ASTM D1072-90(1999)

(Test Method)Standard Test Method for Total Sulfur in Fuel Gases

Standard Test Method for Total Sulfur in Fuel Gases

SCOPE

1.1 This test method covers the determination of total sulfur in combustible fuel gases, when present in concentrations between 1 and 30 grains of sulfur per 100 cubic feet (25 and 700 mg/m ). It is applicable to natural gases, manufactured gases, and mixed gases, such as are distributed by gas utility companies.

1.2 The values stated in inch-pound units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn

Contact ASTM International (www.astm.org) for the lastest information

Designation:D1072–90(Reapproved 1999)

Standard Test Method for

Total Sulfur in Fuel Gases

This standard is issued under the fixed designation D1072; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodcoversthedeterminationoftotalsulfur

in combustible fuel gases, when present in concentrations

between 1 and 30 grains of sulfur per 100 ft (25 and 700

mg/m ). It is applicable to natural gases, manufactured gases,

and mixed gases, such as are distributed by gas utility

companies.

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

as standard.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

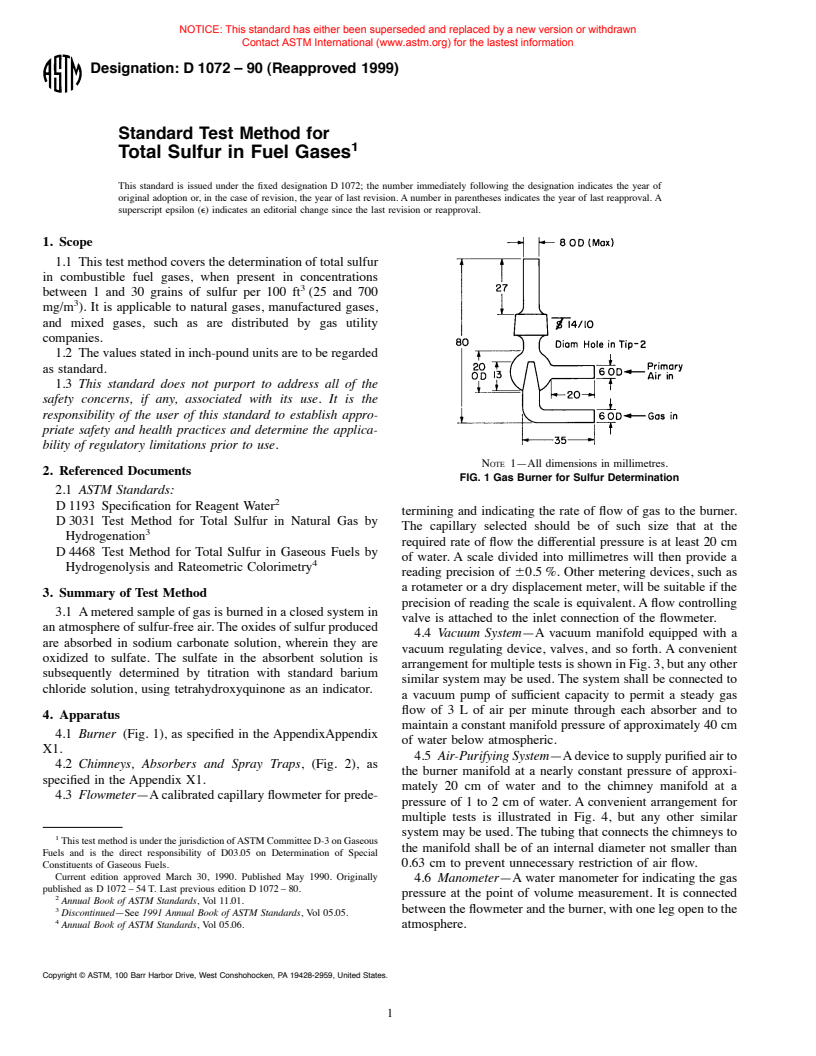

NOTE 1—All dimensions in millimetres.

2. Referenced Documents

FIG. 1 Gas Burner for Sulfur Determination

2.1 ASTM Standards:

D1193 Specification for Reagent Water

termining and indicating the rate of flow of gas to the burner.

D3031 Test Method for Total Sulfur in Natural Gas by

The capillary selected should be of such size that at the

Hydrogenation

required rate of flow the differential pressure is at least 20 cm

D4468 Test Method for Total Sulfur in Gaseous Fuels by

of water. A scale divided into millimetres will then provide a

Hydrogenolysis and Rateometric Colorimetry

reading precision of 60.5%. Other metering devices, such as

a rotameter or a dry displacement meter, will be suitable if the

3. Summary of Test Method

precision of reading the scale is equivalent.Aflow controlling

3.1 Ameteredsampleofgasisburnedinaclosedsystemin

valve is attached to the inlet connection of the flowmeter.

anatmosphereofsulfur-freeair.Theoxidesofsulfurproduced

4.4 Vacuum System—A vacuum manifold equipped with a

are absorbed in sodium carbonate solution, wherein they are

vacuum regulating device, valves, and so forth. A convenient

oxidized to sulfate. The sulfate in the absorbent solution is

arrangementformultipletestsisshowninFig.3,butanyother

subsequently determined by titration with standard barium

similar system may be used. The system shall be connected to

chloride solution, using tetrahydroxyquinone as an indicator.

a vacuum pump of sufficient capacity to permit a steady gas

flow of 3 L of air per minute through each absorber and to

4. Apparatus

maintain a constant manifold pressure of approximately 40 cm

4.1 Burner (Fig. 1), as specified in the AppendixAppendix

of water below atmospheric.

