SIST ISO 16760:2020

Graphic technology - Prepress data exchange - Preparation and visualization of RGB images to be used in RGB-based graphics arts workflows

Graphic technology - Prepress data exchange - Preparation and visualization of RGB images to be used in RGB-based graphics arts workflows

ISO 16760:2014 specifies requirements for an RGB workflow for graphic arts printing based on the use of reflection prints (RGB Reference Prints) as the evaluation vehicle for coloured images. It provides guidelines on the creation of print-targeted RGB images (RGB Reference Images) and simulation prints.

This International Standard requires the identification of a pair of ICC profiles for each image: an image profile and a profile describing the reference printing system. These profiles provide individual colour transformations for gamut mapping and colour separation. This International Standard does not provide any guidance as to how these gamut mapping or colour separation transforms can be specified.

Technologie graphique - Échange de données pré-impression - Préparation et visualisation d'images RGB à utiliser dans les flux de travail des arts graphiques basés sur le RGB

Grafična tehnologija - Izmenjava podatkov v grafični pripravi - Priprava in vizualizacija RGB-upodobitev za uporabo v grafičnih delovnih procesih na osnovi RGB

General Information

- Status

- Published

- Publication Date

- 10-Mar-2020

- Technical Committee

- GRT - Graphical technology

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 27-Feb-2020

- Due Date

- 03-May-2020

- Completion Date

- 11-Mar-2020

Overview - SIST ISO 16760:2020 (Graphic technology, RGB workflows)

SIST ISO 16760:2020 defines requirements and guidelines for preparing and visualizing RGB images intended for RGB-based graphics arts workflows. The standard uses reflection prints (called RGB Reference Prints) as the evaluation vehicle and describes the creation of RGB Reference Images and simulation prints for print-targeted RGB work. It mandates the use and identification of a pair of ICC profiles for each image - one image profile and one profile describing the reference printing system - to enable colour transformations for gamut mapping and colour separation. The standard does not prescribe how to implement those gamut-mapping or colour-separation transforms.

Key topics and technical requirements

- Purpose: Establish a controlled RGB workflow for graphic arts prepress data exchange and image visualization.

- Evaluation vehicle: Use of reflection RGB Reference Prints for consistent visual assessment of colour images.

- RGB Reference Images: Guidelines for creating print-targeted RGB image files suitable for RGB-based printing workflows.

- ICC profile requirement: Each image must be associated with two ICC profiles:

- Image profile (characterizes the image color encoding)

- Reference printing system profile (describes the target printing system)

- Colour transformations: Profiles provide per-image gamut mapping and colour separation paths; the standard does not specify the algorithms or parameters for these transforms.

- Deliverables: Support for producing simulation prints and other visualization artifacts to validate how RGB images will appear when produced.

Practical applications and who uses SIST ISO 16760:2020

- Prepress and colour management specialists who prepare RGB content for print.

- Print service providers adopting RGB-based workflows to streamline prepress and proofing.

- Graphic designers and art directors needing predictable print simulation and evaluation.

- Software developers and RIP/DFE vendors implementing image handling, ICC profile management, and visualization tools.

- Equipment manufacturers producing proofing printers and display systems for RGB reference prints.

Practical uses include standardized file handover in prepress data exchange, creating print-targeted RGB images for predictable colour reproduction, and producing simulation prints for quality control and client approval.

Related standards (applicable)

- ICC profile specifications (ICC) - for colour profile structure and interchange.

- ISO 12647 series - process control for graphic technology (printing process standards).

- ISO 3664 - viewing conditions for graphic technology (visual assessment environments).

Keywords: SIST ISO 16760:2020, RGB workflow, prepress data exchange, RGB Reference Prints, RGB Reference Images, ICC profiles, gamut mapping, colour separation, graphic technology, simulation prints.

ISO 16760:2014 - Graphic technology -- Prepress data exchange -- Preparation and visualization of RGB images to be used in RGB-based graphics arts workflows

ISO 16760:2014 - Graphic technology -- Prepress data exchange -- Preparation and visualization of RGB images to be used in RGB-based graphics arts workflows

Frequently Asked Questions

SIST ISO 16760:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Graphic technology - Prepress data exchange - Preparation and visualization of RGB images to be used in RGB-based graphics arts workflows". This standard covers: ISO 16760:2014 specifies requirements for an RGB workflow for graphic arts printing based on the use of reflection prints (RGB Reference Prints) as the evaluation vehicle for coloured images. It provides guidelines on the creation of print-targeted RGB images (RGB Reference Images) and simulation prints. This International Standard requires the identification of a pair of ICC profiles for each image: an image profile and a profile describing the reference printing system. These profiles provide individual colour transformations for gamut mapping and colour separation. This International Standard does not provide any guidance as to how these gamut mapping or colour separation transforms can be specified.

ISO 16760:2014 specifies requirements for an RGB workflow for graphic arts printing based on the use of reflection prints (RGB Reference Prints) as the evaluation vehicle for coloured images. It provides guidelines on the creation of print-targeted RGB images (RGB Reference Images) and simulation prints. This International Standard requires the identification of a pair of ICC profiles for each image: an image profile and a profile describing the reference printing system. These profiles provide individual colour transformations for gamut mapping and colour separation. This International Standard does not provide any guidance as to how these gamut mapping or colour separation transforms can be specified.

SIST ISO 16760:2020 is classified under the following ICS (International Classification for Standards) categories: 35.240.30 - IT applications in information, documentation and publishing; 37.100.99 - Other standards related to graphic technology. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST ISO 16760:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2020

Grafična tehnologija - Izmenjava podatkov v grafični pripravi - Priprava in

vizualizacija RGB-upodobitev za uporabo v grafičnih delovnih procesih na osnovi

RGB

Graphic technology - Prepress data exchange - Preparation and visualization of RGB

images to be used in RGB-based graphics arts workflows

Technologie graphique - Échange de données pré-impression - Préparation et

visualisation d'images RGB à utiliser dans les flux de travail des arts graphiques basés

sur le RGB

Ta slovenski standard je istoveten z: ISO 16760:2014

ICS:

