ASTM E2375-22

(Practice)Standard Practice for Ultrasonic Testing of Wrought Products

Standard Practice for Ultrasonic Testing of Wrought Products

SIGNIFICANCE AND USE

4.1 This practice is intended primarily for the examination of wrought metals, forged, rolled, machined parts or components to an ultrasonic class most typically specified in the purchase order or other contract document.

SCOPE

1.1 Purpose—This practice establishes the minimum requirements for ultrasonic examination of wrought products.

Note 1: This practice was adopted to replace MIL-STD-2154, 30 Sept. 1982. This practice is intended to be used for the same applications as the document which it replaced. Users should carefully review its requirements when considering its use for new, or different applications, or both.

1.2 Application—This practice is applicable for examination of materials such as, wrought metals and wrought metal products having a thickness or cross section equal to 0.250 in. (6.35 mm) or greater.

1.2.1 Wrought Aluminum Alloy Products—Examination shall be in accordance with Practice B594. Angle beam scans of wrought aluminum alloy products shall be performed in accordance with this practice as agreed upon by the purchaser and supplier.

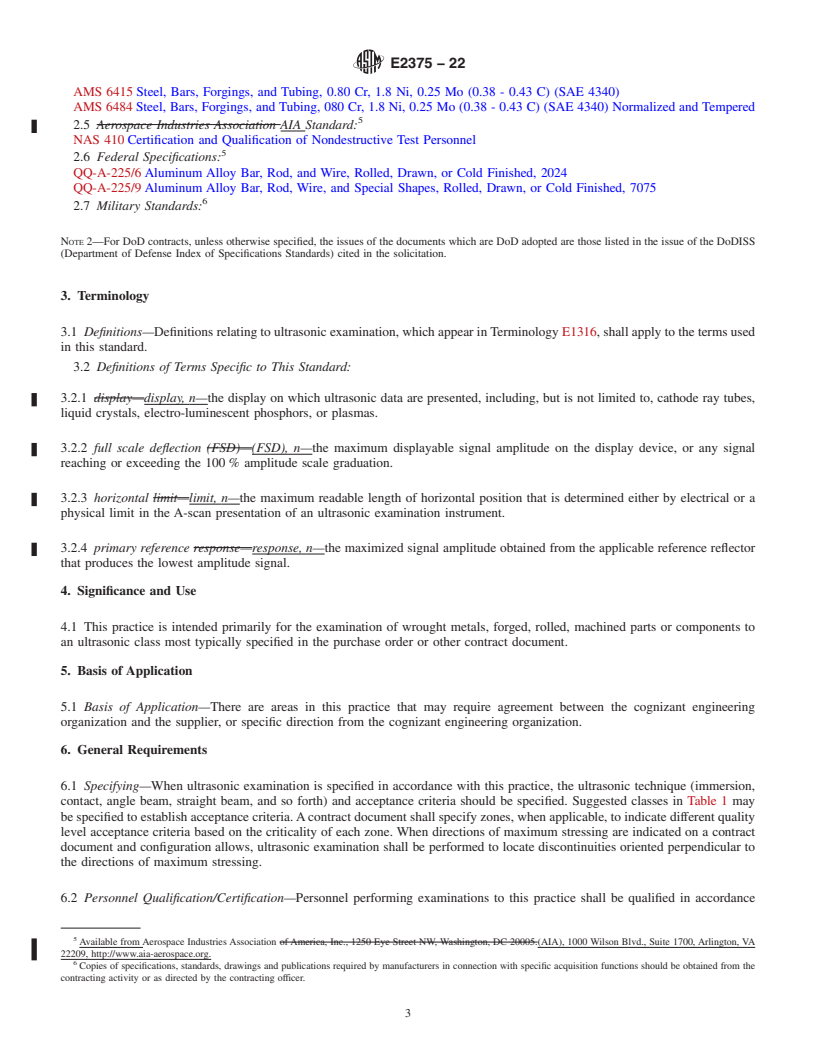

1.3 Acceptance Class—When examination is performed in accordance with this practice, engineering drawings, specifications, or other applicable documents shall indicate the acceptance criteria. Five ultrasonic acceptance classes are defined in Table 1. One or more of these classes may be used to establish the acceptance criteria or additional or alternate criteria may be specified.

1.4 Order of Precedence—Contractual requirements and authorized direction from the cognizant engineering organization may add to or modify the requirements of this practice. Otherwise, in the event of conflict between the text of this practice and the references cited herein, the text of this practice takes precedence. Nothing in this practice, however, supersedes applicable laws and regulations unless a specific exemption has been obtained.

1.5 Measurement Values—The values stated in inch-pounds are to be regarded as standard. The metric equivalents are in parentheses.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2375 − 22

Standard Practice for

1

Ultrasonic Testing of Wrought Products

This standard is issued under the fixed designation E2375; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 Purpose—This practice establishes the minimum re-

responsibility of the user of this standard to establish appro-

quirements for ultrasonic examination of wrought products.

priate safety, health, and environmental practices and deter-

NOTE1—ThispracticewasadoptedtoreplaceMIL-STD-2154,30Sept.

mine the applicability of regulatory limitations prior to use.

1982.This practice is intended to be used for the same applications as the

1.7 This international standard was developed in accor-

document which it replaced. Users should carefully review its require-

ments when considering its use for new, or different applications, or both.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

1.2 Application—Thispracticeisapplicableforexamination

Development of International Standards, Guides and Recom-

of materials such as, wrought metals and wrought metal

mendations issued by the World Trade Organization Technical

products having a thickness or cross section equal to 0.250 in.

Barriers to Trade (TBT) Committee.

(6.35 mm) or greater.

