SIST EN 13921:2007

(Main)Personal protective equipment - Ergonomic principles

Personal protective equipment - Ergonomic principles

This European Standard provides guidance on the generic ergonomic characteristics related to personal protective equipment (PPE).

It specifies for the writers of PPE product standards, principles relating to:

anthropometric characteristics related to PPE;

the biomechanical interaction between PPE and the human body;

the thermal interaction between PPE and the human body;

the interaction between PPE and the human senses: vision; hearing; smell and taste; and skin contact.

This European Standard does not cover requirements related to the specific hazard for which PPE is designed.

Persönliche Schutzausrüstung - Ergonomische Grundsätze

Diese Europäische Norm enthält einen Leitfaden zu den allgemeinen ergonomischen Eigenschaften persönlicher Schutzausrüstungen (PSA).

Sie macht Angaben zulegt Grundsätzen für die Verfasser von Produktnormen im Bereich PSA fest:

zu anthropometrischen Eigenschaften in Bezug auf PSA;

zur biomechanischen Interaktion zwischen PSA und dem menschlichen Körper;

zur thermischen Interaktion zwischen PSA und dem menschlichen Körper;

zur Interaktion zwischen PSA und den menschlichen Sinnen: Sehen, Hören, Riechen und Schmecken sowie Berührungsempfinden.

Diese Europäische Norm enthält keine Anforderungen bezüglich der spezifischen Gefährdung, gegen die die PSA bestimmungsgemäß schützen soll.

Equipements de protection individuelle - Principes ergonomiques

La présente Norme européenne fournit des recommandations sur les caractéristiques ergonomiques génériques des équipements de protection individuelle (EPI).

Elle spécifie à l’intention des rédacteurs de normes de produits sur les EPI, des principes en rapport avec :

- les caractéristiques anthropométriques liées aux EPI ;

- l’interaction biomécanique entre l’EPI et le corps humain ;

- l’interaction thermique entre l’EPI et le corps humain ;

- l’interaction entre l’EPI et les 5 sens : la vue, l’ouïe, l’odorat, le goût et le toucher.

La présente Norme européenne ne traite pas des exigences relatives au phénomène dangereux spécifique pour lequel l’EPI est conçu

Osebna varovalna oprema – Ergonomska načela

General Information

- Status

- Published

- Publication Date

- 20-Jun-2007

- Technical Committee

- VSN - Safety of machinery

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 18-Jun-2007

- Due Date

- 23-Aug-2007

- Completion Date

- 21-Jun-2007

Overview

EN 13921:2007 - Personal protective equipment (PPE) - Ergonomic principles is a CEN European Standard that provides generic guidance on ergonomic characteristics for PPE. It is intended for writers of PPE product standards and focuses on human-centred design aspects - anthropometrics, biomechanical and thermal interactions, and sensory effects - rather than hazard-specific performance requirements.

Key Topics

- Anthropometric characteristics: guidance on applying body measurements and user-group variability to PPE design and sizing.

- Biomechanical interaction: principles related to mass distribution, restriction or prevention of movement, compression/abrasion risks, and effects on body segments and physical loading.

- Thermal interaction: factors influencing body heat balance, thermal insulation and evaporative resistance of clothing ensembles, and assessment of thermal strain and comfort.

- Sensory interaction: impacts of PPE on vision, hearing, smell/taste and skin contact (comfort, irritation, tactile feedback).

- Ergonomic verification and testing: structured approach for specifying test methods and procedures to verify ergonomic characteristics (see clauses 4–5). Annex A gives guidance on ergonomic assessment using panels of test subjects and wearer trials.

- Normative references: includes cross-references such as EN ISO 12894 (medical supervision in extreme thermal environments).

Practical Applications

- PPE product standard writers use EN 13921:2007 to incorporate ergonomic requirements and appropriate test methods into harmonised product standards.

- Manufacturers and designers apply the principles to improve fit, comfort, usability and safety - balancing protective performance with wearer acceptability.

- Test laboratories and conformity assessors use the verification approach to evaluate anthropometric fit, biomechanical load, thermal impact and sensory effects.

- Occupational health professionals, safety managers and ergonomists apply the guidance when selecting or specifying PPE for worker groups to reduce secondary risks (discomfort, restricted movement, heat stress).

- Useful for regulatory compliance where ergonomics is part of conformity assessment under EU directives (informative Annex ZA).

Who Should Use This Standard

- Standards committees and technical writers drafting PPE product standards

- PPE designers and R&D teams

- Certification bodies and test houses

- Occupational safety professionals and ergonomists

- Employers specifying PPE for diverse user groups

Related Standards

- EN ISO 12894 (Ergonomics of the thermal environment - medical supervision)

- Product-specific PPE standards (EN series) - EN 13921:2007 is complementary and not a substitute for hazard-specific requirements.

EN 13921:2007 is essential for integrating ergonomic principles into PPE design and standards, helping ensure protective equipment is effective, usable and acceptable for intended user groups.

