ASTM E2928/E2928M-23

(Practice)Standard Practice for Examination of Drillstring Threads Using the Alternating Current Field Measurement Technique

Standard Practice for Examination of Drillstring Threads Using the Alternating Current Field Measurement Technique

SIGNIFICANCE AND USE

5.1 The purpose of the alternating current field measurement method is to evaluate threads for surface breaking discontinuities such as fatigue cracks running along the thread root. The examination results may then be used to determine the fate of the test piece. This may involve re-examination by an alternative technique, immediate scrapping of the test piece, or reworking to remove discontinuities (beyond the scope of this practice). This practice is not intended for the examination of threads for non-surface breaking discontinuities.

SCOPE

1.1 This practice describes procedures to be followed during alternating current field measurement examination of drillstring threads on tubulars used for oil and gas exploration and production for detection and, if required, sizing of service-induced surface breaking discontinuities transverse to the pipe.

1.2 This practice is intended for use on threads in any metallic material.

1.3 This practice does not establish acceptance criteria. Typical industry practice is to reject these connections on detection of a confirmed crack.

1.4 While the alternating current field measurement technique is capable of detecting discontinuities in these connections, supplemental surface NDT methods such as magnetic particle testing for ferrous metals and penetrant testing for non-ferrous metals may detect additional discontinuities.

1.5 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system might not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from both systems may result in nonconformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2928/E2928M − 23

Standard Practice for

Examination of Drillstring Threads Using the Alternating

1

Current Field Measurement Technique

This standard is issued under the fixed designation E2928/E2928M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This practice describes procedures to be followed during 2.1 ASTM Standards:

alternating current field measurement examination of drill- E543 Specification for Agencies Performing Nondestructive

string threads on tubulars used for oil and gas exploration and Testing

production for detection and, if required, sizing of service- E1316 Terminology for Nondestructive Examinations

induced surface breaking discontinuities transverse to the pipe. E2261 Practice for Examination of Welds Using the Alter-

nating Current Field Measurement Technique

1.2 This practice is intended for use on threads in any

metallic material.

3. Terminology

1.3 This practice does not establish acceptance criteria.

3.1 For definitions of terms relating to this practice refer to

Typical industry practice is to reject these connections on

Terminology E1316, Section A, Common NDT terms, and

detection of a confirmed crack.

Section C, Electromagnetic testing. The following definitions

1.4 While the alternating current field measurement tech-

are specific to the alternating current field measurement tech-

nique is capable of detecting discontinuities in these

nique:

connections, supplemental surface NDT methods such as

3.2 Definitions:

magnetic particle testing for ferrous metals and penetrant

3.2.1 detector, n—one or more coils or elements used to

testing for non-ferrous metals may detect additional disconti-

sense or measure a magnetic field; also known as a receiver.

nuities.

3.2.2 exciter, n—a device that generates a time varying

1.5 Units—The values stated in either inch-pound units or

electromagnetic field, usually a coil energized with alternating

SI units are to be regarded separately as standard. The values

current (AC); also known as a transmitter.

stated in each system might not be exact equivalents; therefore,

3.2.3 uniform field, n—as applied to nondestructive testing

each system shall be used independently of the other. Combin-

with magnetic fields, the area of uniform magnetic field over

ing values from both systems may result in nonconformance

the surface of the material under examination produced by a

with the standard.

parallel induced alternating current, which has been passed

1.6 This standard does not purport to address all of the

through the test piece and is observable beyond the direct

safety concerns, if any, associated with its use. It is the

coupling of the exciting coil.

responsibility of the user of this standard to establish appro-

3.3 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

3.3.1 alternating current field measurement system, n—the

mine the applicability of regulatory limitations prior to use.

electronic instrumentation, software, probes, and all associated

1.7 This international standard was developed in accor-

components and cables required for performing an examination

dance with internationally recognized principles on standard-

using the alternating current field measurement technique.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.3.2 box, n—the female thread in a drillstring connection.

