ASTM D1481-02(2007)

(Test Method)Standard Test Method for Density and Relative Density (Specific Gravity) of Viscous Materials by Lipkin Bicapillary Pycnometer

Standard Test Method for Density and Relative Density (Specific Gravity) of Viscous Materials by Lipkin Bicapillary Pycnometer

SIGNIFICANCE AND USE

Density is a fundamental physical property that can be used in conjunction with other properties to characterize both the light and heavy fractions of petroleum and to access the quality of crude oils.

Determination of the density or relative density of petroleum and its products is necessary for the conversion of measured volumes to volumes at the standard temperatures of 15°C.

The determination of densities at the elevated temperatures of 40 and 100°C is particularly useful in providing the data needed for the conversion of kinematic viscosities in centistokes (mm2/s) to the corresponding dynamic viscosities in centipoises (mPa·s).

SCOPE

1.1 This test method covers the determination of the density of oils more viscous than 15 cSt at 20°C (mm2/s), and of viscous oils and melted waxes at elevated temperatures, but not at temperatures at which the sample would have a vapor pressure of 100 mm Hg (13 kPa) or above.

Note 1—To determine the densities of less viscous liquids at 20 or 25°C use Test Method D 1217.

1.2 This test method provides a calculation procedure for converting density to relative density (specific gravity).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1481 −02(Reapproved 2007)

Standard Test Method for

Density and Relative Density (Specific Gravity) of Viscous

Materials by Lipkin Bicapillary Pycnometer

This standard is issued under the fixed designation D1481; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 density—the weight in a vacuum (that is, the mass) of

a unit volume of the material at any given temperature.

1.1 Thistestmethodcoversthedeterminationofthedensity

3.1.2 relative density (specific gravity)—the ratio of the

of oils more viscous than 15 cSt at 20°C (mm /s), and of

mass (weight in a vacuum) of a given volume of material at a

viscousoilsandmeltedwaxesatelevatedtemperatures,butnot

temperature, t , to the mass of an equal volume of water at a

at temperatures at which the sample would have a vapor

reference temperature, t ; or the ratio of the density of the

pressure of 100 mm Hg (13 kPa) or above.

material at t to the density of water at t .

1 2

NOTE 1—To determine the densities of less viscous liquids at 20 or

25°C use Test Method D1217. 3

4. Summary of Test Method

1.2 This test method provides a calculation procedure for

4.1 The liquid is drawn into the bicapillary pycnometer

converting density to relative density (specific gravity).

through the removable siphon arm and adjusted to volume at

1.3 The values stated in SI units are to be regarded as the temperature of test, in such a manner that there is

standard. The values given in parentheses are for information

practically no drainage in the unfilled tubing. After equilibra-

only. tion at the test temperature, liquid levels are read, and the

pycnometer is removed from the thermostated bath, cooled to

1.4 This standard does not purport to address all of the

room temperature, and weighed.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.2 Density or relative density (specific gravity), as desired,

priate safety and health practices and determine the applica-

is then calculated from the volume at the test temperature and

bility of regulatory limitations prior to use.

theweightofthesample.Theeffectofairbuoyancyisincluded

in the calculations.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

D1217Test Method for Density and Relative Density (Spe- 5.1 Density is a fundamental physical property that can be

cific Gravity) of Liquids by Bingham Pycnometer

used in conjunction with other properties to characterize both

D1250Guide for Use of the Petroleum MeasurementTables the light and heavy fractions of petroleum and to access the

quality of crude oils.

3. Terminology

5.2 Determination of the density or relative density of

3.1 Definitions:

petroleum and its products is necessary for the conversion of

measured volumes to volumes at the standard temperatures of

15°C.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

5.3 The determination of densities at the elevated tempera-

D02.04.0D on Physical and Chemical Methods.

tures of 40 and 100°C is particularly useful in providing the

Current edition approved Nov. 1, 2007. Published January 2008. Originally

approved in 1957. Last previous edition approved in 2002 as D1481–02. DOI:

data needed for the conversion of kinematic viscosities in

10.1520/D1481-02R07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM For a more complete discussion of this procedure, see Lipkin, M. R., Mills, I.

