ASTM G205-10

(Guide)Standard Guide for Determining Corrosivity of Crude Oils

Standard Guide for Determining Corrosivity of Crude Oils

SIGNIFICANCE AND USE

In the absence of water, the crude oil is noncorrosive. The presence of sediment and water makes crude oil corrosive. Test Methods , , , and provide methods for the determination of the water and sediment content of crude oil.

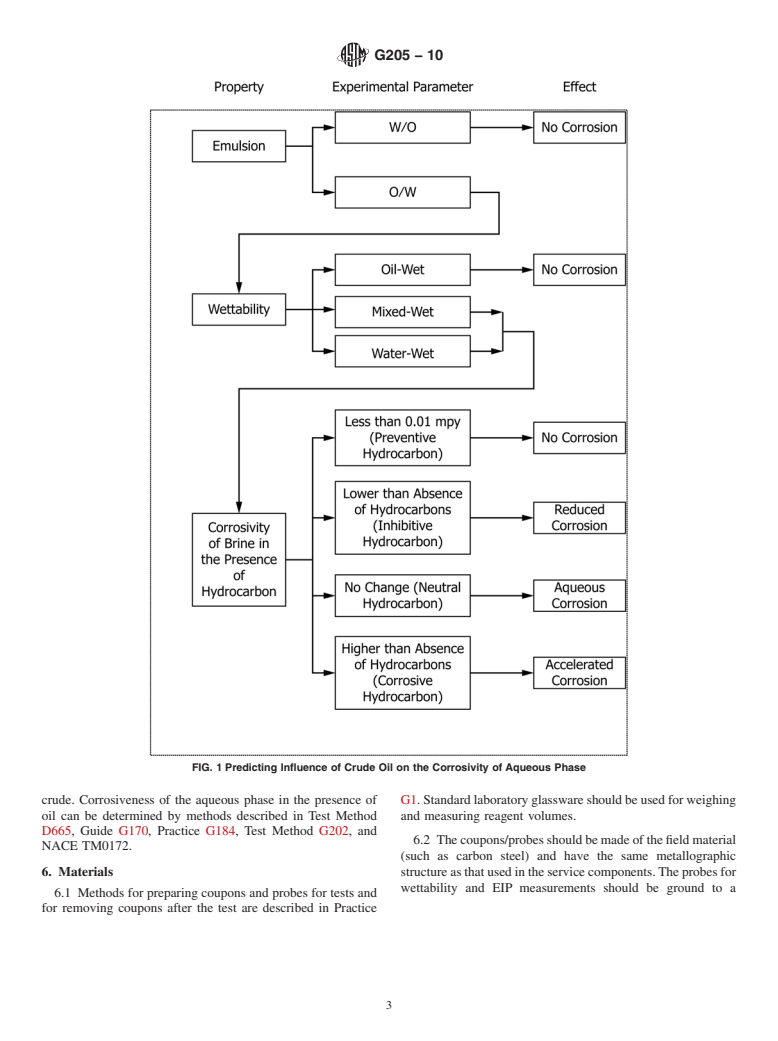

The corrosivity of crude oil containing water can be determined by a combination of three properties (Fig. 1) (1) : the type of emulsion formed between oil and water, the wettability of the steel surface, and the corrosivity of water phase in the presence of oil.

Water and oil are immiscible but, under certain conditions, they can form emulsion. There are two kinds of emulsion: O/W and W/O. W/O emulsion (in which oil is the continuous phase) has low conductivity and is thus less corrosive; whereas O/W (in which water is the continuous phase) has high conductivity and, hence, is corrosive (see ISO 6614) (2). The conductivities of various liquids are provided in Table 1(3). The percentage of water at which W/O converts to O/W is known as the emulsion inversion point (EIP). EIP can be determined by measuring the conductivity of the emulsion. At and above the EIP, a continuous phase of water or free water is present. Therefore, there is a potential for corrosion.

Whether water phase can cause corrosion in the presence of oil depends on whether the surface is oil wet (hydrophobic) or water wet (hydrophilic) (4-8). Because of higher resistance, an oil-wet surface is not susceptible to corrosion, but a water-wet surface is. Wettability can be characterized by measuring the contact angle or the conductivity (spreading method).

In the contact angle method, the tendency of water to displace hydrocarbon from steel is measured directly by observing the behavior of the three phase system. The contact angle is determined by the surface tensions (surface free energies) of the three phases. A hydrocarbon-steel interface will be replaced by a water-steel interface if this action will result in an energy decrease of the system. To determine whether the ...

SCOPE

1.1 This guide presents some generally accepted laboratory methodologies that are used for determining the corrosivity of crude oil.

1.2 This guide does not cover detailed calculations and methods, but rather a range of approaches that have found application in evaluating the corrosivity of crude oil.

