ASTM C1652/C1652M-21

(Test Method)Standard Test Method for Measuring Optical Distortion in Flat Glass Products Using Digital Photography of Grids

Standard Test Method for Measuring Optical Distortion in Flat Glass Products Using Digital Photography of Grids

SIGNIFICANCE AND USE

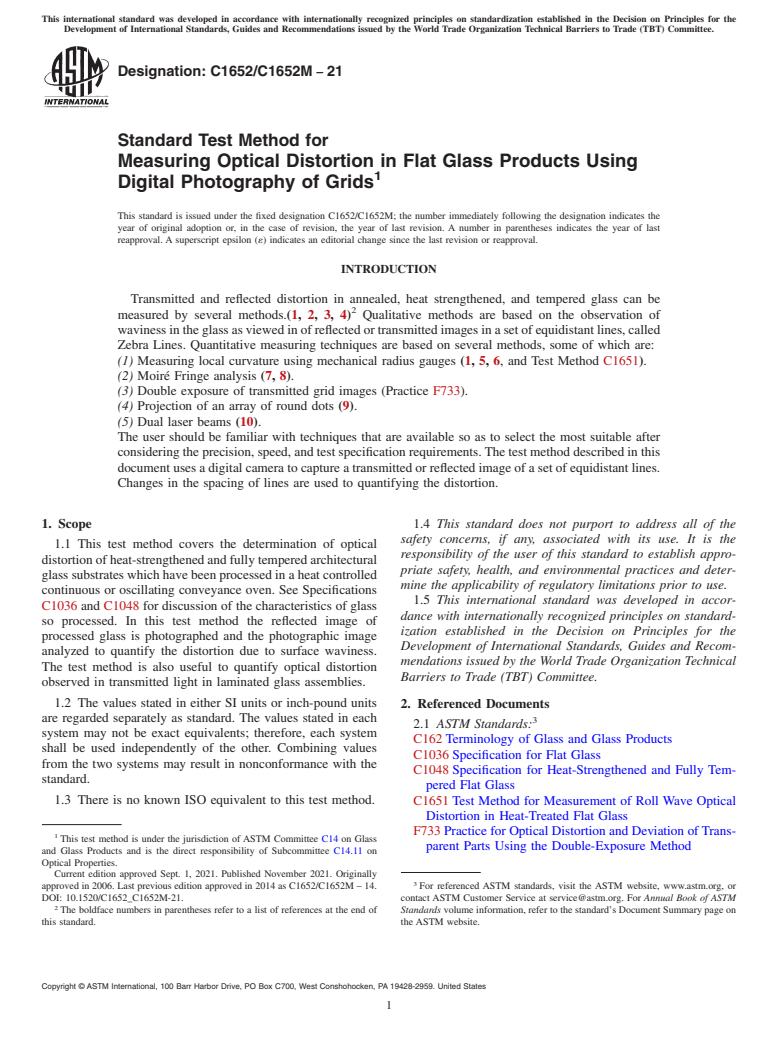

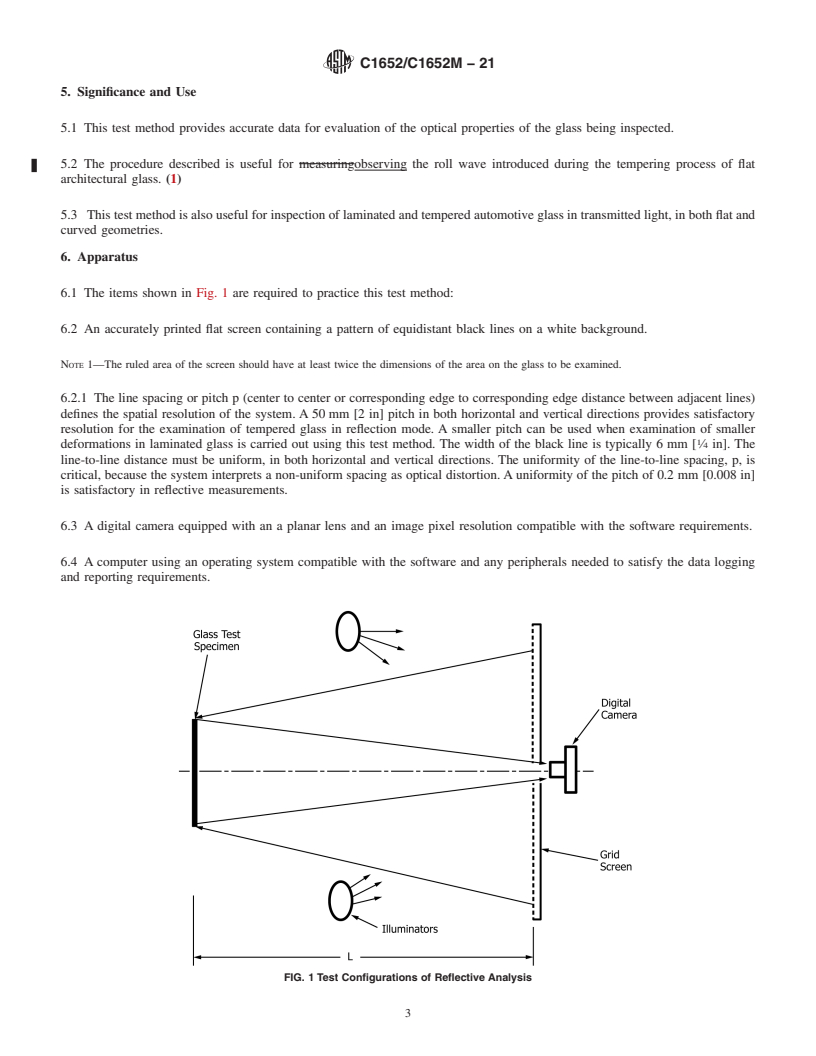

5.1 This test method provides accurate data for evaluation of the optical properties of the glass being inspected.

5.2 The procedure described is useful for observing the roll wave introduced during the tempering process of flat architectural glass. (1)

5.3 This test method is also useful for inspection of laminated and tempered automotive glass in transmitted light, in both flat and curved geometries.

