ASTM D3350-00

(Specification)Standard Specification for Polyethylene Plastics Pipe and Fittings Materials

Standard Specification for Polyethylene Plastics Pipe and Fittings Materials

SCOPE

1.1 This specification covers the identification of polyethylene plastic pipe and fittings materials according to a cell classification system. It is not the function of this specification to provide specific engineering data for design purposes, to specify manufacturing tolerances, or to determine suitability for use for a specific application.

1.2 Polyethylene plastic materials, being thermoplastic, are reprocessable and recyclable (Note 2). This specification allows for the use of those polyethylene materials, provided that all specific requirements of this specification are met.

Note 1—The notes in this specification are for information only and shall not be considered part of this specification.

Note 2—See Guide D5033 for information and definitions related to recycled plastics.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 3—There is no similar or equivalent ISO standard.

1.5 For information regarding Molding and Extrusion Materials see D4976 Specification for Polyethylene Plastics Molding and Extrusion Materials. For information regarding Wire and Cable Materials see D1248 Specification for Polyethylene Plastics Extrusion Materials for Wire and Cable.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3350 – 00

Standard Specification for

Polyethylene Plastics Pipe and Fittings Materials

This standard is issued under the fixed designation D 3350; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * and Reinforced Plastics and Electrical Insulating Materi-

als

1.1 This specification covers the identification of polyeth-

D 792 Test Methods for Density and Specific Gravity (Rela-

ylene plastic pipe and fittings materials according to a cell

tive Density) of Plastics by Displacement

classification system. It is not the function of this specification

D 883 Terminology Relating to Plastics

to provide specific engineering data for design purposes, to

D 1238 Test Method for Flow Rates of Thermoplastics by

specify manufacturing tolerances, or to determine suitability

Extrusion Plastometer

for use for a specific application.

D 1248 Specification for Polyethylene Plastics Extrusion

1.2 Polyethylene plastic materials, being thermoplastic, are

Materials for Wire and Cable

reprocessable and recyclable (Note 2). This specification al-

D 1505 Test Method for Density of Plastics by the Density-

lows for the use of those polyethylene materials, provided that

Gradient Technique

all specific requirements of this specification are met.

D 1603 Test Method for Carbon Black in Olefin Plastics

NOTE 1—The notes in this specification are for information only and

D 1693 Test Method for Environmental Stress-Cracking of

shall not be considered part of this specification.

Ethylene Plastics

NOTE 2—See Guide D 5033 for information and definitions related to

D 1898 Practice for Sampling of Plastics

recycled plastics.

D 1928 Practice for Preparation of Compression-Molded

1.3 The values stated in SI units are to be regarded as the

Polyethylene Test Sheets and Test Specimens

standard.

D 2837 Test Method for Obtaining Hydrostatic Design

1.4 This standard does not purport to address all of the

Basis for Thermoplastic Pipe Materials

safety concerns, if any, associated with its use. It is the

D 3892 Practice for Packaging/Packing of Plastics

responsibility of the user of this standard to establish appro-

D 4976 Specification for Polyethylene Plastics Molding and

priate safety and health practices and determine the applica- 5

Extrusion Materials

bility of regulatory limitations prior to use.

D 5033 Guide for the Development of Standards Relating to

the Proper Use of Recycled Plastics

NOTE 3—There is no similar or equivalent ISO standard.

F 1473 Test Method for Notch Tensile Test to Measure the

1.5 For information regarding Molding and Extrusion Ma-

Resistance to Slow Crack Growth of Polyethylene Pipes

terials see D 4976 Specification for Polyethylene Plastics

and Resins

Molding and Extrusion Materials. For information regarding

Wire and Cable Materials see D 1248 Specification for Poly-

3. Terminology

ethylene Plastics Extrusion Materials for Wire and Cable.

3.1 Definitions—Terms as described in Terminology D 883

shall apply in this specification.

2. Referenced Documents

3.1.1 polyethylene plastics—as defined by this specification,

2.1 ASTM Standards:

2 plastics or resins prepared by the polymerization of no less than

D 618 Practice for Conditioning Plastics for Testing

85 % ethylene and no less than 95 % of total olefins with

D 638 M/[Metric] Test Method for Tensile Properties of

2 additional compounding ingredients.

Plastics

3.2 Definitions of Terms Specific to This Standard:

D 746 Test Method for Brittleness Temperature of Plastics

2 3.2.1 materials—polyethylene (PE) resins with the added

and Elastomers by Impact

compounding ingredients.

