ASTM D7846-16

(Practice)Standard Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Graphites

Standard Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Graphites

SIGNIFICANCE AND USE

5.1 Two- and three-parameter formulations exist for the Weibull distribution. This practice is restricted to the two-parameter formulation. An objective of this practice is to obtain point estimates of the unknown Weibull distribution parameters by using well-defined functions that incorporate the failure data. These functions are referred to as estimators. It is desirable that an estimator be consistent and efficient. In addition, the estimator should produce unique, unbiased estimates of the distribution parameters (6). Different types of estimators exist, including moment estimators, least-squares estimators, and maximum likelihood estimators. This practice details the use of maximum likelihood estimators.

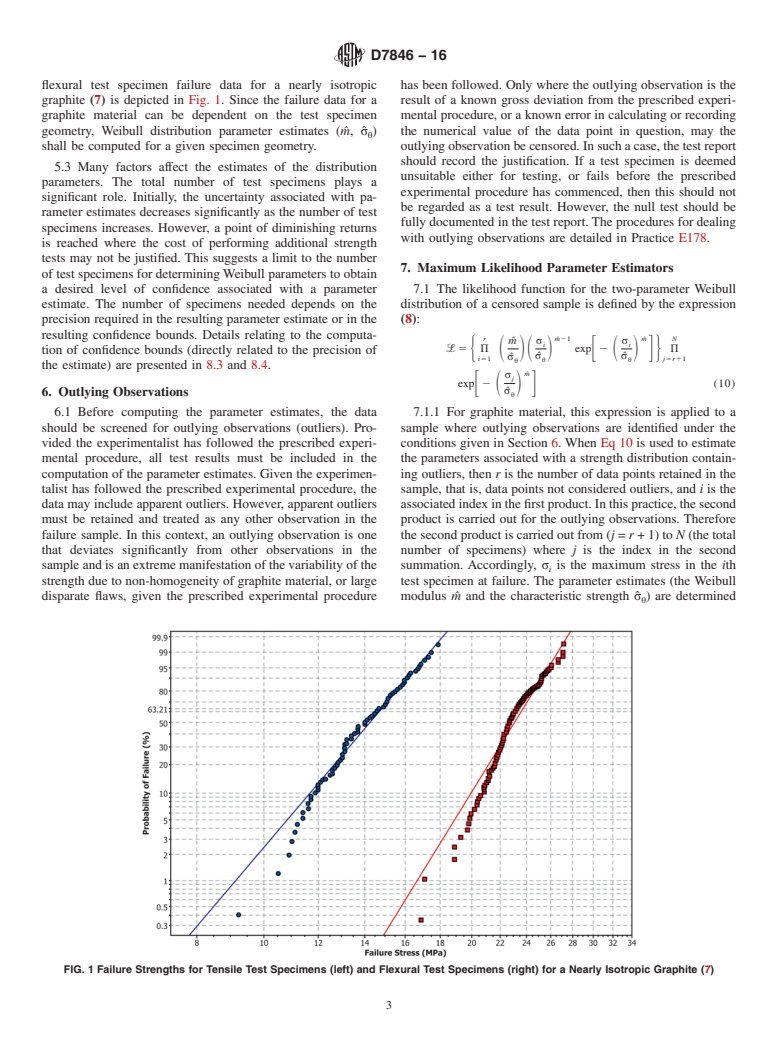

5.2 Tensile and flexural specimens are the most commonly used test configurations for graphite. The observed strength values depend on specimen size and test geometry. Tensile and flexural test specimen failure data for a nearly isotropic graphite (7) is depicted in Fig. 1. Since the failure data for a graphite material can be dependent on the test specimen geometry, Weibull distribution parameter estimates (m^, σ^θ) shall be computed for a given specimen geometry.

5.3 Many factors affect the estimates of the distribution parameters. The total number of test specimens plays a significant role. Initially, the uncertainty associated with parameter estimates decreases significantly as the number of test specimens increases. However, a point of diminishing returns is reached where the cost of performing additional strength tests may not be justified. This suggests a limit to the number of test specimens for determining Weibull parameters to obtain a desired level of confidence associated with a parameter estimate. The number of specimens needed depends on the precision required in the resulting parameter estimate or in the resulting confidence bounds. Details relating to the computation of confidence bounds (directly related to the precision of the estimate) ...

