ASTM C1048-97b

(Specification)Standard Specification for Heat-Treated Flat Glass--Kind HS, Kind FT Coated and Uncoated Glass

Standard Specification for Heat-Treated Flat Glass--Kind HS, Kind FT Coated and Uncoated Glass

SCOPE

1.1 This specification covers the requirements for flat heat-strengthened and flat fully tempered coated and uncoated glass used in general building construction.

1.2 The dimensional values, except thickness designations, stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 11, of this specification: This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: C 1048 – 97b

Standard Specification for

Heat-Treated Flat Glass—Kind HS, Kind FT Coated and

Uncoated Glass

This standard is issued under the fixed designation C 1048; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.2 ANSI Standard:

Z97.1 Safety Performance Specifications and Methods of

1.1 This specification covers the requirements for flat heat-

Test for Safety Glazing Materials Used in Buildings

strengthened and flat fully tempered coated and uncoated glass

2.3 Other Documents:

used in general building construction.

CPSC 16CFR1201 ConsumerProduct Safety Commission

1.2 The dimensional values stated in SI units are to be

Standard on Architectural Glazing Materials

regarded as the standard. The units given in parentheses are for

information only.

3. Terminology

1.3 The following safety hazards caveat pertains only to the

3.1 Definitions: For definitions of terms used in this speci-

test method portion, Section 11, of this specification: This

fication, refer to Terminology C 162 and Specification C 1036.

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

4. Classification

of this standard to establish appropriate safety and health

4.1 Kinds—Flat glass furnished under this specification

practices and determine the applicability of regulatory limita-

2 shall be of the following kinds, as specified (see Section 6):

tions prior to use.

4.1.1 Kind HS—Heat-strengthened glass shall be flat glass,

either transparent or patterned, in accordance with the appli-

2. Referenced Documents

cable requirements of Specification C 1036 as further pro-

2.1 ASTM Standards:

3 cessed to conform with the requirements hereinafter specified

C 162 Terminology of Glass and Glass Products

for heat-strengthened glass.

C 346 Test Method for 45-deg Specular Gloss of Ceramic

4 4.1.2 Kind FT—Fully tempered glass shall be flat glass,

Materials

either transparent or patterned in accordance with the appli-

C 724 Test Methods for Acid Resistance of Ceramic Deco-

3 cable requirements of Specification C 1036 as further pro-

rations on Architectural–Type Glass

cessed to conform with the requirements hereinafter specified

C 978 Test Method for Photoelastic Determination of Re-

for fully tempered glass.

sidual Stress in a Transparent Glass Matrix Using a

4.2 Conditions—Glass furnished under this specification

Polarizing Microscope and Optical Retardation Compen-

3 shall be of the following conditions, as specified (see Section

sation Procedures

3 6):

C 1036 Specification for Flat Glass

4.2.1 Condition A—Uncoated surfaces.

C 1203 Test Method for Quantitative Determination of

3 4.2.2 Condition B—Spandrel glass, one surface ceramic

Alkali Resistance of a Ceramic-Glass Enamel

coated.

C 1279 Test Method for Non-Destructive Photoelastic Mea-

4.2.3 Condition C—Other coated glass.

surement of Edge and Surface Stresses in Annealed,

4.3 Types, Classes, Styles, Forms, Qualities, and Finishes—

Heat-Strengthened, and Fully Tempered Flat Glass

Glass substrate shall be of the following types, classes, styles,

forms, qualities, and finishes, as specified (see Section 6):

This specification is under the jurisdiction of ASTM Committee C-14 on Glass 4.3.1 Type I—Transparent Glass, Flat:

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat

4.3.1.1 Class 1—Clear:

Glass.

Current edition approved Oct. 10, 1997. Published February 1998. Originally

published as C 1048 – 85. Last previous edition C 1048 – 97a.

2 5

Reference to these documents shall be the latest issue unless otherwise Available from American National Standards Institute, 11 W. 42nd St., 13th

specified by the authority applying this specification. Floor, New York, NY 10036.

