ASTM D7448-09

(Practice)Standard Practice for Establishing the Competence of Laboratories Using ASTM Procedures in the Sampling and Analysis of Coal and Coke

Standard Practice for Establishing the Competence of Laboratories Using ASTM Procedures in the Sampling and Analysis of Coal and Coke

SIGNIFICANCE AND USE

International standard ANS/ISO/IEC 17025 promotes the use of documented accountability and quality control procedures to assure a laboratory and its clients that the laboratory can produce technically valid data and results in the routine performance of its sampling, sample preparation and testing activities.

A laboratory shall use ANSI/ISO/IEC 17025 to develop its quality system. Clause 4 of ANS/ISO/IEC 17025 specifies the requirements for sound management. Clause 5 of ANS/ISO/IEC 17025 specifies the requirements for technical competence for the type of tests or calibrations, or both the laboratory undertakes.

In addition to complying with the requirements of ANS/ISO/IEC 17025, the Annex of this standard practice contains information that shall be considered important for the evaluation and operation of a competent Coal and Coke sampling or testing facility, or both. The information in this Annex is presented where it is not otherwise covered in ANS/ISO/IEC 17025 or the applicable ASTM methods.

Laboratory clients, regulatory authorities, and accreditation bodies that recognize the competence of testing and calibration laboratories can use this standard practice as the basis for their evaluation.

The primary significance of this practice is to establish that for a laboratory to generate measurements traceable to SI units, it must:

Have a clear understanding of the work requested by the client.

Meet the quality system requirements of the internationally accepted ANS/ISO/IEC 17025 standard.

Use test methods which have been shown to be traceable to SI units of measurement

Be able to demonstrate that the laboratory is in statistical control at the time the measurements are made.

SCOPE

1.1 This practice specifies requirements to operate and evaluate the quality and management systems in a laboratory that provides services with respect to sample collection, sample preparation, or testing of coal, coke, and ash derived from coal or coke using ASTM standards that are under the jurisdiction of Committee D05 on Coal and Coke.

Note 1—The word “laboratory” is used throughout this practice when referring to an organization that provides services in coal sampling or testing, or both. It is recognized, however, that the word may not be appropriate to an organization that does not perform actual laboratory sample testing.

1.2 International standard ANS/ISO/IEC 17025 shall be the governing document specifying requirements for management, technical competence and evaluation of a laboratory.

Note 2—An accrediting body or user of laboratory services can also impose technical or non-technical requirements not specifically addressed in ANS/ISO/IEC 17025 provided they do not invalidate the requirements of ANS/ISO/IEC 17025.

1.3 This practice is used to evaluate only those capabilites specifically claimed by a laboratory.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7448 − 09

StandardPractice for

Establishing the Competence of Laboratories Using ASTM

Procedures in the Sampling and Analysis of Coal and Coke

This standard is issued under the fixed designation D7448; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4749 Test Method for Performing the Sieve Analysis of

Coal and Designating Coal Size

1.1 This practice specifies requirements to operate and

D5061 Test Method for Microscopical Determination of the

evaluate the quality and management systems in a laboratory

Textural Components of Metallurgical Coke

thatprovidesserviceswithrespecttosamplecollection,sample

D5515 Test Method for Determination of the Swelling

preparation, or testing of coal, coke, and ash derived from coal

Properties of Bituminous Coal Using a Dilatometer

orcokeusingASTMstandardsthatareunderthejurisdictionof

D6172 Test Method for Determining the Volume of Bulk

Committee D05 on Coal and Coke.

Materials Using Contours or Cross Sections Created by

NOTE 1—The word “laboratory” is used throughout this practice when

DirectOperatorCompilationUsingPhotogrammetricPro-

referring to an organization that provides services in coal sampling or

testing, or both. It is recognized, however, that the word may not be

cedures

appropriate to an organization that does not perform actual laboratory

D6349 Test Method for Determination of Major and Minor

sample testing.

Elements in Coal, Coke, and Solid Residues from Com-

1.2 International standardANS/ISO/IEC 17025 shall be the

bustion of Coal and Coke by Inductively Coupled

governing document specifying requirements for management,

Plasma—Atomic Emission Spectrometry

technical competence and evaluation of a laboratory.

E177 Practice for Use of the Terms Precision and Bias in

NOTE 2—An accrediting body or user of laboratory services can also

ASTM Test Methods

impose technical or non-technical requirements not specifically addressed

E456 Terminology Relating to Quality and Statistics

in ANS/ISO/IEC 17025 provided they do not invalidate the requirements

E2554 Practice for Estimating and Monitoring the Uncer-

of ANS/ISO/IEC 17025.

tainty of Test Results of a Test Method Using Control

1.3 This practice is used to evaluate only those capabilites

Chart Techniques

specifically claimed by a laboratory.