Standards volume information, refer to the standard’s Document Summary page on W., Martin, C. C., and Harvey,W.T., Analytical Chemistry,ANCHA,Vol 21, 1949,

the ASTM website. p. 504.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1481−02 (2007)

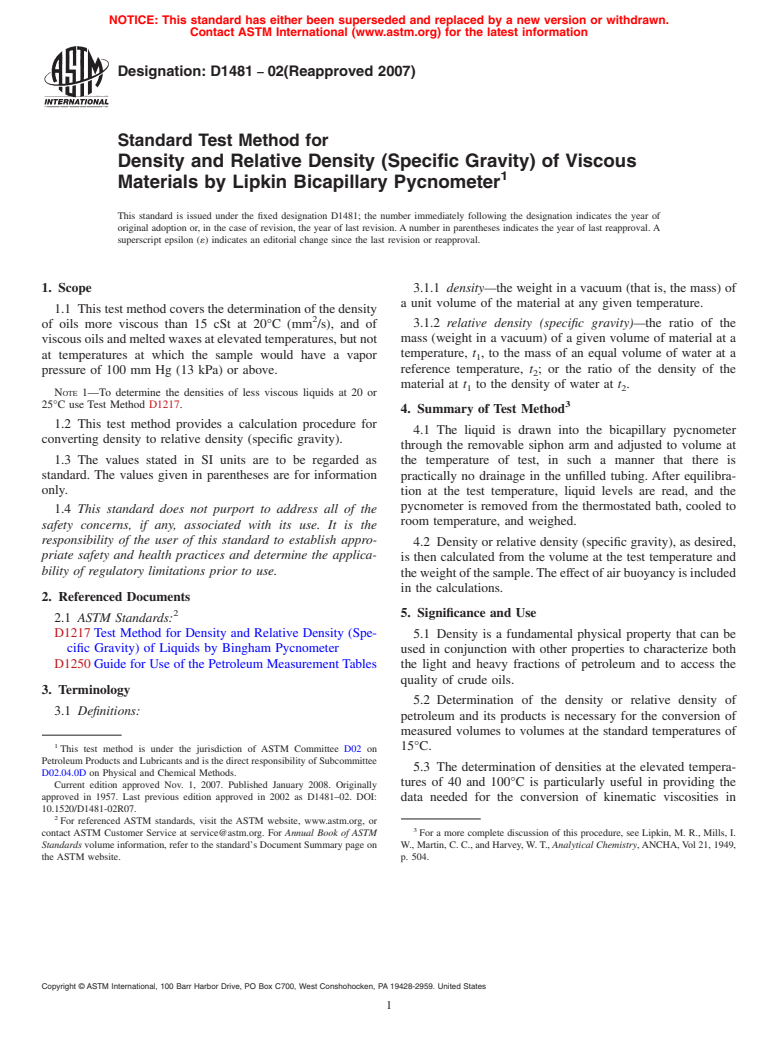

FIG. 1 Pycnometer

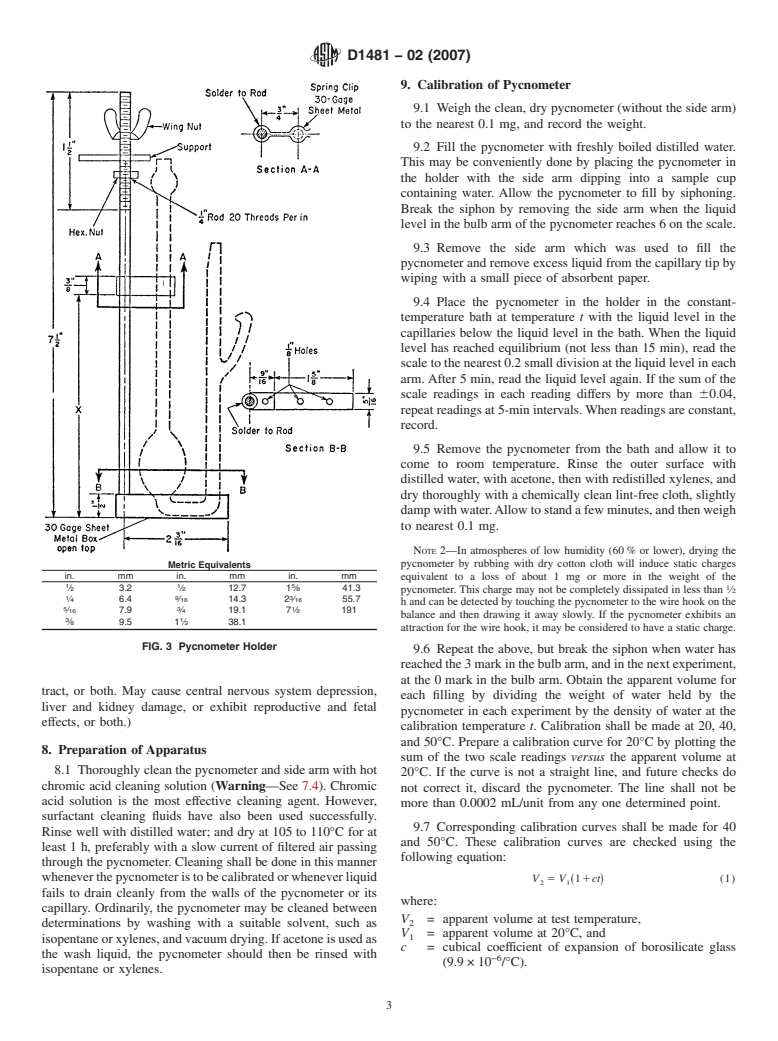