1.3 Only those methodologies that have found wide acceptance in crude oil corrosivity evaluation are considered in this guide.

1.4 This guide does not address the change in oil/water ratio caused by accumulation of water at low points in a pipeline system.

1.5 This guide is intended to assist in the selection of methodologies that can be used for determining the corrosivity of crude oil under conditions in which water is present in the liquid state (typically up to 100°C). These conditions normally occur during oil and gas production, storage, and transportation in the pipelines.

1.6 This guide does not cover the evaluation of corrosivity of crude oil at higher temperatures (typically above 300°C) that occur during refining crude oil in refineries.

1.7 This guide involves the use of electrical currents in the presence of flammable liquids. Awareness of fire safety is critical for the safe use of this guide.

1.8 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G205 − 10

Standard Guide for

Determining Corrosivity of Crude Oils

This standard is issued under the fixed designation G205; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This guide presents some generally accepted laboratory

methodologies that are used for determining the corrosivity of

2. Referenced Documents

crude oil.

2.1 ASTM Standards:

1.2 This guide does not cover detailed calculations and

D96 Test Method for Water and Sediment in Crude Oil by

methods, but rather a range of approaches that have found 3

Centrifuge Method (Field Procedure) (Withdrawn 2000)

application in evaluating the corrosivity of crude oil.

D473 Test Method for Sediment in Crude Oils and Fuel Oils

1.3 Only those methodologies that have found wide accep- by the Extraction Method

tance in crude oil corrosivity evaluation are considered in this D665 Test Method for Rust-Preventing Characteristics of

guide. Inhibited Mineral Oil in the Presence of Water

D724 Test Method for Surface Wettability of Paper (Angle-

1.4 Thisguidedoesnotaddressthechangeinoil/waterratio

of-Contact Method) (Withdrawn 2009)

caused by accumulation of water at low points in a pipeline

D1125 Test Methods for Electrical Conductivity and Resis-

system.

tivity of Water

1.5 This guide is intended to assist in the selection of

D1129 Terminology Relating to Water

methodologies that can be used for determining the corrosivity

D1141 Practice for the Preparation of Substitute Ocean

of crude oil under conditions in which water is present in the

Water

liquid state (typically up to 100°C). These conditions normally

D1193 Specification for Reagent Water

occurduringoilandgasproduction,storage,andtransportation

D4006 Test Method for Water in Crude Oil by Distillation

in the pipelines.

D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.6 This guide does not cover the evaluation of corrosivity

ofcrudeoilathighertemperatures(typicallyabove300°C)that D4377 Test Method forWater in Crude Oils by Potentiomet-

ric Karl Fischer Titration

occur during refining crude oil in refineries.

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

1.7 This guide involves the use of electrical currents in the

sion Test Specimens

presence of flammable liquids. Awareness of fire safety is

G31 Guide for Laboratory Immersion Corrosion Testing of

critical for the safe use of this guide.

Metals

1.8 The values stated in SI units are to be regarded as

G111 Guide for Corrosion Tests in High Temperature or

standard. No other units of measurement are included in this

High Pressure Environment, or Both

standard.

G170 Guide for Evaluating and Qualifying Oilfield and

1.9 This standard does not purport to address all of the Refinery Corrosion Inhibitors in the Laboratory

safety concerns, if any, associated with its use. It is the G184 Practice for Evaluating and Qualifying Oil Field and

responsibility of the user of this standard to establish appro- Refinery Corrosion Inhibitors Using Rotating Cage

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This guide is under the jurisdiction ofASTM Committee G01 on Corrosion of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory Standards volume information, refer to the standard’s Document Summary page on

Corrosion Tests. the ASTM website.

Current edition approved Sept. 1, 2010. Published October 2010. DOI: 10.1520/ The last approved version of this historical standard is referenced on

G0205–10. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G205 − 10

G193 Terminology and Acronyms Relating to Corrosion 4.4 The corrosiveness of water phase in the presence of

G202 Test Method for UsingAtmospheric Pressure Rotating crude oil can be determined using several methods.

Cage

5. Significance and Use

2.2 ISO Standard:

ISO 6614 Petroleum products—Determination of Water

5.1 In the absence of water, the crude oil is noncorrosive.

Separability of Petroleum Oils and Synthetic Fluids

The presence of sediment and water makes crude oil corrosive.

2.3 NACE Standard:

Test Methods D96, D473, D4006, and D4377 provide methods

TM0172 Standard Test Method Determining Corrosive

for the determination of the water and sediment content of

Properties of Cargoes in Petroleum Product Pipelines

crude oil.

5.2 The corrosivity of crude oil containing water can be

3. Terminology

determined by a combination of three properties (Fig. 1)(1) :

3.1 Definitions—The terminology used herein, if not spe-

the type of emulsion formed between oil and water, the

cifically defined otherwise, shall be in accordance with Guide

wettability of the steel surface, and the corrosivity of water

G170, Terminology and Acronyms G193, and Terminology

phase in the presence of oil.

