ASTM G205-23

(Guide)Standard Guide for Determining Emulsion Properties, Wetting Behavior, and Corrosion-Inhibitory Properties of Crude Oils

Standard Guide for Determining Emulsion Properties, Wetting Behavior, and Corrosion-Inhibitory Properties of Crude Oils

SIGNIFICANCE AND USE

5.1 In the absence of water, the crude oil is noncorrosive. However, trace amounts of water and sediment have the potential to create corrosive situations during crude oil handling or transport if such materials accumulate and persist on steel surfaces. Test Methods D473 and D4006 provide methods for determination of the water and sediment content of crude oil.

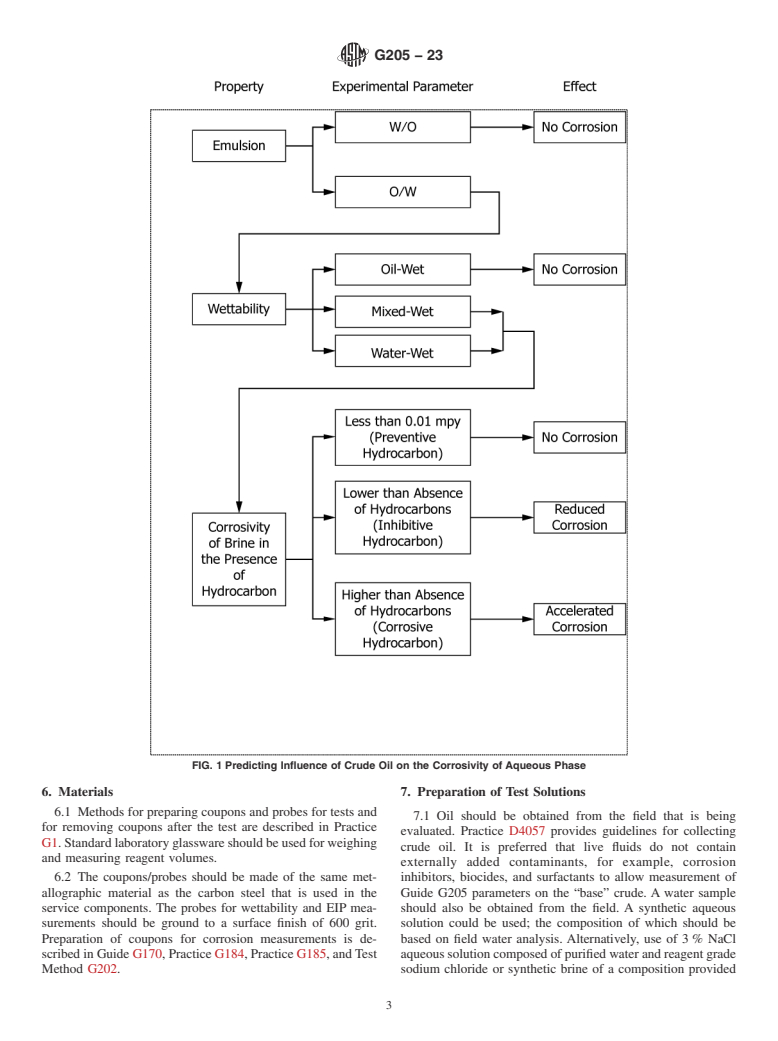

5.2 The potential for a corrosive situation to develop during the handling and transport of crude oil that contains water can be determined by a combination of three properties (Fig. 1) (1)6: the type of emulsion formed between oil and water, the wettability of the steel surface, and the corrosivity of water phase in the presence of oil.

FIG. 1 Predicting Influence of Crude Oil on the Corrosivity of Aqueous Phase

5.3 Water and oil are immiscible but, under certain conditions, they can form emulsion. There are two kinds of emulsion: oil-in-water (O/W) and water-in-oil (W/O). W/O emulsion (in which oil is the continuous phase) has low conductivity and is thus less corrosive; whereas O/W (in which water is the continuous phase) has high conductivity and, hence, is corrosive (2) (see ISO 6614). The percentage of water at which W/O converts to O/W is known as the emulsion inversion point (EIP). EIP can be determined by measuring the conductivity of the emulsion. At and above the EIP, a continuous phase of water or free water is present. Therefore, there is a potential for corrosion.