2.2 ANS/ISO/IEC Document:

1.4 This standard does not purport to address all of the

17025 General Requirements for the Competence of Cali-

safety concerns, if any, associated with its use. It is the

bration and Testing Laboratories

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3. Significance and Use

bility of regulatory limitations prior to use.

3.1 International standard ANS/ISO/IEC 17025 promotes

the use of documented accountability and quality control

2. Referenced Documents

procedures to assure a laboratory and its clients that the

2.1 ASTM Standards:

laboratory can produce technically valid data and results in the

D121 Terminology of Coal and Coke

routine performance of its sampling, sample preparation and

D3174 Test Method forAsh in theAnalysis Sample of Coal

testing activities.

and Coke from Coal

3.2 Alaboratory shall useANSI/ISO/IEC 17025 to develop

D4239 Test Method for Sulfur in the Analysis Sample of

its quality system. Clause 4 of ANS/ISO/IEC 17025 specifies

Coal and Coke Using High-Temperature Tube Furnace

the requirements for sound management. Clause 5 of ANS/

Combustion

ISO/IEC 17025 specifies the requirements for technical com-

petence for the type of tests or calibrations, or both the

This practice is under the jurisdiction of ASTM Committee D05 on Coal and laboratory undertakes.

CokeandisthedirectresponsibilityofSubcommitteeD05.24onQualityAssurance.

3.3 In addition to complying with the requirements of

Current edition approved Nov. 1, 2009. Published December 2009. DOI:

10.1520/D7448-09. ANS/ISO/IEC 17025, the Annex of this standard practice

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7448 − 09

contains information that shall be considered important for the 3.5.4 Be able to demonstrate that the laboratory is in

evaluation and operation of a competent Coal and Coke statistical control at the time the measurements are made.

sampling or testing facility, or both. The information in this

4. Selection of an Evaluator

Annex is presented where it is not otherwise covered in

4.1 The evaluator(s) shall have sufficient technical back-

ANS/ISO/IEC 17025 or the applicable ASTM methods.

ground to competently evaluate the application of ASTM

3.4 Laboratory clients, regulatory authorities, and accredi-

standards employed for the sampling, preparation and analysis

tation bodies that recognize the competence of testing and

of coal, coke, and ash derived from coal or coke.

calibration laboratories can use this standard practice as the

4.2 The evaluator(s) shall review the laboratory with the aid

basis for their evaluation.

of a worksheet or checklist. Worksheets or checklists shall be

3.5 The primary significance of this practice is to establish

developed from the requirements of Clause 4 and Clause 5 of

that for a laboratory to generate measurements traceable to SI

ANS/ISO/IEC17025inconcertwithspecifictechnicalrequire-

units, it must:

ments specified in the ASTM standard(s) to be evaluated.

3.5.1 Have a clear understanding of the work requested by

4.3 Observationsandcommentsmadebytheevaluatorshall

the client.

be keyed to item numbers in the checklist.

3.5.2 Meet the quality system requirements of the interna-

5. Keywords

tionally accepted ANS/ISO/IEC 17025 standard.

3.5.3 Use test methods which have been shown to be

5.1 accuracy; competence; evaluation; laboratory; manage-

traceable to SI units of measurement ment; stability

ANNEX

(Mandatory Information)

A1.

INTRODUCTION

Factors that can influence the technical validity of tests performed by a laboratory include but are

not limited to:

(1) Sampling apparatus operation,

(2) Sampling procedures,

(3) Sample preparation apparatus,

(4) Sample preparation operation,

(5) Sample preparation procedures,

(6) Laboratory equipment,

(7) Laboratory equipment operation,

(8) Test methods,

(9) Calibration, control and consumable materials,

(10) Calibration,

(11) Uncertainty of measurement,

(12) Control charts,

(13) Reporting procedures,

(14) Qualification of laboratory personnel, and

(15) Environmental conditions (sampling, sample preparation and analyses).

This annex while mandatory, identifies several items as a “typical practice”.A“typical practice” is

not to be considered the only correct practice. Typical practices have been included throughout this

Annex only for the purpose of clarifying the content of this Annex.

The extent to which the factors contribute to the technical validity of results can differ considerably

between tests. The laboratory shall have procedures that address these factors where these are

applicable and under the laboratory’s control.