mendations issued by the World Trade Organization Technical

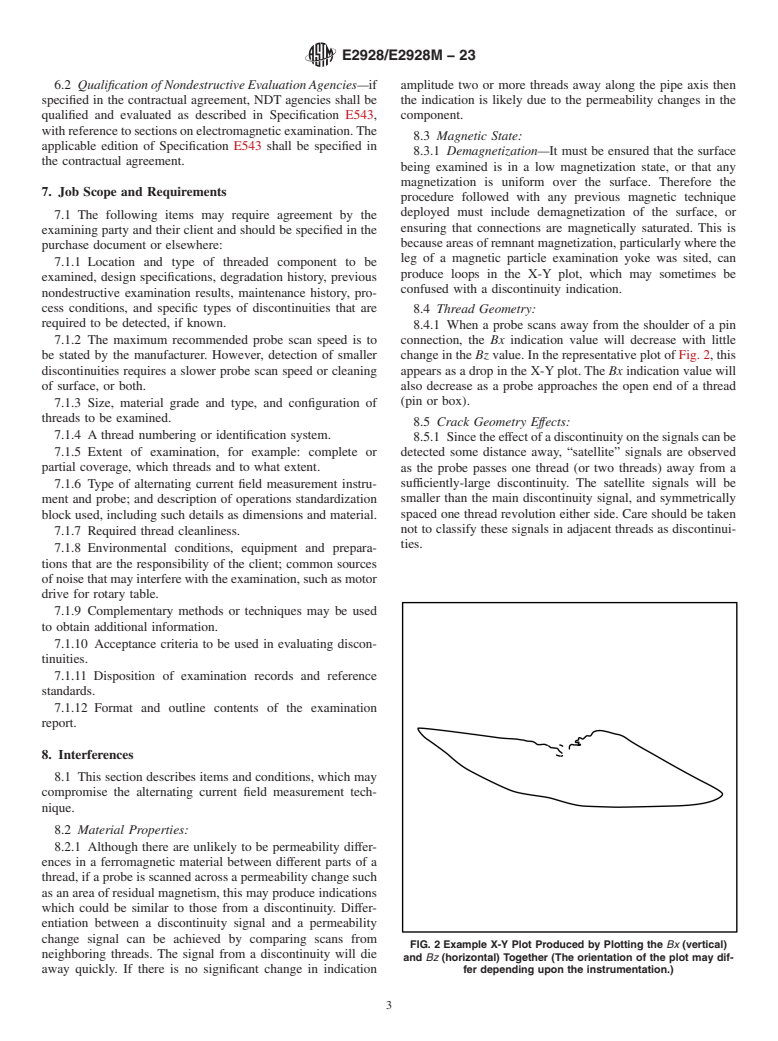

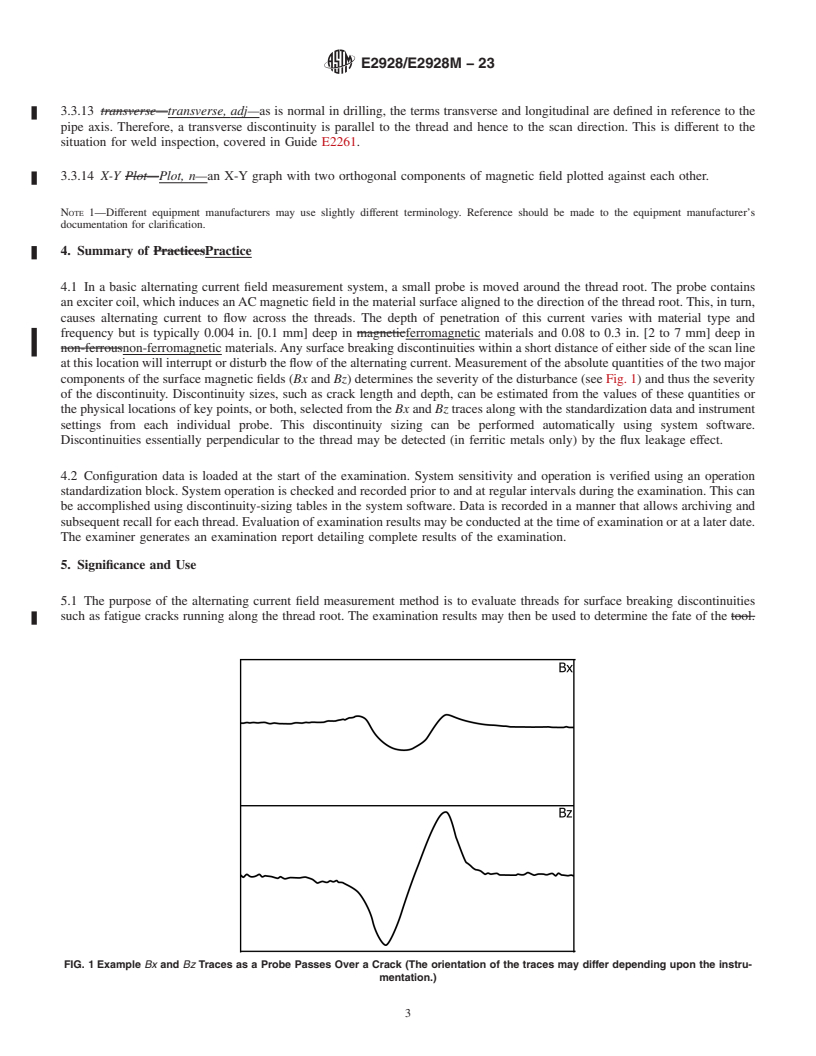

3.3.3 Bx, n—the x component of the magnetic field, parallel

Barriers to Trade (TBT) Committee.

to the thread root, the magnitude of which is proportional to the

current density set up by the electric field.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.07 on

2

Electromagnetic Method. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2023. Published March 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2013. Last previous edition approved in 2017 as E2928/E2928M – 17. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E2928_E2928M-23. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM Internation

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2928/E2928M − 17 E2928/E2928M − 23

Standard Practice for

Examination of Drillstring Threads Using the Alternating

1

Current Field Measurement Technique

This standard is issued under the fixed designation E2928/E2928M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice describes procedures to be followed during alternating current field measurement examination of drillstring

threads on tubulars used for oil and gas exploration and production for detection and, if required, sizing of service-induced surface

breaking discontinuities transverse to the pipe.

1.2 This practice is intended for use on threads in any metallic material.

1.3 This practice does not establish acceptance criteria. Typical industry practice is to reject these connections on detection of a

confirmed crack.

1.4 While the alternating current field measurement technique is capable of detecting discontinuities in these connections,

supplemental surface NDT methods such as magnetic particle testing for ferrous metals and penetrant testing for non-ferrous

metals may detect moreadditional discontinuities.

