ASTM F1309-23

(Practice)Standard Practice for Installation Procedures for Fitting Chocks to Marine Machinery Foundations

Standard Practice for Installation Procedures for Fitting Chocks to Marine Machinery Foundations

SIGNIFICANCE AND USE

3.1 This practice provides the three principal methods of fitting chocks to marine machinery foundations to ensure that the machinery is free of vibration and perfectly aligned after installation.

3.1.1 The three principal methods of installing chocks described herein are as follows:

3.1.1.1 Type A—Epoxy-based resin, nonshrinking, and

3.1.1.2 Type B—Two-piece wedge chocks.

3.1.1.3 Type C—Solid, one-piece fitted chocks.

SCOPE

1.1 This practice covers the acceptable methods of fitting chocks to marine machinery foundations.

1.2 The values stated in SI units shall be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1309 − 23 An American National Standard

Standard Practice for

Installation Procedures for Fitting Chocks to Marine

1

Machinery Foundations

This standard is issued under the fixed designation F1309; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope American Welding Society Publication, AWS D1.1 Struc-

4

tural Welding Code

1.1 This practice covers the acceptable methods of fitting

chocks to marine machinery foundations.

3. Significance and Use

1.2 The values stated in SI units shall be regarded as

3.1 This practice provides the three principal methods of

standard. The values in parentheses are for information only.

fitting chocks to marine machinery foundations to ensure that

1.3 This standard does not purport to address all of the

the machinery is free of vibration and perfectly aligned after

safety concerns, if any, associated with its use. It is the

installation.

responsibility of the user of this standard to establish appro-

3.1.1 The three principal methods of installing chocks

priate safety, health, and environmental practices and deter-

described herein are as follows:

mine the applicability of regulatory limitations prior to use.

3.1.1.1 Type A—Epoxy-based resin, nonshrinking, and

1.4 This international standard was developed in accor-

3.1.1.2 Type B—Two-piece wedge chocks.

dance with internationally recognized principles on standard-

3.1.1.3 Type C—Solid, one-piece fitted chocks.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4. Procedure

mendations issued by the World Trade Organization Technical

4.1 General Requirements for Types A, B, and C Chocking

Barriers to Trade (TBT) Committee.

Systems:

2. Referenced Documents

4.1.1 Machining:

2

4.1.1.1 Type A chocks, machinery bedplates, foundation

2.1 ASTM Standards:

plates, and bolts do not require finish machining if the chocks

A370 Test Methods and Definitions for Mechanical Testing

are not designed to be removed. Unless specified otherwise,

of Steel Products

Types B and C chock, bolts/studs, machinery bedplate, foun-

D638 Test Method for Tensile Properties of Plastics

dation plates, and fitted holes need to be finished machined and

D648 Test Method for Deflection Temperature of Plastics

fitted.

Under Flexural Load in the Edgewise Position

4.1.1.2 Surfaces in way of the chock areas on the machinery

D695 Test Method for Compressive Properties of Rigid

bedplate and the foundation plate may be machined before

Plastics

installation or while the ship is not waterborne, or both.

2.2 Other Documents:

4.1.1.3 Unless otherwise specified, all finished surfaces

American Bureau of Shipping Rules for Building and

3

shall be finished to a maximum of 0.003–mm roughness height

Classing Steel Vessels

average (RHA).

4.1.1.4 Finished areas on the machinery bedplate and the

foundation plate in way of the chocks shall be sufficiently

greater in size than the chock to prevent interference from the

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

unfinished area with the chock during installation.

Marine Technology and is the direct responsibility of Subcommittee F25.03 on

4.1.1.5 Spotface hole edge radius shall be such that there

Outfitting and Deck Machinery.

Current edition approved July 1, 2023. Published July 2023. Originally approved

will not be any interference between it and the bolt head-to-

in 1990. Last previous edition approved in 2018 as F1309 – 98 (2018). DOI:

shank radius. The spotface area shall be sufficiently greater in

10.1520/F1309-23.

area than that of the bolt head or nut so as not to cause any

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855 Available from American Welding Society (AWS), 8669 NW 36 St., #130,

Northchase Dr., Houston, TX 77060, http://www.eagle.org. Miami, FL 33166-6672, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1309 − 23