D 790 Test Methods for Flexural Properties of Unreinforced

3.2.2 PE compounds—has the same meaning as PE plastics

materials, compounds, and plastics.

3.3 Historical usage and user group conventions have re-

This specification is under the jurisdiction of ASTM Committee D20 on sulted in inconsistent terminology used to categorize and

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

Current edition approved Nov. 10, 2000. Published January 2001. Originally Annual Book of ASTM Standards, Vol 08.04.

published as D 3350 – 74. Last previous edition D 3350 – 99. Annual Book of ASTM Standards, Vol 08.02.

2 5

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 08.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3350

describe polyethylene resins and compounds. The following classified according to density, melt index, flexural modulus

terminology is in use in ASTM specifications pertaining to tensile strength at yield, environmental stress-crack resistance,

polyethylene:

and the hydrostatic design basis at 23°C in Table 1.

3.3.1 Specification D 1248:

NOTE 4—It has been a long-standing practice to use the following terms

3.3.1.1 Type (0, I, II, III, IV) = density ranges (same,

in describing polyethylene plastics:

respectively, as Class in Specification D 4976).

Type I (0.910 to 0.925) = Low Density

3.3.1.2 Class (A, B, C, D) = composition and use.

Type II (0.926 to 0.940) = Medium Density

3.3.1.3 Category (1, 2, 3, 4, 5) = melt index ranges (same as

Type III (0.941 to 0.965) = High Density

Grade in Specification D 4976).

NOTE 5—The manner in which materials are identified in the cell

3.3.1.4 Grade (E, J, D, or W followed by one or two digits)

classification is illustrated for Class PE233424B as follows (refer also to

= specific requirements from tables.

Table 1 and 6.2):

3.3.2 Specification D 3350:

3.3.2.1 Type (I, II, III) = density ranges (same as Types I, II,

and III in Specification D 1248 and Classes 1, 2, and 3 in

Specification D 4976).

3.3.2.2 Class = a line callout system consisting of “PE”

followed by six cell numbers from Table 1 plus a letter (A, B,

C, D, E) denoting color and UV stabilizer.

3.3.2.3 Grade = simplified line callout system using “PE”

followed by density and slow crack growth cell numbers from

Table 1.

3.3.3 Specification D 4976:

3.3.3.1 Group (1, 2) = branched or linear polyethylene.

3.3.3.2 Class (5, 1, 2, 3, 4) = density ranges (same,

respectively, as Type in Specification D 1248).

3.3.3.3 Grade (1, 2, 3, 4, 5) = melt index ranges (same as

Category in Specification D 1248). 4.2 Materials used in polyethylene plastic pipe and fittings