35.240.30 Uporabniške rešitve IT v IT applications in information,

informatiki, dokumentiranju in documentation and

založništvu publishing

37.100.99 Drugi standardi v zvezi z Other standards related to

grafično tehnologijo graphic technology

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

INTERNATIONAL ISO

STANDARD 16760

First edition

2014-12-15

Graphic technology — Prepress

data exchange — Preparation and

visualization of RGB images to be used

in RGB-based graphics arts workflows

Technologie graphique — Échange de données pré-impression —

Préparation et visualisation d’images RGB à utiliser dans les flux de

travail des arts graphiques basés sur le RGB

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

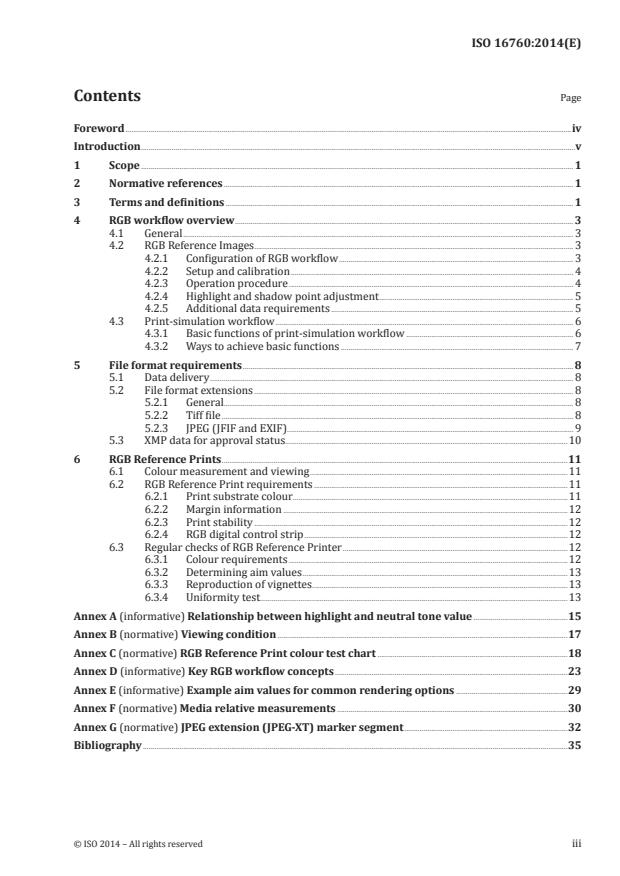

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 RGB workflow overview . 3

4.1 General . 3

4.2 RGB Reference Images . 3

4.2.1 Configuration of RGB workflow . 3

4.2.2 Setup and calibration . 4

4.2.3 Operation procedure . 4

4.2.4 Highlight and shadow point adjustment . 5

4.2.5 Additional data requirements . 5

4.3 Print-simulation workflow . 6

4.3.1 Basic functions of print-simulation workflow . 6

4.3.2 Ways to achieve basic functions . 7

5 File format requirements . 8

5.1 Data delivery . 8

5.2 File format extensions . 8

5.2.1 General. 8

5.2.2 Tiff file . 8

5.2.3 JPEG (JFIF and EXIF) . . 9

5.3 XMP data for approval status.10

6 RGB Reference Prints .11

6.1 Colour measurement and viewing .11

6.2 RGB Reference Print requirements .11

6.2.1 Print substrate colour . . .11

6.2.2 Margin information .12

6.2.3 Print stability .12

6.2.4 RGB digital control strip .12

6.3 Regular checks of RGB Reference Printer .12

6.3.1 Colour requirements .12

6.3.2 Determining aim values .13

6.3.3 Reproduction of vignettes .13

6.3.4 Uniformity test . .13

Annex A (informative) Relationship between highlight and neutral tone value .15

Annex B (normative) Viewing condition .17

Annex C (normative) RGB Reference Print colour test chart .18

Annex D (informative) Key RGB workflow concepts .23

Annex E (informative) Example aim values for common rendering options .29

Annex F (normative) Media relative measurements .30

Annex G (normative) JPEG extension (JPEG-XT) marker segment .32

Bibliography .35

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT), see the following URL: Foreword — Supplementary information.

The committee responsible for this document is ISO/TC 130, Graphic technology.

iv © ISO 2014 – All rights reserved

Introduction

This International Standard provides guidelines for image preparation and print simulation in a graphic

arts print workflow using RGB images (RGB workflow).

Digital still camera (DSC) images have now largely replaced film in the prepress stage of graphic arts

printing and most images printed originate from digital cameras. Standard document exchange using

PDF/X-4 and PDF/X-5 formats supports the use of RGB content and provides a ‘late binding’ printing

solution where colour conversion is performed only when the document is printed. In this way, all of the

original image data can be retained and the conversion for print can be optimised based on the original

image content, key image attributes, and the available press colour gamut. These standard document

formats provide an ideal framework for RGB workflow.

The current best practice for image preparation is to view and adjust images on display. When RGB

images are adjusted, proofing mode is selected for a reference printing condition and a calibrated

monitor is used. In this way, users can see an accurate preview of the printed result. This workflow is

shown in Figure 1.

This document

was made to show

how RGB Workflow

should work.

Figure 1 — Current best practice RGB workflow

There are a number of limitations in this workflow:

— Although it is possible to set up a calibrated monitor and viewing environment defined by

Adobe RGB (1998) Colour Image Encoding or ISO/IEC 61966-2-1, it is not usually the case that

all stakeholders have a calibrated monitor and the same viewing conditions. In the proposed

RGB workflow, an RGB Reference Print can be shared easily among stakeholders.

— For inexperienced users, critical colour judgement on screen is harder than on print and so the

resulting colour might not be what the user desires. The proposed RGB workflow is described for

both experts and inexperienced users.

— The intended printing condition needs to be communicated to every stakeholder by independent

means and all users need to know how to set up a viewing environment appropriate to the printing

condition. In the proposed RGB workflow, the intended printing condition is included as metadata

with the image.

— The approval status of an image is not clearly shown. In the proposed RGB workflow, the approval

status is included as metadata with the image.

The proposed RGB workflow addresses these limitations as shown in Figure 2. In this RGB workflow,

candidate images are printed on an RGB Reference Printer that has been calibrated to produce an

accurate simulation of the intended printing condition. These printed images are checked in a controlled

print viewing environment and, if necessary, further adjustments are made until the intended print

result is achieved. When RGB image files are created and checked in this way, metadata that describes

the intended printing condition and the image approval status is added.

CaptureImage preparation Documentcreation and printing

Calibrated to simulate

intended printing

condition

Digital

printer

R’G’B’

Digitalcamera RGB

RGB Reference Image Document Conventional

scene capture Reference

Printcreation approved? creation press

and rendering Image

Digital

press

Add Output intent metadata

Add reference

Retouch

corresponding to

printer’sOutputIntent

intended print condition

Other

Figure 2 — RGB workflow from scene to printing via RGB image data

Careful preparation of RGB images holds the key to a successful RGB workflow. There are a number of

aspects to consider when preparing images for print, including the identification of image highlight and

shadow points and the careful mapping of important image colours into the colour gamut of the printing

press. Since most printing processes have a significantly different colour gamut size and shape from the

set of colours represented in an image, care needs to be taken when editing images so that important

colours are retained. This is done most effectively by associating the RGB image with a CMYK press

profile. This International Standard describes how to prepare these RGB images. Figure 2 shows the

RGB workflow described by this International Standard and R’G’B’ is the prepared RGB image.

NOTE For the proposed workflow, although a calibrated soft proof viewing environment is not required, the

calibration of a reference printer is required and this print needs to be viewed in a standard calibrated viewing

environment. If possible, printers with automatic calibration need to be used in cases where users are not familiar

with the calibration process.

When this workflow is adopted, images can be prepared and incorporated in documents which can be

printed on multiple printing systems producing prints with a similar appearance.

When the RGB image data are approved based on a hardcopy print, consistent judgement can be made.

This workflow is supported by the PDF/X-4 and PDF/X-5 standard document formats. Documents are

expected to be approved using ISO 12647-8 (validation print) or ISO 12647-7 (contract proof).