Frequently Asked Questions

SIST EN 13921:2007 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Personal protective equipment - Ergonomic principles". This standard covers: This European Standard provides guidance on the generic ergonomic characteristics related to personal protective equipment (PPE). It specifies for the writers of PPE product standards, principles relating to: anthropometric characteristics related to PPE; the biomechanical interaction between PPE and the human body; the thermal interaction between PPE and the human body; the interaction between PPE and the human senses: vision; hearing; smell and taste; and skin contact. This European Standard does not cover requirements related to the specific hazard for which PPE is designed.

This European Standard provides guidance on the generic ergonomic characteristics related to personal protective equipment (PPE). It specifies for the writers of PPE product standards, principles relating to: anthropometric characteristics related to PPE; the biomechanical interaction between PPE and the human body; the thermal interaction between PPE and the human body; the interaction between PPE and the human senses: vision; hearing; smell and taste; and skin contact. This European Standard does not cover requirements related to the specific hazard for which PPE is designed.

SIST EN 13921:2007 is classified under the following ICS (International Classification for Standards) categories: 13.180 - Ergonomics; 13.340.01 - Protective equipment in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13921:2007 is associated with the following European legislation: EU Directives/Regulations: 2016/425, 89/686/EEC, 93/68/EEC, 93/95/EEC, 96/58/EC; Standardization Mandates: M/031. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13921:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Personal protective equipment - Ergonomic principlesEquipements de protection individuelle - Principes ergonomiquesPersönliche Schutzausrüstung - Ergonomische GrundsätzeTa slovenski standard je istoveten z:EN 13921:2007SIST EN 13921:2007en,fr,de13.340.01Varovalna oprema na splošnoProtective equipment in general13.180ErgonomijaErgonomicsICS:SLOVENSKI

STANDARDSIST EN 13921:200701-september-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13921May 2007ICS 13.180; 13.340.01 English VersionPersonal protective equipment - Ergonomic principlesEquipements de protection individuelle - PrincipesergonomiquesPersönliche Schutzausrüstung - Ergonomische GrundsätzeThis European Standard was approved by CEN on 15 March 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13921:2007: E

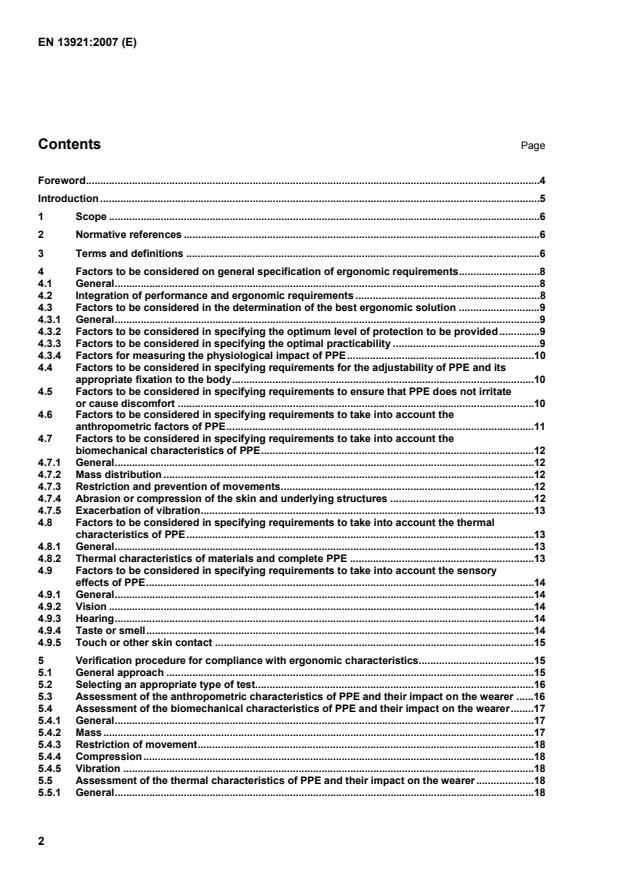

Ergonomic assessment of PPE using panels of test subjects.22 A.1 Introduction.22 A.2 Principle.22 A.3 Wearer trials.23 A.4 Duration of tests.24 A.5 Test of thermal impact.24 A.5.1 General.24 A.5.2 Task.24 A.5.3 Subjects.25 A.5.4 Subject safety.25 A.5.5 Measurements.25 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 89/686.27 Bibliography.28