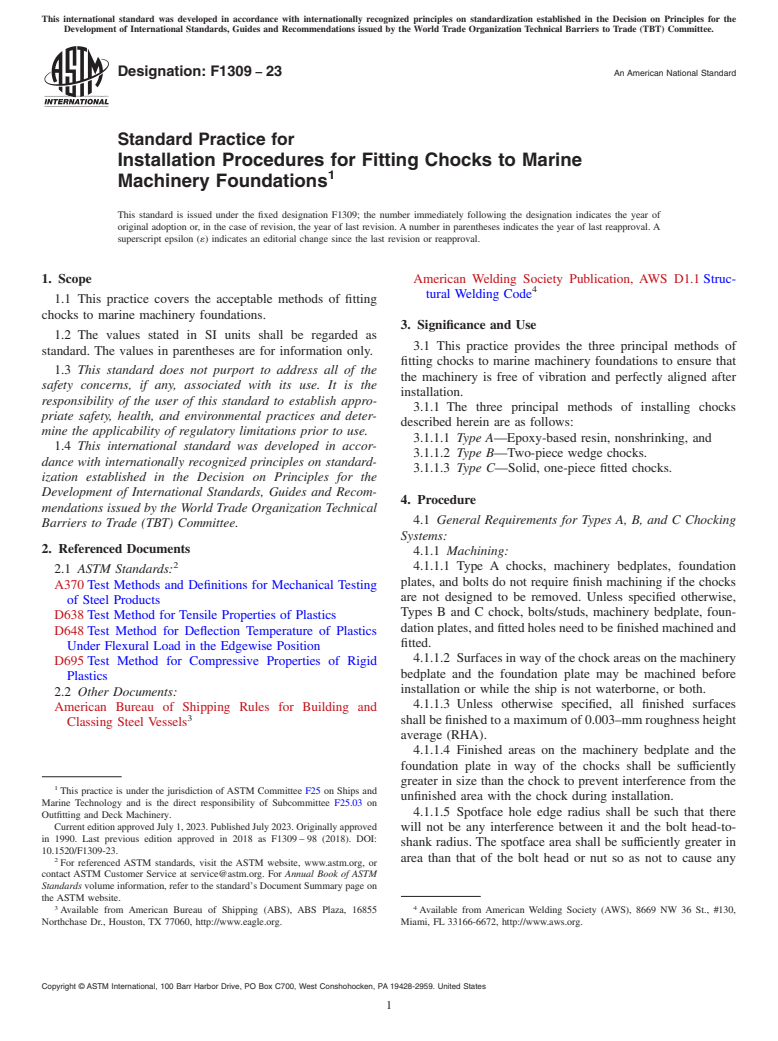

interference when tightening or with the tooling used. The 4.2.1 Provision for Future Machinery Removal—To prevent

spotface surfaces shall b

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1309 − 98 (Reapproved 2018) F1309 − 23 An American National Standard

Standard Practice for

Installation Procedures for Fitting Chocks to Marine

1

Machinery Foundations

This standard is issued under the fixed designation F1309; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the acceptable methods of fitting chocks to marine machinery foundations.

1.2 The values stated in SI units shall be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

D638 Test Method for Tensile Properties of Plastics

D648 Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

D695 Test Method for Compressive Properties of Rigid Plastics

2.2 Other Documents:

3

American Bureau of Shipping Rules for Building and Classing Steel Vessels

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.03 on Outfitting

and Deck Machinery.

Current edition approved April 1, 2018July 1, 2023. Published May 2018July 2023. Originally approved in 1990. Last previous edition approved in 20122018 as

F1309 – 98 (2012).(2018). DOI: 10.1520/F1309-98R18.10.1520/F1309-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855 Northchase Dr., Houston, TX 77060, http://www.eagle.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1309 − 23

4

American Welding Society Publication, AWS D1.1 Structural Welding Code

3. Significance and Use

3.1 This practice provides the three principal methods of fitting chocks to marine machinery foundations to ensure that the

machinery is free of vibration and perfectly aligned after installation.

3.1.1 The three principal methods of installing chocks described herein are as follows:

3.1.1.1 Type A—Epoxy-based resin, nonshrinking Chockfast Orange PR 610 TCF by Philadelphia Resin Corp., or equal,

nonshrinking, and

3.1.1.2 Type B—Two-piece wedge chocks.

3.1.1.3 Type C—Solid, one-piece fitted chocks.

4. Procedure

4.1 General Requirements for Types A, B, and C Chocking Systems:

4.1.1 Machining:

4.1.1.1 Type A chocks, machinery bedplates, foundation plates, and bolts do not require finish machining if the chocks are not

designed to be removed. Unless specified otherwise, Types B and C chock, bolts/studs, machinery bedplate, foundation plates, and

fitted holes need to be finished machined and fitted.

4.1.1.2 Surfaces in way of the chock areas on the machinery bedplate and the foundation plate may be machined before installation

or while the ship is not waterborne, or both.

4.1.1.3 Unless otherwise specified, all finished surfaces shall be finished to a maximum of 0.003–mm roughness height average

(RHA).

4.1.1.4 Finished areas on the machinery bedplate and the foundation plate in way of the chocks shall be sufficiently greater in size

than the chock to prevent interference from the unfinished area with the chock during installation.

4.1.1.5 Spotface hole edge radius shall be such that there will not be any interference between it and the bolt head-to-shank radius.

The spotface area shall be sufficiently greater in area than that of the bolt head or nut so as no

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.