It is envisaged that printing systems will be developed to produce prints that conform to this International

Standard. It can be the case that systems that already conform to the requirements of ISO 12647-8 or

ISO 12647-7 will be extended to produce RGB Reference Prints. Such systems will provide an easy means

for users to ensure that images and the documents that include these images are printed reliably.

vi © ISO 2014 – All rights reserved

This workflow relates to images that are destined for four-colour commercial printing. Photographers need

to be aware that alternative file versions of an image can still be required for specialized printing conditions.

Annex D provides further details of key RGB workflow concepts.

INTERNATIONAL STANDARD ISO 16760:2014(E)

Graphic technology — Prepress data exchange —

Preparation and visualization of RGB images to be used in

RGB-based graphics arts workflows

1 Scope

This International Standard specifies requirements for an RGB workflow for graphic arts printing based on

the use of reflection prints (RGB Reference Prints) as the evaluation vehicle for coloured images. It provides

guidelines on the creation of print-targeted RGB images (RGB Reference Images) and simulation prints.

This International Standard requires the identification of a pair of ICC profiles for each image: an image

profile and a profile describing the reference printing system. These profiles provide individual colour

transformations for gamut mapping and colour separation. This International Standard does not provide

any guidance as to how these gamut mapping or colour separation transforms can be specified.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3664:2009, Graphic technology and photography — Viewing conditions

ISO 11664-4 (CIE S 014-4/E:2007), Colorimetry — Part 4: CIE 1976 L*a*b* Colour space

ISO 12234-1, Electronic still-picture imaging — Removable memory — Part 1: Basic removable-memory model

ISO 13655, Graphic technology — Spectral measurement and colorimetric computation for graphic arts images

ISO 15076-1:2010, Image technology colour management — Architecture, profile format and data

structure — Part 1: Based on ICC.1:2010

ISO 15790, Graphic technology and photography — Certified reference materials for reflection and

transmission metrology — Documentation and procedures for use, including determination of combined

standard uncertainty

1)

ISO 18619 , Image technology colour management — Black point compensation

2)

ISO 19445 , Graphic technology — Metadata for graphic arts workflow — XMP metadata for image and

document proofing

ISO/IEC 10918-1, Information technology — Digital compression and coding of continuous-tone still images:

Requirements and guidelines — Part 1

ISO/CIE 11664-6 (CIE S 014-6/E:2013), Colorimetry — Part 6: CIEDE2000 Colour-difference formula

TIFF, Revision 6.0 Final, Adobe Systems Incorporated, June 3, 1992

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

1) Under preparation.

2) Under preparation.

3.1

RGB colour space

three-component colour encoding defined by a linear transform from CIE XYZ

Note 1 to entry: Such a transform can be specified as a 3 × 3 matrix, and the transform between XYZ and additive

RGB is then performed by multiplying by this matrix or its inverse.

Note 2 to entry: Adobe RGB (1998) is an example of an RGB colour space.

3.2

characterized printing condition

printing condition for which process control aims are defined and for which the relationship between

input data (printing-tone values, usually CMYK) and the colorimetry of the printed image is documented

Note 1 to entry: The relationship between input data (printing tone values) and the colorimetry of the printed

image is commonly referred to as characterization.

Note 2 to entry: It is generally preferred that the process control aims of the printing condition and the associated

characterization data be made publicly available via the accredited standards process or industry trade

associations.

3.3

colour gamut

solid in a colour space, consisting of all those colours that are: present in a specific scene, artwork,

photograph, photomechanical, or other reproduction; or capable of being created using a particular

output device and/or medium

[SOURCE: ISO 22028-1:2004, 3.8]

3.4

colour rendering

mapping of image data representing the colour space coordinates of the elements of a scene to output-

referred image data representing the colour space coordinates of the elements of a reproduction

Note 1 to entry: Colour rendering generally consists of one or more of the following: compensating for differences

in the input and output viewing conditions, tone scale and colour gamut mapping to map the scene colours onto

the dynamic range and colour gamut of the reproduction, and applying preference adjustments.

Note 2 to entry: In the terminology defined in ISO 22028-1, some of the transforms described in this International

Standard would be better described as colour re-rendering, however, this International Standard does not differentiate

between colour rendering and colour re-rendering transforms and uses the term ‘colour rendering’ for both.

[SOURCE: ISO 22028-1:2004, 3.11]

3.5

highlight point

luminance level or image area corresponding to a reference white in the principal subject area of a scene

Note 1 to entry: Lightness of the objects in the scene are viewed in relation to this reference white. This can be a

white “object” such as a piece of paper, a shirt, etc. or some such object which does not even appear in the scene

but with which a comparison is made by reference to one’s memory of such objects.

Note 2 to entry: Image areas brighter than this point are called highlights. These include specular highlights,

diffuse highlights that are more highly illuminated than the principal area and fluorescent colours.

[22] [23]

Note 3 to entry: This wording is based on Bartleson and Breneman and Giorgianni and Madden .

3.6

output intent

metadata used to communicate the intended printing condition, usually by means of an ICC Profile

2 © ISO 2014 – All rights reserved

3.7

prepress

first stage of the graphic technology workflow, prior to printing, that includes all the operations

necessary for the preparation of images and image carriers

3.8

RGB Reference Image

RGB image prepared according to this specification which can provide a reliable reference to printed

appearance for evaluation by stakeholders

3.9

RGB Reference Print

print of an RGB Reference Image that has been prepared in conformance with this International Standard

3.10

RGB Reference Printer

printing system that is capable of producing RGB Reference Prints

Note 1 to entry: RGB Reference Printers do not use RGB inks but typically use CMYK inks, converting from RGB to

CMYK before printing.

3.11

shadow point

luminance level or image area corresponding to a maximum dark point and/or area of a scene that

should be reproduced as a dark end of grey gradient on a print or a display

4 RGB workflow overview

4.1 General

RGB images are represented in an RGB colour space such as sRGB or Adobe RGB (1998) and as part of

the prepress processing need to be converted to CMYK or similar colour space for printing. It is now

standard industry practice to convert to a characterized printing condition, for example, CGA/TS 21-

CRPC6, Fogra39, or JapanColor using ICC colour conversion.

NOTE The reference printing conditions that are provided as examples here are for offset lithography;

however, the principles of this International Standard apply to all standardised printing conditions.

This Clause describes how to make RGB Reference Images (4.2) and how to make simulation prints

(RGB Reference Prints) based on the characterized printing condition (4.3).

4.2 RGB Reference Images

4.2.1 Configuration of RGB workflow

Figure 3 shows image-processing workflow using RGB Reference Images. A process to convert

RGB images to RGB Reference Images shall be supported and a process to convert RGB Reference Images

to simulation print should be supported.

Monitor

Application software RGB RGB

RGB ICC colour

includingimage Reference Reference

image conversion

processing Image Print

GUI

Adjustgreybalance,

tone,highlight point,

shadowpoint,colour,

cropping, sharpness, e.t.c.

Figure 3 — Image processing workflow for creating RGB reference print

Components of this workflow comprise processing hardware, processing software, and image data files.

Processing hardware comprises a computer, a monitor, and a printer.

Processing software usually comprises operating system software of the computer and application

software. These software components shall support ICC profile-based colour management.

