ASTM C1422/C1422M-15

(Specification)Standard Specification for Chemically Strengthened Flat Glass

Standard Specification for Chemically Strengthened Flat Glass

SCOPE

1.1 This specification covers the requirements for chemically strengthened glass products that are used in general building construction, transportation, and other applications, such as PC screens, notebooks, tablets, smart phones, and E-readers, as well as copy machine scanners, computer disks, and flat glass screens for television monitors. Techniques such as ion implantation, dealkalization, etch-strengthening, and glaze coatings are specifically excluded.

1.2 Classification of chemically strengthened glass products is based on the laboratory measurements of surface (depth of compression) compression and case depth and not on the modulus of rupture (MOR). This specification does not purport to address end-use performance.

1.3 A test method for the measurement of case depth and surface compression is included in Section 8.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1422/C1422M −15

Standard Specification for

1

Chemically Strengthened Flat Glass

This standard is issued under the fixed designation C1422/C1422M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Polarizing Microscope and Optical Retardation Compen-

sation Procedures

1.1 This specification covers the requirements for chemi-

C1036Specification for Flat Glass

cally strengthened glass products that are used in general

C1279Test Method for Non-Destructive Photoelastic Mea-

building construction, transportation, and other applications,

surement of Edge and Surface Stresses in Annealed,

such as PC screens, notebooks, tablets, smart phones, and

Heat-Strengthened, and Fully Tempered Flat Glass

E-readers, as well as copy machine scanners, computer disks,

F218Test Method for Measuring Optical Retardation and

and flat glass screens for television monitors. Techniques such

Analyzing Stress in Glass

as ion implantation, dealkalization, etch-strengthening, and

3

glaze coatings are specifically excluded. 2.2 ANSI Standard:

Z97.1–2009Safety Glazing Materials Used in Buildings-

1.2 Classificationofchemicallystrengthenedglassproducts

Safety Performance, Specifications and Methods of Tests

is based on the laboratory measurements of surface (depth of

4

compression) compression and case depth and not on the 2.3 Federal Document:

modulusofrupture(MOR).Thisspecificationdoesnotpurport CPSC 16CFR 1201Consumer Product Safety Commission

to address end-use performance. Safety Standard for Architectural Glazing Materials

1.3 A test method for the measurement of case depth and

3. Terminology

surface compression is included in Section 8.

3.1 Definitions:

1.4 The values stated in either SI units or inch-pound units

3.1.1 Refer to Terminology C162, as appropriate.

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each 3.1.2 blemishes—RefertoSpecificationC1036forflatglass.

system shall be used independently of the other. Combining

3.2 Definitions of Terms Specific to This Standard:

values from the two systems may result in non-conformance

3.2.1 case depth—depth of compression below the surface

with the standard.

to the nearest zero stress plane.

1.5 This standard does not purport to address all of the

3.2.2 chemically strengthened glass—glass which has been

safety concerns, if any, associated with its use. It is the

strengthened by ion exchange to produce a compressive stress

responsibility of the user of this standard to establish appro-

layer at the treated surface.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.2.3 depth of compression (DOC)-—see case depth.

3.2.4 ion exchange process—the exchange of constituent

2. Referenced Documents

ions in the glass with externally supplied ions (generally at

2

2.1 ASTM Standards:

temperatures near the strain point of the glass). This may be

C162Terminology of Glass and Glass Products

accomplished by immersing glass in a molten salt bath or

C978Test Method for Photoelastic Determination of Re-

solution with or without electric field, ultrasonic or other

sidual Stress in a Transparent Glass Matrix Using a

assistance, exposing glass to plasma, applying a paste on the

glasssurface,orcontactingglasswithmoltensaltsinafurnace.

1

This specification is under the jurisdiction ofASTM Committee C14 on Glass

3.2.5 surface compression—an in-plane stress which tends

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat

to compact the atoms in the surface.

Glass.

Current edition approved Nov. 1, 2015. Published December 2015. Originally

approved in 1999. Last previous edition approved in 2010 as C1422/C1422M–10.

DOI: 10.1520/C1422_C1422M-15.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on AvailablefromU.S.ConsumerProductSafetyCommission(CPSC),4330East

the ASTM website. West Hwy., Bethesda, MD 20814, http://www.cpsc.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1422/C1422M−15