X1.

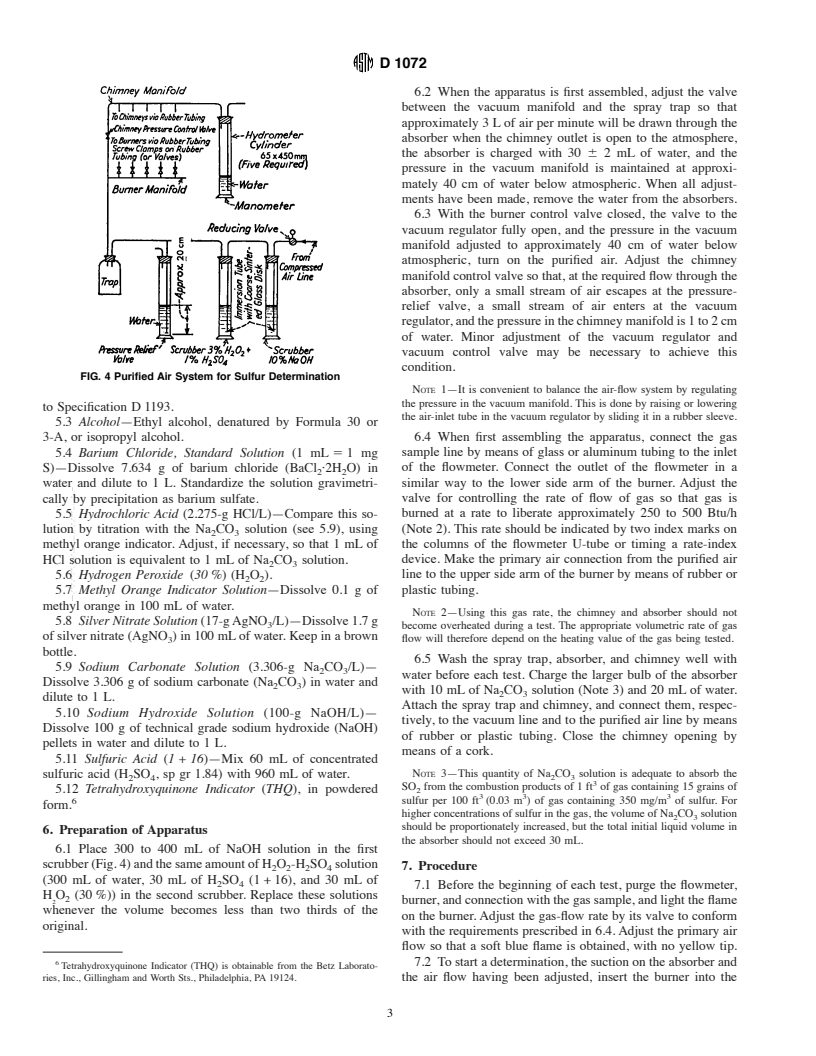

4.5 Air-PurifyingSystem—Adevicetosupplypurifiedairto

4.2 Chimneys, Absorbers and Spray Traps, (Fig. 2), as

the burner manifold at a nearly constant pressure of approxi-

specified in the Appendix X1.

mately 20 cm of water and to the chimney manifold at a

4.3 Flowmeter—Acalibratedcapillaryflowmeterforprede-

pressure of 1 to 2 cm of water. A convenient arrangement for

multiple tests is illustrated in Fig. 4, but any other similar

system may be used.The tubing that connects the chimneys to

ThistestmethodisunderthejurisdictionofASTMCommitteeD-3onGaseous

the manifold shall be of an internal diameter not smaller than

Fuels and is the direct responsibility of D03.05 on Determination of Special

0.63 cm to prevent unnecessary restriction of air flow.

Constituents of Gaseous Fuels.

Current edition approved March 30, 1990. Published May 1990. Originally

4.6 Manometer—Awater manometer for indicating the gas

published as D1072–54T. Last previous edition D1072–80.

pressure at the point of volume measurement. It is connected

Annual Book of ASTM Standards, Vol 11.01.

3 betweentheflowmeterandtheburner,withonelegopentothe

Discontinued—See 1991 Annual Book of ASTM Standards, Vol 05.05.

Annual Book of ASTM Standards, Vol 05.06. atmosphere.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D1072

NOTE 1—In the case of those dimensions for which no specific tolerances are designated above, the permissible variation is 610% to the nearest 1

mm, provided, however, that in no case shall the deviation be greater than 5 mm.

