ASTM D2557-98(2010)e1

(Test Method)Standard Test Method for Tensile-Shear Strength of Adhesives in the Subzero Temperature Range from -267.8 to -55°C (-450 to -67°F)

Standard Test Method for Tensile-Shear Strength of Adhesives in the Subzero Temperature Range from -267.8 to -55°C (-450 to -67°F)

SCOPE

1.1 This test method covers the determination of the comparative shear strength of adhesives for bonding metals when tested on a standard specimen and under specified conditions of preparation and testing at extreme subzero temperatures.

1.2 This test method is applicable to the temperature range from -267.8 to -55°C (-450 to -67°F).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautions are given in 8.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D2557 − 98 (Reapproved 2010)

Standard Test Method for

Tensile-Shear Strength of Adhesives in the Subzero

Temperature Range from −267.8 to −55°C (−450 to −67°F)

This standard is issued under the fixed designation D2557; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Section 8.6.4 was editorially corrected in October 2010.

1. Scope Lap-Joint Adhesively Bonded Metal Specimens by Ten-

sion Loading (Metal-to-Metal)

1.1 This test method covers the determination of the com-

D4896Guide for Use ofAdhesive-Bonded Single Lap-Joint

parative shear strength of adhesives for bonding metals when

Specimen Test Results

testedonastandardspecimenandunderspecifiedconditionsof

preparation and testing at extreme subzero temperatures.

3. Terminology

1.2 This test method is applicable to the temperature range

3.1 Definitions—Many terms in this test method are defined

from -267.8 to -55°C (-450 to -67°F).

in Terminology D907.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

4. Significance and Use

only.

4.1 This test method may be used as an accelerated screen-

1.4 This standard does not purport to address all of the

ing test for assessing the strength properties of adhesives and

safety concerns, if any, associated with its use. It is the

adhesive joints at subzero temperatures. This test method may

responsibility of the user of this standard to establish appro-

also be used to determine the effects of various surface

priate safety and health practices and determine the applica-

preparations, substrates, or adhesive systems on the durability

bility of regulatory limitations prior to use. Specific precau-

of the adhesive joints at subzero temperatures.

tions are given in 8.3.

4.2 Tensile shear strengths of various adhesives, surface

2. Referenced Documents

preparations,andsubstratesmaybecomparedbyusingthistest

2.1 ASTM Standards: method for uniform sets of conditions. To assess the overall

A167 Specification for Stainless and Heat-Resisting tensile shear strength of a given adhesive, surface preparation,

Chromium-Nickel Steel Plate, Sheet, and Strip (With- and substrate should be tested under a range of stress and

drawn 2014) temperatures. For a specific end use, the needed strength

B209Specification for Aluminum and Aluminum-Alloy properties using only one set of test conditions may be

Sheet and Plate obtained.

B265Specification for Titanium and Titanium Alloy Strip,

4.3 The misuse of strength values obtained from this test

Sheet, and Plate

method as design-allowable stress values for structural joints

D907Terminology of Adhesives

could lead to product failure, property damage, and human

D1002Test Method for Apparent Shear Strength of Single-

injury.

4.3.1 The apparent shear strength of an adhesive obtained

from a given small single-lap specimen may differ from that

This test method is under the jurisdiction of ASTM Committee D14 on

obtained from a joint made with different adherends or by a

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

Bonding Adhesives.

differentbondingprocess.Thenormalvariationoftemperature

Current edition approved Oct. 1, 2010. Published October 2010. Originally

and moisture in the service environment causes the adherends

approved in 1966. Last previous edition approved in 2004 as D2557–98(2004).

and the adhesive to swell or shrink. The adherends and

DOI: 10.1520/D2557-98R10E01.

adhesive are likely to have different thermal and moisture

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

coefficients of expansion. Even in small specimens, short-term

Standards volume information, refer to the standard’s Document Summary page on

environment changes can induce internal stresses of chemical

the ASTM website.

changes in the adhesive that permanently affect the apparent

The last approved version of this historical standard is referenced on

www.astm.org. strength and other properties of the adhesive.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D2557 − 98 (2010)

NOTE 1—“A” dimension varies with specimen thickness.