FIG. 2 Rack for Filling Pycnometer

centistokes (mm /s) to the corresponding dynamic viscosities

in centipoises (mPa·s).

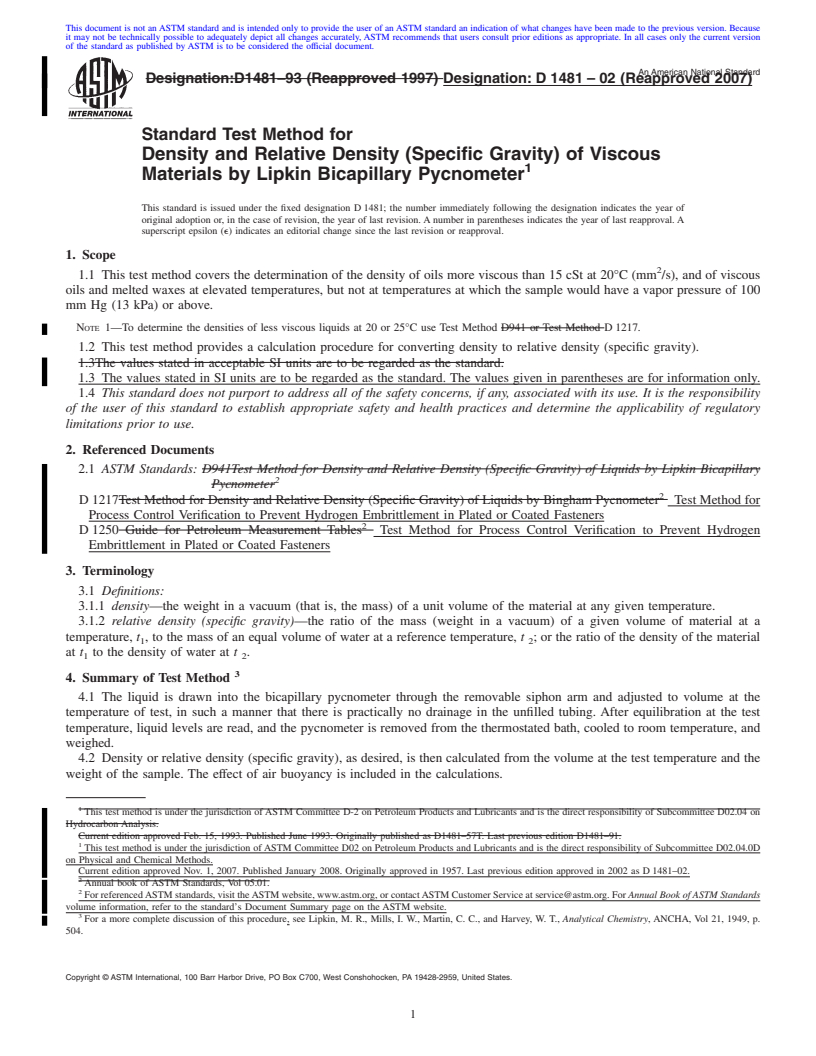

6.6 Pycnometer Holder—A holder, as shown in Fig. 3,is

recommended for supporting the pycnometer in the bath. A

6. Apparatus

single clamp device may be used.

