ASTM E191-64(2017)

(Specification)Standard Specification for Apparatus For Microdetermination of Carbon and Hydrogen in Organic and Organo-Metallic Compounds (Withdrawn 2024)

Standard Specification for Apparatus For Microdetermination of Carbon and<brk/> Hydrogen in Organic and Organo-Metallic Compounds (Withdrawn 2024)

ABSTRACT

This specification covers the design requirements of each component and basic equipment comprising the apparatus used for the microdetermination of carbon and hydrogen in organic and organometallic compounds along the lines of the conventional method of Pregl, but with modifications more in line with modern practice. Due to the diversity of this apparatus by which correct results can be obtained, this specification is intended to indicate what is acceptable rather than what is mandatory. The components covered here are the oxygen supply, pressure, regulator, drying and purifying tube, flowmeter, combustion unit, absorption tubes, guard tube, Mariotte bottle, and weighing accessories.

SCOPE

1.1 This specification covers apparatus and basic equipment for the determination of carbon and hydrogen in organic and organometallic compounds along the lines of the conventional method of Pregl, but with modifications more in line with modern practice. Owing to the diversity of apparatus by which correct results can be obtained, this specification is intended to indicate what is acceptable rather than what is mandatory.

Note 1: Specifications for several items subsequently listed were developed by the Committee for the Standardization of Microchemical Apparatus, Division of Analytical Chemistry, American Chemical Society.2

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

WITHDRAWN RATIONALE

This specification covered apparatus and basic equipment for the determination of carbon and hydrogen in organic and organometallic compounds along the lines of the conventional method of Pregl, but with modifications more in line with modern practice.

Formerly under the jurisdiction of Committee E41 on Laboratory Apparatus, this specification was withdrawn in February 2024. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E191 −64 (Reapproved 2017)

Standard Specification for

Apparatus For Microdetermination of Carbon and

Hydrogen in Organic and Organo-Metallic Compounds

This standard is issued under the fixed designation E191; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Pressure Regulator

