ASTM E3044/E3044M-22

(Practice)Standard Practice for Ultrasonic Testing of Polyethylene Butt Fusion Joints

Standard Practice for Ultrasonic Testing of Polyethylene Butt Fusion Joints

SIGNIFICANCE AND USE

5.1 This practice is intended primarily for the automated or semi-automated ultrasonic examination of butt fusion joints used in the construction of polyethylene piping systems.

5.2 Polyethylene piping has been used in lieu of steel alloys in the petrochemical, power, water, gas distribution and mining industries due to its reliability and resistance to corrosion and erosion. Recently, polyethylene pipe has also been used for nuclear safety-related cooling water applications.

5.3 Two ultrasonic techniques have proven useful to provide examination of fusion joint integrity; Ultrasonic time-of-flight-diffraction (TOFD) and phased array ultrasonic testing (PAUT). These techniques are often considered complementary but may be used independently of each other. The choice of the technique used may depend on a variety of parameters including diameter, thickness, surface access, detection capabilities near surfaces, and quality level required.

5.4 The joining process can be subject to a variety of flaws including, but not limited to: lack of fusion, particulate contamination, inclusions, and voids.

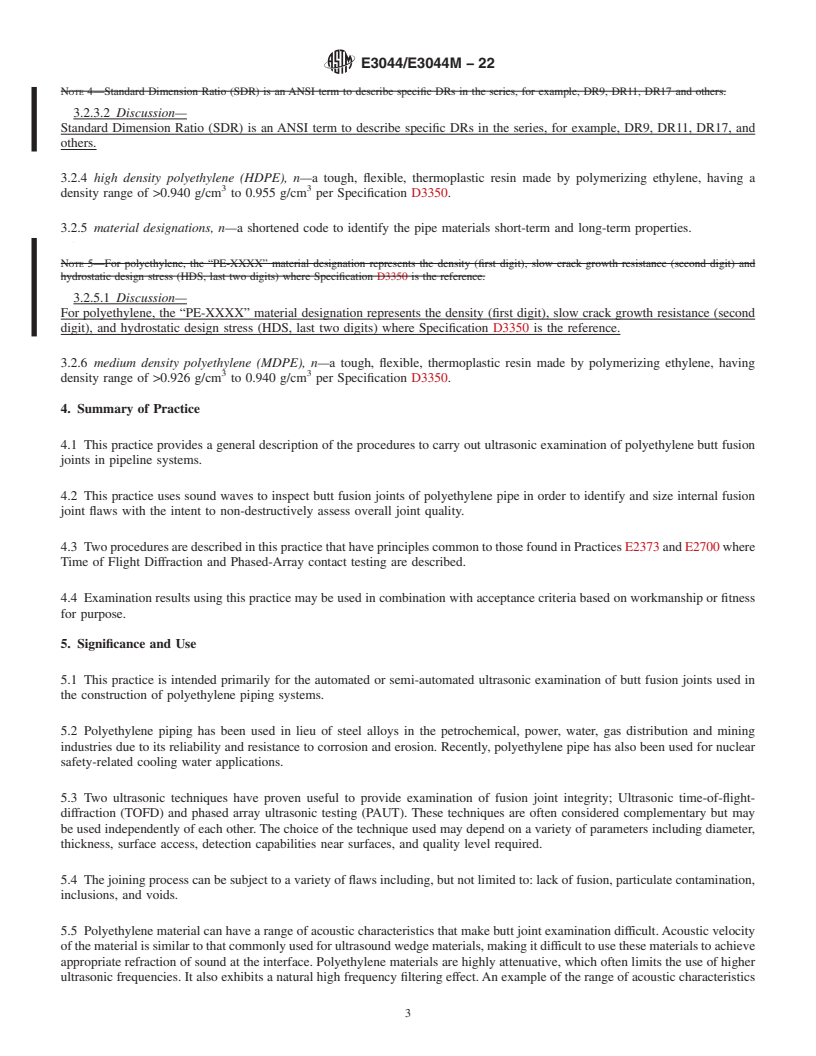

5.5 Polyethylene material can have a range of acoustic characteristics that make butt joint examination difficult. Acoustic velocity of the material is similar to that commonly used for ultrasound wedge materials, making it difficult to use these materials to achieve appropriate refraction of sound at the interface. Polyethylene materials are highly attenuative, which often limits the use of higher ultrasonic frequencies. It also exhibits a natural high frequency filtering effect. An example of the range of acoustic characteristics is provided in Table 1. The table notes the wide range of acoustic velocities reported in the literature. This makes it essential that the reference blocks are made of the same cell classification6 as that examined. This shall be confirmed by measuring the acoustic velocity of the pipe being examined as described in Practice E494. The acous...