shall use a cell-type format for the identification, close char-

4. Classification

acterization, and specification of material properties. The

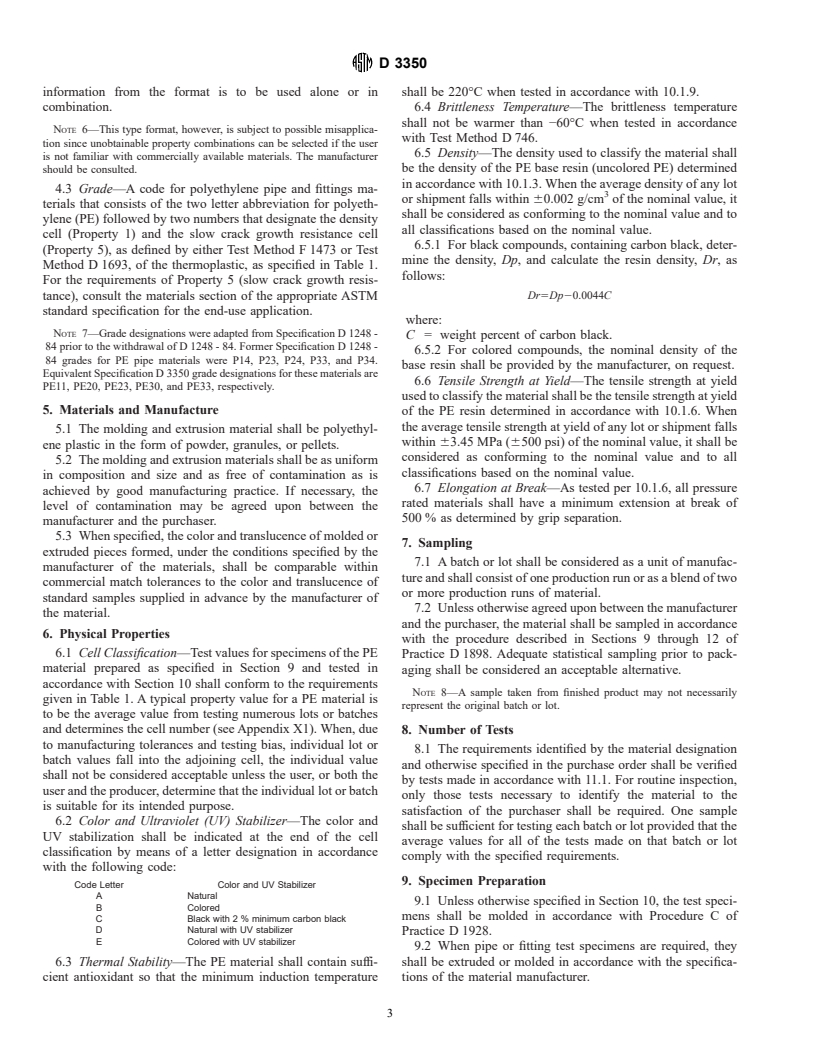

4.1 Polyethylene plastic pipe and fittings compounds are

TABLE 1 Primary Properties—Cell Classification Limits

Property Test Method 0 1 2 3 4 5 6 7

1 Density, g/cm D 1505 Unspecified 0.925 or >0.925 – >0.940 – >0.955 . . . . . . specify value

lower 0.940 0.955

A

2 Melt index D 1238 Unspecified >1.0 1.0 to 0.4 <0.4 to 0.15 <0.15 specify value

3 Flexural modulus, MPa D 790 Unspecified <138 138 – <276 276 – <552 552 – <758 758 – <1103 >1103 specify value

(psi) (<20 000) (20 000 to (40 000 to (80 000 to (110 000) to (>160 000)

<40 000) 80 000) 110 000) <160 000)

4 Tensile strength at yield, D 638 Unspecified <15 15 – <18 18 – <21 21 – <24 24 – <28 >28 specify value

MPa (psi) (<2200) (2200– (2600– (3000– (3500– (>4000)

<2600) <3000) <3500) <4000)

5 Slow Crack Growth

Resistance

I. ESCR D 1693 Unspecified

a. Test condition A B C C . . . . . . specify value

(100% Igepal.)

b. Test duration, h 48 24 192 600

c. Failure, max, % Unspecified 50 50 20 20 specify value

II. PENT (hours) F 1473

Molded plaque, 0.1 1 3 10 30 100

80°C, 2.4 MPa

Notch depth, F 1473, Unspecified specify value

Table 1

B

6 Hydrostatic design D 2837 NPR 5.52 6.89 8.62 11.03 . .

basis, MPa (psi), (800) (1000) (1250) (1600)

(23°C)

A

Refer to 10.1.4.1.

B

NPR = Not Pressure Rated.

D 3350

information from the format is to be used alone or in shall be 220°C when tested in accordance with 10.1.9.

combination. 6.4 Brittleness Temperature—The brittleness temperature

shall not be warmer than −60°C when tested in accordance

NOTE 6—This type format, however, is subject to possible misapplica-

with Test Method D 746.

tion since unobtainable property combinations can be selected if the user

6.5 Density—The density used to classify the material shall

is not familiar with commercially available materials. The manufacturer

should be consulted. be the density of the PE base resin (uncolored PE) determined

in accordance with 10.1.3. When the average density of any lot

4.3 Grade—A code for polyethylene pipe and fittings ma-

or shipment falls within 60.002 g/cm of the nominal value, it

terials that consists of the two letter abbreviation for polyeth-

shall be considered as conforming to the nominal value and to

ylene (PE) followed by two numbers that designate the density

all classifications based on the nominal value.

cell (Property 1) and the slow crack growth resistance cell

6.5.1 For black compounds, containing carbon black, deter-

(Property 5), as defined by either Test Method F 1473 or Test

mine the density, Dp, and calculate the resin density, Dr,as

Method D 1693, of the thermoplastic, as specified in Table 1.

follows:

For the requirements of Property 5 (slow crack growth resis-

tance), consult the materials section of the appropriate ASTM Dr5Dp20.0044C

standard specification for the end-use application.

where:

NOTE 7—Grade designations were adapted from Specification D 1248 -

C = weight percent of carbon black.