1.2.1 Wrought Aluminum Alloy Products—Examination

2. Referenced Documents

shall be in accordance with Practice B594. Angle beam scans

2.1 The following documents form a part of this practice to

of wrought aluminum alloy products shall be performed in

the extent specified herein:

accordance with this practice as agreed upon by the purchaser

2

and supplier.

2.2 ASTM Standards:

B107/B107MSpecification for Magnesium-Alloy Extruded

1.3 Acceptance Class—When examination is performed in

Bars, Rods, Profiles, Tubes, and Wire

accordance with this practice, engineering drawings,

B221Specification forAluminum andAluminum-Alloy Ex-

specifications, or other applicable documents shall indicate the

truded Bars, Rods, Wire, Profiles, and Tubes

acceptance criteria. Five ultrasonic acceptance classes are

B241/B241MSpecification for Aluminum and Aluminum-

defined in Table 1. One or more of these classes may be used

Alloy Seamless Pipe and Seamless Extruded Tube

to establish the acceptance criteria or additional or alternate

B594Practice for Ultrasonic Inspection ofAluminum-Alloy

criteria may be specified.

Wrought Products

1.4 Order of Precedence—Contractual requirements and

E127Practice for Fabrication and Control of Flat Bottomed

authorized direction from the cognizant engineering organiza-

Hole Ultrasonic Standard Reference Blocks

tion may add to or modify the requirements of this practice.

E164Practice for Contact Ultrasonic Testing of Weldments

Otherwise, in the event of conflict between the text of this

E213Practice for Ultrasonic Testing of Metal Pipe and

practiceandthereferencescitedherein,thetextofthispractice

Tubing

takes precedence. Nothing in this practice, however, super-

E317PracticeforEvaluatingPerformanceCharacteristicsof

sedes applicable laws and regulations unless a specific exemp-

Ultrasonic Pulse-Echo Testing Instruments and Systems

tion has been obtained.

without the Use of Electronic Measurement Instruments

E543Specification forAgencies Performing Nondestructive

1.5 Measurement Values—The values stated in inch-pounds

Testing

are to be regarded as standard. The metric equivalents are in

E1065Practice for Evaluating Characteristics of Ultrasonic

parentheses.

Search Units

E1316Terminology for Nondestructive Examinations

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.06 on

2

Ultrasonic Method. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2022. Published January 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2004. Last previous edition approved in 2016 as E2375–16. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2375-22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM I

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2375 − 16 E2375 − 22

Standard Practice for

1

Ultrasonic Testing of Wrought Products

This standard is issued under the fixed designation E2375; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 Purpose—This practice establishes the minimum requirements for ultrasonic examination of wrought products.

NOTE 1—This standardpractice was adopted to replace MIL-STD-2154, 30 Sept. 1982. This standardpractice is intended to be used for the same

applications as the document which it replaced. Users should carefully review its requirements when considering its use for new, or different applications,

or both.

1.2 Application—This practice is applicable for examination of materials such as, wrought metals and wrought metal products

having a thickness or cross section equal to 0.250 in. (6.35 mm) or greater.

1.2.1 Wrought Aluminum Alloy Products—Examination shall be in accordance with Practice B594. Angle beam scans of wrought

aluminum alloy products shall be performed in accordance with this practice as agreed upon by the purchaser and supplier.

1.3 Acceptance Class—When examination is performed in accordance with this practice, engineering drawings, specifications, or

other applicable documents shall indicate the acceptance criteria. Five ultrasonic acceptance classes are defined in Table 1. One

or more of these classes may be used to establish the acceptance criteria or additional or alternate criteria may be specified.

1.4 Order of Precedence—Contractual requirements and authorized direction from the cognizant engineering organization may

add to or modify the requirements of this practice. Otherwise, in the event of conflict between the text of this practice and the

references cited herein, the text of this practice takes precedence. Nothing in this practice, however, supersedes applicable laws

and regulations unless a specific exemption has been obtained.

1.5 Measurement Values—The values stated in inch-pounds are to be regarded as standard. The metric equivalents are in

parentheses.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents form a part of this practice to the extent specified herein:

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic Method.

Current edition approved Dec. 1, 2016Dec. 1, 2022. Published January 2017January 2023. Originally approved in 2004. Last previous edition approved in 20132016 as

E2375 - 08E2375 – 16.(2013). DOI: 10.1520/E2375-16.10.1520/E2375-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2375 − 22

TABLE 1 Ultrasonic Classes

C D

Single Discontinuity Loss of Back

Multiple Linear Discontinuity G,H

Class Noise

A,B E,F

Response Discontinuities Length and Response Reflection Percent

H

3 3 1

AAA 25 % of ⁄64 in.FB 10 % of ⁄64 in. ⁄8 in. (3.176 mm) long or 10 % of 50 alarm level

3

(0.119 mm) FB ⁄64 in. (0.119 mm) FB

H I

3 2 1

AA ⁄64 in. (1.19 mm) ⁄64 in. (0.794 mm) ⁄2 in. (12. 7 mm) 50 alarm level

FB

FB long

2

⁄64 in. response (0.794 mm)

FB

5 3

A ⁄64 in. (1.98 mm) ⁄64 in. (1.191 mm) 1 in. (25.4 mm) 50 alarm level

FB FB long

3

⁄64 in. response (1.19 mm)

FB

8 5

B ⁄64 in. (3.18 mm) ⁄64 (1.98 mm) 1 in. (25.4 mm) 50 alarm level

FB FB long

5

⁄64 in. response (1.98 mm)

FB

8

C ⁄64 in. (3.18 mm) Not Applicable Not Applicable 50 alarm level

A B

Any discontinuity with a response gre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.