D7448 − 09

ANS/ISO/IEC 17025 Clause 4.1.5 states:

“The laboratory shall have managerial and technical personnel who, irrespective of other

responsibilities, have the authority and resources needed to carry out their duties, including the

implementation, maintenance and improvement of the management system, and to identify the

occurrence of departures from the management system or from the procedures for performing tests

and/or calibrations and to initiate actions to prevent or minimize such departures.”

Managerial and technical personnel shall have the authority and resources to implement the

practices specified in this Annex in a manner that ensures laboratory procedures produce data of the

type and quality needed for the intended end use.

A1.1 Sampling Apparatus Operation A1.4.1.6 Minimizing contamination at each stage of sam-

pling and sample preparation.

A1.1.1 The laboratory shall have procedures describing

A1.4.1.7 Minimizingdustlossandverifyingmaterialrecov-

acceptance requirements for all sampling equipment.

ery at each stage of sampling and sample preparation.

A1.1.2 The laboratory shall have procedures describing

A1.4.1.8 Verifying particle size reduction equipment pro-

verification of all sampling equipment.

duce samples of the appropriate particle size criteria and

homogeneity.

A1.2 Sampling Procedures

A1.4.1.9 Minimizing changes in moisture and or oxidation

A1.2.1 The laboratory shall have sampling procedures de-

of the sample(s) during transportation, preparation, storage and

scribing all processes under its control.

handling.

A1.4.1.10 Mixing to minimize selection of a biased size

A1.2.2 The laboratory shall have procedures describing

fraction at each stage of sampling, including extraction of test

requirements for bias tests.

portions from the laboratory analysis sample.

A1.2.3 The laboratory shall have procedures describing

A1.4.1.11 Recording date and time the sample(s) are re-

requirements for periodic bias tests after initial bias testing and

ceived in the laboratory.

acceptance of sampling systems.

A1.4.1.12 Verifying compliance or corrective action with

A1.2.4 The laboratory shall have procedures describing

respect to all elements of the management plan, or both.

requirements for bias tests subsequent to maintenance and

A1.4.1.13 Approval of changes or exceptions to the sam-

or/modification of sampling systems.

pling and sample preparation procedures

A1.3 Sample Preparation Apparatus

A1.5 Sample Preparation Procedures

A1.3.1 The laboratory shall have procedures describing:

A1.5.1 Thelaboratoryshallhaveproceduresforallstagesof

A1.3.1.1 Acceptance requirements for all sample prepara-

sample preparation that are under its control.

tion equipment.

A1.6 Laboratory Equipment

A1.3.1.2 Procedures for verification of all sample prepara-

tion equipment.

A1.6.1 The laboratory shall utilize equipment that meets the

specifications of the relevant sampling/test methods.

A1.4 Sample Preparation Operation

A1.7 Laboratory Equipment Operation

A1.4.1 The laboratory shall have a documented manage-

ment plan which shall include requirements for:

A1.7.1 The laboratory shall have procedures describing

A1.4.1.1 Maintaining a chain of custody for samples.

equipment set-up and startup where appropriate.

A1.4.1.2 Identifying the source of the sample.

A1.7.2 Equipmentthatisoperatedoutsideofnormalparam-

A1.4.1.3 Identifying date and time of initial sampling.

eters shall be subject to verification.

A1.4.1.4 Identifying the individual(s) responsible for sam-

pling and sample preparation. A1.7.3 The laboratory shall have procedures describing the

A1.4.1.5 Describing test and reserve sample(s) collected at minimum quality control that is required to validate the

each stage of sampling and sample preparation including date, equipment is in statistical control at the time the measurements

time, top size and mass. are made.

