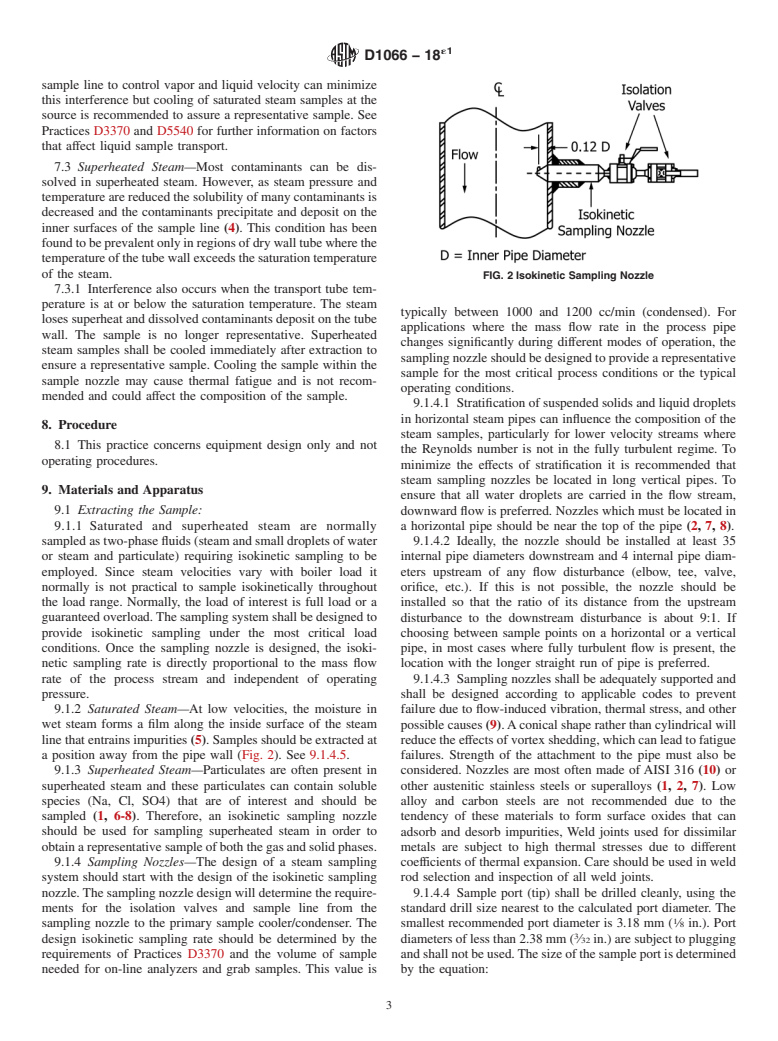

3.2.1 isokinetic sampling, n—a condition wherein the

tion only and are not considered standard.

sample entering the port (tip) of the sampling nozzle has the

1.4 This standard does not purport to address all of the

same velocity vector (velocity and direction) as the stream

safety concerns, if any, associated with its use. It is the

being sampled.

responsibility of the user of this standard to establish appro-

3.2.1.1 Discussion—Isokineticsamplingensuresarepresen-

priate safety, health, and environmental practices and deter-

tative sample of dissolved chemicals, solids, particles, chemi-

mine the applicability of regulatory limitations prior to use.

cals absorbed on solid particles, and in the case of saturated

and wet steam, water droplets are extracted from a process

1.5 This international standard was developed in accor-

stream.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 3.2.2 sample cooler, n—a small heat exchanger designed to

Development of International Standards, Guides and Recom- provide cooling/condensing of process sampling streams of

water or steam.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.2.3 sampling, n—the extraction of a representative portion

of the steam flowing in the boiler drum lead or pipeline by

means of a sampling nozzle and the delivery of this portion of

steam in a representative manner for analysis.

3.2.4 saturated steam, n—a vapor whose temperature cor-

responds to the boiling water temperature at the particular

1

This practice is under the jurisdiction of ASTM Committee D19 on Water and existing pressure.

is the direct responsibility of Subcommittee D19.03 on Sampling Water and

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use,

2

On-Line Water Analysis, and Surveillance of Water. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2018. Published August 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1949. Last previous edition approved in 2011 as D1066 – 11. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1066-18E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D1066 − 18

FIG. 1 Effect of Non-Isokinetic Sampling

3.2.5 superheated steam, n—a vapor whose temperature is 6. Hazards

above the boiling water temperature at the particular existing

6.1 The transport of steam samples may present high

pressure.

temperatu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.