ASTM A575-96

(Specification)Standard Specification for Steel Bars, Carbon, Merchant Quality, M-Grades

Standard Specification for Steel Bars, Carbon, Merchant Quality, M-Grades

SCOPE

1.1 This specification covers hot-wrought merchant quality carbon steel bars produced to a chemical composition. Merchant quality bars are used for structural and similar miscellaneous bar applications involving moderate cold bending, moderate hot forming, punching, and welding as used in the production of noncritical parts. Moderate cold bending involves a generous bend radius with the axis of the bend transverse to the direction of rolling.

1.2 Special quality hot-wrought carbon steel bars are covered in Specification A 576.

1.3 Some end uses may require one or more of the available designations shown under Supplementary Requirements.

1.4 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: A 575 – 96 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Steel Bars, Carbon, Merchant Quality, M-Grades

This standard is issued under the fixed designation A 575; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense. Consult the DoD Index of Specifications and

Standards for the specific year of issue which has been adopted by the Department of Defense.

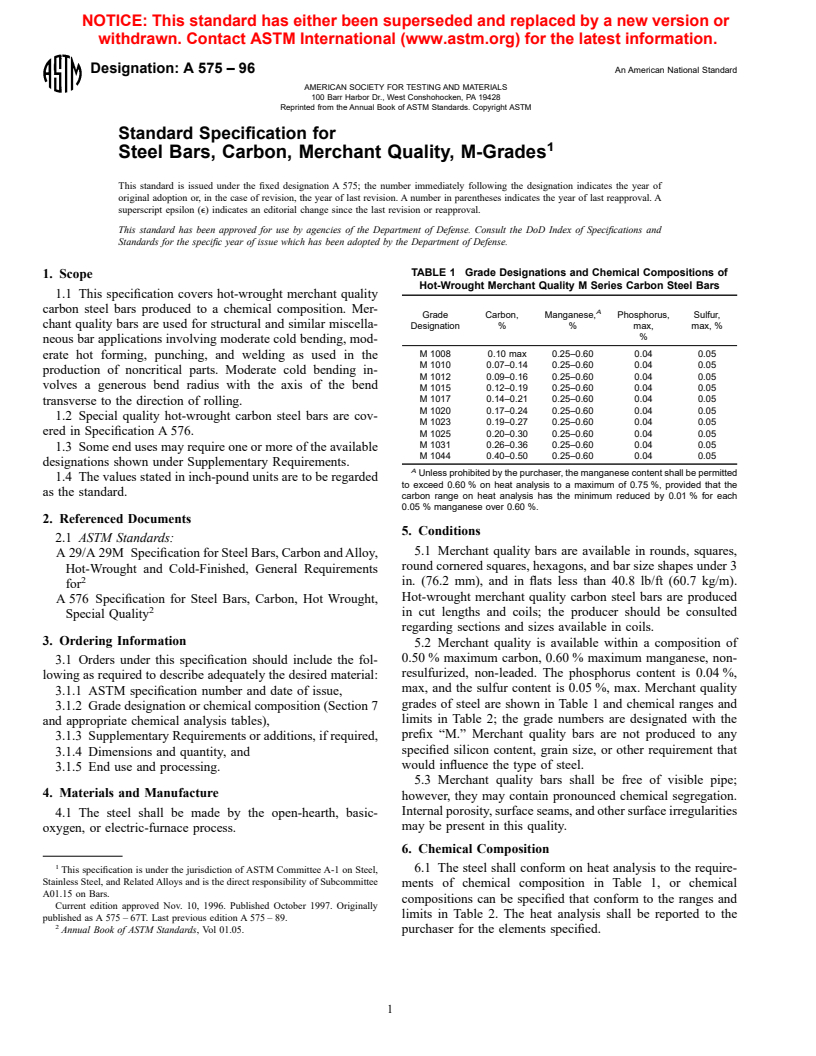

TABLE 1 Grade Designations and Chemical Compositions of

1. Scope

Hot-Wrought Merchant Quality M Series Carbon Steel Bars

1.1 This specification covers hot-wrought merchant quality

carbon steel bars produced to a chemical composition. Mer-

A

Grade Carbon, Manganese, Phosphorus, Sulfur,

chant quality bars are used for structural and similar miscella- Designation % % max, max, %