FIG. 2 Detailed Drawing of Combustion and Absorption Apparatus for Sulfur Determination

all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

5.2 PurityofWater—Unlessotherwiseindicated,references

towatershallbeunderstoodtomeanreagentwaterconforming

FIG. 3 Suction System for Sulfur Determination

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

5. Reagents and Materials

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

5.1 Purity of Reagents—Reagent grade chemicals shall be

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

used in all tests. Unless otherwise indicated, it is intended that MD.

--``,`````,,,,`,`,`````,,```,`-`-`,,`,,`,`,,`---

D1072

6.2 When the apparatus is first assembled, adjust the valve

between the vacuum manifold and the spray trap so that

approximately 3 Lof air per minute will be drawn through the

absorber when the chimney outlet is open to the atmosphere,

the absorber is charged with 30 6 2 mL of water, and the

pressure in the vacuum manifold is maintained at approxi-

mately 40 cm of water below atmospheric. When all adjust-

ments have been made, remove the water from the absorbers.

6.3 With the burner control valve closed, the valve to the

vacuum regulator fully open, and the pressure in the vacuum

manifold adjusted to approximately 40 cm of water below

atmospheric, turn on the purified air. Adjust the chimney

manifoldcontrolvalvesothat,attherequiredflowthroughthe

absorber, only a small stream of air escapes at the pressure-

relief valve, a small stream of air enters at the vacuum

regulator,andthepressureinthechimneymanifoldis1to2cm

of water. Minor adjustment of the vacuum regulator and

vacuum control valve may be necessary to achieve this

condition.

FIG. 4 Purified Air System for Sulfur Determination

NOTE 1—It is convenient to balance the air-flow system by regulating

the pressure in the vacuum manifold. This is done by raising or lowering

to Specification D1193.

the air-inlet tube in the vacuum regulator by sliding it in a rubber sleeve.

5.3 Alcohol—Ethyl alcohol, denatured by Formula 30 or

3-A, or isopropyl alcohol. 6.4 When first assembling the apparatus, connect the gas

5.4 Barium Chloride, Standard Solution (1 mL51 mg sample line by means of glass or aluminum tubing to the inlet

S)—Dissolve 7.634 g of barium chloride (BaCl ·2H O) in of the flowmeter. Connect the outlet of the flowmeter in a

2 2

water and dilute to 1 L. Standardize the solution gravimetri- similar way to the lower side arm of the burner. Adjust the

cally by precipitation as barium sulfate. valve for controlling the rate of flow of gas so that gas is

burned at a rate to liberate approximately 250 to 500 Btu/h

5.5 Hydrochloric Acid (2.275-g HCl/L)—Compare this so-

lution by titration with the Na CO solution (see 5.9), using (Note 2). This rate should be indicated by two index marks on

2 3

the columns of the flowmeter U-tube or timing a rate-index

methyl orange indicator. Adjust, if necessary, so that 1 mL of

HCl solution is equivalent to 1 mL of Na CO solution. device. Make the primary air connection from the purified air

2 3

line to the upper side arm of the burner by means of rubber or

5.6 Hydrogen Peroxide (30%) (H O ).

2 2

5.7 Methyl Orange Indicator Solution—Dissolve 0.1 g of plastic tubing.

methyl orange in 100 mL of water.

NOTE 2—Using this gas rate, the chimney and absorber should not

5.8 SilverNitrateSolution(17-gAgNO /L)—Dissolve1.7g

become overheated during a test. The appropriate volumetric rate of gas

ofsilvernitrate(AgNO )in100mLofwater.Keepinabrown

flow will therefore depend on the heating value of the gas being tested.

bottle.

6.5 Wash the spray trap, absorber, and chimney well with

5.9 Sodium Carbonate Solution (3.306-g Na CO /L)—

2 3

water before each test. Charge the larger bulb of the absorber

Dissolve 3.306 g of sodium carbonate (Na CO ) in water and

2 3

with 10 mLof Na CO solution (Note 3) and 20 mLof water.

2 3

dilute to 1 L.

Attach the spray trap and chimney, and connect them, respec-

5.10 Sodium Hydroxide Solution (100-g NaOH/L)—

tively, to the vacuum line and to the purified air line by means

Dissolve 100 g of technical grade sodium hydroxide (NaOH)

of rubber or plastic tubing. Close the chimney opening by

pellets in water and dilute to 1 L.

means of a cork.

5.11 Sulfuric Acid (1+16)—Mix 60 mL of concentrated

NOTE 3—This quantity of Na CO solution is adequate to absorb the

sulfuric acid (H SO , sp gr 1.84) with 960 mL of water.

2 3

2 4

SO from the combustion products of 1 ft of gas containing 15 grains of

5.12 Tetrahydroxyquinone Indicator (THQ), in powdered 2

3 3 3

6 sulfur per 100 ft (0.03 m ) of gas containing 350 mg/m of sulfur. For

form.

higher concentrations of sulfur in the gas, the volume of Na CO solution

2 3

should be proportionately increased, but the total initial liquid volume in

6. Preparation of Apparatus

the absorbe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.