ASTM D7247-07a

(Test Method)Standard Test Method for Evaluating the Shear Strength of Adhesive Bonds in Laminated Wood Products at Elevated Temperatures

Standard Test Method for Evaluating the Shear Strength of Adhesive Bonds in Laminated Wood Products at Elevated Temperatures

SIGNIFICANCE AND USE

A discussion of the issues and limitations associated with the measurement of strength properties of adhesive bonds in shear by compression loading is found in Test Method D 905.

While various combinations of test temperature and heat exposure duration can be used, the provisions specified in 7.2.4 shall be based on the understanding that the objective of this test method is to evaluate adhesive bond performance just before wood begins to burn and the elevated temperature is selected to be slightly below the unpiloted ignition temperature for wood when taken into account the specific product and its end-use applications.

When using this test method, consideration shall be given to the unique production conditions, such as wood moisture content, applied spread rate, press pressure, and curing temperature of the adhesive.

SCOPE

1.1 This standard describes a test method for evaluating the comparative shear strength of a planar adhesive bond at both ambient and elevated temperatures relative to the performance of solid wood under the same conditions. The test method is based on the breaking load after the specimen is exposed to either ambient or a constant elevated temperature for a specified duration as described in Section . This standard does not preclude the development and implementation of other methods that provide equivalent performance meeting the intent of this method.

1.2 This test method is intended for the evaluation of adhesives that can be used to assemble test specimens in accordance with Test Method D 905. The evaluation of other types of adhesives, such as the binder systems used for strand-based products, is beyond the scope of this test method.

1.3 This test method is intended for the evaluation of adhesives as a component of laminated wood products at elevated temperatures. The evaluation of fire performance on fire-rated laminated wood products or assemblies is beyond the scope of this test method.

1.4 While it is preferable to use solid wood specimens as described in Section 6 as the control, structural composite lumber products as defined in Specification D 5456 shall be permitted for use provided they are matched with the bonded specimens in accordance with Section 6 and the ignition temperature is not significantly lower than solid wood of the same species.

1.5 The exact formulation of adhesive supplied to the manufacturer of laminated wood products shall be evaluated. Modifications to the adhesive formulation require a separate evaluation unless approved by the manufacturer of the laminated wood product, qualified agency, and code evaluation agency.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, such as the fire hazard, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7247–07a

Standard Test Method for

Evaluating the Shear Strength of Adhesive Bonds in

1

Laminated Wood Products at Elevated Temperatures

This standard is issued under the fixed designation D 7247; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

1.1 This standard describes a test method for evaluating the

only.

comparative shear strength of a planar adhesive bond at both

1.7 This standard does not purport to address all of the

ambient and elevated temperatures relative to the performance

safety concerns, such as the fire hazard, associated with its use.

of solid wood under the same conditions. The test method is

It is the responsibility of the user of this standard to establish

based on the breaking load after the specimen is exposed to

appropriate safety and health practices and determine the

either ambient or a constant elevated temperature for a speci-

applicability of regulatory limitations prior to use.

fied duration as described in Section 7. This standard does not

preclude the development and implementation of other meth-

2. Referenced Documents

ods that provide equivalent performance meeting the intent of

2

2.1 ASTM Standards:

this method.

D 905 Test Method for Strength Properties of Adhesive

1.2 This test method is intended for the evaluation of

Bonds in Shear by Compression Loading

adhesives that can be used to assemble test specimens in

D 907 Terminology of Adhesives

accordance with Test Method D 905. The evaluation of other

D 2395 Test Methods for Specific Gravity of Wood and

types of adhesives, such as the binder systems used for

Wood-Based Materials

strand-based products, is beyond the scope of this test method.

D 2915 Practice for Evaluating Allowable Properties for

1.3 This test method is intended for the evaluation of

Grades of Structural Lumber

adhesives as a component of laminated wood products at

D 4933 Guide for Moisture Conditioning of Wood and

elevated temperatures. The evaluation of fire performance on

Wood-Based Materials

fire-rated laminated wood products or assemblies is beyond the

D 5266 Practice for Estimating the Percentage of Wood

scope of this test method.

