ASTM D6751-02

(Specification)Standard Specification for Biodiesel Fuel (B100) Blend Stock for Distillate Fuels

Standard Specification for Biodiesel Fuel (B100) Blend Stock for Distillate Fuels

SCOPE

1.1 This specification covers low sulfur biodiesel (B100) for use as a blend component with diesel fuel oils defined by Specification D 975 Grades 1-D, 2-D, and low sulfur 1-D and 2-D.

1.2 Biodiesel may be blended with fuel oils whose sulfur or aromatic levels are outside Specification D 975 Grades 1-D, 2-D, and low sulfur 1-D and 2-D, provided the finished mixture meets pertinent national and local specifications and requirements for these properties.

1.3 This specification, unless otherwise provided by agreement between the purchaser and the supplier, prescribes the required properties of biodiesel fuel at the time and place of delivery.

1.4 Nothing in this specification shall preclude observance of federal, state, or local regulations which may be more restrictive.

Note 1—The generation and dissipation of static electricity can create problems in the handling of distillate fuel oils with which biodiesel may be blended. For more information on the subject, see Guide D 4865.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6751 – 02

Standard Specification for

Biodiesel Fuel (B100) Blend Stock for Distillate Fuels

This standard is issued under the fixed designation D 6751; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 874 Test Method for Sulfated Ash from Lubricating Oils

and Additives

1.1 This specification covers low sulfur biodiesel (B100) for

D 974 Test Method for Acid and Base Number by Color-

use as a blend component with diesel fuel oils defined by

Indicator Titration

Specification D 975 Grades 1-D, 2-D, and low sulfur 1-D and

D 975 Specification for Diesel Fuel Oils

2-D.

D 976 Test Methods for Calculated Cetane Index of Distil-

1.2 Biodiesel may be blended with fuel oils whose sulfur or

late Fuels

aromatic levels are outside Specification D 975 Grades 1-D,

D 1160 Test Method for Distillation of Petroleum Products

2-D, and low sulfur 1-D and 2-D, provided the finished mixture

at Reduced Pressure

meets pertinent national and local specifications and require-

D 1266 Test Method for Sulfur in Petroleum Products

ments for these properties.

(Lamp Method)

1.3 This specification, unless otherwise provided by agree-

D 1796 Test Method for Water and Sediment in Fuel Oils by

ment between the purchaser and the supplier, prescribes the

the Centrifuge Method (Laboratory Procedure)

required properties of biodiesel fuel at the time and place of

D 2274 Test Method for Oxidation Stability of Distillate

delivery.

Fuel Oil (Accelerated Method)

1.4 Nothing in this specification shall preclude observance

D 2500 Test Method for Cloud Point of Petroleum Prod-

of federal, state, or local regulations which may be more

ucts

restrictive.

D 2622 Test Method for Sulfur in Petroleum Products by

NOTE 1—The generation and dissipation of static electricity can create 4

Wavelength Dispersive X-ray Fluorescence Spectrometry

problems in the handling of distillate fuel oils with which biodiesel may

D 2709 Test Method for Water and Sediment in Middle

be blended. For more information on the subject, see Guide D 4865.

Distillate Fuels by Centrifuge

D 2880 Specification for Gas Turbine Fuel Oils

2. Referenced Documents

D 3117 Test Method for Wax Appearance Point of Distillate

2.1 ASTM Standards:

Fuels

D 93 Test Methods for Flash-Point by Pensky-Martens

2 D 3120 Test Method for Trace Quantities of Sulfur in Light

Closed Cup Tester

Liquid Petroleum Hydrocarbons by Oxidative Microcou-

D 130 Test Method for Detection of Copper Corrosion from

2 lometry

Petroleum Products by the Copper Strip Tarnish Test

D 3242 Test Method for Acidity in Aviation Turbine Fuel

D 189 Test Method for Conradson Carbon Residue of

2 D 3828 Test Method for Flash Point by Small Scale Closed

Petroleum Products

Tester

D 445 Test Method for Kinematic Viscosity of Transparent

D 4057 Practice for Manual Sampling of Petroleum and

and Opaque Liquids (the Calculation of Dynamic Viscos-

Petroleum Products

ity)

D 4177 Practice for Automatic Sampling of Petroleum and

D 524 Test Method for Ramsbottom Carbon Residue of

Petroleum Products

Petroleum Products

3 D 4294 Test Method for Sulfur in Petroleum and Petroleum

D 613 Test Method for Cetane Number of Diesel Fuel Oil

Products by Energy Dispersive X-ray Fluorescence Spec-

D 664 Test Method for Acid Number of Petroleum Products

2 trometry

by Potentiometric Titration

D 4530 Test Method for Determination of Carbon Residue

(Micro Method)

1 D 4737 Test Method for Calculated Cetane Index by Four

This specification is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee Variable Equation

D02.Eon Burner, Diesel, Non-Aviation Gas Turbine and Marine Fuels.