Image data files are of two types: “RGB image” which is an unprocessed input image data file (RGB

image in Figure 3) and the second ‘RGB Reference Image’ which is an output image data file prepared for

printing (RGB Reference Image in Figure 3). Both images shall be display-referred.

NOTE Examples of display-referred images include images encoded as sRGB and Adobe RGB (1998) (commonly

referred to as “Adobe RGB images” and “sRGB images”).

4.2.2 Setup and calibration

Setup and calibration of system hardware and software shall be performed prior to its use.

Monitors shall be calibrated and profiled using appropriate hardware and software. Each monitor

should have a gamut that can adequately represent the intended print condition(s).

NOTE 1 ISO 12646 and ISO 14861 provide a good reference to ensure that monitors are set up appropriately for

soft proofing.

NOTE 2 In some cases, software-based calibration can reduce the number of levels and so it is usually more

effective to use hardware calibration where the monitor’s physical controls and/or its internal lookup tables are

modified, perhaps in conjunction with the graphic card’s lookup tables.

Printers shall be calibrated and profiled using appropriate hardware and software to ensure that prints

produced meet the aims specified in Clause 6.

4.2.3 Operation procedure

Creation of RGB Reference Images shall be performed as follows.

a) Open input RGB image to be displayed using colour management of system software and

application software.

b) Adjust grey balance, highlight point, and shadow point using application software (tone-setup).

4 © ISO 2014 – All rights reserved

c) Adjust colour to make preferred reproduction.

d) Check print-simulation image on the monitor (optional when an RGB Reference Print is made).

e) Create an RGB Reference Print and view in standard conditions to check image result (optional but

highly recommended for inexperienced users).

f) Store RGB Reference Image (R’G’B’) and add output-intent tag as specified in 5.2 using application

software.

NOTE 1 At step a), the RGB image is likely to be display-referred.

NOTE 2 In some instances, legacy profiles might produce a sub-standard perceptual rendering and fail to

achieve an acceptable appearance match. Additional image editing might be required. Alternatively, a print

that achieves an appearance match to the original RGB image can be made using an ICC Profile that provides an

appearance match transform (for example, using CIECAM) in its Perceptual Rendering Intent.

4.2.4 Highlight and shadow point adjustment

The way in which the highlight point and shadow point is selected is beyond the scope of this document.

Users shall select desired highlight and shadow points for each image.

For an average-key image encoded in 8 bits, the desired highlight and shadow points of an RGB Reference

Image are approximately code values of 246 and 15 respectively. The relationship between these values

and tone reproduction of typical press printing profiles is shown in Annex A.

4.2.5 Additional data requirements

In order to provide colour rendering information, in particular the intended output rendering of the

RGB Reference Print and to enable automatic printing of the RGB Reference Print (Figure 6 — Case C),

the following rendering information and parameters shall be added to the image files:

a) colour characterization of source data;

b) rendering intent;

c) black point compensation;

d) output intent profile.

Colour characterization of source data shall be included in the form of an ICC Profile or colour space

name as specified for the appropriate file format.

Colour rendering parameters b) to d) are specified for each file format in the following clauses. The

parameters shall be included as specified in this clause as extensions to the file format as specified in

5.2 or as XMP metadata as specified in 5.3.

At the time of image preparation, these parameters shall be attached to the image file either before an

RGB Reference Print is made or following the approval of the RGB Reference Print.

When RGB Reference Prints are created and when RGB Reference Soft Proofs are displayed from an

RGB reference image, these parameters shall be recognized and the appropriate colour transforms

applied to the image to meet the output colour rendering condition to ensure that the printed output

meets the reproduction tolerances specified in Clause 6.

4.3 Print-simulation workflow

4.3.1 Basic functions of print-simulation workflow

Figure 4 shows the basic image-processing functions of the print-simulation workflow and Figure 5

shows a more concrete example using actual ICC profiles.

NOTE The Reference RGB image will usually be different from the original RGB image as its colour is

constrained by the gamut of the intended printing condition.

RGB

Source profile

CIELab values of the

colours corresponding CIELab

to the RGB values

Intended printing condition prof ile B2A

CMYK values for the

CMYK

intended printing conditio n

Intended printing condition profile A2B

(Relative Colorimetric, BPC off)

CIELab values for the

reproduction colours on the CIELab

intended printing conditio n

Reference printer profile B2A

(Relative Colorimetric, BPC off)

Printer device values to

simulate the intended RGB or CMYK

printing conditio n

Figure 4 — Basic image-processing components of print-simulation workflow

a b

JapanColor2001

AdobeRGB AdobeRGB

CIELab PressReference

image ICC profile

ICC profileB2A0

c d

JapanColor2001

Printer ICC

Press Reference

profileB2A1

ICC profileA2B1

Printerdevice

CMYK

values

e

DeviceLinkprofilefor

JapanColor2001

Key:

Data

Transform

Figure 5 — Print-simulation workflow using commonly available ICC profiles and rendering intents

Figure 5 shows various states of image data and transformation of image data. The image processing

workflow shall be as follows:

a) conversion from display-referred RGB values to CIELAB values using ICC profile of display-referred RGB;

b) conversion from CIELAB values to CMYK tone values using ICC profile of intended printing system;

6 © ISO 2014 – All rights reserved

NOTE Perceptual intent (B2A0) for the conversion steps a) and b) for colour communication among

stakeholders is recommended.

c) conversion from CMYK values to CIELAB values of print using ICC profile of intended printing system;

d) conversion from CIELAB values of print to reference printer device values (typically RGB or CMYK)

using ICC profile of the reference printer.

RelativeColorimetric Intent (A2B1 and B2A1 table of the ICC profile) should be used for conversion steps

c) and d). A DeviceLink profile may be used for this conversion (step e in Figure 5).

4.3.2 Ways to achieve basic functions

There are three ways to achieve the basic functions as shown in Figure 6 and each case is further

explained below in more detail.

RGB CIELAB CMYK CIELAB RGB or CMYK

Application software

Case A

Case B Application software Printer

Case C Printer

Figure 6 — Three methods to achieve basic functions

a) The application software executes all colour conversions using the source profile, the intended

printing condition profile, and the reference printer profile and sends the device value image to the

printer. The printer or the printer driver receives the device value image and prints it.

b) The application software applies the colour conversion from RGB to CMYK using the source profile

and the intended printing condition profile and sends CMYK image including the intended printing

condition profile to the printer. The printer or the printer driver receives the CMYK image and

applies the colour conversion from CMYK to the device values of the reference printer using the

intended printing condition profile and the reference printer profile and makes the RGB Reference

Print for the intended printing condition.

NOTE 1 In some cases, the application software might send only CMYK image and an operator sets the

printer or printer driver to simulation mode for the intended printing condition.

c) The application software sends RGB image including the source profile and the intended printing

condition profile to the printer. The printer or the printer driver receives the RGB image and

performs all colour conversions using the source profile, the intended printing condition profile, and

the reference printer profile and makes the RGB Reference Print for the reference printing condition.

NOTE 2 In some case, the application software might send only RGB image and an operator specifies the source

profile and the intended printing condition profile at the printer or printer driver.

