ASTM F466-79(1992)

(Test Method)Test Method for Small-Signal Scattering Parameters of Low-Power Transistors in the 0.2 to 2.0 GHZ Frequency Range (Withdrawn 1997)

Test Method for Small-Signal Scattering Parameters of Low-Power Transistors in the 0.2 to 2.0 GHZ Frequency Range (Withdrawn 1997)

General Information

Standards Content (Sample)

ASTM F4bb 79 m 0759510 0512250 238 m

Designation: F 466 - 79 (Reapproved 1992)

Standard Test Method for

Small-Signal Scattering Parameters of Low-Power Transistors

in the 0.2 to 2.0-GHz Frequency Range’

This standard is issued under the fixed designation F 466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope parameters. A capital S is used when refemng to the entire

matrix (for example, S matrix), and a lowercase s is used

1.1 This test method covers the measurement of the scat-

when referring to individual elements of the matrix (for

tering parameters of transistors operating under small-signal

example, s, I, s2,, etc.).

conditions at power levels low enough to permit continuous

3.2.1. 1 In the symbols for the individual S parameters, the

operation at safe junction temperatures without the use of

first digit of the subscript indicates the port (pair of termi-

elaborate heat sinks. It is generally applicable in the frequency

nais) at which the signal is to be read with respect to the

range between 0.2 and 2.0 GHz.

signal incident on the port indicated by the second digit. The

1.2 Procedures are given for the use of manual measuring

1 and 2 are used to designate the input and output

numbers

equipment.

S parameters that describe a

ports, respectively. The four

1.3 Mathematical transformations for converting scatter-

two-port network are defined as follows:

ing parameters to h, y, or 2 parameters are listed in Appendix

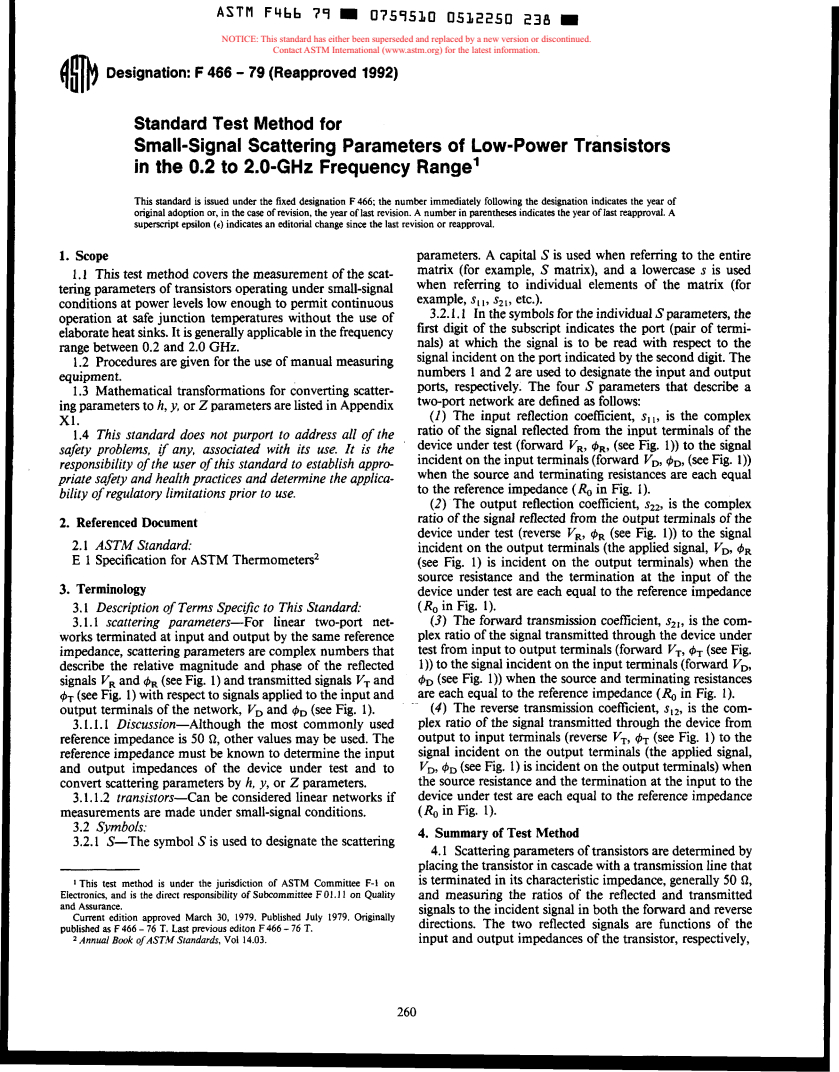

(I) The input reflection coefficient, sI,, is the complex

x1.

ratio of the signal reflected from the input terminals of the

1.4 This standard does not purport to address all of the

device under test (forward VR, C$R, (see Fig. 1)) to the signal

safety problems, if any, associated with its use. It is the

incident on the input terminals (forward V,, (see Fig. 1))

responsibility of the user of this standard to establish appro-

when the source and terminating resistances are each equal

priute safetv and health practices und determine the applica-

to the reference impedance (4 in Fig. I).

bility of regulatory limitations prior to use.

(2) The output reflection coefficient, s22, is the complex

ratio of the signal reflected from the output terminals of the

2. Referenced Document

device under test (reverse VR, C$R (see Fig. i)) to the signal

2.1 ASTM Standard:

incident on the output terminals (the applied signal, VD, 4R

E 1 Specification for ASTM Thermometers2

(see Fig. 1) is incident on the output terminals) when the

source resistance and the termination at the input of the

3. Terminology

device under test are each equal to the reference impedance

(R, in Fig. 1).

3.1 Description of Terms Specific to This Standard:

(3) The forward transmission coefficient, s21, is the com-

3.1,l scattering parameters-For linear two-port net-

of the signal transmitted through the device under

plex ratio

works terminated at input and output by the same reference

test from input to output terminals (forward VT, dT (see Fig.

impedance, scattering parameters are complex numbers that

i)) to the signal incident on the input terminals (forward V,,

describe the relative magnitude and phase of the reflected

4, (see Fig. 1)) when the source and terminating resistances

signals VR and $R (see Fig. 1) and transmitted signals VT and

are each equal to the reference impedance (& in Fig. 1).

$T (see Fig. 1) with respect to signais applied to the input and

..

(4) The reverse transmission coefficient, sI2, is the com-

output terminals of the network, V, and bD (see Fig. 1).

plex ratio of the signal transmitted through the device from

3.1.1.1 Discussion-Although the most commonly used

output to input terminals (reverse V,, @T (see Fig. 1) to the

reference impedance is 50 SI, other values may be used. The

signal incident on the output terminals (the applied signal,

reference impedance must be known to determine the input

V,, $D (see Fig. 1) is incident on the output terminals) when

and output impedances of the device under test and to

the source resistance and the termination at the input to the

convert scattering parameters by h, y, or 2 parameters.

device under test are each equal to the reference impedance

3.1.1.2 transistors-Can be considered linear networks if

(R, in Fig. 1).

measurements are made under small-signal conditions.

3.2 Symbols:

4. Summary of Test Method

3.2.1 S-The symbol S is used to designate the scattering

4.1 Scattering parameters of transistors are determined by

placing the transistor in cascade with a transmission line that

is terminated in its characteristic impedance, generally 50 Q,

1 This test method is under the jurisdiction of ASTM Committee F-1 on

Electronics, and is the direct responsibility of Subcommittee F01.i 1 on Quality

and measuring the ratios of the reflected and transmitted

and Assurance.

signals to the incident signal in both the forward and reverse

Current edition approved March 30, 1979. Published July 1979. Onginally

directions. The two reflected signals are functions of the

published as F 466 - 76 T. Last previous editon F466 - 76 T.