D 4865 Guide for Generation and Dissipation of Static

Current edition approved Jan. 10, 2002. Published February 2002. Originally

published as PS 121 – 99.

Annual Book of ASTM Standards, Vol 05.01.

3 4

Annual Book of ASTM Standards, Vol 05.05. Annual Book of ASTM Standards, Vol 05.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6751

Electricity in Petroleum Fuel Systems 4.2 Unless otherwise specified, samples for analysis shall be

D 4951 Test Method for Determination of Additive Ele- taken by the procedure described in Practices D 4057 or

ments in Lubricating Oils by Inductively Coupled Plasma D 4177.

Atomic Emission Spectromety 4.3 The biodiesel specified shall conform to the detailed

D 5453 Test Method for Determination of Total Sulfur in requirements shown in Table 1.

Light Hydrocarbons, Motor Fuels and Oils by Ultraviolet

NOTE 2—A considerable amount of experience exists in the U.S. with

Fluorescence

a 20 % blend of biodiesel, primarily produced from soybean oil, with

D 6217 Test Method for Particulate Contamination in

80 % diesel fuel (B20). Experience with biodiesel produced from animal

Middle Distillate Fuels by Laboratory Filtration fat and other oils is similar. Although biodiesel (B100) can be used, blends

of over 20 % biodiesel with diesel fuel (B20) should be evaluated on a

D 6450 Test Method for Flash Point by Continuously

case by case basis until further experience is available.

Closed Cup (CCCFP) Tester

NOTE 3—In certain items of fuel injection equipment in compression

D 6469 Guide for Microbial Contamination in Fuels and

ignition engines, such as rotary/distributor fuel pumps and injectors, the

Fuel Systems

fuel functions as a lubricant as well as a source for combustion. Blending

D 6584 Test Method for Determination of Free and Total

biodiesel fuel with petroleum based compression-ignition fuel typically

Glycerine in B-100 Biodiesel Methyl Esters by Gas

improves fuel lubricity.

Chromatography NOTE 4—The use of biodiesel or biodiesel blends in and of itself will

not void fuel injection equipment (FIE) warranties. Fuel injection equip-

2.2 Government Standard:

ment manufacturers, however, can accept no legal liability for failures

40 CFR Part 79 Registration of Fuels and Fuel Additives

attributed to operating their products with fuels for which their products

Section 211(b) Clean Air Act

were not designed or with fuels not meeting agreed-to standards. Some

FIE manufacturers have special equipment designed for high blends of

3. Terminology

biodiesel, including B100. The FIE manufacturers should always be

3.1 Definitions of Terms Specific to This Standard:

consulted regarding the application limits of their products.

3.1.1 biodiesel, n—a fuel comprised of mono-alkyl esters of

long chain fatty acids derived from vegetable oils or animal

5. Test Methods

fats, designated B100.

5.1 The requirements enumerated in this specification shall

3.1.1.1 Discussion—Biodiesel, as defined above, is regis-

be determined in accordance with the following methods.

tered with the U.S. EPA as a fuel and a fuel additive under

5.1.1 Flash Point—Test Methods D 93, except where other

Section 211(b) of the Clean Air Act. There is, however, other

methods are prescribed by law. Test Methods D 3828 or

usage of the term biodiesel in the marketplace. Due to its EPA

D 6450 can also be used. The precision and bias of Test

registration and the widespread commercial use of the term

Methods D 3828 and D 6450 with biodiesel is not known and

biodiesel in the U.S. marketplace, the term biodiesel will be

is currently under investigation. Test Method D 93 shall be the

maintained for this specification.

referee method.