Failure in Adhesive Bonded Joints

1.4 While it is preferable to use solid wood specimens as

D 5456 Specification for Evaluation of Structural Compos-

described in Section 6 as the control, structural composite

ite Lumber Products

lumber products as defined in Specification D 5456 shall be

2.2 Other Documents:

permitted for use provided they are matched with the bonded

ANSI/AITCA190.1 American National Standard for Wood

specimens in accordance with Section 6 and the ignition

3

Products — Structural Glued Laminated Timber

temperature is not significantly lower than solid wood of the

ANSI/AF&PANDS-2005 National Design — Specification

same species.

3

for Wood Construction (NDS)

1.5 The exact formulation of adhesive supplied to the

4

Wood Handbook Wood as an Engineering Material

manufacturer of laminated wood products shall be evaluated.

Modifications to the adhesive formulation require a separate

3. Terminology

evaluation unless approved by the manufacturer of the lami-

3.1 Definitions:

nated wood product, qualified agency, and code evaluation

agency.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This test method is under the jurisdiction of ASTM Committee D14 on the ASTM website.

3

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood Available from American Institute of Timber Construction (AITC), 7012 S.

Adhesives. Revere Parkway, Suite 140, Centennial, CO 80112, http://www.aitc-glulam.org.

4

Current edition approved July 15, 2007. Published July 2007. Originally AvailablefromU.S.DepartmentofAgriculture,ForestService,ForestProducts

approved in 2006. Last previous edition approved in 2007 as D 7247 - 07. Laboratory, One Gifford Pinchot Drive Madison, WI 53726.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7247–07a