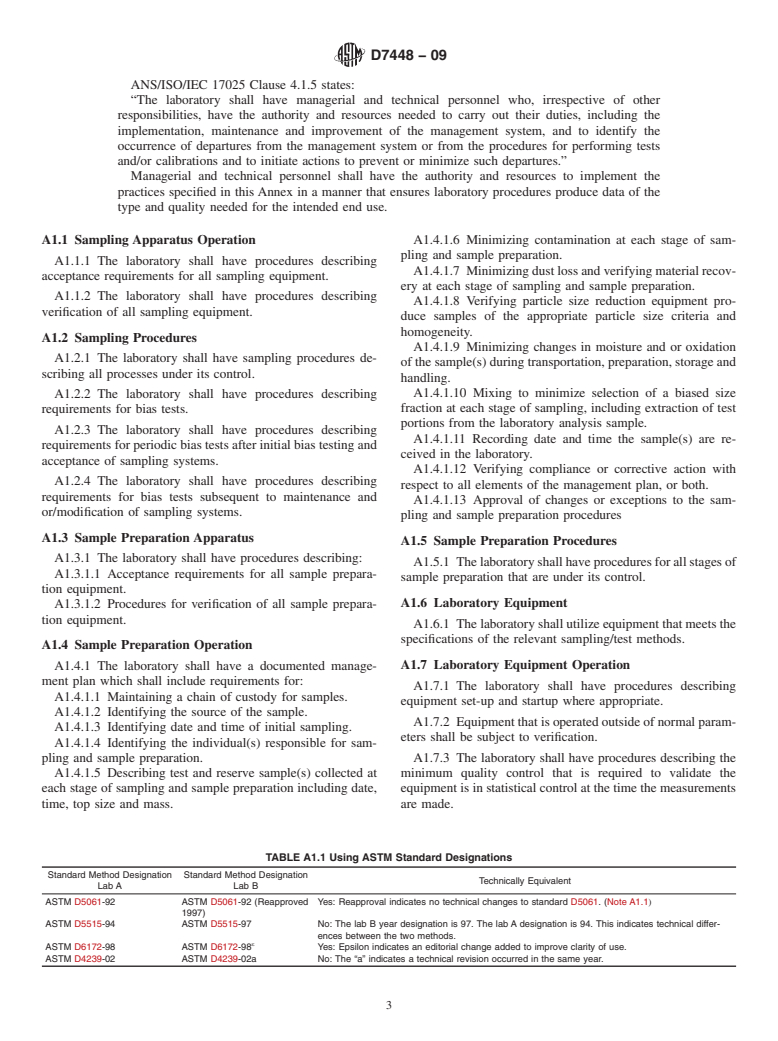

TABLE A1.1 Using ASTM Standard Designations

Standard Method Designation Standard Method Designation

Technically Equivalent

Lab A Lab B

ASTM D5061-92 ASTM D5061-92 (Reapproved Yes: Reapproval indicates no technical changes to standard D5061.(Note A1.1)

1997)

ASTM D5515-94 ASTM D5515-97 No: The lab B year designation is 97. The lab A designation is 94. This indicates technical differ-

ences between the two methods.

ε

ASTM D6172-98 ASTM D6172-98 Yes: Epsilon indicates an editorial change added to improve clarity of use.

ASTM D4239-02 ASTM D4239-02a No: The “a” indicates a technical revision occurred in the same year.

D7448 − 09

A1.7.4 The laboratory shall maintain all original instrument have expired are clearly identified and are not subsequently

observations in accordance with their records control proce- employed for calibration or verification purposes. These pro-

dures. cedures shall ensure that discarded materials can not be

subsequently used.

A1.8 Test Methods

A1.9.7 Calibration and Control Materials:

A1.8.1 Laboratory procedures can consist of standard and

A1.9.7.1 All reference materials must meet the require-

non-standard methods. A non-standard method includes the

ments of a certified reference material (CRM) and can include

application of a standard method to samples that fall outside

pure substances, pure mixtures, external reference materials

the scope or validated range of the standard method or that

(ERMs) and internal reference materials (IRMs) in a solid,

allow conditions of test which depart from those specified in a

liquid, or gaseous state.

standard method.

A1.9.7.2 Certified reference materials include primary ref-

A1.8.2 Publications from the AOAC International, (1) as

erence materials, secondary reference materials and other

well as ISO (2, 3) describe procedures for establishing the

reference materials.

precision and accuracy of a non-standard method or demon-

(1) A primary reference material is defined by ISO as a

strating the equivalency of a non-standard method with a

reference material “whose quantity value and measurement

standard method.

uncertainty are established without relation to another mea-

A1.8.3 The laboratory shall identify by ASTM (or other

surement standard for a quantity of the same kind.” (4)

source) designation including revision, all standard and non-

(2) A secondary reference material is defined by ISO as a

standard sampling, sample preparation and test procedures

reference material “whose quantity value and measurement

employed by the laboratory. The ASTM designation system

uncertainty are assigned through calibration against, or com-

allows users to determine the potential for technical discrep-

parison with, a primary measurement standard for a quantity of

ancies to exist between laboratories claiming to employ the

the same kind.” (4)

same ASTM test method.

(3) An internal reference material is one generated by a

laboratory solely for its own use.

A1.8.4 Table A1.1 provides examples of how this system

operates. (a) The laboratory shall have procedures describing the

NOTEA1.1—Referenced documents within a method or practice always

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.