5.4 Whether water phase can cause corrosion in the presence of oil depends on whether the surface is oil-wet (hydrophobic) or water-wet (hydrophilic) (1, 3-5). Because of higher resistance, an oil-wet surface is not susceptible to corrosion, but a water-wet surface is. Wettability can be characterized by measuring the contact angle or by evaluating the tendency of water to displace oil from a multi-electrode array by measuring the resistance (or conductors) between the electrodes (spreading methodology).

5.4.1 In the con...

SCOPE

1.1 This guide covers some generally accepted laboratory methodologies that are used for determining emulsion forming tendency, wetting behavior, and corrosion-inhibitory properties of crude oil.

1.2 This guide does not cover detailed calculations and methods, but rather covers a range of approaches that have found application in evaluating emulsions, wettability, and the corrosion rate of steel in crude oil/water mixtures.

1.3 Only those methodologies that have found wide acceptance in the industry are considered in this guide.

1.4 This guide is intended to assist in the selection of methodologies that can be used for determining the corrosivity of crude oil under conditions in which water is present in the liquid state (typically up to 100 °C). These conditions normally occur during oil and gas production, storage, and transportation in the pipelines.

1.5 This guide is not applicable at higher temperatures (typically above 300 °C) that occur during refining crude oil in refineries.

1.6 This guide involves the use of electrical currents in the presence of flammable liquids. Awareness of fire safety is critical for the safe use of this guide.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G205 − 23

Standard Guide for

Determining Emulsion Properties, Wetting Behavior, and

1

Corrosion-Inhibitory Properties of Crude Oils

This standard is issued under the fixed designation G205; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This guide covers some generally accepted laboratory

mendations issued by the World Trade Organization Technical

methodologies that are used for determining emulsion forming

Barriers to Trade (TBT) Committee.

tendency, wetting behavior, and corrosion-inhibitory properties

of crude oil.

2. Referenced Documents

1.2 This guide does not cover detailed calculations and

2

2.1 ASTM Standards:

methods, but rather covers a range of approaches that have

D473 Test Method for Sediment in Crude Oils and Fuel Oils

found application in evaluating emulsions, wettability, and the

by the Extraction Method

corrosion rate of steel in crude oil/water mixtures.

D665 Test Method for Rust-Preventing Characteristics of

1.3 Only those methodologies that have found wide accep-

Inhibited Mineral Oil in the Presence of Water

tance in the industry are considered in this guide.

D724 Test Method for Surface Wettability of Paper (Angle-

3

of-Contact Method) (Withdrawn 2009)

1.4 This guide is intended to assist in the selection of

D1125 Test Methods for Electrical Conductivity and Resis-

methodologies that can be used for determining the corrosivity

tivity of Water

of crude oil under conditions in which water is present in the

D1129 Terminology Relating to Water

liquid state (typically up to 100 °C). These conditions normally

D1141 Practice for Preparation of Substitute Ocean Water

occur during oil and gas production, storage, and transportation

D4006 Test Method for Water in Crude Oil by Distillation

in the pipelines.

D4057 Practice for Manual Sampling of Petroleum and

1.5 This guide is not applicable at higher temperatures

Petroleum Products

(typically above 300 °C) that occur during refining crude oil in

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

refineries.

sion Test Specimens

1.6 This guide involves the use of electrical currents in the

G31 Guide for Laboratory Immersion Corrosion Testing of

presence of flammable liquids. Awareness of fire safety is

Metals

critical for the safe use of this guide.

G111 Guide for Corrosion Tests in High Temperature or

High Pressure Environment, or Both

1.7 The values stated in SI units are to be regarded as

G170 Guide for Evaluating and Qualifying Oilfield and

standard. No other units of measurement are included in this

Refinery Corrosion Inhibitors in the Laboratory

standard.