SCOPE

1.1 This practice establishes procedures for ultrasonic testing (UT) of butt fusion joints in polyethylene pipe. Although high density polyethylene (HDPE) and medium density polyethylene (MDPE) materials are most commonly used, the procedures described may apply to other types of polyethylene.

Note 1: The notes in this practice are for information only and shall not be considered part of this specification.

Note 2: This practice references HDPE and MDPE for pipe applications as defined by Specification D3350.

1.2 This practice does not address ultrasonic examination of electrofusion joints (coupling joints), socket joints, or saddles.

1.3 This practice provides two ultrasonic examination procedures. Each has its own merits and requirements for examination and shall be selected as agreed upon in a contractual document.

1.3.1 Examination Procedure A, Time of Flight Diffraction (TOFD), uses a pair of probes, one transmitting and the other receiving. The procedure usually, although not necessarily, requires access to both sides of the joint from one surface. Provided that position encoding is used, the procedure can be conducted by semi-automated or automated means that provide recoded imaging.

1.3.2 Examination Procedure B, Phased Array Ultrasonic Testing (PAUT), uses low velocity refracting wedges or water gaps to produce angled compression mode pulses. The procedure can be applied where access is limited to one side of the joint from one surface. Provided that position encoding is used, the procedure can be conducted by semi-automated or automated means that provide recoded imaging.

1.4 The practice is intended to be used on thicknesses of 9 to 60 mm [0.375 to 2.4 in.] and diameters 100 mm [4 in.] and greater. Greater and lesser thicknesses and lesser diameters may be tested using this standard practice if the technique can be demonstrated to provide adequate detection on mockups of the same wall thickn...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3044/E3044M − 22

Standard Practice for

1

Ultrasonic Testing of Polyethylene Butt Fusion Joints

ThisstandardisissuedunderthefixeddesignationE3044/E3044M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.6 Units—The values stated in either SI units or inch-

pound units are to be regarded separately as standard. The

1.1 This practice establishes procedures for ultrasonic test-

values stated in each system are not necessarily exact equiva-

ing (UT) of butt fusion joints in polyethylene pipe. Although

lents; therefore, to ensure conformance with the standard, each

high density polyethylene (HDPE) and medium density poly-

system shall be used independently of the other, and values

ethylene (MDPE) materials are most commonly used, the

from the two systems shall not be combined.

proceduresdescribedmayapplytoothertypesofpolyethylene.

NOTE 1—The notes in this practice are for information only and shall 1.7 This standard does not purport to address all of the

not be considered part of this specification.

safety concerns, if any, associated with its use. It is the

NOTE 2—This practice references HDPE and MDPE for pipe applica-

responsibility of the user of this standard to establish appro-

tions as defined by Specification D3350.

priate safety, health, and environmental practices and deter-

1.2 This practice does not address ultrasonic examination of

mine the applicability of regulatory limitations prior to use.

electrofusion joints (coupling joints), socket joints, or saddles.

1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.3 This practice provides two ultrasonic examination pro-

ization established in the Decision on Principles for the

cedures. Each has its own merits and requirements for exami-

Development of International Standards, Guides and Recom-

nation and shall be selected as agreed upon in a contractual

mendations issued by the World Trade Organization Technical

document.

Barriers to Trade (TBT) Committee.

1.3.1 Examination Procedure A, Time of Flight Diffraction

(TOFD), uses a pair of probes, one transmitting and the other

2. Referenced Documents

receiving. The procedure usually, although not necessarily,

2.1 The following documents form a part of this practice to

requires access to both sides of the joint from one surface.

the extent specified herein.

Provided that position encoding is used, the procedure can be

2

conductedbysemi-automatedorautomatedmeansthatprovide

2.2 ASTM Standards:

recoded imaging.