%

neous bar applications involving moderate cold bending, mod-

M 1008 0.10 max 0.25–0.60 0.04 0.05

erate hot forming, punching, and welding as used in the

M 1010 0.07–0.14 0.25–0.60 0.04 0.05

production of noncritical parts. Moderate cold bending in-

M 1012 0.09–0.16 0.25–0.60 0.04 0.05

volves a generous bend radius with the axis of the bend

M 1015 0.12–0.19 0.25–0.60 0.04 0.05

M 1017 0.14–0.21 0.25–0.60 0.04 0.05

transverse to the direction of rolling.

M 1020 0.17–0.24 0.25–0.60 0.04 0.05

1.2 Special quality hot-wrought carbon steel bars are cov-

M 1023 0.19–0.27 0.25–0.60 0.04 0.05

ered in Specification A 576.

M 1025 0.20–0.30 0.25–0.60 0.04 0.05

M 1031 0.26–0.36 0.25–0.60 0.04 0.05

1.3 Some end uses may require one or more of the available

M 1044 0.40–0.50 0.25–0.60 0.04 0.05

designations shown under Supplementary Requirements.

A

Unless prohibited by the purchaser, the manganese content shall be permitted

1.4 The values stated in inch-pound units are to be regarded

to exceed 0.60 % on heat analysis to a maximum of 0.75 %, provided that the

as the standard.

carbon range on heat analysis has the minimum reduced by 0.01 % for each

0.05 % manganese over 0.60 %.

2. Referenced Documents

5. Conditions

2.1 ASTM Standards:

5.1 Merchant quality bars are available in rounds, squares,

A 29/A 29M Specification for Steel Bars, Carbon and Alloy,

round cornered squares, hexagons, and bar size shapes under 3

Hot-Wrought and Cold-Finished, General Requirements

2

in. (76.2 mm), and in flats less than 40.8 lb/ft (60.7 kg/m).

for

Hot-wrought merchant quality carbon steel bars are produced

A 576 Specification for Steel Bars, Carbon, Hot Wrought,

2

in cut lengths and coils; the producer should be consulted

Special Quality

regarding sections and sizes available in coils.

3. Ordering Information

5.2 Merchant quality is available within a composition of

0.50 % maximum carbon, 0.60 % maximum manganese, non-

3.1 Orders under this specification should include the fol-

resulfurized, non-leaded. The phosphorus content is 0.04 %,

lowing as required to describe adequately the desired material:

max, and the sulfur content is 0.05 %, max. Merchant quality

3.1.1 ASTM specification number and date of issue,

grades of steel are shown in Table 1 and chemical ranges and

3.1.2 Grade designation or chemical composition (Section 7

limits in Table 2; the grade numbers are designated with the

and appropriate chemical analysis tables),

prefix “M.” Merchant quality bars are not produced to any

3.1.3 Supplementary Requirements or additions, if required,

specified silicon content, grain size, or other requirement that

3.1.4 Dimensions and quantity, and

would influence the type of steel.

3.1.5 End use and processing.

5.3 Merchant quality bars shall be free of visible pipe;

4. Materials and Manufacture

however, they may contain pronounced chemical segregation.

Internal porosity, surface seams, and other surface irregularities

4.1 The steel shall be made by the open-hearth, basic-

may be present in this quality.

oxygen, or electric-furnace process.

6. Chemical Composition

1

6.1 The steel shall conform on heat analysis to the require-

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

ments of chemical composition in Table 1, or chemical

A01.15 on Bars.

compositions can be specified that conform to the ranges and

Current edition approved Nov. 10, 1996. Published October 1997. Originally

limits in Table 2. The heat analysis shall be reported to the

published as A 575 – 67T. Last

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.