6.1 Pycnometer —Aside-arm type of pycnometer conform-

6.7 Balance—Abalanceabletoreproduceweighingswithin

ing to the dimensions given in Fig. 1 and made of borosilicate

0.1 mg when carrying a load of 35 g or less on each pan. The

glass. The weight shall not exceed 35 g without the side arm.

balance shall be located in a room shielded from drafts and

6.2 Rack—Arack to use in filling the pycnometer (see Fig.

fumes and in which the temperature changes between related

2).

weighings (empty and filled pycnometer) do not cause a

6.3 Constant-Temperature Oven—An oven for use in filling significant change in the ratio of the balance arms. Otherwise,

weighings shall be made by the substitution method in which

the pycnometer. Any oven capable of holding the filling rack,

the calibrated weights and pycnometer are alternatively

and of maintaining a temperature of approximately 100°C, can

be used. weighed on the same balance pan. The same balance shall be

used for all related weighings.

6.4 Constant-Temperature Bath—A mixture of water and

glycerin, or oil bath having a depth of at least 305 mm (12 in.) 6.8 Weights—Weights shall be used whose relative values

are known to the nearest 0.05 mg or better. The same set of

and provided with heating, stirring, and thermostating devices

adequatetomaintaindesiredtemperaturesintherangefrom20 weightsshallbeusedforthecalibrationofthepycnometerand

the determination of the densities, or the sets of weights shall

to 100°C with an accuracy of 60.01°C.

be calibrated relative to each other.

6.5 Bath Thermometers—Thermometers graduated in 0.1°C

subdivisions and standardized for the range of use to the

7. Reagents and Materials

nearest 0.01°C (ASTM Saybolt Viscosity Thermometers 17C

7.1 Acetone—(Warning —Extremely flammable. Use ad-

to 22C are recommended). For most hydrocarbons, the density

equate ventilation.)

coefficient is about 0.0008 units/°C, and therefore a tempera-

ture error of 60.013°C would cause an error of 60.00001 in

7.2 Isopentane—( Warning—Extremely flammable. Avoid

density.

buildupofvaporsandremoveallsourcesofignition,especially

nonexplosion-proof electrical apparatus.)

7.3 Chromic Acid (Potassium Dichromate/Conc. Sulfuric

The sole source of supply of the pycnometers known to the committee at this

Acid)—(Warning—Causes severe burns. A recognized car-

time is Reliance Glass Co., 220 Gateway Rd., Bensenville, IL 60106-0825 have

beenfoundsatisfactory.Ifyouareawareofalternativesuppliers,pleaseprovidethis cinogen. Do not get in eyes, on skin or clothing.)

information to ASTM International Headquarters. Your comments will receive

7.4 Xylenes—(Warning —Flammable liquid. Aspiration

careful consideration at a meeting of the responsible technical committee, which

you may attend. hazard. May irritate skin, eyes, respiratory tract or digestive

D1481−02 (2007)

9. Calibration of Pycnometer

9.1 Weigh the clean, dry pycnometer (without the side arm)

to the nearest 0.1 mg, and record the weight.

9.2 Fill the pycnometer with freshly boiled distilled water.

This may be conveniently done by placing the pycnometer in

the holder with the side arm dipping into a sample cup

containing water. Allow the pycnometer to fill by siphoning.

Break the siphon by removing the side arm when the liquid

level in the bulb arm of the pycnometer reaches 6 on the scale.

9.3 Remove the side arm which was used to fill the

pycnometer and remove excess liquid from the capillary tip by

wiping with a small piece of absorbent paper.

9.4 Place the pycnometer in the holder in the constant-

temperature bath at temperature t with the liquid level in the

capillaries below the liquid level in the bath. When the liquid

level has reached equilibrium (not less than 15 min), read the

scaletothenearest0.2smalldivisionattheliquidlevelineach

arm.After 5 min, read the liquid level again. If the sum of the

scale readings in each reading differs by more than 60.04,

repeatreadingsat5-minintervals.Whenreadingsareconstant,

record.

9.5 Remove the pycnometer from the bath and allow it to

come to room temperature. Rinse the outer surface with

distilled water, with acetone, then with redistilled xylenes, and

dry thoroughly with a chemically clean lint-free cloth, slightly

dampwithwater.Allowtostandafewminutes,andthenweigh

to nearest 0.1 mg.