D3350 Specification for Polyethylene Plastics Pipe and Fit-

1.3.2 Examination Procedure B, Phased Array Ultrasonic

tings Materials

Testing (PAUT), uses low velocity refracting wedges or water

E494 Practice for Measuring Ultrasonic Velocity in Materi-

gaps to produce angled compression mode pulses. The proce-

als by Comparative Pulse-Echo Method

dure can be applied where access is limited to one side of the

E543 Specification forAgencies Performing Nondestructive

jointfromonesurface.Providedthatpositionencodingisused,

Testing

the procedure can be conducted by semi-automated or auto-

E1316 Terminology for Nondestructive Examinations

mated means that provide recoded imaging.

E2373 Practice for Use of the Ultrasonic Time of Flight

Diffraction (TOFD) Technique

1.4 The practice is intended to be used on thicknesses of 9

E2700 Practice for Contact Ultrasonic Testing of Welds

to 60 mm [0.375 to 2.4 in.] and diameters 100 mm [4 in.] and

Using Phased Arrays

greater. Greater and lesser thicknesses and lesser diameters

F2620 PracticeforHeatFusionJoiningofPolyethylenePipe

may be tested using this standard practice if the technique can

and Fittings

be demonstrated to provide adequate detection on mockups of

3

2.3 ASNT Standards:

the same wall thickness and geometry.

ASNT Practice SNT-TC-1A Personnel Qualification and

1.5 This practice does not specify acceptance criteria.

Certification in Nondestructive Testing

1 2

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

structive Testing and is the direct responsibility of Subcommittee E07.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Ultrasonic Method. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2022. Published February 2022. Originally the A

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E3044/E3044M − 16 E3044/E3044M − 22

Standard Practice for

1

Ultrasonic Testing of Polyethylene Butt Fusion Joints

This standard is issued under the fixed designation E3044/E3044M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Subsection 5.2 corrected editorially in September 2016.

1. Scope Scope*

1.1 This standard practice establishes procedures for ultrasonic testing (UT) of butt fusion joints in polyethylene pipe. Although

high density polyethylene (HDPE) and medium density polyethylene (MDPE) materials are most commonly used, the procedures

described may apply to other types of polyethylene.

NOTE 1—The notes in this specificationpractice are for information only and shall not be considered part of this specification.

NOTE 2—This standardpractice references HDPE and MDPE for pipe applications as defined by Specification D3350.

1.2 This standard practice does not address ultrasonic examination of electrofusion joints (coupling joints), socket joints, or

saddles.

1.3 This practice provides two ultrasonic examination procedures. Each has its own merits and requirements for examination and

shall be selected as agreed upon in a contractual document.

1.3.1 Examination Procedure A, Time of Flight Diffraction (TOFD), uses a pair of probes, one transmitting and the other receiving.

The procedure usually, although not necessarily, requires access to both sides of the joint from one surface. Provided that position

encoding is used, the procedure can be conducted by semi-automated or automated means that provide recoded imaging.

1.3.2 Examination Procedure B, Phased Array Ultrasonic Testing (PAUT), uses low velocity refracting wedges or water gaps to

produce angled compression mode pulses. The procedure can be applied where access is limited to one side of the joint from one

surface. Provided that position encoding is used, the procedure can be conducted by semi-automated or automated means that

provide recoded imaging.

1.4 The practice is intended to be used on thicknesses of 9 to 60 mm (0.375[0.375 to 2.4 in.)in.] and diameters 100 mm (4 in.)[4

in.] and greater. Greater and lesser thicknesses and lesser diameters may be tested using this standard practice if the technique can

be demonstrated to provide adequate detection on mockups of the same wall thickness and geometry.

1.5 This practice does not specify acceptance criteria.

1.6 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic Method.

Current edition approved Aug. 1, 2016Feb. 1, 2022. Published August 2016February 2022. Originally approved in 2016. Last previous edition approved in 2016 as

ε1

E3044/E3044M – 16 . DOI: 10.1520/E3044_E3044M-16.10.1520/E3044_E3044M-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3044/E3044M − 22

each system mayare not benecessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be

used independently of the other. Combiningother, and values from the two systems may result in non-conformance with the

standard.shall not be combined.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents form a part of this practice to the extent specified herein.

2

2.2 ASTM Standards:

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.