3.1.1.2 Discussion—Biodiesel is typically produced by a

5.1.2 Water and Sediment—Test Method D 2709. Test

reaction of a vegetable oil or animal fat with an alcohol such as

Method D 1796 may also be used. Test Method D 2709 shall be

methanol or ethanol in the presence of a catalyst to yield

the referee method. The precision and bias of these test

mono-alkyl esters and glycerin, which is removed. The finished

biodiesel derives approximately 10 % of its mass from the A

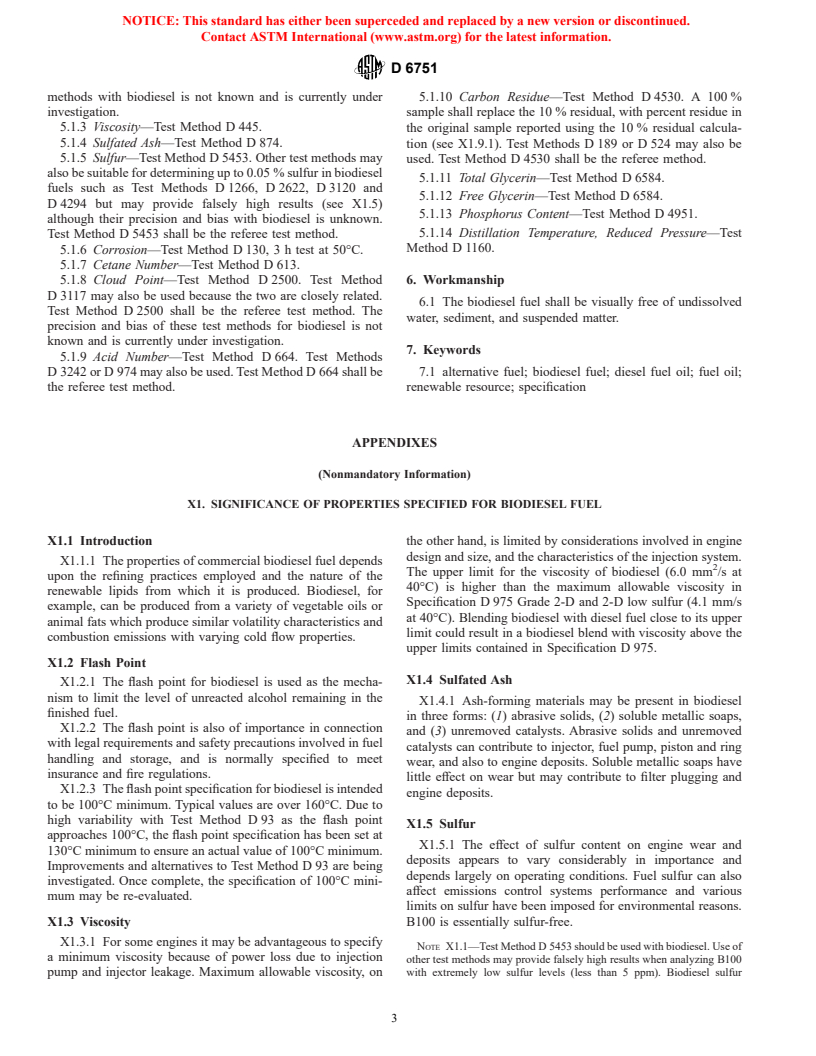

TABLE 1 Detailed Requirements for Biodiesel (B100)

reacted alcohol. The alcohol used in the reaction may or may

B

Property Test Method Limits Units

not come from renewable resources.

Flash point (closed cup) D 93 130.0 min °C

3.1.2 biodiesel blend, BXX, n—a blend of biodiesel fuel

Water and sediment D 2709 0.050 max % volume

C 2

with petroleum-based diesel fuel. Kinematic viscosity, 40°C D 445 1.9–6.0 mm /s

Sulfated ash D 874 0.020 max % mass

3.1.2.1 Discussion—In the abbreviation BXX, the XX rep-

D

Sulfur D 5453 0.05 max % mass

resents the volume percentage of biodiesel fuel in the blend.

Copper strip corrosion D 130 No. 3 max

Cetane number D 613 47 min

3.1.3 biodiesel fuel, n—synonymn for biodiesel.

E

Cloud point D 2500 Report °C

3.1.4 diesel fuel, n—a light or middle petroleum distillate

F

Carbon residue D 4530 0.050 max % mass

fuel.

Acid number D 664 0.80 max mg KOH/g

3.1.5 free glycerin, n—a measure of the amount of glycerin Free glycerin D 6584 0.020 % mass

Total glycerin D 6584 0.240 % mass

remaining in the fuel.

Phosphorus content D 4951 0.001 max % mass

3.1.6 total glycerin, n—the sum of the free glycerin and the

Distillation temperature, D 1160 360 max °C

Atmospheric equivalent temperature,

glycerin portion of any unreacted or partially reacted oil or fat.

90 % recovered

4. Requirements

A

To meet special operating conditions, modifications of individual limiting

requirements may be agreed upon between purchaser, seller, and manufacturer.

4.1 The biodiesel specified shall be mono-alkyl esters of

B

The test methods indicated are the approved referee methods. Other accept-

long chain fatty acids derived from vegetable oils and animal

able methods are indicated in 5.1.