In all cases, the output intent tag shall be added to the RGB image file to communicate the intended

printing condition to stakeholders.

5 File format requirements

5.1 Data delivery

RGB Reference Images shall be delivered as EXIF (JPEG) as defined in ISO 12234-1, or as JFIF (JPEG) as

defined in ISO/IEC 10918-5, or as TIFF (RGB) as defined in TIFF Revision 6 (Baseline).

Except by prior agreement between all of the stakeholders in the RGB workflow, all three image formats

shall be supported.

Subsequently, these parameters indicate the reference print condition for which the image was checked.

NOTE By prior agreement between the stakeholders, images might also be delivered as PDF as long as the

metadata required by this International Standard is included.

5.2 File format extensions

5.2.1 General

Some image writing software may find it more convenient to add the additional parameters as

extensions to the file format and this clause describes how this shall be done. Care needs to be taken to

ensure consistency between the XMP metadata and the file extension data. The guidelines defined by

the metadata working group should be followed to ensure consistency between these two sets of data.

5.2.2 Tiff file

5.2.2.1 RenderingIntent

This field is used to specify the colour rendering intent to be used for colour conversion as defined

by ISO 15076-1.

Tag = 51126 (C7B6 H)

Type = SHORT

Count = 1

Default = value of RenderingIntent from header of embedded ICC profile or media relative

colorimetric, if no profile is embedded.

Allowed values:

0 = Perceptual

1 = Media relative colorimetric

2 = Saturation

3 = ICC absolute colorimetric

5.2.2.2 UseBlackPtComp

This field is used to indicate whether or not black point compensation should be used for colour

conversion as defined by ISO 18619.

Tag = 51127 (C7B7 H)

Type = SHORT

8 © ISO 2014 – All rights reserved

Count = 1

Default = off

Allowed values:

0 = black point compensation shall not be used

1 = black point compensation shall be used

5.2.2.3 OutputIntentProfileURL

This field is used to encode the URL of an ICC profile that should be used as the destination profile

when converting to CMYK. When this tag is used, only profiles from the ICC profile registry should be

referenced. This tag shall not be used when the OutputIntentProfile tag is used.

Tag = 51128 (C7B8 H)

Type = ASCII

Count = length

5.2.2.4 OutputIntentProfile

If this tag is used, the output intent profile for the reference printing condition is embedded in the file.

This tag shall not be used when the OutputIntentProfileURL tag is used.

Tag = 51129 (C7B9 H)

Type = UNDEFINED (treated as 8-bit bytes)

Count = size of embedded ICC profile in bytes

Offset = the file offset, in bytes, to the beginning of the ICC profile

If this tag is used, the output intent profile specified in OutputIntentProfileDescription is embedded in

the file. Like all IFD entry values, the embedded profile data shall begin on a 2-byte boundary, so the

value offset will always be an even number.

5.2.3 JPEG (JFIF and EXIF)

5.2.3.1 General

Parameters and metadata for RGB images that are required when making RGB Reference Prints are

added using the generic box structure and the box embedding mechanism defined in Annex G to JPEG-

based image interchange formats including EXIF or JFIF as specified in ISO/IEC 10918-1/ITU-T T.81.

5.2.3.2 RenderingIntent

This box is used to specify the colour rendering intent to be used for colour conversion as defined

by ISO 15076-1.

Box Type (TBox) = “Rint” (52696E74 H)

Payload Type = 2-byte integer

Box Length (LBox) = 10 (0A H)

Payload allowed values:

0 = Perceptual

1 = Media relative colorimetric

2 = Saturation

3 = ICC absolute colorimetric

5.2.3.3 UseBlackPtComp

This box is used to indicate whether or not black point compensation should be used for colour conversion

as defined by ISO 18619.

Box Type (TBox) = “UBPC” (55425043 H)

Payload Type = 2-byte integer

Box Length (LBox) = 10 (0A H)

Payload allowed values:

0 = black point compensation shall not be used

1 = black point compensation shall be used

5.2.3.4 OutputIntentProfileURL

This box is used to encode the URL of an ICC profile that should be used as the destination profile

when converting to CMYK. When this tag is used, only profiles from the ICC profile registry should be

referenced. This box shall not be used when the OutputIntentProfile box is used.

Box Type (TBox) = “OUrl” (4F55726C H)

Payload Type = ASCII

Box Length (LBox) = 8 + length

5.2.3.5 OutputIntentProfile

If this box is used, the output intent profile for the reference printing condition is embedded in the file.

This box shall not be used when the OutputIntentProfileURL box is used.

Box Type (TBox) = “Oipr” (4F697072 H)

Payload Type = sequence of 8-bit bytes

Box Length (LBox) = 8 + size of embedded ICC profile in bytes

NOTE If this box is used, the output intent profile specified in OutputIntentProfileURL is embedded in the file.

5.3 XMP data for approval status

Rendering information and parameters may be provided as XMP metadata. Where XMP metadata is

used, it shall conform to the requirements for image proofing defined in ISO 19445.

10 © ISO 2014 – All rights reserved

6 RGB Reference Prints

6.1 Colour measurement and viewing

Colour measurements shall be made using a spectrocolourimeter that is in accordance with ISO 13655

and standardized correctly to its factory settings and that takes accurate and repeatable measurements

within the specified tolerances. The CIELAB colour coordinates L*, a*, b* shall be calculated as detailed

in ISO 13655.

The ISO 13655 measurement condition and backing should be selected based on correspondence with

the measurement condition used in the characterization of the reference printing condition. Where the

measurement condition requirements are not known or measurements are being made of substrate

alone, measurement conditions shall be as specified in ISO 13655 for M0 and white backing and should

be as specified in ISO 13655 for M1 and white backing. Typical aim values for common reference printing

conditions are provided in Annex E.

In some cases, colour aim values are defined relative to the substrate. In these cases, the aim values shall be

converted to absolute colour values using the method specified in Annex F using the measurement of the

actual print substrate. In this way, the measured values can easily be compared to these absolute colours.

CIEDE2000 (ΔE ) colour differences shall be calculated as detailed in ISO/CIE 11664-6. In this

specification approximate CIELAB 1976 (ΔE ) colour differences, calculated as detailed in ISO 13655

ab

are shown in brackets and because there is no direct correlation with ΔE , these should be regarded as

informative references.

All colour measurements and computed colour differences shall be reported, accompanied by an

associated total uncertainty (using the coverage factor k = 1). The evaluation method should be

performed as outlined in ISO 15790. It should include an estimate of the inter-instrument agreement

between the two different measurement instruments both believed to be conforming to ISO 13655. The

value may also be extracted from the manufacture’s specification or from a certificate of calibration from

the manufacturer. The inter-instrument agreement, uncertainly, should be added in quadrature to the

uncertainty determined by experimental readings, as outlined in ISO 15790. If not defined otherwise,

this criterion can be considered as having been fulfilled when the tolerance limit(s) occupy no more than

50 % of the covered uncertainty.

All

...