2 Annual Book of ASTM Standards, Vol 14.03. input and output impedances of the transistor, respectively,

AST! F4bb 79

O759510 0512251 174

1,

I f SDUIICt' n O R FZ A T

O

L

-

II

''I IlANflSIDR 5

h;ro -

AQA?ltR I

I +j

I

U ML

I'

I

¿

BIAS

L

$?

LI I

I

l

RATIO REFLECTED

I

SIGNAL I

VR/V,Of VT'y) VR I

REFERENCE

S16NAL

-9 i

r * TRANSMlTTfO I

0D PHASE

DIFFERENCE SIGNAL I

I

(%-OD] VT, 0T

I

or (UT-00)

I

L

FORWARD

REVERSE ps2_/

and the two transmitted signals are related to its forward and These networks shall be capable of attenuating the r-f signal

coupled to the power supply by at least 80 dB.

reverse transfer characteristics.

7.4 Directional Couplers (labeled D, R, and T in Fig. 1)

5. Significance and Use for sampling the incident, reflected, and transmitted signals,

respectively. The directivity of the directional couplers shall

5.1 This test method provides a means of characterizing

not be less than 35 dB; the reflection coeficients at terminals

transistors in a frequency range in which the measurement of

F and G shall not exceed O. 1 (-20 dB).

h, y, and 2 parameters is impractical because of the difficulty

of obtaining adequate short-circuit and open-circuit termina-

NOTE 1-The directivity of the directional couplers and the load and

tions. Scattering parameters can be used directly for circuit

source match at terminals F and G can be considered to meet the

requirements of 7.4 if the residual reflection coefficients at terminals F

design. If desired, they can be transformed mathematically to

and G do not exceed 0.023 (-32.8 dB), as specified in Annex A1.4.10.

h, y, or 2 parameters as indicated in Appendix X1.

7.5 Transistor Adapter (labeled A in Fig. i), connecting

6. Interferences

the transistor socket to the coaxial system. The reflection

6.1 The signal level applied to transistors for the measure-

coefficient caused by mismatch between the transistor

ment of small-signal parameters is very critical, especially in

adapter and terminals F and G shall not exceed 0.05 (-26

the measurement of forward characteristics. For this reason,

dB), as specified in Annex A 1.5.5. When the transistor socket

it is important not to exceed the signal level specified in

is empty, the coupling through the adapter between termi-

11.1.3. If there is doubt, the test specified in 9.4 should be

F and G shall not be greater than 0.005 (-46 dB), as

nals

applied to determine if the signal level is low enough to

specified in Annex A1.6.4.

satis@ small-signal conditions.

7.5.1 Transistor Socket providing repeatable, low-resist-

ance contact between the transistor leads and the transistor

7. Apparatus

socket within 0.5 mm of the reference plane established by

the calibration standards (see 7.7). The socket shall provide

7.1 rIf Source-Source capable of furnishing 6 to 20 mW

for the elimination of high-frequency effects caused by

of r-f power over a frequency range from 0.2 to 2.0 GHz. The

unused portions of the transistor leads.

frequency shall be accurate within f 1 % of the set value, and

7.6 Ratio- and Phase-Measuring Instruments-Instm-

the level of the predominant harmonic shall be at least 20 dB

ments capable of measuring the ratio and phase difference

below that of the fundamental.

between the signal incident on the device under test and

7.2 r-fLoad (labeled L in Fig. i), terminating the system

either the signal reflected from it or the signal transmitted

in its characteristic impedance, R,. The reflection coefficient

through it, depending on the setting of coaxial switch SI (see

of the load shall not exceed 0.005 (46 dB).

Fig. 1). When identical signals are applied to both terminals

7.3 Bias Decoupling Networks (labeled N in Fig. i),

of these instruments, the indicated ratio shall be within 2 5%

providing for the connection of bias to the device under test.