NOTE 2—In atmospheres of low humidity (60% or lower), drying the

pycnometer by rubbing with dry cotton cloth will induce static charges

Metric Equivalents

in. mm in. mm in. mm

equivalent to a loss of about 1 mg or more in the weight of the

1 1 5

⁄2 3.2 ⁄2 12.7 1 ⁄8 41.3

pycnometer. This charge may not be completely dissipated in less than ⁄2

1 9 3

⁄4 6.4 ⁄16 14.3 2 ⁄16 55.7

handcanbedetectedbytouchingthepycnometertothewirehookonthe

5 3 1

⁄16 7.9 ⁄4 19.1 7 ⁄2 191

balance and then drawing it away slowly. If the pycnometer exhibits an

3 1

⁄8 9.5 1 ⁄2 38.1

attraction for the wire hook, it may be considered to have a static charge.

FIG. 3 Pycnometer Holder

9.6 Repeat the above, but break the siphon when water has

reachedthe3markinthebulbarm,andinthenextexperiment,

at the 0 mark in the bulb arm. Obtain the apparent volume for

tract, or both. May cause central nervous system depression,

each filling by dividing the weight of water held by the

liver and kidney damage, or exhibit reproductive and fetal

pycnometer in each experiment by the density of water at the

effects, or both.)

calibration temperature t. Calibration shall be made at 20, 40,

and 50°C. Prepare a calibration curve for 20°C by plotting the

8. Preparation of Apparatus

sum of the two scale readings versus the apparent volume at

8.1 Thoroughlyclean

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D1481–93 (Reapproved 1997) Designation: D 1481 – 02 (Reapproved 2007)

Standard Test Method for

Density and Relative Density (Specific Gravity) of Viscous

Materials by Lipkin Bicapillary Pycnometer

This standard is issued under the fixed designation D1481; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the density of oils more viscous than 15 cSt at 20°C (mm /s), and of viscous

oils and melted waxes at elevated temperatures, but not at temperatures at which the sample would have a vapor pressure of 100

mm Hg (13 kPa) or above.

NOTE 1—To determine the densities of less viscous liquids at 20 or 25°C use Test Method D941 or Test Method D1217.

1.2 This test method provides a calculation procedure for converting density to relative density (specific gravity).

1.3The values stated in acceptable SI units are to be regarded as the standard.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards: D941Test Method for Density and Relative Density (Specific Gravity) of Liquids by Lipkin Bicapillary

Pycnometer

D1217Test Method for Density and Relative Density (Specific Gravity) of Liquids by Bingham Pycnometer Test Method for

Process Control Verification to Prevent Hydrogen Embrittlement in Plated or Coated Fasteners

D1250 Guide for Petroleum Measurement Tables Test Method for Process Control Verification to Prevent Hydrogen

Embrittlement in Plated or Coated Fasteners

3. Terminology

3.1 Definitions:

3.1.1 density—the weight in a vacuum (that is, the mass) of a unit volume of the material at any given temperature.

3.1.2 relative density (specific gravity)—the ratio of the mass (weight in a vacuum) of a given volume of material at a

temperature, t , to the mass of an equal volume of water at a reference temperature, t ; or the ratio of the density of the material

1 2

at t to the density of water at t .

1 2

4. Summary of Test Method

4.1 The liquid is drawn into the bicapillary pycnometer through the removable siphon arm and adjusted to volume at the

temperature of test, in such a manner that there is practically no drainage in the unfilled tubing. After equilibration at the test

temperature, liquid levels are read, and the pycnometer is removed from the thermostated bath, cooled to room temperature, and

weighed.

4.2 Density or relative density (specific gravity), as desired, is then calculated from the volume at the test temperature and the

weight of the sample. The effect of air buoyancy is included in the calculations.

This test method is under the jurisdiction ofASTM Committee D-2 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.04 on

Hydrocarbon Analysis.

Current edition approved Feb. 15, 1993. Published June 1993. Originally published as D1481–57T. Last previous edition D1481–91.

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.04.0D

on Physical and Chemical Methods.

Current edition approved Nov. 1, 2007. Published January 2008. Originally approved in 1957. Last previous edition approved in 2002 as D1481–02.

Annual book of ASTM Standards, Vol 05.01.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

For a more complete discussion of this procedure, see Lipkin, M. R., Mills, I. W., Martin, C. C., and Harvey, W. T., Analytical Chemistry, ANCHA, Vol 21, 1949, p.

504.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 1481 – 02 (2007)

5. Significance and Use

5.1 Density is a fundamental physical property that can be used in conjunction with other properties to characterize both the

light and heavy fractions of petroleum and to access the quality of crude oils.