INTERNATIONAL ISO

STANDARD 16760

First edition

2014-12-15

Graphic technology — Prepress

data exchange — Preparation and

visualization of RGB images to be used

in RGB-based graphics arts workflows

Technologie graphique — Échange de données pré-impression —

Préparation et visualisation d’images RGB à utiliser dans les flux de

travail des arts graphiques basés sur le RGB

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 RGB workflow overview . 3

4.1 General . 3

4.2 RGB Reference Images . 3

4.2.1 Configuration of RGB workflow . 3

4.2.2 Setup and calibration . 4

4.2.3 Operation procedure . 4

4.2.4 Highlight and shadow point adjustment . 5

4.2.5 Additional data requirements . 5

4.3 Print-simulation workflow . 6

4.3.1 Basic functions of print-simulation workflow . 6

4.3.2 Ways to achieve basic functions . 7

5 File format requirements . 8

5.1 Data delivery . 8

5.2 File format extensions . 8

5.2.1 General. 8

5.2.2 Tiff file . 8

5.2.3 JPEG (JFIF and EXIF) . . 9

5.3 XMP data for approval status.10

6 RGB Reference Prints .11

6.1 Colour measurement and viewing .11

6.2 RGB Reference Print requirements .11

6.2.1 Print substrate colour . . .11

6.2.2 Margin information .12

6.2.3 Print stability .12

6.2.4 RGB digital control strip .12

6.3 Regular checks of RGB Reference Printer .12

6.3.1 Colour requirements .12

6.3.2 Determining aim values .13

6.3.3 Reproduction of vignettes .13

6.3.4 Uniformity test . .13

Annex A (informative) Relationship between highlight and neutral tone value .15

Annex B (normative) Viewing condition .17

Annex C (normative) RGB Reference Print colour test chart .18

Annex D (informative) Key RGB workflow concepts .23

Annex E (informative) Example aim values for common rendering options .29

Annex F (normative) Media relative measurements .30

Annex G (normative) JPEG extension (JPEG-XT) marker segment .32

Bibliography .35

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT), see the following URL: Foreword — Supplementary information.

The committee responsible for this document is ISO/TC 130, Graphic technology.

iv © ISO 2014 – All rights reserved

Introduction

This International Standard provides guidelines for image preparation and print simulation in a graphic

arts print workflow using RGB images (RGB workflow).

Digital still camera (DSC) images have now largely replaced film in the prepress stage of graphic arts

printing and most images printed originate from digital cameras. Standard document exchange using

PDF/X-4 and PDF/X-5 formats supports the use of RGB content and provides a ‘late binding’ printing

solution where colour conversion is performed only when the document is printed. In this way, all of the

original image data can be retained and the conversion for print can be optimised based on the original

image content, key image attributes, and the available press colour gamut. These standard document

formats provide an ideal framework for RGB workflow.

The current best practice for image preparation is to view and adjust images on display. When RGB

images are adjusted, proofing mode is selected for a reference printing condition and a calibrated

monitor is used. In this way, users can see an accurate preview of the printed result. This workflow is

shown in Figure 1.

This document

was made to show

how RGB Workflow

should work.

Figure 1 — Current best practice RGB workflow

There are a number of limitations in this workflow:

— Although it is possible to set up a calibrated monitor and viewing environment defined by

Adobe RGB (1998) Colour Image Encoding or ISO/IEC 61966-2-1, it is not usually the case that

all stakeholders have a calibrated monitor and the same viewing conditions. In the proposed

RGB workflow, an RGB Reference Print can be shared easily among stakeholders.

— For inexperienced users, critical colour judgement on screen is harder than on print and so the

resulting colour might not be what the user desires. The proposed RGB workflow is described for

both experts and inexperienced users.

— The intended printing condition needs to be communicated to every stakeholder by independent

means and all users need to know how to set up a viewing environment appropriate to the printing

condition. In the proposed RGB workflow, the intended printing condition is included as metadata

with the image.

— The approval status of an image is not clearly shown. In the proposed RGB workflow, the approval

status is included as metadata with the image.

The proposed RGB workflow addresses these limitations as shown in Figure 2. In this RGB workflow,

candidate images are printed on an RGB Reference Printer that has been calibrated to produce an

accurate simulation of the intended printing condition. These printed images are checked in a controlled

print viewing environment and, if necessary, further adjustments are made until the intended print

result is achieved. When RGB image files are created and checked in this way, metadata that describes

the intended printing condition and the image approval status is added.

CaptureImage preparation Documentcreation and printing

Calibrated to simulate

intended printing

condition

Digital

printer

R’G’B’

Digitalcamera RGB

RGB Reference Image Document Conventional

scene capture Reference

Printcreation approved? creation press

and rendering Image

Digital

press

Add Output intent metadata

Add reference

Retouch

corresponding to

printer’sOutputIntent

intended print condition

Other

Figure 2 — RGB workflow from scene to printing via RGB image data

Careful preparation of RGB images holds the key to a successful RGB workflow. There are a number of

aspects to consider when preparing images for print, including the identification of image highlight and

shadow points and the careful mapping of important image colours into the colour gamut of the printing

press. Since most printing processes have a significantly different colour gamut size and shape from the

set of colours represented in an image, care needs to be taken when editing images so that important

colours are retained. This is done most effectively by associating the RGB image with a CMYK press

profile. This International Standard describes how to prepare these RGB images. Figure 2 shows the

RGB workflow described by this International Standard and R’G’B’ is the prepared RGB image.

NOTE For the proposed workflow, although a calibrated soft proof viewing environment is not required, the

calibration of a reference printer is required and this print needs to be viewed in a standard calibrated viewing

environment. If possible, printers with automatic calibration need to be used in cases where users are not familiar

with the calibration process.

When this workflow is adopted, images can be prepared and incorporated in documents which can be

printed on multiple printing systems producing prints with a similar appearance.

When the RGB image data are approved based on a hardcopy print, consistent judgement can be made.

This workflow is supported by the PDF/X-4 and PDF/X-5 standard document formats. Documents are

expected to be approved using ISO 12647-8 (validation print) or ISO 12647-7 (contract proof).

It is envisaged that printing systems will be developed to produce prints that conform to this International

Standard. It can be the case that systems that already conform to the requirements of ISO 12647-8 or

ISO 12647-7 will be extended to produce RGB Reference Prints. Such systems will provide an easy means

for users to ensure that images and the documents that include these images are printed reliably.

vi © ISO 2014 – All rights reserved

This workflow relates to images that are destined for four-colour commercial printing. Photographers need

to be aware that alternative file versions of an image can still be required for specialized printing conditions.

Annex D provides further details of key RGB workflow concepts.

INTERNATIONAL STANDARD ISO 16760:2014(E)

Graphic technology — Prepress data exchange —

Preparation and visualization of RGB images to be used in

RGB-based graphics arts workflows

1 Scope

This International Standard specifies requirements for an RGB workflow for graphic arts printing based on

the use of reflection prints (RGB Reference Prints) as the evaluation vehicle for coloured images. It provides

guidelines on the creation of print-targeted RGB images (RGB Reference Images) and simulation prints.