3 6

Annual Book of ASTM Standards, Vol 15.02. Available from Superintendent of Documents, U.S. Government Printing

Annual Book of ASTM Standards, Vol 02.05. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C 1048 – 97b

6. Ordering Information

Quality

q —Glazing select

6.1 Purchasers should select the preferred options permitted

q —Glazing A

in this specification and include the following information in

q —Glazing B

q —Greenhouse

procurement documents:

6.1.1 Title, number, and data of this specification.

4.3.1.2 Class 2—Tinted Heat-Absorbing and Light-

6.1.2 Kind, condition, type, class, style, form, quality, finish,

Reducing:

and pattern of glass as applicable (see Section 4).

6.1.3 Fabrication requirements (see 7.1).

Quality

6.1.4 Requirements for fittings and hardware (see 7.2).

q —Glazing select

4 6.1.5 Specific location of tong marks, when required (see

q —Glazing A

q —Glazing B

7.3).

Style A—Higher light transmittance

6.1.6 Custom design or texture required (see 7.7).

Style B—Lower light transmittance

6.1.7 Glass thickness (see 9.1).

4.3.1.3 Class 3—Tinted Light-Reducing: 6.1.8 Pattern-cut glass must be within the tolerances speci-

fied (see 9.3).

6.1.9 When surface or edge compression test is required for

Quality

q —Glazing select Kind HS or Kind FT glass (see 8.1.1).

q —Glazing A

6.1.10 When break impact is required for fully tempered

q —Glazing B

(Kind FT) glass (see 8.1.2).

4.3.2 Type II—Patterned Glass, Flat: 6.1.11 Color or tint of glass (see 8.2).

6.1.12 Luminous transmittance, Class 3 glasses (see 8.4).

Class

1—Clear

6.1.13 When either permanent or temporary identification

2—Tinted heat-absorbing and light-reducing

marking is required (see Section 12).

Style A—Higher light transmittance

6.1.14 Surface treatment or coatings for Condition B and

Style B—Lower light transmittance

3—Tinted Light Reducing

Condition C glass (see 8.5 and 8.6).

6.1.15 When addition of fallout resistance capability is

Forms (Classes 1, 2, and 3)

3—Patterned required for Condition A, Condition B, or Condition C glasses

used as spandrels. (Normally achieved by adhering a reinforc-

Quality

7 ing material to the glass surface.) (See 11.3.)

q —Decorative

q —Glazing

7. Fabrication Requirements

Finish

f -Patterned one side

7.1 Fabrication—All fabrication, such as cutting to overall

f -Patterned both sides

dimensions, edgework, drilled holes, notching, grinding, sand-

blasting, and etching, shall be performed before strengthening

Pattern (Forms 2 and 3)

p —Linear or tempering and shall be as specified (see Section 6 and 7.8).

p —Geometric

After the glass has been heat strengthened or tempered, it shall

p —Random

4 not be modified except as recommended by the fabricator; for

p —Special

example, some Condition C coatings. No modification shall be

made that will affect its structural characteristics or integrity as

5. Intended Use

specified in this specification.

5.1 Kind HS, Types I and II—Heat-strengthened glass is

7.2 Fittings and Hardware—Requirements for fittings and

generally twice as strong as annealed glass of the same

hardware shall be as specified (see Section 6) or as shown on

thickness and configuration. When broken, the fragments are

plans or drawings. Fittings and hardware specified shall be

generally somewhat larger than for fully tempered glass.

compatible with glass fabrication limitations.

Intended for general glazing when additional strength is

7.3 Tong Marks—The center of tong marks, when present,

desired but not requiring the strength of fully tempered glass. 1

shall be located a maximum of 12.7 mm ( ⁄2 in.) from one edge

of the glass on thicknesses up to and including 9.5 mm ( ⁄8 in.).

NOTE 1—Caution: Heat-strengthened glass may not be suitable for

On thicknesses over 9.5 mm, the center of tong marks, when

safety glazing as defined by ANSI Z97.1 or CPSC 16CFR1201.

present, shall be located a maximum of 19 mm ( ⁄4 in.) from

5.2 Kind FT, Types I and II—Fully tempered glass is up to

one edge of the glass. Tong marks shall be located on a specific

five times as strong as annealed glass of the same thickness and

edge when specified (see Section 6). For location of tong marks

configuration. When broken, it breaks into innumerable small

on glass with special fabrication or irregular patterns, consult

fragments of more or less cubical shape. Intended for general

fabricators.