26 1

ASTM Fqbb 79 W 0759510 0512252 O00 W

4m F466

If no signal level has been agreed upon, perform the following

(0.2 dB) and the phase difference shall not exceed 0.25'.

test to determine if the test signal level is low enough to

7.7 Calibration Standards-Equipment for calibrating

the system for measurement of reflection and transmission assure linear operation of the device being measured:

parameters, consisting of the following: 9.4.1 Select the lowest frequency at which measurements

are to be made.

7.7.1 Short Circuit-A device to be inserted into the

transistor socket for providing a short-circuit termination at 9.4.2 Calibrate the system for the measurement of s21 (see

10.4).

the reference plane on which measurements are to be made.

9.4.3 Insert a typical transistor of the type to be measured

7.7.2 Through Line-A device to be inserted into the

transistor socket for connecting the input and output termi- into the test socket, apply the prescribed biases (see 12.3,

nals of the socket in a manner which preserves the character- and measure s21 (see 12.7.3).

9.4.4 Reduce the signal applied to the transistor by a

istic impedance of the system.

factor of two by inserting a coaxial, 3-dB attenuator (see

7.8 Accessories for Performance Verifcation-Equipment

7.8.1) in series with the r-f input to the system; for example,

for checking the performance of the system, consisting of the

E of Fig. 1.

following: at terminal

9.4.5 Recheck the calibration of the system.

7.8.1 Attenuator-A 3-dB fixed coaxial attenuator for

9.4.6 Remeasure transistor s21.

determining if the r-f signal level meets the requirements for

9.4.7 If the change in the magnitude of is greater than

small-signal operation of the device under test. The

1 % (0.1 dB), reduce the signal level to the device under test

attenuator shall be designed for operation in a system with

and repeat 9.4.2 through 9.4.6 until the change in s21

impedance Ro and shall be fitted with connectors that mate

magnitude caused by the 3dB reduction in signal level is less

with those used at the r-f input of the measurement system.

7.8.2 Resistive Termination (Transistor Socket)-A resis- than 1 % (0.1 dB).

tive termination to be inserted into the transistor socket for

determining the reflection coefficients at the socket. The

10. Calibration and Standardization

reflection coefficient of the termination shall not exceed

10.1 Select a circuit configuration (for example, common

0.005 (-46 dB).

base) that is compatible with the calibration standards to be

7.8.3 Short Circuit (Coaxial)-A shorî circuit for cali-

used. This may be different from the circuit configuration

brating the system at terminals F and G (see Fig. 1). The

used for transistor measurement.

device shall be fitted with a connector that mates with those

10.2 Check to see that biases are not applied to the

of the terminals (not required if 7.8.2 is available).

transistor socket.

7.8.4 Resistive Termination (Coaxial)-A resistive termi-

10.3 Calibrate for the measurement of reflection coeff-

nation for measuring the reflection coefficients at terminals

cients if both reflection and transmission coefficients are to

F and G (see Fig. 1). The reflection coefficient of the

be measured or if reflection coefficients only are to be mea-

termination shall not exceed 0.005 (-46 dB); the connector

sured. Choose for calibration the reflection coefficient that is

shall mate with those of terminals F and G (not required if

the more critical in the intended application of the transistor.

7.8.2 is available).

Adjust this reflection coeffcient to the correct response to a

7.9 Coaxial Switches (labeled S1 and S2 in Fig. i), for

short circuit (that is, unity at 180") and record the residual

connecting the ratio- and phase-measuring instruments to

values of the other S parameters. The procedure which

the reflected and transmitted signals and for facilitating the

follows in 10.3.1 through 10.3.4 should be followed when s1 I

conversion of the system for the measurement of the forward

is the more critical of the reflection parameters; if s22 is the

and reverse characteristics of the device under test.

more critical, substitute the material in brackets.

7.10 Coaxial Transmission Lines-Coaxial lines of im-

10.3.1 Adjust sI [sZ2] as follows:

pedance Ro connecting the components of the system.