D1129. Definitions provided herein and not given in Guide

5.3 Water and oil are immiscible but, under certain

G170, Terminology and Acronyms G193, and Terminology

conditions, they can form emulsion. There are two kinds of

D1129 are limited only to this guide.

emulsion: O/W and W/O. W/O emulsion (in which oil is the

3.2 Definitions of Terms Specific to This Standard:

continuous phase) has low conductivity and is thus less

3.2.1 emulsion, n—two-phase immiscible liquid system in

corrosive; whereas O/W (in which water is the continuous

which one phase is dispersed as droplets in the other phase.

phase) has high conductivity and, hence, is corrosive (see ISO

3.2.2 emulsion-inversion point, n—percentage of water at

6614) (2).The conductivities of various liquids are provided in

which a water-in-oil (W/O) emulsion converts into an oil-in-

Table 1(3). The percentage of water at which W/O converts to

water (O/W) emulsion.

O/W is known as the emulsion inversion point (EIP). EIP can

be determined by measuring the conductivity of the emulsion.

3.2.3 wettability,n—tendencyofaliquidtowetoradhereon

AtandabovetheEIP,acontinuousphaseofwaterorfreewater

to a solid surface.

is present. Therefore, there is a potential for corrosion.

3.3 Acronyms:

5.4 Whether water phase can cause corrosion in the pres-

CO = Carbon dioxide

ence of oil depends on whether the surface is oil wet (hydro-

EIP = Emulsion inversion point

phobic) or water wet (hydrophilic) (4-8). Because of higher

H S = Hydrogen sulfide

resistance, an oil-wet surface is not susceptible to corrosion,

KOH = Potassium hydroxide

but a water-wet surface is. Wettability can be characterized by

NaCl = Sodium chloride

measuring the contact angle or the conductivity (spreading

Na CO = Sodium carbonate

2 3

method).

NaHCO = Sodium bicarbonate

5.4.1 In the contact angle method, the tendency of water to

NaOH = Sodium hydroxide

displace hydrocarbon from steel is measured directly by

Na S = Sodium sulfide

observing the behavior of the three phase system. The contact

O/W = Oil-in-water

angle is determined by the surface tensions (surface free

W/O = Water-in-oil

energies) of the three phases. A hydrocarbon-steel interface

4. Summary of Guide

will be replaced by a water-steel interface if this action will

result in an energy decrease of the system. To determine

4.1 This guide describes methods for determining the cor-

whether the surface is oil wet, mixed wet, or water wet, the

rosivity of crude oils by a combination of three properties: (1)

angle at the oil-water-solid intersection is observed and mea-

theemulsionoftheoilandwater, (2)thewettabilityofthesteel

sured.

surface, and (3) the corrosivity of water phase in the presence

5.4.2 In the spreading method of determining wettability,

of oil.

the resistance between steel pins is measured. If a conducting

4.2 Conductivity of emulsion can be used to determine the

phase (for example, water) covers (wets) the distance between

typeofemulsion:oilinwater(O/W)orwaterinoil(W/O).The

the pins, conductivity between them will be high. On the other

conductivity of the O/W emulsion (in which water is the

hand,ifanonconductingphase(forexample,oil)covers(wets)

continuous phase) is high. The conductivity of the W/O

the distance between the pins, the conductivity between them

emulsion (in which oil is the continuous phase) is low.

will be low.

4.3 The wettability of a steel surface is determined using

5.5 Dissolution of ingredients from crude oils may alter the

two methods: (1) contact angle method and (2) spreading

corrosiveness of the aqueous phase. Based on how the corro-

method.

sivity of the aqueous phase changes in its presence, a crude oil

can be classified as corrosive, neutral, inhibitory, or preventive

Available from theAmerican National Standards Institute, 25W. 43rd St., New

York, NY 10036.

5 6

AvailablefromtheNationalAssociationofCorrosionEngineers,1440S.Creek The boldface numbers in parentheses refer to a list of references at the end of

Dr., Houston, TX 77084-4906. this standard.

G205 − 10

FIG. 1 Predicting Influence of Crude Oil on the Corrosivity of Aqueous Phase

crude. Corrosiveness of the aqueous phase in the presence of G1.Standardlaboratoryglasswareshouldbeusedforweighing

oil can be determined by methods described in Test Method and measuring reagent volumes.

D665, Guide G170, Practice G184, Test Method G202, and

6.2 Thecoupons/probesshouldbemadeofthefieldmaterial

NACE TM0172.