1 Scope This European Standard provides guidance on the generic ergonomic characteristics related to personal protective equipment (PPE). It specifies for the writers of PPE product standards, principles relating to: anthropometric characteristics related to PPE; the biomechanical interaction between PPE and the human body; the thermal interaction between PPE and the human body; the interaction between PPE and the human senses: vision; hearing; smell and taste; and skin contact. This European Standard does not cover requirements related to the specific hazard for which PPE is designed. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN ISO 12894, Ergonomics of the thermal environment — Medical supervision of individuals exposed to extreme hot or cold environments (ISO 12894:2001) 3 Terms and definitions For the purposes of this European Standard, the following terms and definitions apply. 3.1 anthropometrics of PPE application of human body measurements to the design of PPE including variation in dimensions within the user group 3.2 auditory aspects qualities which interfere with the users ability to hear 3.3 biomechanics of PPE application of principles and methods from physics and engineering to describe the effect undergone by the human body and various body segments and the forces acting on these body segments including physical loading which may be caused by PPE 3.4 body heat balance increase or decrease in the heat content of the body caused by an imbalance between heat production and heat loss, usually expressed in terms of unit area of total body surfaces

or may appear unexpectedly (e.g. explosion, crushing hazard as a consequence of an unintended/unexpected start-up, ejection as a consequence of a breakage, fall as a consequence of acceleration/deceleration). [EN ISO 12100-1:2003; 3.6] 3.8 local thermal comfort subjective satisfaction with the thermal environment, based on local body area sensations 3.9 masking effect process by which the threshold of hearing of one sound is raised due to the presence of another 3.10 PPE user group group of people exposed to a hazard which requires the use of PPE

3.11 risk combination of the probability of occurrence of harm and the severity of that harm

[EN ISO 12100-1:2003; 3.11]

3.12 skin contact information from skin contact and touch, such as irritation, tickle, cold, hot, pressure and pain 3.13 smell odours or the modification of existing odours which may adversely affect any performance-related sensation or otherwise impair acceptability

3.15 thermal sensation subjective perception of thermal state 3.16 thermal state relation between heat production and heat loss in the human body 3.17 thermal strain physiological responses of the human body to cold or heat exposure 3.18 vestibular orientation sensations of the orientation of the head, together with movement and accelerative forces 3.19 visual aspects prevention or impairment of the ability to see visual signals or information 4 Factors to be considered on general specification of ergonomic requirements 4.1 General Harmonised product standards for PPE should contain ergonomic requirements and test methods, or should make normative reference to other standards to be applied. Usually, ergonomic assessments of PPE have to be made while people are wearing it. Wherever possible, the assessments should be objective, although some aspects can only be assessed subjectively. Examples of how to make assessments are given in Annex A. 4.2 Integration of performance and ergonomic requirements The primary purpose of PPE is to provide protection against specific hazards that cannot be eliminated or adequately reduced by other means. Product standards should therefore contain performance requirements and test methods to ensure that the products provide the appropriate protection against the identified hazards, and that they are ergonomically suitable for the users. Product standards writers should consider the tasks being performed; the equipment being used; the duration of the usage of the PPE; and the environments likely to be encountered. They should ensure as far as possible that the PPE does not create hazards for the users. This may be by incorporating in product standards requirements and test methods based on this European Standard. Where the presence of more than one risk or the need to cover more parts of the body makes it necessary for a worker to use simultaneously more than one item of PPE, such equipment shall be mutually compatible and continue to be effective against the risk or risks in question. In addition to interactive effects on technical performance, interaction between different forms of PPE may influence ergonomic aspects. Thus, although the effect of individual items of PPE tested in isolation may not be significant, it will be the combined effect that will determine the overall load and consequent acceptability. For example, both a half-mask respirator and a safety helmet may intrude upon the visual field. Either in isolation may be acceptable but, when worn together the combined impact may not be. At its most extreme,

For example, a standard for gloves designed specifically for use by surgeons may define a minimum necessary level of tactile sensation. A standard for general industrial gloves however, may require a classification of tactile sensation as fine, medium, or coarse on the basis of test scores, thus allowing potential users to select a level of tactile sensation based upon an assessment of their needs. Such measures may in fact combine more than one sensory modality. For example, tests of dexterity may involve a combination of touch sensation and proprioception. 4.9.2 Vision PPE can hinder the correct observation of visual signals or information. It can affect the wearer's vision in two different ways, which are sometimes combined. These are a decrease in the extent of the visual field and a reduction in optical transmission within the field of view i.e. a reduction in the quantity or quality of visual information. When designing any head-worn PPE, e.g. helmets, spectacles, goggles, face shield, visors and respiratory devices, the impact on visual aspects should be taken into account. PPE should also be designed to allow users of corrective glasses to comply with the wearing of the PPE whilst obtaining the necessary visual correction and still achieve both protection and comfort. 4.9.3 Hearing PPE can hinder the receipt of auditory signals or information which the user either wants to hear (e.g. speech) or needs to hear (e.g. danger signals). For example, PPE may cover the ears or create disturbing noise or vibration. 4.9.4 Taste or smell Strong smells or tastes from the PPE might create a hazard to health by masking the taste or smell of a dangerous substance. Unpleasant smell or taste can also cause discomfort either when using the PPE or after, if the smell persists, and may be given as a reason for not using PPE.

it is necessary to define to ensure adequate fit across the range of users; means of establishing actual PPE dimensions (including tolerances) for intended size category(ies) within range of users; means of describing size category(ies) to ensure correct selection of PPE by users.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...