glazing and safety glazing such as sliding doors, storm doors,

7.4 Distortion:

building entrances, bath and shower enclosures, counter tops,

7.4.1 Thermally tempered and heat-strengthened glass is

showcases, interior partitions, and other uses where the supe-

made by heating glass in a furnace to a temperature at which

rior strength characteristics and safety properties of fully

the glass becomes slightly plastic. Immediately after heating,

tempered glass are required. the glass surfaces are rapidly cooled by quenching with air

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C 1048 – 97b

from a series of nozzles. The original flatness of the glass is before being heat treated. Consult suppliers for special edges or

slightly modified by the heat treatment, causing reflected irregular patterns or, when required, on a specific type of edge.

images to be distorted. When viewing images through the The following guidelines may be used for normal fabrication

glass, the distortion, in most glazing applications, is less than requirements.

that of reflected images and is not as noticeable.

7.8.1 Heat-treated glass can be furnished with holes,

7.4.2 Fully tempered and heat-strengthened glass that has notches, cutouts, and bevels.

been made in a vertical furnace contains small surface depres-

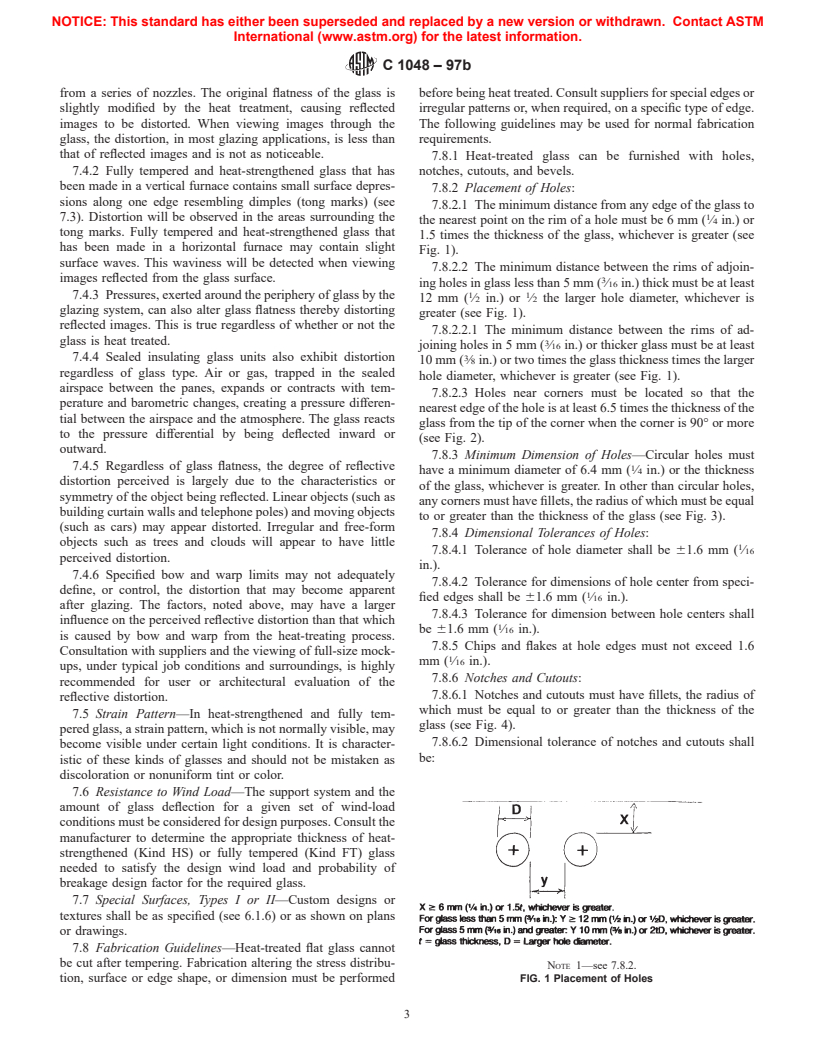

7.8.2 Placement of Holes:

sions along one edge resembling dimples (tong marks) (see

7.8.2.1 The minimum distance from any edge of the glass to

7.3). Distortion will be observed in the areas surrounding the 1

the nearest point on the rim of a hole must be 6 mm ( ⁄4 in.) or

tong marks. Fully tempered and heat-strengthened glass that

1.5 times the thickness of the glass, whichever is greater (see

has been made in a horizontal furnace may contain slight

Fig. 1).