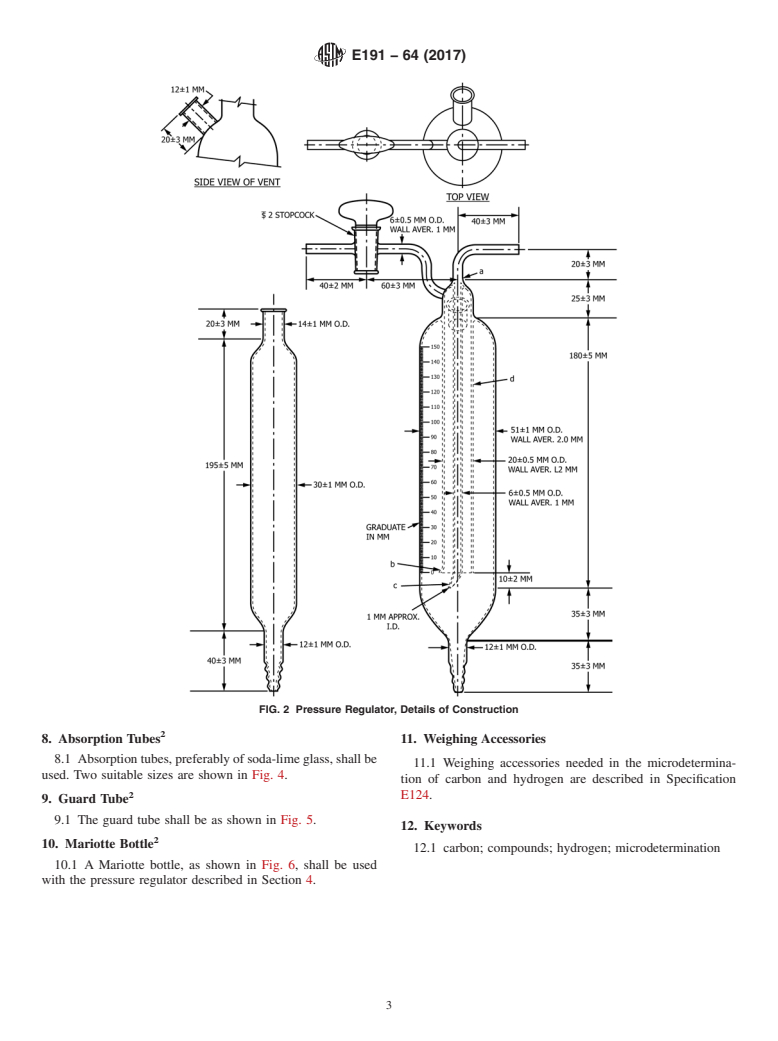

1.1 This specification covers apparatus and basic equipment 4.1 The pressure regulator, shown in Fig. 1 and Fig. 2,

for the determination of carbon and hydrogen in organic and consisting of a bell and inlet tube submerged in a suitable

organometallic compounds along the lines of the conventional confining liquid, shall be used to supply air or oxygen, or both,

method of Pregl, but with modifications more in line with at constant pressure to the combustion system. Substitution of

modern practice. Owing to the diversity of apparatus by which a fine gas-control valve and flowmeter for the pressure regu-

correct results can be obtained, this specification is intended to lator is optional.

indicate what is acceptable rather than what is mandatory.

5. Drying and Purifying Tube

NOTE 1—Specifications for several items subsequently listed were

5.1 The conventional bubble-container U-tube shown in

developed by the Committee for the Standardization of Microchemical

Fig. 3 shall be used for drying and purifying the entering air or

Apparatus, Division of Analytical Chemistry, American Chemical Soci-

ety. oxygen, or both.

1.2 The values stated in inch-pound units are to be regarded

6. Flowmeter

as the standard. The metric equivalents of inch-pound units

6.1 The rate of gas flow shall be determined by the bubble

may be approximate.

counter of the bubble-counter U-tube, or by a more accurate

flow-meter, such as the floating ball-in-column.

2. Referenced Documents

2.1 ASTM Standards: 7. Combustion Unit

E124 Specification for Weighing and Drying Apparatus for

7.1 The combustion unit shall consist of a long furnace, a

Microchemical Analysis

sample furnace, a constant-temperature heating mortar, a

E148 Specification for Apparatus for Microdetermination of

combustion tube, and a combustion-tube closure.

Nitrogen by the Dumas Method (Withdrawn 1987)

7.1.1 Long Furnace:

7.1.1.1 The long furnace shall have a maximum over-all

3. Oxygen Supply

length of 8 in. (203 mm) with the wall thickness at the ends not

3.1 Any cylinder or other suitable source of oxygen free of ⁄4 in. (6 mm). The furnace shall accommodate

to exceed

hydrogen and organic impurities may be used. Oxygen pre-

combustion tubes up to 13 mm in outside diameter. Electric

pared from liquid air is satisfactory. heating elements shall be easily replaceable. The furnace shall

be mounted firmly on a substantial support.

7.1.1.2 Thefurnaceshallbecapableofcontinuousoperation

This specification is under the jurisdiction of ASTM Committee E41 on attemperaturesupto900°Casmeasuredinsidethecombustion

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

tube at the middle of the furnace. The temperature drop from

Laboratory Ware and Supplies.

the center to points 1 in. (25 mm) and 1 ⁄4 in. (45 mm) from

Current edition approved Jan. 1, 2017. Published February 2017. Originally

either end shall not exceed 15 and 7 %, respectively, based

approved in 1962. Discontinued in 1988 and reinstated in 1989. Last previous

edition approved in 2011 as E191 – 64 (2011). DOI: 10.1520/E0191-64R17.

upon the temperature in the middle of the furnace. Means

Committee for the Standardization of Microchemical Apparatus. Division of

shall be provided for varying the temperature.

Analytical Chemistry,American Chemistry Society, 1949 Report on Recommended

Specifications for Microchemical Apparatus, Carbon-Hydrogen, Dumas Nitrogen,

Sulfur, and Halogen, Analytical Chemistry Vol 21, p. 1555 (1949). Furter, M. F., and Steyermark, A., “Pressure Regulator for Use in Microdeter-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or mination of Carbon and Hydrogen,” Analytical Chemistry, Vol 20, 1948, p. 257.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Kuck, J. A., and Altieri, P. L., “Spherical Ground-Glass Joints vs. Rubber

Standards volume information, refer to the standard’s Document Summary page on Tubing Connectors on the C and HAbsorptionTrain,” MikrochimicaActa,1956,p.

the ASTM website. 1556.