84 prior to the withdrawal of D 1248 - 84. Former Specification D 1248 -

6.5.2 For colored compounds, the nominal density of the

84 grades for PE pipe materials were P14, P23, P24, P33, and P34.

base resin shall be provided by the manufacturer, on request.

Equivalent Specification D 3350 grade designations for these materials are

6.6 Tensile Strength at Yield—The tensile strength at yield

PE11, PE20, PE23, PE30, and PE33, respectively.

used to classify the material shall be the tensile strength at yield

5. Materials and Manufacture

of the PE resin determined in accordance with 10.1.6. When

the average tensile strength at yield of any lot or shipment falls

5.1 The molding and extrusion material shall be polyethyl-

within 63.45 MPa (6500 psi) of the nominal value, it shall be

ene plastic in the form of powder, granules, or pellets.

considered as conforming to the nominal value and to all

5.2 The molding and extrusion materials shall be as uniform

classifications based on the nominal value.

in composition and size and as free of contamination as is

6.7 Elongation at Break—As tested per 10.1.6, all pressure

achieved by good manufacturing practice. If necessary, the

rated materials shall have a minimum extension at break of

level of contamination may be agreed upon between the

500 % as determined by grip separation.

manufacturer and the purchaser.

5.3 When specified, the color and translucence of molded or

7. Sampling

extruded pieces formed, under the conditions specified by the

7.1 A batch or lot shall be considered as a unit of manufac-

manufacturer of the materials, shall be comparable within

ture and shall consist of one production run or as a blend of two

commercial match tolerances to the color and translucence of

or more production runs of material.

standard samples supplied in advance by the manufacturer of

7.2 Unless otherwise agreed upon between the manufacturer

the material.

and the purchaser, the material shall be sampled in accordance

6. Physical Properties

with the procedure described in Sections 9 through 12 of

6.1 Cell Classification—Test values for specimens of the PE

Practice D 1898. Adequate statistical sampling prior to pack-

material prepared as specified in Section 9 and tested in

aging shall be considered an acceptable alternative.

accordance with Section 10 shall conform to the requirements

NOTE 8—A sample taken from finished product may not necessarily

given in Table 1. A typical property value for a PE material is

represent the original batch or lot.

to be the average value from testing numerous lots or batches

and determines the cell number (see Appendix X1). When, due 8. Number of Tests

to manufacturing tolerances and testing bias, individual lot or

8.1 The requirements identified by the material designation

batch values fall into the adjoining cell, the individual value

and otherwise specified in the purchase order shall be verified

shall not be considered acceptable unless the user, or both the

by tests made in accordance with 11.1. For routine inspection,

user and the producer, determine that the individual lot or batch

only those tests necessary to identify the material to the

is suitable for its intended purpose.

satisfaction of the purchaser shall be required. One sample

6.2 Color and Ultraviolet (UV) Stabilizer—The color and

shall be sufficient for testing each batch or lot provided that the

UV stabilization shall be indicated at the end of the cell

average values for all of the tests made on that batch or lot

classification by means of a letter designation in accordance

comply with the specified requirements.

with the following code:

9. Specimen Preparation

Code Letter Color and UV Stabilizer

A Natural

9.1 Unless otherwise specified in Section 10, the test speci-

B Colored

mens shall be molded in accordance with Procedure C of

C Black with 2 % minimum carbon black

D Natural with UV stabilizer

Practice D 1928.

E Colored with UV stabilizer

9.2 When pipe or fitting test specimens are required, they

6.3 Thermal Stability—The PE material shall contain suffi- shall be extruded or molded in accordance with the specifica-

cient antioxidant so that the minimum induction temperature tions of the material manufacturer.

D 3350

FIG. 1 Mounting Film Specimen in Cup

NOTE 9—Flow rate is the general term used for all results obtained with

10. Test Methods

Test Method D 1238. Although the flow rate of polyethylene plastics may

10.1 The properties enumerated in this specification shall be

be measured under any of the conditions listed for it under 7.2 of Test

determined in accordance with the following test methods:

Method D 1238, only measurements made at Condition 190/2.16 may be

10.1.1 Conditioning— Unless otherwise specified in the test

identified as “Melt Index.”

methods or in this specification, for those tests where condi-

10.1.5 Flexural Modulus— Test Methods D 790, using

tioning is required, condition the molded test specimens in

Method 1, Procedure B, and a 50-mm (2-in.) test span. Test five

accordance wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.