G184 Practice for Evaluating and Qualifying Oil Field and

1.8 This standard does not purport to address all of the

Refinery Corrosion Inhibitors Using Rotating Cage

safety concerns, if any, associated with its use. It is the

G185 Practice for Evaluating and Qualifying Oil Field and

responsibility of the user of this standard to establish appro-

Refinery Corrosion Inhibitors Using the Rotating Cylinder

priate safety, health, and environmental practices and deter-

Electrode

mine the applicability of regulatory limitations prior to use.

G193 Terminology and Acronyms Relating to Corrosion

1.9 This international standard was developed in accor-

G202 Test Method for Using Atmospheric Pressure Rotating

dance with internationally recognized principles on standard-

Cage

1 2

This guide is under the jurisdiction of ASTM Committee G01 on Corrosion of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Corrosion Tests. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2023. Published January 2024. Originally the ASTM website.

3

approved in 2010. Last previous edition approved in 2016 as G205 – 16. DOI: The last approved version of this historical standard is referenced on

10.1520/G0205-23. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G205 − 23

4

2.2 ISO Standard: dling or transport if such materials accumulate and persist on

ISO

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G205 − 16 G205 − 23

Standard Guide for

Determining Emulsion Properties, Wetting Behavior, and

1

Corrosion-Inhibitory Properties of Crude Oils

This standard is issued under the fixed designation G205; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide presentscovers some generally accepted laboratory methodologies that are used for determining emulsion forming

tendency, wetting behavior, and corrosion-inhibitory properties of crude oil.

1.2 This guide does not cover detailed calculations and methods, but rather covers a range of approaches that have found

application in evaluating emulsions, wettability, and the corrosion rate of steel in crude oil/water mixtures.

1.3 Only those methodologies that have found wide acceptance in the industry are considered in this guide.

1.4 This guide is intended to assist in the selection of methodologies that can be used for determining the corrosivity of crude oil

under conditions in which water is present in the liquid state (typically up to 100°C).100 °C). These conditions normally occur

during oil and gas production, storage, and transportation in the pipelines.

1.5 This guide is not applicable at higher temperatures (typically above 300°C)300 °C) that occur during refining crude oil in

refineries.

1.6 This guide involves the use of electrical currents in the presence of flammable liquids. Awareness of fire safety is critical for

the safe use of this guide.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This guide is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory Corrosion

Tests.

Current edition approved Nov. 1, 2016Dec. 1, 2023. Published December 2016January 2024. Originally approved in 2010. Last previous edition approved in 20102016

as G205 – 10.G205 – 16. DOI: 10.1520/G0205-16.10.1520/G0205-23.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G205 − 23

2. Referenced Documents

2

2.1 ASTM Standards:

3

D96 Test Method for Water and Sediment in Crude Oil by Centrifuge Method (Field Procedure) (Withdrawn 2000)

D473 Test Method for Sediment in Crude Oils and Fuel Oils by the Extraction Method

D665 Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water

3

D724 Test Method for Surface Wettability of Paper (Angle-of-Contact Method) (Withdrawn 2009)

D1125 Test Methods for Electrical Conductivity and Resistivity of Water

D1129 Terminology Relating to Water

D1141 Practice for Preparation of Substitute Ocean Water

D1193 Specification for Reagent Water

D4006 Test Method for Water in Crude Oil by Distillation

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

3

D4377 Test Method for Water in Crude Oils by Potentiometric Karl Fischer Titration (Withdrawn 2020)

G1 Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens

G31 Guide for Laboratory Immersion Corrosion Testing of Metals

G111 Guide for Corrosion Tests in High Temperature or High Pressure Environment, or Both

G170 Guide for Evaluating and Qualifying Oilfield and Refinery Corrosion Inhibitors in the Laboratory

G184 Practice for Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using Rotating Cage

G185 Practice for Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using the Rotating Cylinder Electrode

G193 Terminology and Acronyms Relating to Corrosion

G202 Test Method for Usi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.