ASTM D4070-91(1996)e1

(Specification)Standard Specification for Adhesive Lubricant for Installation of Preformed Elastomeric Bridge Compression Seals in Concrete Structures (Withdrawn 2005)

Standard Specification for Adhesive Lubricant for Installation of Preformed Elastomeric Bridge Compression Seals in Concrete Structures (Withdrawn 2005)

SCOPE

1.1 This specification covers an adhesive lubricant for facilitating the insertion and positioning of preformed elastomeric bridge compression seals in either concrete or steel-faced joints, and which bonds the seal to the joint faces to waterproof the joint.

WITHDRAWN RATIONALE

This specification covers an adhesive lubricant for facilitating the insertion and positioning of preformed elastomeric bridge compression seals in either concrete or steel-faced joints, and which bonds the seal to the joint faces to waterproof the joint.

Originally under the jurisdiction of Committee D04 on Road and Paving Materials, this specification was withdrawn in January 2005 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 4070 – 91 (Reapproved 1996)

Standard Specification for

Adhesive Lubricant for Installation of Preformed

Elastomeric Bridge Compression Seals in Concrete

Structures

This standard is issued under the fixed designation D 4070; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in July 1996.

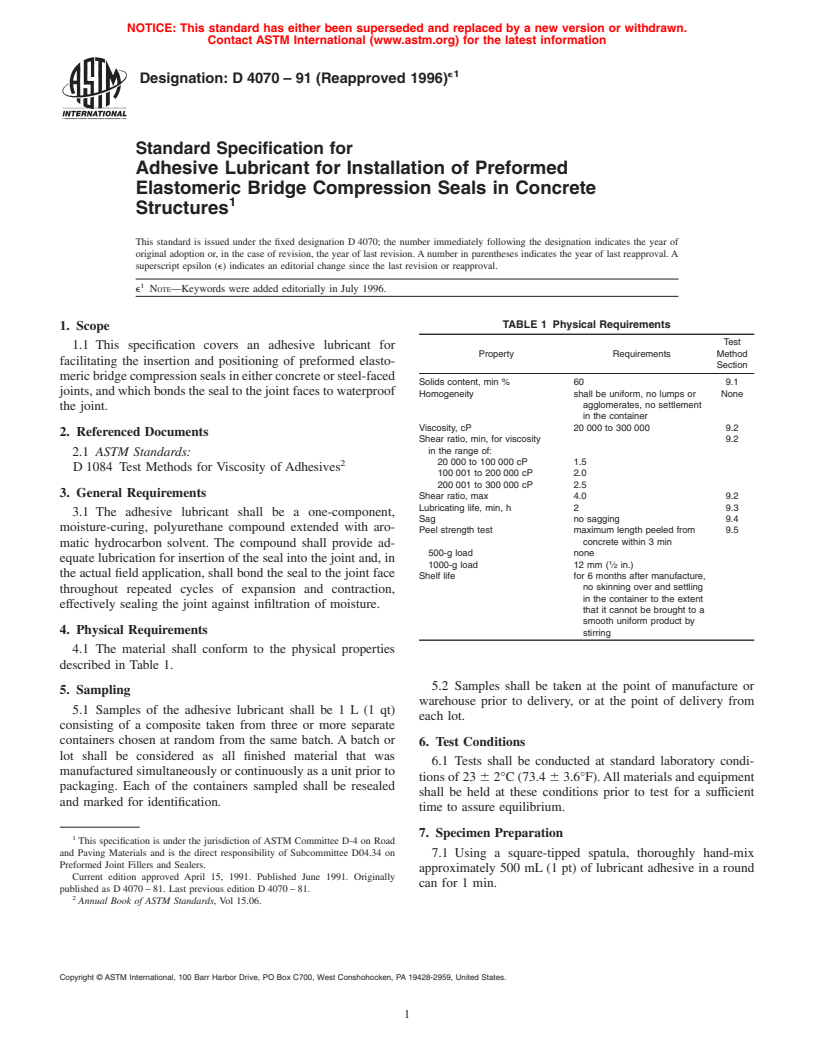

TABLE 1 Physical Requirements

1. Scope

Test

1.1 This specification covers an adhesive lubricant for

Property Requirements Method

facilitating the insertion and positioning of preformed elasto-

Section

mericbridgecompressionsealsineitherconcreteorsteel-faced

Solids content, min % 60 9.1

joints, and which bonds the seal to the joint faces to waterproof

Homogeneity shall be uniform, no lumps or None

agglomerates, no settlement

the joint.

in the container

Viscosity, cP 20 000 to 300 000 9.2

2. Referenced Documents

Shear ratio, min, for viscosity 9.2

in the range of:

