ASTM B666/B666M-20

(Practice)Standard Practice for Identification Marking of Aluminum and Magnesium Products

Standard Practice for Identification Marking of Aluminum and Magnesium Products

ABSTRACT

This practice establishes the requirements for physical item identification marking of aluminum and magnesium products. Package marking for shipment and inspection acceptance is not within the scope of this standard. Wrought aluminum and magnesium mill products shall be marked for identification purposes only with the following information on the product or on tags attached to the product: (1) name or registered trademark of the company, (2) alloy and temper of the product, (3) basic number of the specification to which the product was produced, (4) specified (ordered) dimensions of the following products: sheet and plate, coiled wire and spooled wire, straight length tube and coiled tube, and pipe, (5) lot number, and (6) the word "seamless" on certain tube or pipe. Spot marking requirements for the following wrought aluminum and magnesium mill products are detailed and illustrated: (1) coiled sheet, (2) flat sheet and plate, (3) circles, (4) tread plate, (5) foil, (6) rod, bar, and extruded profiles, (7) structural profiles, (8) tube and pipe, (9) wire, (10) bus bar, and (11) forgings such as hand and die forgings. Requirements for marking cast aluminum and magnesium products (castings, remelt ingot for castings, and ingot or billet for fabricating), unalloyed aluminum and magnesium ingot, and special products are specified.

SCOPE

1.1 This practice establishes the physical item marking requirements for identification purposes for aluminum and magnesium products. Package marking for shipment and inspection acceptance is not within the scope of this standard.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B666/B666M −20

Standard Practice for

Identification Marking of Aluminum and Magnesium

1

Products

This standard is issued under the fixed designation B666/B666M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B404/B404M Specification for Aluminum and Aluminum-

Alloy Seamless Condenser and Heat-Exchanger Tubes

1.1 This practice establishes the physical item marking

3

with Integral Fins (Withdrawn 2006)

requirements for identification purposes for aluminum and

B881 Terminology Relating toAluminum- and Magnesium-

magnesium products. Package marking for shipment and

Alloy Products

inspection acceptance is not within the scope of this standard.

4

2.3 ANSI Standards:

1.2 The values stated in either SI units or inch-pound units

ANSI H35.1/H35.1M Alloy and Temper Designation Sys-

are to be regarded separately as standard. The values stated in

tems for Aluminum

each system are not necessarily exact equivalents; therefore, to

5

2.4 Military Standards:

ensure conformance with the standard, each system shall be

MIL-STD-409 Alloy Nomenclature and Temper Designa-

used independently of the other, and values from the two

tion System for Magnesium Base Alloys

systems shall not be combined.

1.3 This standard does not purport to address all of the 3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions:

responsibility of the user of this standard to establish appro-

3.1.1 Refer to Terminology B881 for definitions of product

priate safety, health, and environmental practices and deter-

terms used in this practice.

mine the applicability of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

1.4 This international standard was developed in accor-

3.2.1 Marking:

dance with internationally recognized principles on standard-

3.2.1.1 spot marking—marking the identification only once

ization established in the Decision on Principles for the

on the product.