(such as carbon steel) and have the same metallographic

6. Materials structureasthatusedintheservicecomponents.Theprobesfor

wettability and EIP measurements should be ground to a

6.1 Methods for preparing coupons and probes for tests and

for removing coupons after the test are described in Practice

G205 − 10

TABLE 1 Conductivities of Selected Hydrocarbons and Aqueous

quired to be saturated with acid gases such as hydrogen sulfide

Phases (3)

(H S) and carbon dioxide (CO ). H S and CO are corrosive

2 2 2 2

A

Liquid Temperature, °C Conductivity

gases. H S is poisonous and shall not be released to the

-9

Acetic acid 0 5 × 10

atmosphere. The appropriate composition of gas can be ob-

-8

Aniline 25 2.4 × 10

tained by mixing H S, CO , and methane streams from the

-8

2 2

Benzene . 7.6 × 10

-5

standard laboratory gas supply. Nitrogen or any other inert gas

Formic acid 25 6.4 × 10

-8

Glycerol 25 6.4 × 10

can be used as a diluent to obtain the required partial pressures

-7

Glycol 25 3 ×10

-13 of the corrosive gases. Alternatively, gas mixtures of the

Heptane . <1 ×10

-18

appropriate compositions can be purchased from suppliers of

Hexane 18 <1 × 10

-8

Kerosene 25 <1.7 × 10

industrial gases. The composition of gas depends on the field

-10

Pentane 19.5 <2 × 10

gas composition. The oxygen concentration in solution de-

-12

Sulfur 115 1 × 10

-8

Sulfur dioxide 35 1.5 × 10 ) pends on the quality of gases used to purge the solution. The

-2

Sulfuric acid 25 1 × 10

oxygen content of nitrogen or the inert gas should be less then

-8

Sulfuryl chloride, S0 C1 25 3×10

2 2

-8 10ppmbyvolume.Leaksthroughthevessel,tubing,andjoints

Water 18 4×10

B

KOH 18 234 should be avoided.

B

NaCl 18 106.5

B 7.4 The test vessels should be heated slowly to avoid

NaOH 18 208

B

1/2Na S 18 104.3 (N= 1.0)

2 overheating. The thermostat in the heater or thermostatic bath

B

NaHC0 25 93.5

should be set not more than 20°C above the solution tempera-

B

1/2Na C0 18 112

2 3

ture until the test temperature is reached. The pressure in the

A

Electrical conductivity is the reciprocal of the ac resistance in ohms measured

vessel should be monitored during heating to make sure it does

between opposite faces of a 1-cm cube of an aqueous solution at a specified

temperature (in accordance with Test Methods D1125). The unit of electrical not exceed the relief pressure. If necessary, some of the gas in

conductivity is Siemens per centimetre (S/cm). The previously used units of

the vessel may be bled off to reduce the pressure. The test

mhos/cm are numerically equivalent to S/cm. At low concentrations to obtain the

temperature should be maintained within +2°C of the specified

conductivity of electrolyte the conductivity of pure solvent should be subtracted

from that of the solution. temperature. Once the test temperature is reached, the test

B -1 2 -1

Equivalent conductivity of an electrolyte, Λ (Ω ·cm · equiv ) – the sum of

pressure should be adjusted to the predetermined value. The

contributions of the individual ions; Λ = κ/C, where C is concentration in

pressure should be maintained within +10 % of the specified

equivalents per litre. The volume of the solution in cubic centimetres per equivalent

is equal to 1000/C, andΛ = 1000κ/C. The values are taken at 0.001 concentration

value for the duration of the test.

(N), except where specified otherwise.

7.5 Ageneralproceduretocarryoutexperimentsatelevated

pressure and elevated temperature is described in Guide G111.

For elevated temperature and elevated pressure experiments

surface finish of 600 grit. Preparation of coupons for corrosion

using individual gases, first the autoclave is pressurized with

measurements is described in Guide G170, Practice G184, and

H S to the required partial pressure and left for 10 min. If there

Test Method G202.

is a decrease of pressure, the autoclave is repressurized. This

process is repeated until no further pressure drop occurs.Then,

7. Preparation of Test Solutions

the autoclave is pressurized with CO by opening the CO gas

2 2

7.1 Oil should be obtained from the field that is being

cylinder at a pressure equal to the CO +H S partial pressure

2 2

evaluated. Practice D4057 provides guidelines for collecting

and left for 10 min. If there is a decrease in pressure, the

crude oil. It is important that live fluids do not contain

autoclave is repressurized with CO gas. This process is

externally added contaminants, for example, corrosion

repeated until no further pressure drop is observed. Finally, the

inhibitors, biocides, and surfactants. A water sample should

autoclave is pressurized with an inert gas (for example,

also be obtained from the field. A synthetic aqueous solution

methane) by opening the appropriate cylinder at the total gas

could be used; the composition of which, however, should be

pressure at which the experiments are intended to be carried

based on field water analysis.Alternatively, standard 3 % brine

out.

or synthetic brine (of a com

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.