SCOPE

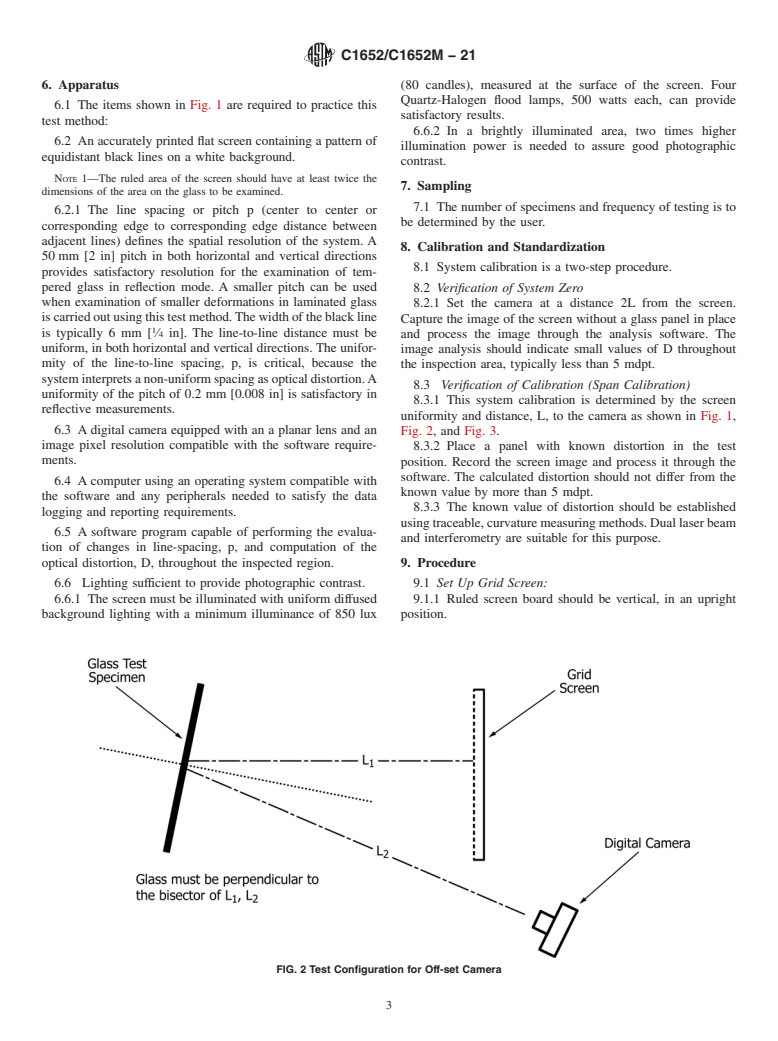

1.1 This test method covers the determination of optical distortion of heat-strengthened and fully tempered architectural glass substrates which have been processed in a heat controlled continuous or oscillating conveyance oven. See Specifications C1036 and C1048 for discussion of the characteristics of glass so processed. In this test method the reflected image of processed glass is photographed and the photographic image analyzed to quantify the distortion due to surface waviness. The test method is also useful to quantify optical distortion observed in transmitted light in laminated glass assemblies.

1.2 The values stated in either SI units or inch-pound units are regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 There is no known ISO equivalent to this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C1652/C1652M −21

Standard Test Method for

Measuring Optical Distortion in Flat Glass Products Using

1

Digital Photography of Grids

This standard is issued under the fixed designation C1652/C1652M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Transmitted and reflected distortion in annealed, heat strengthened, and tempered glass can be

2

measured by several methods.(1, 2, 3, 4) Qualitative methods are based on the observation of

wavinessintheglassasviewedinofreflectedortransmittedimagesinasetofequidistantlines,called

Zebra Lines. Quantitative measuring techniques are based on several methods, some of which are:

(1) Measuring local curvature using mechanical radius gauges (1, 5, 6, and Test Method C1651).

(2) Moiré Fringe analysis (7, 8).

(3) Double exposure of transmitted grid images (Practice F733).

(4) Projection of an array of round dots (9).

(5) Dual laser beams (10).

The user should be familiar with techniques that are available so as to select the most suitable after

considering the precision, speed, and test specification requirements.The test method described in this

document uses a digital camera to capture a transmitted or reflected image of a set of equidistant lines.

Changes in the spacing of lines are used to quantifying the distortion.

1. Scope 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of optical

responsibility of the user of this standard to establish appro-

distortionofheat-strengthenedandfullytemperedarchitectural

priate safety, health, and environmental practices and deter-

glass substrates which have been processed in a heat controlled

mine the applicability of regulatory limitations prior to use.

continuous or oscillating conveyance oven. See Specifications

1.5 This international standard was developed in accor-

C1036 and C1048 for discussion of the characteristics of glass

dance with internationally recognized principles on standard-

so processed. In this test method the reflected image of

ization established in the Decision on Principles for the

processed glass is photographed and the photographic image

Development of International Standards, Guides and Recom-

analyzed to quantify the distortion due to surface waviness.

mendations issued by the World Trade Organization Technical

The test method is also useful to quantify optical distortion

Barriers to Trade (TBT) Committee.

observed in transmitted light in laminated glass assemblies.