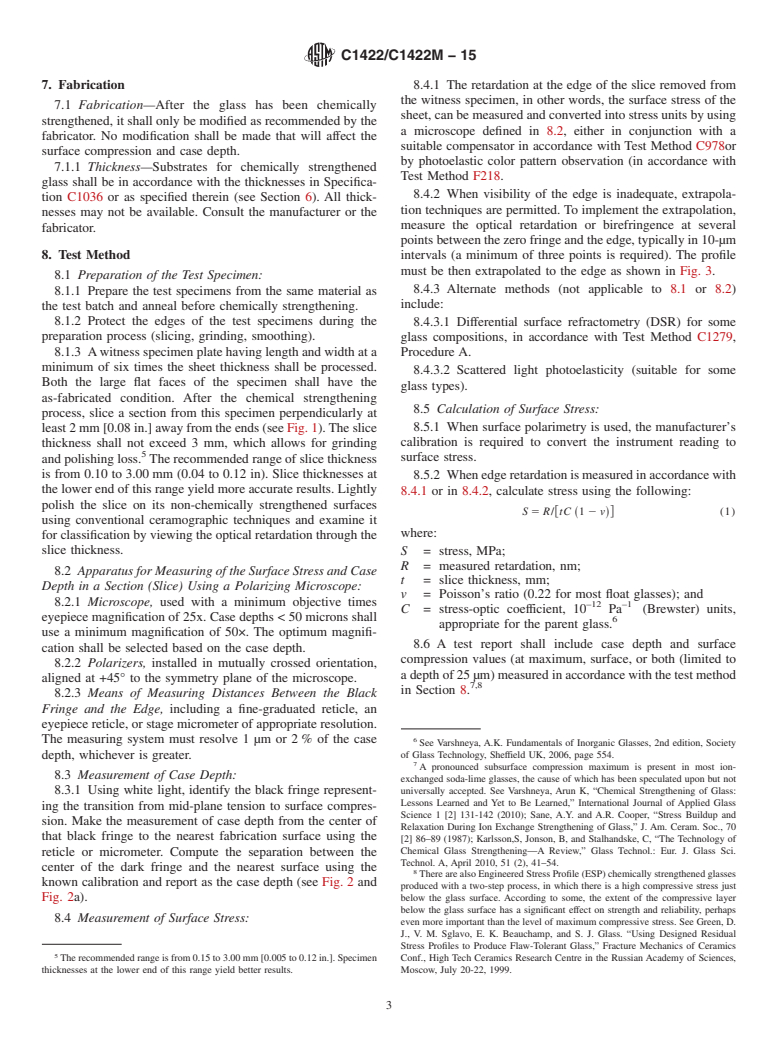

FIG. 1Slice Location

4. Significance and Use 5.1.1.1 Level 1—Surface compression, >7 MPa [1000 psi]

≤172 MPa [25000 psi].

4.1 Chemica

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1422/C1422M − 10 C1422/C1422M − 15

Standard Specification for

1

Chemically Strengthened Flat Glass

This standard is issued under the fixed designation C1422/C1422M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for chemically strengthened glass products that originate from flat glass and are

used in general building construction, transportation, and other specialty applications, such as PC screens, notebooks, tablets,

smart phones, and E-readers, as well as copy machine scanners, computer disks, and flat glass screens for television monitors.

Techniques such as ion implantation, dealkalization, etch-strengthening, and glaze coatings are specifically excluded.

1.2 Classification of chemically strengthened glass products is based on the laboratory measurements of surface (depth of

compression) compression and case depth and not on the modulus of rupture (MOR). This specification does not purport to address

end-use performance.

1.3 A test method for the measurement of case depth and surface compression is included in Section 8.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C162 Terminology of Glass and Glass Products

C978 Test Method for Photoelastic Determination of Residual Stress in a Transparent Glass Matrix Using a Polarizing

Microscope and Optical Retardation Compensation Procedures

C1036 Specification for Flat Glass

C1279 Test Method for Non-Destructive Photoelastic Measurement of Edge and Surface Stresses in Annealed, Heat-

Strengthened, and Fully Tempered Flat Glass

F218 Test Method for Measuring Optical Retardation and Analyzing Stress in Glass

3

2.2 ANSI Standard:

Z97.1–2009 Safety Glazing Materials Used in Buildings-Safety Performance, Specifications and Methods of Tests

4

2.3 Federal Document:

CPSC 16CFR 1201 Consumer Product Safety Commission Safety Standard for Architectural Glazing Materials

3. Terminology

3.1 Definitions:

3.1.1 Refer to Terminology C162, as appropriate.

3.1.2 blemishes—Refer to Specification C1036 for flat glass.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 case depth—depth of compression below the surface to the nearest zero stress plane.

1

This specification is under the jurisdiction of ASTM Committee C14 on Glass and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat Glass.

Current edition approved Oct. 1, 2010Nov. 1, 2015. Published December 2010December 2015. Originally approved in 1999. Last previous edition approved in 20052010

ε1

as C1422–99(2005)C1422/C1422M – 10. . DOI: 10.1520/C1422_C1422M-10.10.1520/C1422_C1422M-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from U.S. Consumer Product Safety Commission (CPSC), 4330 East West Hwy., Bethesda, MD 20814, http://www.cpsc.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1422/C1422M − 15

FIG. 1 Slice Location

3.2.2 chemically strengthened glass—glass which has been strengthened by ion exchange to produce a compressive stress layer

at the treated surface.

3.2.3 depth of compression (DOC)-—see case depth.

3.2.4 ion exchange process—the exchange of constituent ions in the glass with externally supplied ions (generally at

temperatures near the strain point of the glass). This may be a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.