2.1 ASTM Standards:

20 000 to 100 000 cP 1.5

D 1084 Test Methods for Viscosity of Adhesives

100 001 to 200 000 cP 2.0

200 001 to 300 000 cP 2.5

3. General Requirements

Shear ratio, max 4.0 9.2

Lubricating life, min, h 2 9.3

3.1 The adhesive lubricant shall be a one-component,

Sag no sagging 9.4

moisture-curing, polyurethane compound extended with aro-

Peel strength test maximum length peeled from 9.5

concrete within 3 min

matic hydrocarbon solvent. The compound shall provide ad-

500-g load none

equate lubrication for insertion of the seal into the joint and, in

1000-g load 12 mm ( ⁄2 in.)

the actual field application, shall bond the seal to the joint face

Shelf life for 6 months after manufacture,

no skinning over and settling

throughout repeated cycles of expansion and contraction,

in the container to the extent

effectively sealing the joint against infiltration of moisture.

that it cannot be brought to a

smooth uniform product by

4. Physical Requirements

stirring

4.1 The material shall conform to the physical properties

described in Table 1.

5.2 Samples shall be taken at the point of manufacture or

5. Sampling

warehouse prior to delivery, or at the point of delivery from

5.1 Samples of the adhesive lubricant shall be 1 L (1 qt)

each lot.

consisting of a composite taken from three or more separate

containers chosen at random from the same batch. A batch or

6. Test Conditions

lot shall be considered as all finished material that was

6.1 Tests shall be conducted at standard laboratory condi-

manufactured simultaneously or continuously as a unit prior to

tions of 23 6 2°C (73.4 6 3.6°F).All materials and equipment

packaging. Each of the containers sampled shall be resealed

shall be held at these conditions prior to test for a sufficient

and marked for identification.

time to assure equilibrium.

7. Specimen Preparation

This specification is under the jurisdiction of ASTM Committee D-4 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.34 on 7.1 Using a square-tipped spatula, thoroughly hand-mix

Preformed Joint Fillers and Sealers.

approximately 500 mL (1 pt) of lubricant adhesive in a round

Current edition approved April 15, 1991. Published June 1991. Originally

can for 1 min.

published as D 4070 – 81. Last previous edition D 4070 – 81.

Annual Book of ASTM Standards, Vol 15.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4070

8. Apparatus 9.2.2 Shear Ratio—With the spindle used for the viscosity

determination,measuretheviscosityofthematerialat2.5rpm;

8.1 Oven—The oven shall be a circulating air oven capable

and then at 0.5 rpm. Calculate shear ratio as follows:

of maintaining temperature of 105 6 2°C (221 6 4°F.).

8.2 Viscometer—It shall be a Brookfield Model RVT vis- Shear Ratio 5 viscosity at 0.5 rpm/viscosity at 2.5 rpm (2)

cometer with helipath stand and, TA, TB, TC, TD and TE

9.3 Lubricating Life—Apply a 65 to 78 mm wide, by 150

spindles.

mm long, by 0.75 6 0.10 mm thick (2 ⁄2 to 3 in. by 6 in. by

8.3 Rubber Strips—The rubber strips shall be 150 mm (6

0.030 6 0.004 in.) strip of the lubricant adhesive to a glass

in.) long, 25 mm (1 in.) wide and 1.5 mm ( ⁄16 in.) thick, and

plate or smooth-surface paper test chart using a film applicator.

shall be obtained from an outside wall of preformed elasto-

Testlubricatinglifebyrubbingfingeroncoatedchartat30-min

meric bridge seal representative of the seal to be bonded with

intervals. Record lubricating life as the time at which drag or

the adhesive lubricant.

friction increases noticeably and material starts to thicken or

8.4 ConcreteBlocks, 200 by 200 by 75 mm (8 by 8 by 3 in.)

become tacky.

and made of concrete similar to the concrete to which the seal

9.4 Sag—Applya0.7560.01mm(0.030 60.004-in.)thick

is to be bonded. The blocks shall be cured for at least 14 days

film of material to a glass plate or smooth-surface paper test

in a moisture room followed by at least 7 days at normal

chart in the manner as described in 10.3. Support glass plate or

laboratory air condition. The test surface shall be smooth,

chart vertically with the 150-mm (6-in.) axis of the strip

freshly sandblasted before testing.

horizontal. After 1 h, check for sagging or running.

8.5 Steel Roller—A suitable 50 mm (2 in.) wide roller

9.5 Peel Strength Test:

weighing 4.5 kg (10 lb).

9.5.1 Roughen one side of a 25-mm (1-in.) rubber strip with

8.6 Steel Blocks, 165 mm (6 ⁄2 in.) long by 50 mm (2 in.)

a coa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.