Development of International Standards, Guides and Recom-

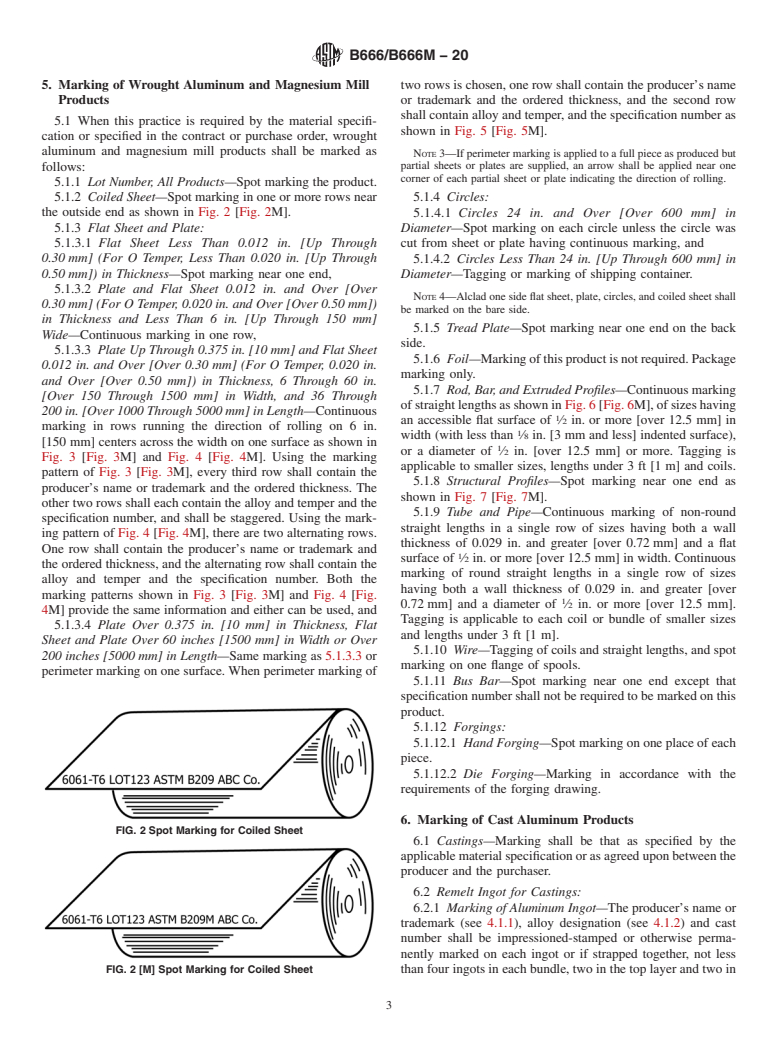

3.2.1.2 continuous marking—recurring marking of the iden-

mendations issued by the World Trade Organization Technical

tification in intervals not greater than 40 in. [1000 mm]

Barriers to Trade (TBT) Committee.

throughout the length of the product.

3.2.1.3 perimeter marking—marking continuously the iden-

2. Referenced Documents

tification in one or two rows adjacent to the four edges of the

2.1 The following documents of the issue in effect on the

product.

date of material purchase form a part of this practice to the

3.2.1.4 tagging—attaching tags bearing the required identi-

extent referenced herein:

fication markings to coils, bundles, or containers of items

2

2.2 ASTM Standards:

which are too small to mark or whose configuration preclude

B361 Specification for Factory-Made Wrought Aluminum

marking otherwise.

and Aluminum-Alloy Welding Fittings

4. Basic Marking Requirements and Application

4.1 When this practice is required by the material specifi-

1

This practice is under the jurisdiction of ASTM Committee B07 on Light

cation or specified in the contract or purchase order, wrought

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

Aluminum Alloy Wrought Products.

Current edition approved Nov. 1, 2020. Published November 2020. Originally

3

approved in 1980. Last previous edition approved in 2019 as B666/B666M – 19. The last approved version of this historical standard is referenced on

DOI: 10.1520/B0666_B0666M-20. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAluminumAssociation, 1400 Crystal Dr., Suite 430,Arlington,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM VA 22202, http://www.aluminum.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B666/B666M − 20