5.2 Determination of the density or relative density of petroleum and its products is necessary for the conversion of measured

volumes to volumes at the standard temperatures of 15°C.

5.3 The determination of densities at the elevated temperatures of 40 and 100°C is particularly useful in providing the data

needed for the conversion of kinematic viscosities in centistokes (mm /s) to the corresponding dynamic viscosities in centipoises

(mPa·s).

6. Apparatus

6.1 Pycnometer —Aside-armtypeofpycnometerconformingtothedimensionsgiveninFig.1andmadeofborosilicateglass.

The weight shall not exceed 35 g without the side arm.

6.2 Rack—A rack to use in filling the pycnometer (see Fig. 2).

6.3 Constant-Temperature Oven—An oven for use in filling the pycnometer.Any oven capable of holding the filling rack, and

of maintaining a temperature of approximately 100°C, can be used.

6.4 Constant-Temperature Bath—A mixture of water and glycerin, or oil bath having a depth of at least 305 mm (12 in.) and

providedwithheating,stirring,andthermostatingdevicesadequatetomaintaindesiredtemperaturesintherangefrom20to100°C

with an accuracy of 60.01°C.

6.5 Bath Thermometers—Thermometers graduated in 0.1°C subdivisions and standardized for the range of use to the nearest

0.01°C (ASTM Saybolt Viscosity Thermometers 17C to 22C are recommended). For most hydrocarbons, the density coefficient

is about 0.0008 units/°C, and therefore a temperature error of 60.013°C would cause an error of 60.00001 in density.

6.6 Pycnometer Holder—A holder, as shown in Fig. 3, is recommended for supporting the pycnometer in the bath. A single

clamp device may be used.

6.7 Balance—A balance able to reproduce weighings within 0.1 mg when carrying a load of 35 g or less on each pan. The

balanceshallbelocatedinaroomshieldedfromdraftsandfumesandinwhichthetemperaturechangesbetweenrelatedweighings

(empty and filled pycnometer) do not cause a significant change in the ratio of the balance arms. Otherwise, weighings shall be

made by the substitution method in which the calibrated weights and pycnometer are alternatively weighed on the same balance

pan. The same balance shall be used for all related weighings.

6.8 Weights—Weights shall be used whose relative values are known to the nearest 0.05 mg or better. The same set of weights

shall be used for the calibration of the pycnometer and the determination of the densities, or the sets of weights shall be calibrated

relative to each other.

Pycnometers available from Reliance Glass Co., 220 Gateway Rd., Bensenville, IL 60106-0825 have been found satisfactory.

ThesolesourceofsupplyofthepycnometersknowntothecommitteeatthistimeisRelianceGlassCo.,220GatewayRd.,Bensenville,IL60106-0825havebeenfound

satisfactory. If you are aware of alternative suppliers, please provide this information toASTM International Headquarters.Your comments will receive careful consideration

at a meeting of the responsible technical committee, which you may attend.

