ASTM D3350-21

(Specification)Standard Specification for Polyethylene Plastics Pipe and Fittings Materials

Standard Specification for Polyethylene Plastics Pipe and Fittings Materials

ABSTRACT

This specification covers the identification of polyethylene plastic pipe and fitting materials. Cell classification of materials shall be according to tests of primary properties like density, melt index, flexural modulus, tensile strength at yield, slow crack growth resistance, and hydrostatic strength classification. Materials shall be manufactured by molding and extrusion of polyethylene plastic in the form of powder, granules, or pellets. Color and ultraviolet stabilizer, thermal stability, brittleness temperature, density, tensile strength at yield, and elongation at break shall conform to this specification.

SCOPE

1.1 This specification covers the identification of polyethylene plastic pipe and fittings materials in accordance with a cell classification system. It is not the function of this specification to provide specific engineering data for design purposes, to specify manufacturing tolerances, or to determine suitability for use for a specific application.

1.1.1 Some plastic pipe and fitting PE compounds classified by this standard are sold as a base material and then combined with other material(s) (for example, color or additive concentrate) by the pipe or fitting manufacturer into a final classified compound either prior to or during production of the final article. This standard, excluding the requirements of Table 1, properties 5 and 6, and 6.1.1, can be used for property verification of the incoming base material(s) in accordance with 8.1.

1.1.2 In the case of PE compounds sold as the compound classified by the standard, see 8.1 regarding property verification of the incoming classified compound.

1.1.3 Compounds with a cell classification value other than ‘0’ for the Hydrostatic Strength Classification (property 6) rely on a defined formulation. The composition of the defined formulation can be obtained from the owner of the formulation.

Note 1: Deviations from the defined formulation may affect the Hydrostatic Strength Classification.

1.2 Polyethylene plastic materials, being thermoplastic, are reprocessable and recyclable (Note 3). This specification allows for the use of those polyethylene materials, provided that all specific requirements of this specification are met.

Note 2: The notes in this specification are for information only and shall not be considered part of this specification.

Note 3: See Guide D5033 for information and definitions related to recycled plastics.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 4: There is no known ISO equivalent to this standard.

1.5 For information regarding molding and extrusion materials see Specification D4976. For information regarding wire and cable materials see Specification D1248.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D3350 −21

Standard Specification for

1

Polyethylene Plastics Pipe and Fittings Materials

This standard is issued under the fixed designation D3350; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This specification covers the identification of polyeth-

mine the applicability of regulatory limitations prior to use.

ylene plastic pipe and fittings materials in accordance with a

cell classification system. It is not the function of this specifi-

NOTE 4—There is no known ISO equivalent to this standard.

cationtoprovidespecificengineeringdatafordesignpurposes,

1.5 For information regarding molding and extrusion mate-

to specify manufacturing tolerances, or to determine suitability

rials see Specification D4976. For information regarding wire

for use for a specific application.

and cable materials see Specification D1248.

1.1.1 Some plastic pipe and fitting PE compounds classified

1.6 This international standard was developed in accor-

by this standard are sold as a base material and then combined

dance with internationally recognized principles on standard-

with other material(s) (for example, color or additive concen-

ization established in the Decision on Principles for the

trate) by the pipe or fitting manufacturer into a final classified

Development of International Standards, Guides and Recom-

compound either prior to or during production of the final

mendations issued by the World Trade Organization Technical

article. This standard, excluding the requirements of Table 1,

Barriers to Trade (TBT) Committee.

properties 5 and 6, and 6.1.1, can be used for property

verification of the incoming base material(s) in accordance

2. Referenced Documents

with 8.1.

2

2.1 ASTM Standards:

1.1.2 In the case of PE compounds sold as the compound

D618Practice for Conditioning Plastics for Testing

classified by the standard, see 8.1 regarding property verifica-

D638Test Method for Tensile Properties of Plastics

tion of the incoming classified compound.