1.5 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in

each system might not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two both systems may result in nonconformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E543 Specification for Agencies Performing Nondestructive Testing

E1316 Terminology for Nondestructive Examinations

E2261 Practice for Examination of Welds Using the Alternating Current Field Measurement Technique

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.07 on Electromagnetic

Method.

Current edition approved June 1, 2017Feb. 1, 2023. Published June 2017March 2023. Originally approved in 2013. Last previous edition approved in 20132017 as

D2928/D2928ME2928/E2928M – 17.–13. DOI: 10.1520/E2928_E2928M–17.10.1520/E2928_E2928M-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2928/E2928M − 23

3

2.2 ASNT Standards

SNT-TC-1A Personnel Qualification and Certification in Nondestructive Testing

ANSI/ASNT-CP-189 Standard for Qualification and Certification of Nondestructive Testing Personnel

4

2.3 ISO Standard:

ISO 9712 Non-Destructive Testing: Qualification and Certification of NDT Personnel

3. Terminology

3.1 For definitions of terms relating to this practice refer to Terminology E1316, Section A, Common NDT terms, and Section C,

Electromagnetic testing. The following definitions are specific to the alternating current field measurement technique:

3.2 Definitions:

3.2.1 detector—detector, n—one or more coils or elements used to sense or measure a magnetic field; also known as a receiver.

3.2.2 exciter—exciter, n—a device that generates a time varying electromagnetic field, usually a coil energized with alternating

current (AC); also known as a transmitter.

3.2.3 uniform field—field, n—as applied to nondestructive testing with magnetic fields, the area of uniform magnetic field over the

surface of the material under

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.