surface waves. This waviness will be detected when viewing

7.8.2.2 The minimum distance between the rims of adjoin-

images reflected from the glass surface.

ing holes in glass less than 5 mm ( ⁄16 in.) thick must be at least

1 1

7.4.3 Pressures, exerted around the periphery of glass by the

12 mm ( ⁄2 in.) or ⁄2 the larger hole diameter, whichever is

glazing system, can also alter glass flatness thereby distorting

greater (see Fig. 1).

reflected images. This is true regardless of whether or not the

7.8.2.2.1 The minimum distance between the rims of ad-

glass is heat treated.

joining holes in 5 mm ( ⁄16 in.) or thicker glass must be at least

7.4.4 Sealed insulating glass units also exhibit distortion

10 mm ( ⁄8 in.) or two times the glass thickness times the larger

regardless of glass type. Air or gas, trapped in the sealed

hole diameter, whichever is greater (see Fig. 1).

airspace between the panes, expands or contracts with tem-

7.8.2.3 Holes near corners must be located so that the

perature and barometric changes, creating a pressure differen-

nearest edge of the hole is at least 6.5 times the thickness of the

tial between the airspace and the atmosphere. The glass reacts

glass from the tip of the corner when the corner is 90° or more

to the pressure differential by being deflected inward or

(see Fig. 2).

outward.

7.8.3 Minimum Dimension of Holes—Circular holes must

7.4.5 Regardless of glass flatness, the degree of reflective

have a minimum diameter of 6.4 mm ( ⁄4 in.) or the thickness

distortion perceived is largely due to the characteristics or

of the glass, whichever is greater. In other than circular holes,

symmetry of the object being reflected. Linear objects (such as

any corners must have fillets, the radius of which must be equal

building curtain walls and telephone poles) and moving objects

to or greater than the thickness of the glass (see Fig. 3).

(such as cars) may appear distorted. Irregular and free-form

7.8.4 Dimensional Tolerances of Holes:

objects such as trees and clouds will appear to have little

7.8.4.1 Tolerance of hole diameter shall be 61.6 mm ( ⁄16

perceived distortion.

in.).

7.4.6 Specified bow and warp limits may not adequately

7.8.4.2 Tolerance for dimensions of hole center from speci-

define, or control, the distortion that may become apparent

fied edges shall be 61.6 mm ( ⁄16 in.).

after glazing. The factors, noted above, may have a larger

7.8.4.3 Tolerance for dimension between hole centers shall

influence on the perceived reflective distortion than that which

be 61.6 mm ( ⁄16 in.).

is caused by bow and warp from the heat-treating process.

7.8.5 Chips and flakes at hole edges must not exceed 1.6

Consultation with suppliers and the viewing of full-size mock-

mm ( ⁄16 in.).

ups, under typical job conditions and surroundings, is highly

7.8.6 Notches and Cutouts:

recommended for user or architectural evaluation of the

7.8.6.1 Notches and cutouts must have fillets, the radius of

reflective distortion.

which must be equal to or greater than the thickness of the

7.5 Strain Pattern—In heat-strengthened and fully tem-

glass (see Fig. 4).

pered glass, a strain pattern, which is not normally visible, may

7.8.6.2 Dimensional tolerance of notches and cutouts shall

become visible under certain light conditions. It is character-

be:

istic of these kinds of glasses and should not be mistaken as

discoloration or nonuniform tint or color.

7.6 Resistance to Wind Load—The support system and the

amount of glass deflection for a given set of wind-load

conditions must be considered for design purposes. Consult the

manufacturer to determine the appropriate thickness of heat-

strengthened (Kind HS) or fully tempered (Kind FT) glass

needed to satisfy the design wind load and probability of

breakage design factor for the required glass.

7.7 Special Surfaces, Types I or II—Custom designs or

textures shall be as specified (see 6.1.6) or as shown on plans

or drawings.

7.8 Fabrication Guidelines—Heat-treated flat glass cannot

be cut after tempering. Fabrication altering the stress distribu-

NOTE 1—see 7.8.2.

tion, surface or edge shape, or dimension mu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.