1.2 The values stated in either SI units or inch-pound units

2. Referenced Documents

are regarded separately as standard. The values stated in each 3

2.1 ASTM Standards:

system may not be exact equivalents; therefore, each system

C162 Terminology of Glass and Glass Products

shall be used independently of the other. Combining values

C1036 Specification for Flat Glass

from the two systems may result in nonconformance with the

C1048 Specification for Heat-Strengthened and Fully Tem-

standard.

pered Flat Glass

1.3 There is no known ISO equivalent to this test method.

C1651 Test Method for Measurement of Roll Wave Optical

Distortion in Heat-Treated Flat Glass

F733 Practice for Optical Distortion and Deviation ofTrans-

1

This test method is under the jurisdiction of ASTM Committee C14 on Glass

parent Parts Using the Double-Exposure Method

and Glass Products and is the direct responsibility of Subcommittee C14.11 on

Optical Properties.

Current edition approved Sept. 1, 2021. Published November 2021. Originally

3

approved in 2006. Last previous edition approved in 2014 as C1652/C1652M – 14. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/C1652_C1652M-21. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1652/C1652M−21

4

2.2 Other Standards: 4. Summary of Test Method

U.S.Patent7345698 OpticalSystemforImagingDistortions

4.1 This test procedure was designed to provide an accurate

in Moving Reflective Sheets (2003)

method of quantifying the opt

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1652/C1652M − 14 C1652/C1652M − 21

Standard Test Method for

Measuring Optical Distortion in Flat Glass Products Using

1

Digital Photography of Grids

This standard is issued under the fixed designation C1652/C1652M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Transmitted and reflected distortion in annealed, heat strengthened, and tempered glass can be

2

measured by several methods.(1, 2, 3, 4) Qualitative methods are based on the observation of

waviness in the glass as viewed in of reflected or transmitted images in a set of equidistant lines, called

Zebra Lines. Quantitative measuring techniques are based on several methods, some of which are:

(1(1)) Measuring local curvature using mechanical radius gages (gauges (1, 5, 6, and Test Method

C1651)).

(2(2)) Moiré Fringe analysis (7, 8)).

(3(3)) Double exposure of transmitted grid images (Practice F733) ).

(4(4)) Projection of an array of round dots (9)).

(5(5)) Dual laser beams (10)).

The user should be familiar with techniques that are available so as to select the most suitable after

considering the precision, speed, and test specification requirements. The test method described in this

document uses a digital camera to capture a transmitted or reflected image of a set of equidistant lines.

Changes in the spacing of lines are used to quantifying the distortion.

1. Scope

1.1 This test method covers the determination of optical distortion of heat-strengthened and fully tempered architectural glass

substrates which have been processed in a heat controlled continuous or oscillating conveyance oven. See Specifications C1036

and C1048 for discussion of the characteristics of glass so processed. In this test method the reflected image of processed glass

is photographed and the photographic image analyzed to quantify the distortion due to surface waviness. The test method is also

useful to quantify optical distortion observed in transmitted light in laminated glass assemblies.

1.2 The values stated in either SI units or inch-pound units are regarded separately as standard. The values stated in each system

may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two

systems may result in nonconformance with the standard.

1.3 There is no known ISO equivalent to this standard.test method.

1

This test method is under the jurisdiction of ASTM Committee C14 on Glass and Glass Products and is the direct responsibility of Subcommittee C14.11 on Optical

Properties.

Current edition approved May 1, 2014Sept. 1, 2021. Published May 2014November 2021. Originally approved in 2006. Last previous edition approved in 20062014 as

C1652/C1652M – 06.14. DOI: 10.1520/C1652_C1652M-14.10.1520/C1652_C1652M-21.

2

The boldface numbers in parentheses refer to a list of references at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1652/C1652M − 21

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of

the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

C162 Terminology of Glass and Glass Products

C1036 Specification for Flat Glass

C1048 Specification for Heat-Strengthened and Fully Tempered Flat Glass

C1651 Test Method for Measurement of Roll Wave Optical Distortion in Heat-Treated Flat Glass

F733 Practice for Optical Distortion and Deviat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.