This International Standard requires the identification of a pair of ICC profiles for each image: an image

profile and a profile describing the reference printing system. These profiles provide individual colour

transformations for gamut mapping and colour separation. This International Standard does not provide

any guidance as to how these gamut mapping or colour separation transforms can be specified.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3664:2009, Graphic technology and photography — Viewing conditions

ISO 11664-4 (CIE S 014-4/E:2007), Colorimetry — Part 4: CIE 1976 L*a*b* Colour space

ISO 12234-1, Electronic still-picture imaging — Removable memory — Part 1: Basic removable-memory model

ISO 13655, Graphic technology — Spectral measurement and colorimetric computation for graphic arts images

ISO 15076-1:2010, Image technology colour management — Architecture, profile format and data

structure — Part 1: Based on ICC.1:2010

ISO 15790, Graphic technology and photography — Certified reference materials for reflection and

transmission metrology — Documentation and procedures for use, including determination of combined

standard uncertainty

1)

ISO 18619 , Image technology colour management — Black point compensation

2)

ISO 19445 , Graphic technology — Metadata for graphic arts workflow — XMP metadata for image and

document proofing

ISO/IEC 10918-1, Information technology — Digital compression and coding of continuous-tone still images:

Requirements and guidelines — Part 1

ISO/CIE 11664-6 (CIE S 014-6/E:2013), Colorimetry — Part 6: CIEDE2000 Colour-difference formula

TIFF, Revision 6.0 Final, Adobe Systems Incorporated, June 3, 1992

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

1) Under preparation.

2) Under preparation.

3.1

RGB colour space

three-component colour encoding defined by a linear transform from CIE XYZ

Note 1 to entry: Such a transform can be specified as a 3 × 3 matrix, and the transform between XYZ and additive

RGB is then performed by multiplying by this matrix or its inverse.

Note 2 to entry: Adobe RGB (1998) is an example of an RGB colour space.

3.2

characterized printing condition

printing condition for which process control aims are defined and for which the relationship between

input data (printing-tone values, usually CMYK) and the colorimetry of the printed image is documented

Note 1 to entry: The relationship between input data (printing tone values) and the colorimetry of the printed

image is commonly referred to as characterization.

Note 2 to entry: It is generally preferred that the process control aims of the printing condition and the associated

characterization data be made publicly available via the accredited standards process or industry trade

associations.

3.3

colour gamut

solid in a colour space, consisting of all those colours that are: present in a specific scene, artwork,

photograph, photomechanical, or other reproduction; or capable of being created using a particular

output device and/or medium

[SOURCE: ISO 22028-1:2004, 3.8]

3.4

colour rendering

mapping of image data representing the colour space coordinates of the elements of a scene to output-

referred image data representing the colour space coordinates of the elements of a reproduction

Note 1 to entry: Colour rendering generally consists of one or more of the following: compensating for differences

in the input and output viewing conditions, tone scale and colour gamut mapping to map the scene colours onto

the dynamic range and colour gamut of the reproduction, and applying preference adjustments.

Note 2 to entry: In the terminology defined in ISO 22028-1, some of the transforms described in this International

Standard would be better described as colour re-rendering, however, this International Standard does not differentiate

between colour rendering and colour re-rendering transforms and uses the term ‘colour rendering’ for both.

[SOURCE: ISO 22028-1:2004, 3.11]

3.5

highlight point

luminance level or image area corresponding to a reference white in the principal subject area of a scene

Note 1 to entry: Lightness of the objects in the scene are viewed in relation to this reference white. This can be a

white “object” such as a piece of paper, a shirt, etc. or some such object which does not even appear in the scene

but with which a comparison is made by reference to one’s memory of such objects.

Note 2 to entry: Image areas brighter than this point are called highlights. These include specular highlights,

diffuse highlights that are more highly illuminated than the principal area and fluorescent colours.

[22] [23]

Note 3 to entry: This wording is based on Bartleson and Breneman and Giorgianni and Madden .

3.6

output intent

metadata used to communicate the intended printing condition, usually by means of an ICC Profile

2 © ISO 2014 – All rights reserved

3.7

prepress

first stage of the graphic technology workflow, prior to printing, that includes all the operations

necessary for the preparation of images and image carriers

3.8

RGB Reference Image

RGB image prepared according to this specification which can provide a reliable reference to printed

appearance for evaluation by stakeholders

3.9

RGB Reference Print

print of an RGB Reference Image that has been prepared in conformance with this International Standard

3.10

RGB Reference Printer

printing system that is capable of producing RGB Reference Prints

Note 1 to entry: RGB Reference Printers do not use RGB inks but typically use CMYK inks, converting from RGB to

CMYK before printing.

3.11

shadow point

luminance level or image area corresponding to a maximum dark point and/or area of a scene that

should be reproduced as a dark end of grey gradient on a print or a display

4 RGB workflow overview

4.1 General

RGB images are represented in an RGB colour space such as sRGB or Adobe RGB (1998) and as part of

the prepress processing need to be converted to CMYK or similar colour space for printing. It is now

standard industry practice to convert to a characterized printing condition, for example, CGA/TS 21-

CRPC6, Fogra39, or JapanColor using ICC colour conversion.

NOTE The reference printing conditions that are provided as examples here are for offset lithography;

however, the principles of this International Standard apply to all standardised printing conditions.

This Clause describes how to make RGB Reference Images (4.2) and how to make simulation prints

(RGB Reference Prints) based on the characterized printing condition (4.3).

4.2 RGB Reference Images

4.2.1 Configuration of RGB workflow

Figure 3 shows image-processing workflow using RGB Reference Images. A process to convert

RGB images to RGB Reference Images shall be supported and a process to convert RGB Reference Images

to simulation print should be supported.

Monitor

Application software RGB RGB

RGB ICC colour

includingimage Reference Reference

image conversion

processing Image Print

GUI

Adjustgreybalance,

tone,highlight point,

shadowpoint,colour,

cropping, sharpness, e.t.c.

Figure 3 — Image processing workflow for creating RGB reference print

Components of this workflow comprise processing hardware, processing software, and image data files.

Processing hardware comprises a computer, a monitor, and a printer.

Processing software usually comprises operating system software of the computer and application

software. These software components shall support ICC profile-based colour management.

Image data files are of two types: “RGB image” which is an unprocessed input image data file (RGB

image in Figure 3) and the second ‘RGB Reference Image’ which is an output image data file prepared for

printing (RGB Reference Image in Figure 3). Both images shall be display-referred.

NOTE Examples of display-referred images include images encoded as sRGB and Adobe RGB (1998) (commonly

referred to as “Adobe RGB images” and “sRGB images”).

4.2.2 Setup and calibration

Setup and calibration of system hardware and software shall be performed prior to its use.

Monitors shall be calibrated and profiled using appropriate hardware and software. Each monitor

should have a gamut that can adequately represent the intended print condition(s).

NOTE 1 ISO 12646 and ISO 14861 provide a good reference to ensure that monitors are set up appropriately for

soft proofing.

NOTE 2 In some cases, software-based calibration can reduce the number of levels and so it is usually more

effective to use hardware calibration where the monitor’s physical controls and/or its internal lookup tables are

modified, perhaps in conjunction with the graphic card’s lookup tables.

Printers shall be calibrated and profiled using appropriate hardware and software to ensure that prints

produced meet the aims specified in Clause 6.