The last approved version of this historical standard is referenced on Several types of commercially available electric furnaces meet these require-

www.astm.org. ments.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E191 − 64 (2017)

FIG. 1 Pressure Regulator, Glass Parts

7.1.1.3 The furnace shall be equipped with some device for mm)/min. An automatic control shall be provided to stop the

indicating the temperature at the middle of the furnace. travel of the sample furnace when it reaches the long furnace.

7.1.2 Sample Furnace, Traveling Type

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E191 − 64 (Reapproved 2017)

Standard Specification for

Apparatus For Microdetermination of Carbon and

Hydrogen in Organic and Organo-Metallic Compounds

This standard is issued under the fixed designation E191; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Pressure Regulator

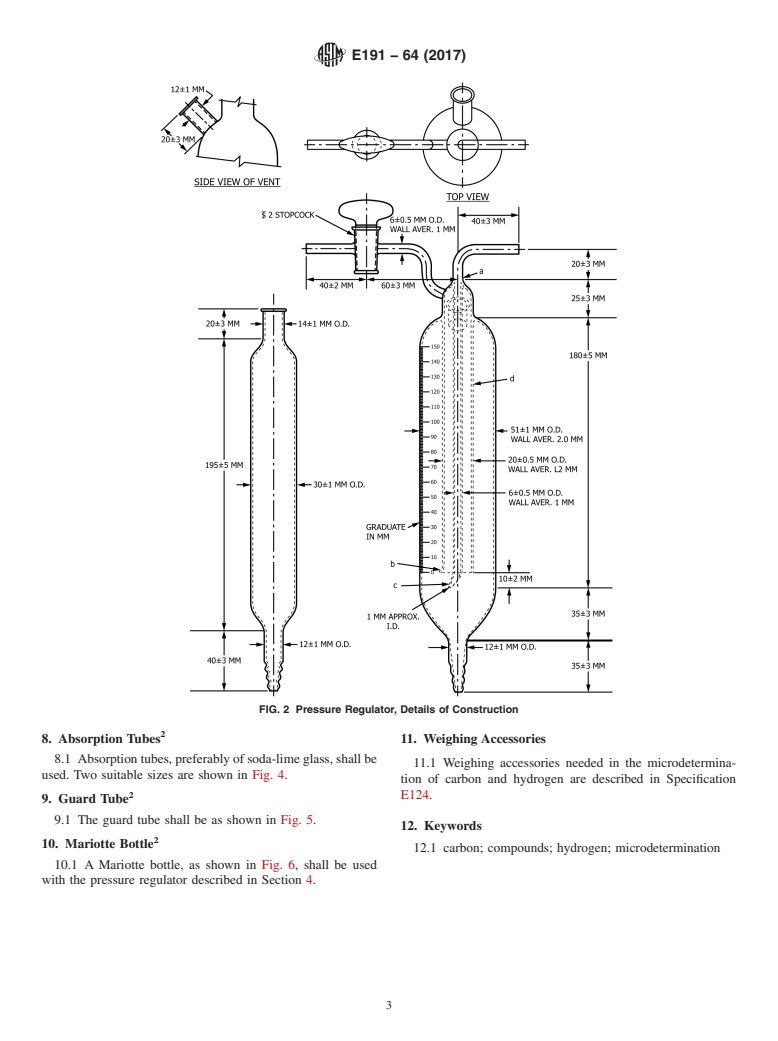

1.1 This specification covers apparatus and basic equipment 4.1 The pressure regulator, shown in Fig. 1 and Fig. 2,

for the determination of carbon and hydrogen in organic and consisting of a bell and inlet tube submerged in a suitable

organometallic compounds along the lines of the conventional confining liquid, shall be used to supply air or oxygen, or both,

method of Pregl, but with modifications more in line with at constant pressure to the combustion system. Substitution of

modern practice. Owing to the diversity of apparatus by which a fine gas-control valve and flowmeter for the pressure regu-

correct results can be obtained, this specification is intended to lator is optional.

indicate what is acceptable rather than what is mandatory.