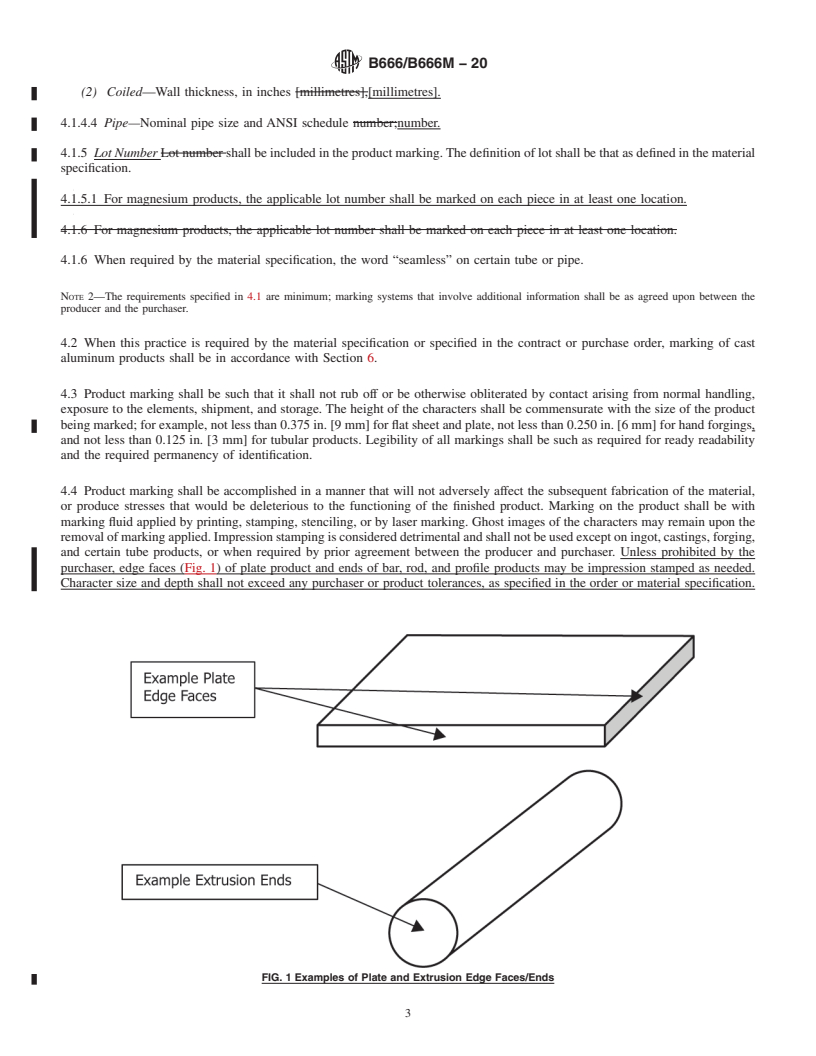

NOTE 2—The requirements specified in 4.1 are minimum; marking

aluminum and magnesium mill products shall be marked

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B666/B666M − 19 B666/B666M − 20

Standard Practice for

Identification Marking of Aluminum and Magnesium

1

Products

This standard is issued under the fixed designation B666/B666M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This practice establishes the physical item marking requirements for identification purposes for aluminum and magnesium

products. Package marking for shipment and inspection acceptance is not within the scope of this standard.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system mayare not benecessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other. Combiningother, and values from the two systems may result in non-conformance with the

standard.shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase form a part of this specificationpractice to the

extent referenced herein:

2

2.2 ASTM Standards:

B361 Specification for Factory-Made Wrought Aluminum and Aluminum-Alloy Welding Fittings

B404/B404M Specification for Aluminum and Aluminum-Alloy Seamless Condenser and Heat-Exchanger Tubes with Integral

3

Fins (Withdrawn 2006)

B881 Terminology Relating to Aluminum- and Magnesium-Alloy Products

4

2.3 ANSI Standards:

ANSI H35.1/H35.1M Alloy and Temper Designation Systems for Aluminum

1

This practice is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Aluminum Alloy

Wrought Products.

Current edition approved Nov. 1, 2019Nov. 1, 2020. Published November 2019November 2020. Originally approved in 1980. Last previous edition approved in 20152019

as B666/B666M – 15.B666/B666M – 19. DOI: 10.1520/B0666_B0666M-19.10.1520/B0666_B0666M-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from Aluminum Association, Inc., 1400 Crystal Drive,Dr., Suite 430, Arlington, VA 22202 (http://www.aluminum.org).22202, http://www.aluminum.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B666/B666M − 20

5

2.4 Military Standards:

MIL-STD-409 Alloy Nomenclature and Temper Designation System for Magnesium Base Alloys

3. Terminology

3.1 DefinitionsDefinitions:—

3.1.1 Refer to Terminology B881 for definitions of product terms used in this practice.Refer to Terminology B881 for definitions

of product terms used in this specification.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Marking:

3.2.2 spot marking—marking the identification only once on the product.

3.2.3 continuous marking—recurring marking of the identification in intervals not greater than 40 in. [1000 mm] throughout the

length of the product.

3.2.4 perimeter marking—marking continuously the identification in one or two rows adjacent to the four edges of the product.

3.2.1 tagging—Marking: attaching tags bearing the required identification markings to coils, bundles, or containers of items which

are too small to mark or whose configuration preclude marking otherwise.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.