C 2

fats.

See X1.3.1. The 6.0 mm /s upper viscosity limit is higher than petrodiesel and

should be taken into consideration when blending.

D

Other sulfur limits can apply in selected areas in the United States and in other

Annual Book of ASTM Standards, Vol 05.03.

countries.

E

Annual Book of ASTM Standards, Vol 05.04.

The cloud point of biodiesel is generally higher than petrodiesel and should be

Available from Superintendent of Documents, U.S. Government Printing taken into consideration when blending.

F

Office, Washington, DC 20402. Carbon residue shall be run on the 100 % sample (see 5.1.10).

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6751

methods with biodiesel is not known and is currently under 5.1.10 Carbon Residue—Test Method D 4530. A 100 %

investigation.

sample shall replace the 10 % residual, with percent residue in

5.1.3 Viscosity—Test Method D 445.

the original sample reported using the 10 % residual calcula-

5.1.4 Sulfated Ash—Test Method D 874.

tion (see X1.9.1). Test Methods D 189 or D 524 may also be

5.1.5 Sulfur—Test Method D 5453. Other test methods may

used. Test Method D 4530 shall be the referee method.

also be suitable for determining up to 0.05 % sulfur in biodiesel

5.1.11 Total Glycerin—Test Method D 6584.

fuels such as Test Methods D 1266, D 2622, D 3120 and

5.1.12 Free Glycerin—Test Method D 6584.

D 4294 but may provide falsely high results (see X1.5)

5.1.13 Phosphorus Content—Test Method D 4951.

although their precision and bias with biodiesel is unknown.

5.1.14 Distillation Temperature, Reduced Pressure—Test

Test Method D 5453 shall be the referee test method.

Method D 1160.

5.1.6 Corrosion—Test Method D 130, 3 h test at 50°C.

5.1.7 Cetane Number—Test Method D 613.

5.1.8 Cloud Point—Test Method D 2500. Test Method 6. Workmanship

D 3117 may also be used because the two are closely related.

6.1 The biodiesel fuel shall be visually free of undissolved

Test Method D 2500 shall be the referee test method. The

water, sediment, and suspended matter.

precision and bias of these test methods for biodiesel is not

known and is currently under investigation.

7. Keywords

5.1.9 Acid Number—Test Method D 664. Test Methods

7.1 alternative fuel; biodiesel fuel; diesel fuel oil; fuel oil;

D 3242 or D 974 may also be used. Test Method D 664 shall be

the referee test method. renewable resource; specification

APPENDIXES

(Nonmandatory Information)

X1. SIGNIFICANCE OF PROPERTIES SPECIFIED FOR BIODIESEL FUEL

X1.1 Introduction the other hand, is limited by considerations involved in engine

design and size, and the characteristics of the injection system.

X1.1.1 The properties of commercial biodiesel fuel depends

The upper limit for the viscosity of biodiesel (6.0 mm /s at

upon the refining practices employed and the nature of the

40°C) is higher than the maximum allowable viscosity in

renewable lipids from which it is produced. Biodiesel, for

Specification D 975 Grade 2-D and 2-D low sulfur (4.1 mm/s

example, can be produced from a variety of vegetable oils or

at 40°C). Blending biodiesel with diesel fuel close to its upper

animal fats which produce similar volatility characteristics and

limit could result in a biodiesel blend with viscosity above the

combustion emissions with varying cold flow properties.

upper limits contained in Specification D 975.

X1.2 Flash Point

X1.4 Sulfated Ash

X1.2.1 The flash point for biodiesel is used as the mecha-

nism to limit the level of unreacted alcohol remaining in the

X1.4.1 Ash-forming materials may be present in biodiesel

finished fuel.

in three forms: (1) abrasive solids, (2) soluble metallic soaps,

X1.2.2 The flash point is also of importance in connection

and (3) unremoved catalysts. Abrasive solids and unremoved

with legal requirements and safety precautions involved in fuel

catalysts can contribute to injector, fuel pump, piston and ring

handling and storage, and is normally specified to meet

wear, and also to engine deposits. Soluble metallic soaps have

insurance and fire regulations.

little effect on wear but may contribute to filter plugging and

X1.2.3 The flash point specification for biodiesel is intended

engine deposits.

to be 100°C minimum. Typical values are over 160°C. Due to

high variability with Test Method D 93 as the flash point

X1.5 Sulfur

approaches 100°C, the flash point specification has been set at

X1.5.1 The effect of sulfur content on engine wear and

130°C minimum to ensure an actual value of 100°C minimum.

deposits appears to vary considerably in importance and

Improvements and alternatives to Tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.