5. Drying and Purifying Tube

NOTE 1—Specifications for several items subsequently listed were

5.1 The conventional bubble-container U-tube shown in

developed by the Committee for the Standardization of Microchemical

Fig. 3 shall be used for drying and purifying the entering air or

Apparatus, Division of Analytical Chemistry, American Chemical Soci-

ety. oxygen, or both.

1.2 The values stated in inch-pound units are to be regarded

6. Flowmeter

as the standard. The metric equivalents of inch-pound units

6.1 The rate of gas flow shall be determined by the bubble

may be approximate.

counter of the bubble-counter U-tube, or by a more accurate

flow-meter, such as the floating ball-in-column.

2. Referenced Documents

2.1 ASTM Standards: 7. Combustion Unit

E124 Specification for Weighing and Drying Apparatus for

7.1 The combustion unit shall consist of a long furnace, a

Microchemical Analysis

sample furnace, a constant-temperature heating mortar, a

E148 Specification for Apparatus for Microdetermination of

combustion tube, and a combustion-tube closure.

Nitrogen by the Dumas Method (Withdrawn 1987)

7.1.1 Long Furnace:

7.1.1.1 The long furnace shall have a maximum over-all

3. Oxygen Supply

length of 8 in. (203 mm) with the wall thickness at the ends not

3.1 Any cylinder or other suitable source of oxygen free of

to exceed ⁄4 in. (6 mm). The furnace shall accommodate

hydrogen and organic impurities may be used. Oxygen pre- combustion tubes up to 13 mm in outside diameter. Electric

pared from liquid air is satisfactory.

heating elements shall be easily replaceable. The furnace shall

be mounted firmly on a substantial support.

7.1.1.2 The furnace shall be capable of continuous operation

at temperatures up to 900°C as measured inside the combustion

This specification is under the jurisdiction of ASTM Committee E41 on

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

tube at the middle of the furnace. The temperature drop from

Laboratory Ware and Supplies.

the center to points 1 in. (25 mm) and 1 ⁄4 in. (45 mm) from

Current edition approved Jan. 1, 2017. Published February 2017. Originally

either end shall not exceed 15 and 7 %, respectively, based

approved in 1962. Discontinued in 1988 and reinstated in 1989. Last previous

edition approved in 2011 as E191 – 64 (2011). DOI: 10.1520/E0191-64R17. upon the temperature in the middle of the furnace. Means

Committee for the Standardization of Microchemical Apparatus. Division of

shall be provided for varying the temperature.

Analytical Chemistry, American Chemistry Society, 1949 Report on Recommended

Specifications for Microchemical Apparatus, Carbon-Hydrogen, Dumas Nitrogen,

Sulfur, and Halogen, Analytical Chemistry Vol 21, p. 1555 (1949). Furter, M. F., and Steyermark, A., “Pressure Regulator for Use in Microdeter-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or mination of Carbon and Hydrogen,” Analytical Chemistry, Vol 20, 1948, p. 257.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Kuck, J. A., and Altieri, P. L., “Spherical Ground-Glass Joints vs. Rubber

Standards volume information, refer to the standard’s Document Summary page on Tubing Connectors on the C and H Absorption Train,” Mikrochimica Acta, 1956 , p.

the ASTM website. 1556.

4 7

The last approved version of this historical standard is referenced on Several types of commercially available electric furnaces meet these require-

www.astm.org. ments.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E191 − 64 (2017)

FIG. 1 Pressure Regulator, Glass Parts

7.1.1.3 The furnace shall be equipped with some device for mm)/min. An automatic control shall be provided to stop the

indicating the temperature at the middle of the furnace.

travel of the sample furnace when it reaches the long furnace.

7.1.2 Sample Furnace, Traveling Type (Note 2) :

NOTE 2—The stationary multiple-section type of sample furnace may

7.1.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.