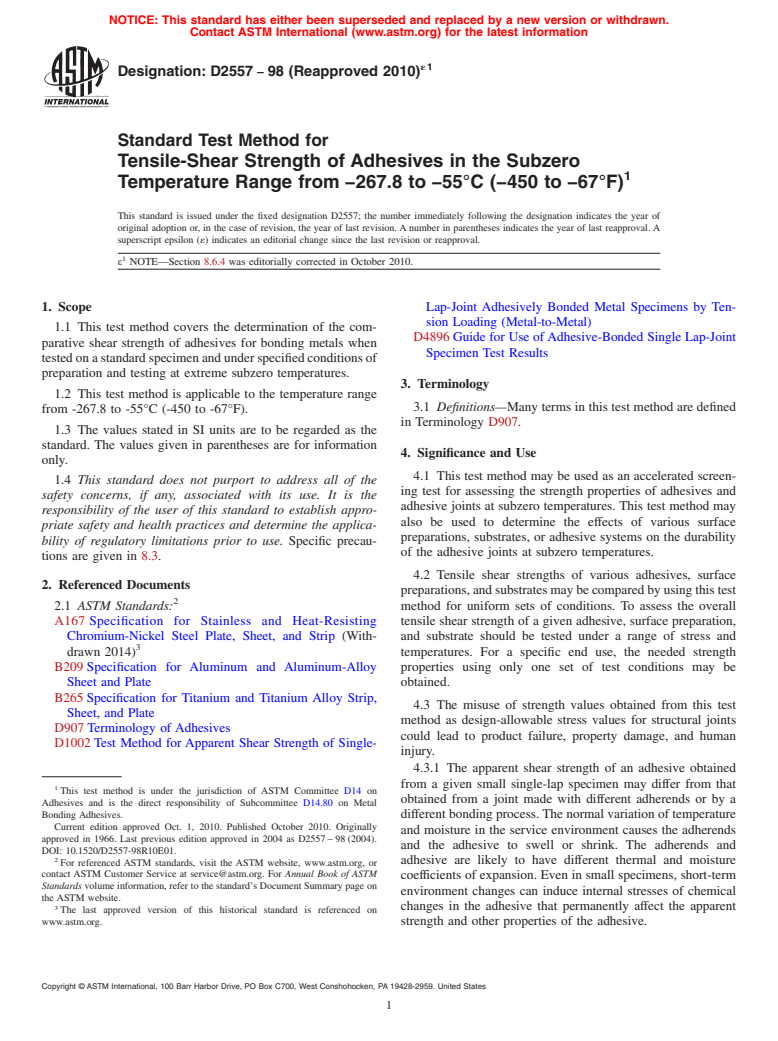

FIG. 1 Clevis for Holding “Pin-Type” Lap Shear Coupons

NOTE 1—Cold box configurations are commercially available which

can be used from room temperature to −185°C. These utilize chilled

gaseous nitrogen or gaseous carbon dioxide.

FIG. 2 Diagrammatic View of Cryostat and Accessories

4.3.2 The problem of predicting joint behavior in a chang- from the joints tested without thorough analysis and under-

ing environment is even more difficult if a different type of standing of the joint and adhesive behaviors.

adherendisusedinalargerstructuraljointthanwasusedinthe 4.3.4 Single-lap tests may be used for comparing and

small specimen. selecting adhesives or bonding processes for susceptibility to

4.3.3 The apparent shear strength measured with a single- fatigueandenvironmentalchanges,butsuchcomparisonsmust

lap specimen is not suitable for determining design-allowable be made with great caution since different adhesives may

stressesfordesigningstructuraljointsthatdifferinanymanner respond differently in different joints. See Guide D4896 for

´1

D2557 − 98 (2010)

further discussion of the concepts relative to interpretation of

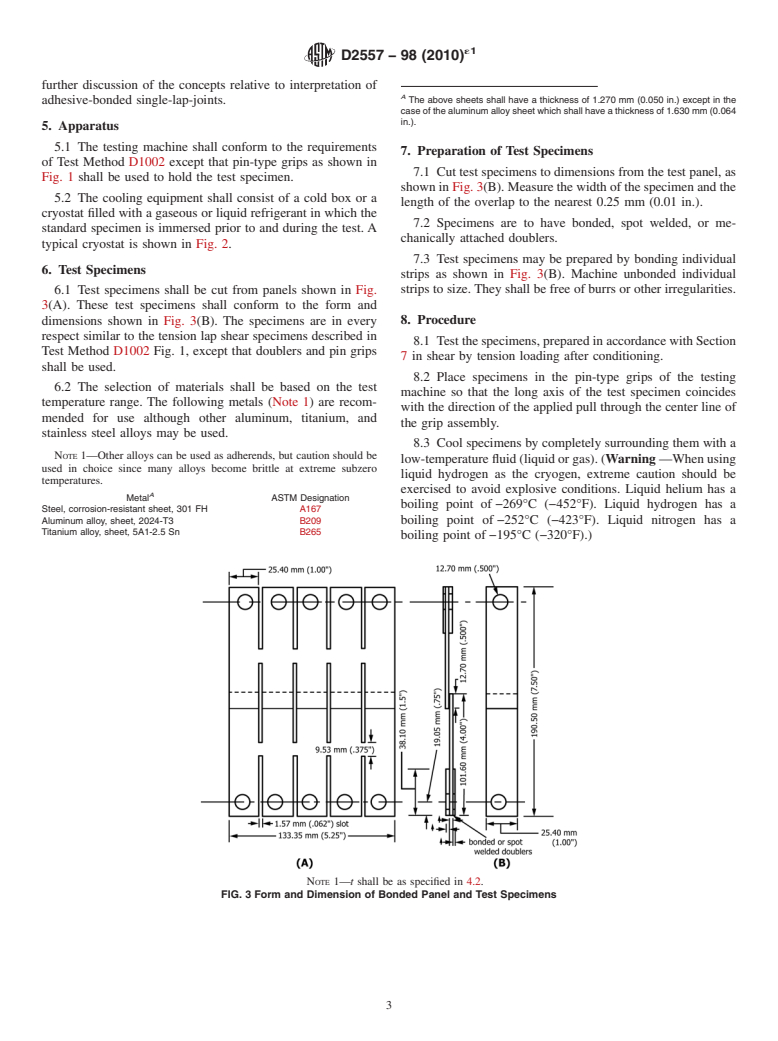

A

The above sheets shall have a thickness of 1.270 mm (0.050 in.) except in the

adhesive-bonded single-lap-joints.

case of the aluminum alloy sheet which shall have a thickness of 1.630 mm (0.064

in.).

5. Apparatus

5.1 The testing machine shall conform to the requirements

7. Preparation of Test Specimens

of Test Method D1002 except that pin-type grips as shown in

7.1 Cut test specimens to dimensions from the test panel, as

Fig. 1 shall be used to hold the test specimen.

showninFig.3(B).Measurethewidthofthespecimenandthe

5.2 The cooling equipment shall consist of a cold box or a

length of the overlap to the nearest 0.25 mm (0.01 i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.