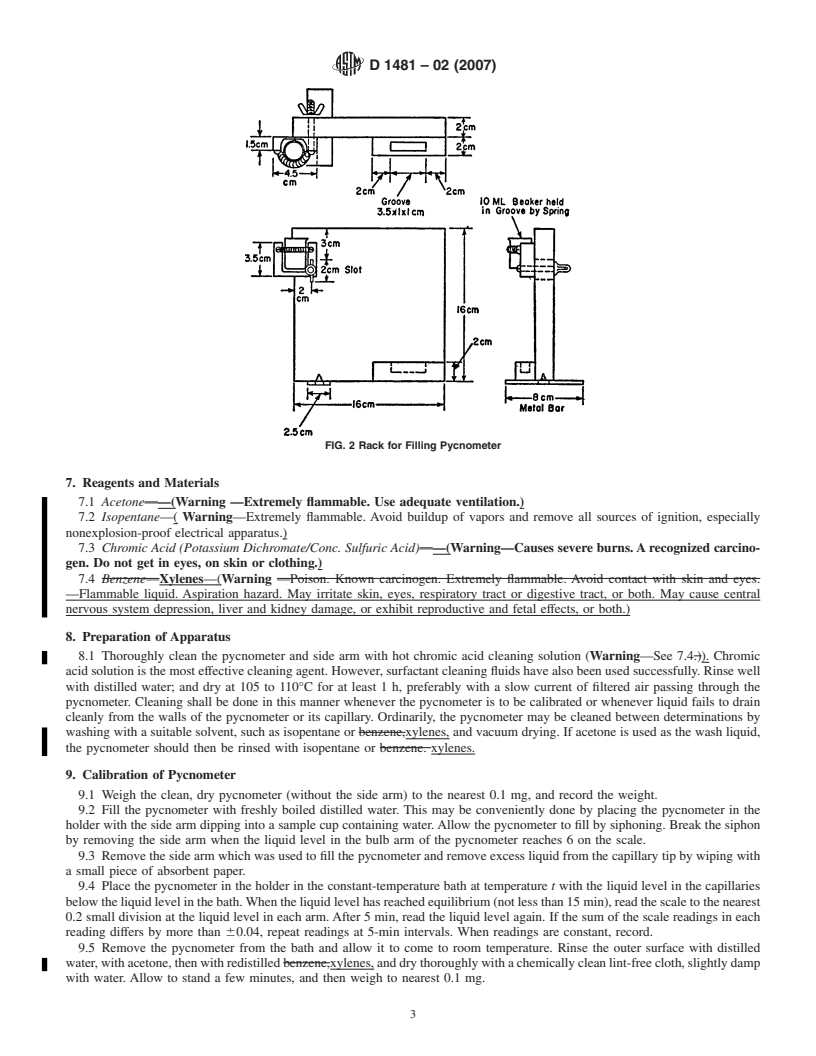

FIG. 1 Pycnometer

D 1481 – 02 (2007)

FIG. 2 Rack for Filling Pycnometer

7. Reagents and Materials

7.1 Acetone——(Warning —Extremely flammable. Use adequate ventilation.)

7.2 Isopentane—( Warning—Extremely flammable. Avoid buildup of vapors and remove all sources of ignition, especially

nonexplosion-proof electrical apparatus.)

7.3 Chromic Acid (Potassium Dichromate/Conc. Sulfuric Acid)——(Warning—Causes severe burns.Arecognized carcino-

gen. Do not get in eyes, on skin or clothing.)

7.4 Benzene—Xylenes—(Warning —Poison. Known carcinogen. Extremely flammable. Avoid contact with skin and eyes.

—Flammable liquid. Aspiration hazard. May irritate skin, eyes, respiratory tract or digestive tract, or both. May cause central

nervous system depression, liver and kidney damage, or exhibit reproductive and fetal effects, or both.)

8. Preparation of Apparatus

8.1 Thoroughly clean the pycnometer and side arm with hot chromic acid cleaning solution (Warning—See 7.4.)). Chromic

acidsolutionisthemosteffectivecleaningagent.However,surfactantcleaningfluidshavealsobeenusedsuccessfully.Rinsewell

with distilled water; and dry at 105 to 110°C for at least 1 h, preferably with a slow current of filtered air passing through the

pycnometer. Cleaning shall be done in this manner whenever the pycnometer is to be calibrated or whenever liquid fails to drain

cleanly from the walls of the pycnometer or its capillary. Ordinarily, the pycnometer may be cleaned between determinations by

washing with a suitable solvent, such as isopentane or benzene,xylenes, and vacuum drying. If acetone is used as the wash liquid,

the pycnometer should then be rinsed with isopentane or benzene. xylenes.

9. Calibration of Pycnometer

9.1 Weigh the clean, dry pycnometer (without the side arm) to the nearest 0.1 mg, and record the weight.

9.2 Fill the pycnometer with freshly boiled distilled water. This may be conveniently done by placing the pycnometer in the

holder with the side arm dipping into a sample cup containing water.Allow the pycnometer to fill by siphoning. Break the siphon

by removing the side arm when the liquid level in the bulb arm of the pycnometer reaches 6 on the scale.

9.3 Remove the side arm which was used to fill the pycnometer and remove excess liquid from the capillary tip by wiping with

a small piece of absorbent paper.

9.4 Place the pycnometer in the holder in the constant-temperature bath at temperature t with the liquid level in the capillaries

belowtheliquidlevelinthebath.Whentheliquidlevelhasreachedequilibrium(notlessthan15min),readthescaletothenearest

0.2 small division at the liquid level in each arm.After 5 min, read the liquid level again. If the sum of the scale readings in each

reading differs by more than 60.04, repeat readings at 5-min intervals. When readings are constant, record.

9.5 Remove the pycnometer from the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.