SCOPE

1.1 This practice covers the reporting of uniaxial strength data for graphite and the estimation of probability distribution parameters for both censored and uncensored data. The failure strength of graphite materials is treated as a continuous random variable. Typically, a number of test specimens are failed in accordance with the following standards: Test Methods C565, C651, C695, C749, Practice C781 or Guide D7775. The load at which each specimen fails is recorded. The resulting failure stresses are used to obtain parameter estimates associated with the underlying population distribution. This practice is limited to failure strengths that can be characterized by the two-parameter Weibull distribution. Furthermore, this practice is restricted to test specimens (primarily tensile and flexural) that are primarily subjected to uniaxial stress states.

1.2 Measurements of the strength at failure are taken for various reasons: a comparison of the relative quality of two materials, the prediction of the probability of failure for a structure of interest, or to establish limit loads in an application. This practice provides a procedure for estimating the distribution parameters that are needed for estimating load limits for a particular level of probability of failure.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7846 − 16

Standard Practice for

Reporting Uniaxial Strength Data and Estimating Weibull

1

Distribution Parameters for Advanced Graphites

This standard is issued under the fixed designation D7846; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C749 Test Method for Tensile Stress-Strain of Carbon and

Graphite

1.1 This practice covers the reporting of uniaxial strength

C781 PracticeforTestingGraphiteMaterialsforGas-Cooled

data for graphite and the estimation of probability distribution

Nuclear Reactor Components

parameters for both censored and uncensored data. The failure

D4175 Terminology Relating to Petroleum Products, Liquid

strengthofgraphitematerialsistreatedasacontinuousrandom

Fuels, and Lubricants

variable. Typically, a number of test specimens are failed in

D7775 Guide for Measurements on Small Graphite Speci-

accordance with the following standards: Test Methods C565,

mens

C651,C695,C749,PracticeC781orGuideD7775.Theloadat

E6 Terminology Relating to Methods of Mechanical Testing

which each specimen fails is recorded. The resulting failure

E178 Practice for Dealing With Outlying Observations

stresses are used to obtain parameter estimates associated with

E456 Terminology Relating to Quality and Statistics

the underlying population distribution. This practice is limited

to failure strengths that can be characterized by the two-

3. Terminology

parameter Weibull distribution. Furthermore, this practice is

restricted to test specimens (primarily tensile and flexural) that

3.1 Proper use of the following terms and equations will

are primarily subjected to uniaxial stress states.

alleviate misunderstanding in the presentation of data and in

1.2 Measurements of the strength at failure are taken for

the calculation of strength distribution parameters.

various reasons: a comparison of the relative quality of two

3.2 Definitions:

materials, the prediction of the probability of failure for a

3.2.1 estimator, n—awell-definedfunctionthatisdependent

structure of interest, or to establish limit loads in an applica-

ontheobservationsinasample.Theresultingvalueforagiven

tion. This practice provides a procedure for estimating the

sample may be an estimate of a distribution parameter (a point

distribution parameters that are needed for estimating load

estimate) associated with the underlying population. The arith-

limits for a particular level of probability of failure.

metic average of a sample is, for example, an estimator of the

distribution mean.

2. Referenced Documents

2

2.1 ASTM Standards: 3.2.2 population, n—the totality of valid observations (per-

formed in a manner that is compliant with the appropriate test

C565 Test Methods for Tension Testing of Carbon and

Graphite Mechanical Materials standards) about which inferences are made.

C651 Test Method for Flexural Strength of Manufactured

3.2.3 population mean, n—the average of all potential

CarbonandGraphiteArticlesUsingFour-PointLoadingat

measurements in a given population weighted by their relative

Room Temperature

frequencies in the population.

C695 Test Method for Compressive Strength of Carbon and

3.2.4 probability density function, n—the function f(x) is a

Graphite

probabilitydensityfunctionforthecontinuousrandomvariable

X if:

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

f~x!$0 (1)

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

mittee D02.F0 on Manufactured Carbon and Graphite Products.

and

Current edition approved Jan. 1, 2016. Published February 2016. Originally

`

approved in 2012. Last previous edition approved in 2012 as D7846 – 12. DOI:

10.1520/D7846-16. f x dx 51 (2)

* ~ !

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 2`

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The probability that the random variable X assumes a

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. value between a and b is given by:

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7846 − 16

b

3.3 For definitions of other statistical terms, terms related to

Pr a , X , b 5 f x dx (3)

~ ! * ~ !

mechanical testing, and terms related to graphite used in this

a

practice, refer to Terminologies D4175, E6, and E456,orto

3.2.5 sample, n—a collection of measurements or observa- 3

appropriate textbooks on

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.