D746Test Method for Brittleness Temperature of Plastics

1.1.3 Compounds with a cell classification value other than

and Elastomers by Impact

‘0’for the Hydrostatic Strength Classification (property 6) rely

D790Test Methods for Flexural Properties of Unreinforced

on a defined formulation. The composition of the defined

and Reinforced Plastics and Electrical Insulating Materi-

formulationcanbeobtainedfromtheowneroftheformulation.

als

NOTE 1—Deviations from the defined formulation may affect the

D792Test Methods for Density and Specific Gravity (Rela-

Hydrostatic Strength Classification.

tive Density) of Plastics by Displacement

1.2 Polyethylene plastic materials, being thermoplastic, are

D883Terminology Relating to Plastics

reprocessable and recyclable (Note 3). This specification al-

D1238Test Method for Melt Flow Rates of Thermoplastics

lows for the use of those polyethylene materials, provided that

by Extrusion Plastometer

all specific requirements of this specification are met.

D1248Specification for Polyethylene Plastics Extrusion

Materials for Wire and Cable

NOTE 2—The notes in this specification are for information only and

D1505Test Method for Density of Plastics by the Density-

shall not be considered part of this specification.

NOTE 3—See Guide D5033 for information and definitions related to Gradient Technique

recycled plastics.

D1603Test Method for Carbon Black Content in Olefin

Plastics

1.3 The values stated in SI units are to be regarded as

standard. D1693Test Method for Environmental Stress-Cracking of

Ethylene Plastics

1.4 This standard does not purport to address all of the

3

D1898Practice for Sampling of Plastics (Withdrawn 1998)

safety concerns, if any, associated with its use. It is the

1 2

This specification is under the jurisdiction of ASTM Committee D20 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Materials. Standards volume information, refer to the standard’s Document Summary page on

CurrenteditionapprovedJuly1,2021.PublishedJuly2021.Originallyapproved the ASTM website.

3

in 1974. Last previous edition approved in 2014 as D3350–14. DOI: 10.1520/ The last approved version of this historical standard

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3350 − 14 D3350 − 21

Standard Specification for

1

Polyethylene Plastics Pipe and Fittings Materials

This standard is issued under the fixed designation D3350; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers the identification of polyethylene plastic pipe and fittings materials in accordance with a cell

classification system. It is not the function of this specification to provide specific engineering data for design purposes, to specify

manufacturing tolerances, or to determine suitability for use for a specific application.

1.1.1 Some plastic pipe and fitting PE compounds classified by this standard are sold as a base material and then combined with

other material(s) (for example, color or additive concentrate) by the pipe or fitting manufacturer into a final classified compound

either prior to or during production of the final article. This standard, excluding the requirements of Table 1, properties 5 and 6,

and 6.1.1, can be used for property verification of the incoming base material(s) in accordance with 8.1.

1.1.2 In the case of PE compounds sold as the compound classified by the standard, see 8.1 regarding property verification of the

incoming classified compound.

1.1.3 Compounds with a cell classification value other than ‘0’ for the Hydrostatic Strength Classification (property 6) rely on a

defined formulation. The composition of the defined formulation can be obtained from the owner of the formulation.

NOTE 1—Deviations from the defined formulation may affect the Hydrostatic Strength Classification.

1.2 Polyethylene plastic materials, being thermoplastic, are reprocessable and recyclable (Note 23). This specification allows for

the use of those polyethylene materials, provided that all specific requirements of this specification are met.

NOTE 2—The notes in this specification are for information only and shall not be considered part of this specification.

NOTE 3—See Guide D5033 for information and definitions related to recycled plastics.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 3—There is no known ISO equivalent to this standard.

NOTE 4—There is no known ISO equivalent to this standard.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved Nov. 1, 2014July 1, 2021. Published December 2014July 2021. Originally approved in 1974. Last previous edition approved in 20122014 as

ϵ1

D3350 – 12D3350 – 14. . DOI: 10.1520/D3350-14.10.1520/D3350-21.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3350 − 21