10.3.1.1 Connect the system for the measurement of

7.11 Thermometer for measuring temperature in the vi-

forward [reverse] characteristics (see Fig. 1).

cinity of the transistor fixture. It shall be capable of mea--

10.3.1.2 Insert the short circuit (see 7.7.1) into the tran-

suring temperatures in the vicinity of room ambient temper-

,

sistor socket.

ature within O. 1°C (0.2'F). ASTM Precision Thermometer

10.3.1.3 Connect the ratio and phasedifference indicators

63F-62 (1 8 to 89'0 or 63C-62 (-8 to 32°C) as prescribed in

for measurement of the reflected signal.

Specification E 1 is suitable for this purpose.

10.3.1.4 Adjust the ratio and phase-difference indicators

to read 1 (O dB) and 180 deg, respectively.

8. Sampling

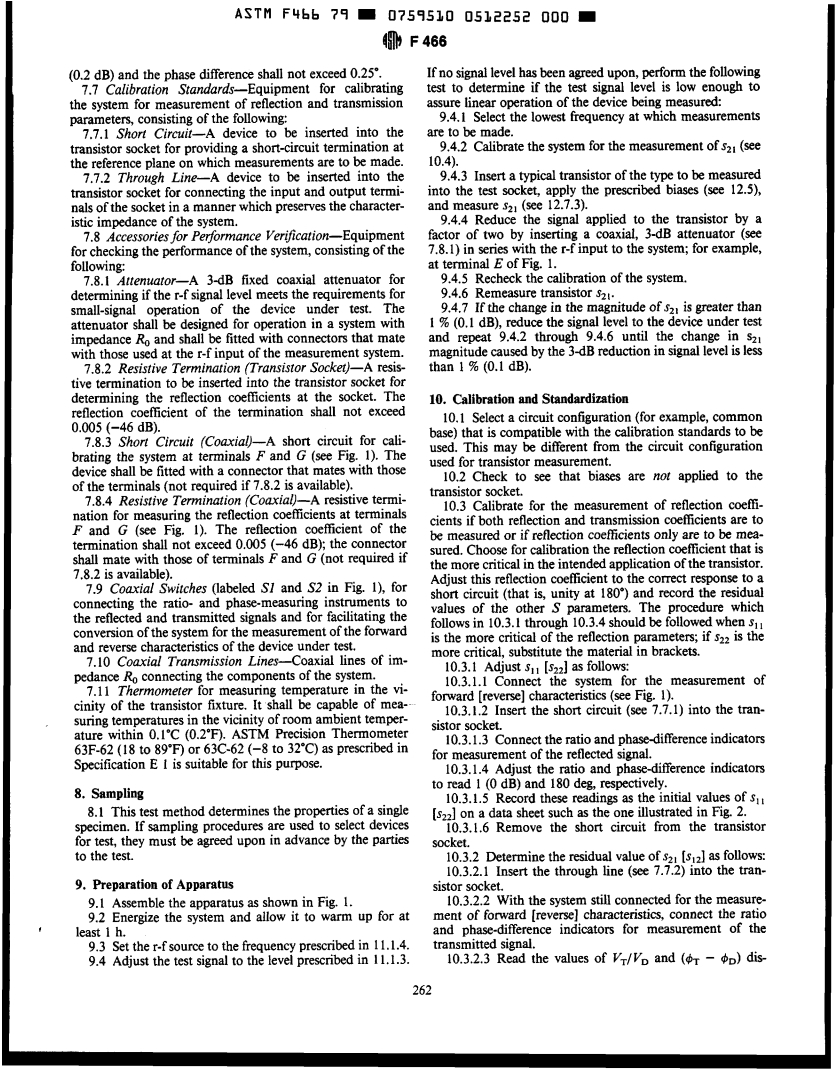

10.3.1.5 Record these readings as the initial values of sli

8.1 This test method determines the properties of a single

[s2J on a data sheet such as the one illustrated in Fig. 2.

specimen. If sampling procedures are used to select devices

10.3.1.6 Remove the short circuit from the transistor

for test, they must be agreed upon in advance by the parties

socket.

to the test.

10.3.2 Determine the residual val

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.