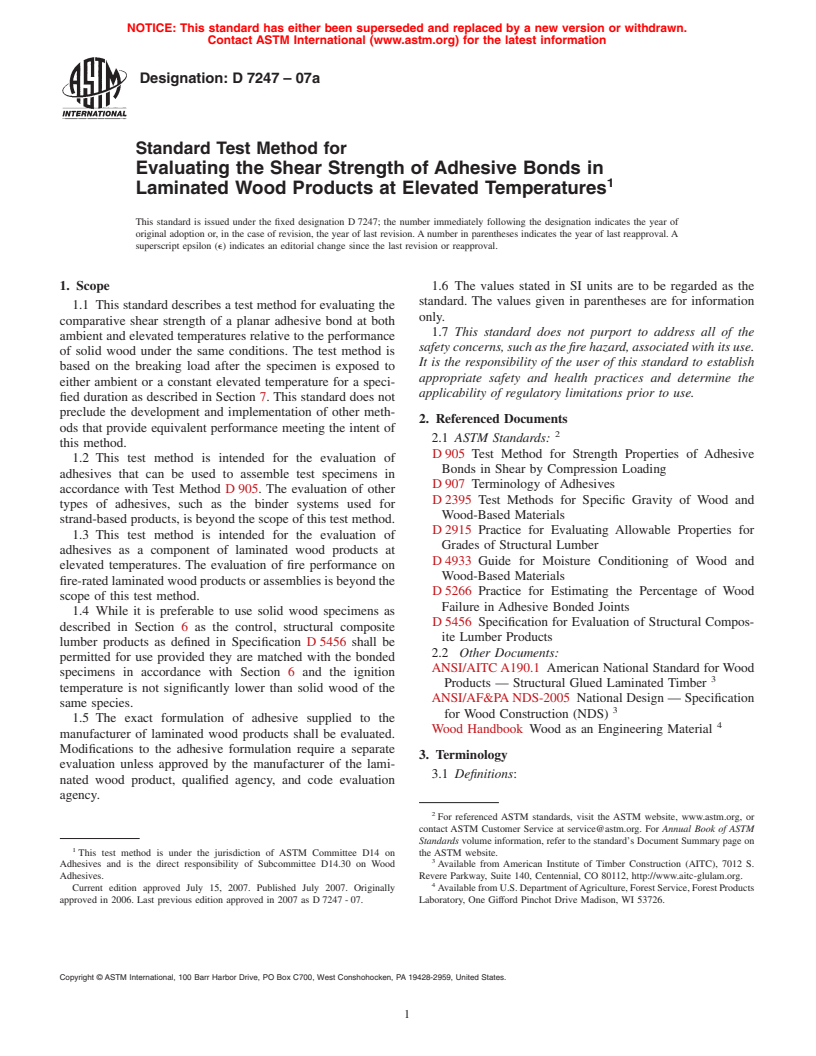

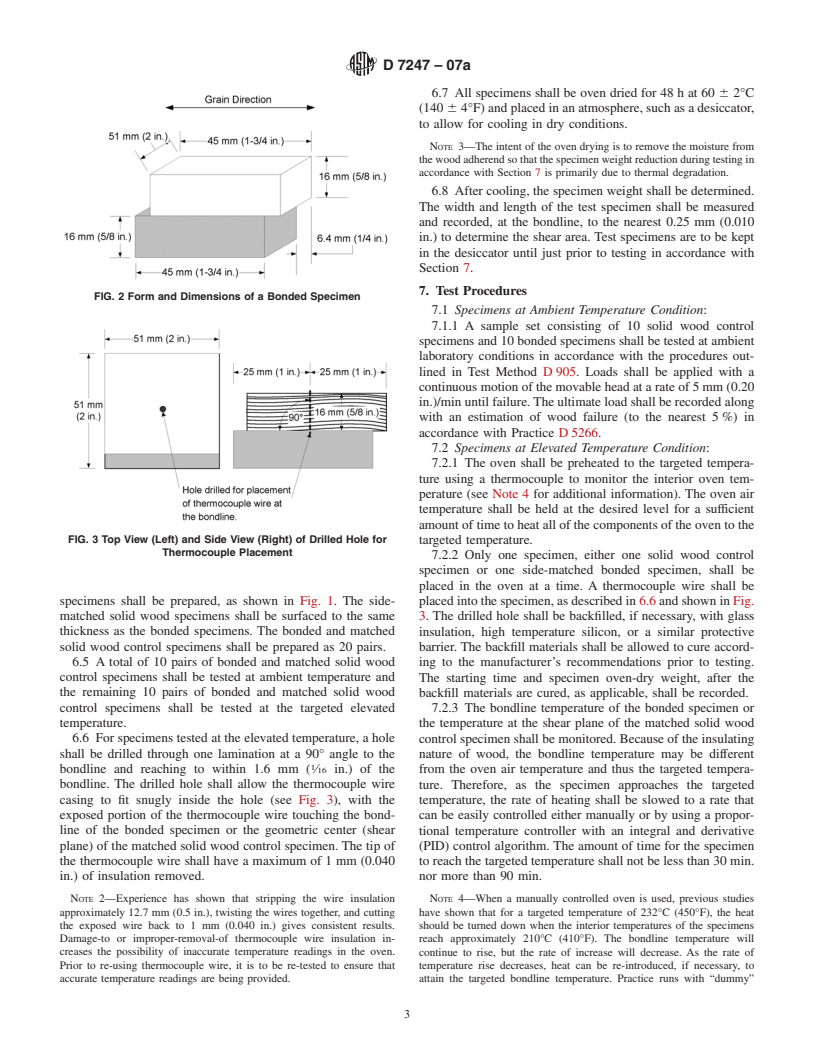

3.1.1 Many terms in this test method are defined in Termi- wide face (vertical grain), and be free of defects and at the

nology D 907. equilibrium moisture content recommended by the manufac-

turer of the adhesive. If no such recommendation exists, the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.