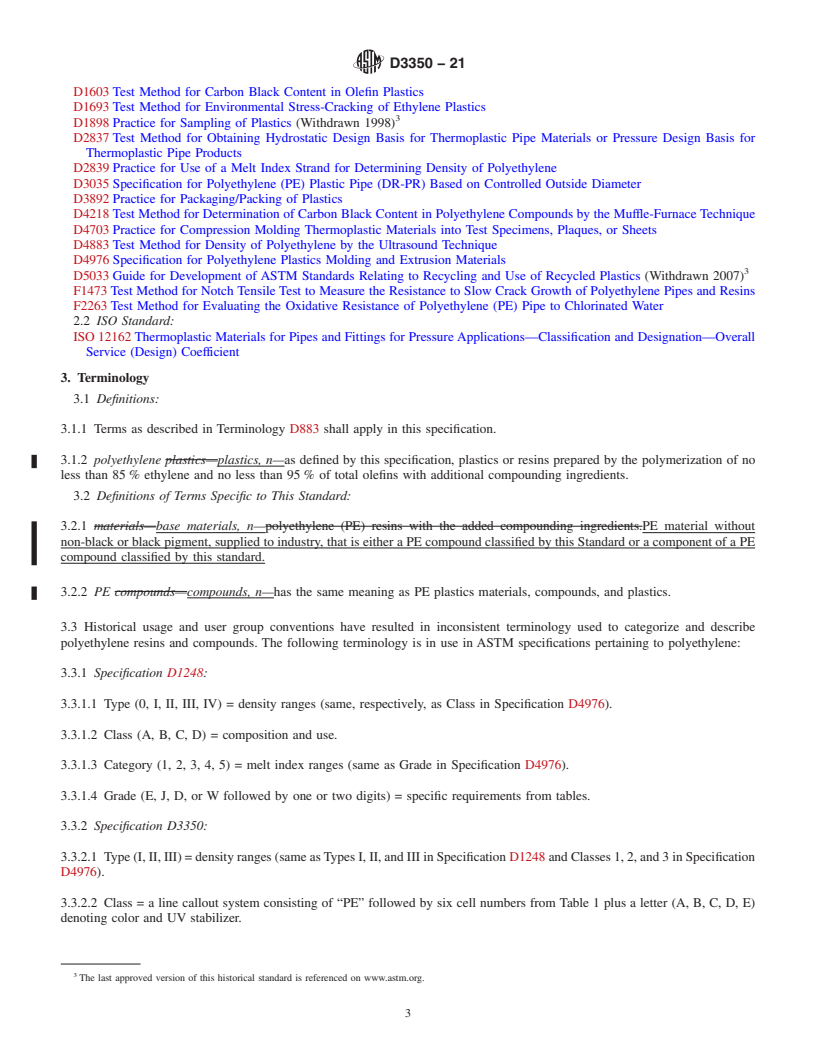

A

TABLE 1 Primary Properties —Cell Classification Limits

Test

Property 0 1 2 3 4 5 6 7 8

Method

3

1. Density, g/cm D1505 Unspecified 0.925 or >0.925- >0.940- >0.947- >0.955 . . . Specify

lower 0.940 0.947 0.955 Value

B C

2. Melt index D1238 Unspecified >1.0 1.0 to <0.4 to <0.15 Specify

0.4 0.15 Value

3. Flexural D790 Unspecified <138 138- 276- 552- 758- >1103 Specify

modulus, MPa (psi) (<20 000) <276 <552 <758 <1103 (>160 000) Value

(20 000 to (40 000 to (80 000 to (110 000 to

<40 000) 80 000) 110 000) <160 000)

4. Tensile strength D638 Unspecified <15 15-<18 18-<21 21-<24 24-<28 >28 Specify

at yield, MPa (psi) (<2200) (2200- (2600- (3000- (3500- (>4000) Value

<2600) <3000) <3500) <4000)

5. Slow Crack

Growth Resistance

I. ESCR D1693 Unspecified

a. Test condition A B C C . . . . . . . . . Specify

D

(100% Igepal.) Value

b. Test duration, h 48 24 192 600

c. Failure, max, % Unspecified 50 50 20 20

II. PENT (hours) F1473

Molded plaque, Unspecified . . . . . . . . . 10 30 100 500 Specify

80°C, 2.4 MPa Value

Notch depth, Unspecified

F1473, Table 1

6. Hydrostatic Strength

Classification

E

I. Hydrostatic design D2837 NPR 5.52 6.89 8.62 11.03 . . . . . .

bas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.