4.2.3 Operation procedure

Creation of RGB Reference Images shall be performed as follows.

a) Open input RGB image to be displayed using colour management of system software and

application software.

b) Adjust grey balance, highlight point, and shadow point using application software (tone-setup).

4 © ISO 2014 – All rights reserved

c) Adjust colour to make preferred reproduction.

d) Check print-simulation image on the monitor (optional when an RGB Reference Print is made).

e) Create an RGB Reference Print and view in standard conditions to check image result (optional but

highly recommended for inexperienced users).

f) Store RGB Reference Image (R’G’B’) and add output-intent tag as specified in 5.2 using application

software.

NOTE 1 At step a), the RGB image is likely to be display-referred.

NOTE 2 In some instances, legacy profiles might produce a sub-standard perceptual rendering and fail to

achieve an acceptable appearance match. Additional image editing might be required. Alternatively, a print

that achieves an appearance match to the original RGB image can be made using an ICC Profile that provides an

appearance match transform (for example, using CIECAM) in its Perceptual Rendering Intent.

4.2.4 Highlight and shadow point adjustment

The way in which the highlight point and shadow point is selected is beyond the scope of this document.

Users shall select desired highlight and shadow points for each image.

For an average-key image encoded in 8 bits, the desired highlight and shadow points of an RGB Reference

Image are approximately code values of 246 and 15 respectively. The relationship between these values

and tone reproduction of typical press printing profiles is shown in Annex A.

4.2.5 Additional data requirements

In order to provide colour rendering information, in particular the intended output rendering of the

RGB Reference Print and to enable automatic printing of the RGB Reference Print (Figure 6 — Case C),

the following rendering information and parameters shall be added to the image files:

a) colour characterization of source data;

b) rendering intent;

c) black point compensation;

d) output intent profile.

Colour characterization of source data shall be included in the form of an ICC Profile or colour space

name as specified for the appropriate file format.

Colour rendering parameters b) to d) are specified for each file format in the following clauses. The

parameters shall be included as specified in this clause as extensions to the file format as specified in

5.2 or as XMP metadata as specified in 5.3.

At the time of image preparation, these parameters shall be attached to the image file either before an

RGB Reference Print is made or following the approval of the RGB Reference Print.

When RGB Reference Prints are created and when RGB Reference Soft Proofs are displayed from an

RGB reference image, these parameters shall be recognized and the appropriate colour transforms

applied to the image to meet the output colour rendering condition to ensure that the printed output

meets the reproduction tolerances specified in Clause 6.

4.3 Print-simulation workflow

4.3.1 Basic functions of print-simulation workflow

Figure 4 shows the basic image-processing functions of the print-simulation workflow and Figure 5

shows a more concrete example using actual ICC profiles.

NOTE The Reference RGB image will usually be different from the original RGB image as its colour is

constrained by the gamut of the intended printing condition.

RGB

Source profile

CIELab values of the

colours corresponding CIELab

to the RGB values

Intended printing condition prof ile B2A

CMYK values for the

CMYK

intended printing conditio n

Intended printing condition profile A2B

(Relative Colorimetric, BPC off)

CIELab values for the

reproduction colours on the CIELab

intended printing conditio n

Reference printer profile B2A

(Relative Colorimetric, BPC off)

Printer device values to

simulate the intended RGB or CMYK

printing conditio n

Figure 4 — Basic image-processing components of print-simulation workflow

a b

JapanColor2001

AdobeRGB AdobeRGB

CIELab PressReference

image ICC profile

ICC profileB2A0

c d

JapanColor2001

Printer ICC

Press Reference

profileB2A1

ICC profileA2B1

Printerdevice

CMYK

values

e

DeviceLinkprofilefor

JapanColor2001

Key:

Data

Transform

Figure 5 — Print-simulation workflow using commonly available ICC profiles and rendering intents

Figure 5 shows various states of image data and transformation of image data. The image processing

workflow shall be as follows:

a) conversion from display-referred RGB values to CIELAB values using ICC profile of display-referred RGB;

b) conversion from CIELAB values to CMYK tone values using ICC profile of intended printing system;

6 © ISO 2014 – All rights reserved

NOTE Perceptual intent (B2A0) for the conversion steps a) and b) for colour communication among

stakeholders is recommended.

c) conversion from CMYK values to CIELAB values of print using ICC profile of intended printing system;

d) conversion from CIELAB values of print to reference printer device values (typically RGB or CMYK)

using ICC profile of the reference printer.

RelativeColorimetric Intent (A2B1 and B2A1 table of the ICC profile) should be used for conversion steps

c) and d). A DeviceLink profile may be used for this conversion (step e in Figure 5).

4.3.2 Ways to achieve basic functions

There are three ways to achieve the basic functions as shown in Figure 6 and each case is further

explained below in more detail.

RGB CIELAB CMYK CIELAB RGB or CMYK

Application software

Case A

Case B Application software Printer

Case C Printer

Figure 6 — Three methods to achieve basic functions

a) The application software executes all colour conversions using the source profile, the intended

printing condition profile, and the reference printer profile and sends the device value image to the

printer. The printer or the printer driver receives the device value image and prints it.

b) The application software applies the colour conversion from RGB to CMYK using the source profile

and the intended printing condition profile and sends CMYK image including the intended printing

condition profile to the printer. The printer or the printer driver receives the CMYK image and

applies the colour conversion from CMYK to the device values of the reference printer using the

intended printing condition profile and the reference printer profile and makes the RGB Reference

Print for the intended printing condition.

NOTE 1 In some cases, the application software might send only CMYK image and an operator sets the

printer or printer driver to simulation mode for the intended printing condition.

c) The application software sends RGB image including the source profile and the intended printing

condition profile to the printer. The printer or the printer driver receives the RGB image and

performs all colour conversions using the source profile, the intended printing condition profile, and

the reference printer profile and makes the RGB Reference Print for the reference printing condition.

NOTE 2 In some case, the application software might send only RGB image and an operator specifies the source

profile and the intended printing condition profile at the printer or printer driver.

In all cases, the output intent tag shall be added to the RGB image file to communicate the intended

printing condition to stakeholders.

5 File format requirements

5.1 Data delivery

RGB Reference Images shall be delivered as EXIF (JPEG) as defined in ISO 12234-1, or as JFIF (JPEG) as

defined in ISO/IEC 10918-5, or as TIFF (RGB) as defined in TIFF Revision 6 (Baseline).

Except by prior agreement between all of the stakeholders in the RGB workflow, all three image formats

shall be supported.

Subsequently, these parameters indicate the reference print condition for which the image was checked.

NOTE By prior agreement between the stakeholders, images might also be delivered as PDF as long as the

metadata required by this International Standard is included.

5.2 File format extensions

5.2.1 General

Some image writing software may find it more convenient to add the additional parameters as

extensions to the file format and this clause describes how this shall be done. Care needs to be taken to

ensure consistency between the XMP metadata and the file extension data. The guidelines defined by

the metadata working group should be followed to ensure consistency between these two sets of data.

5.2.2 Tiff file

5.2.2.1 RenderingIntent

This field is used to specify the colour rendering intent to be used for colour conversion as defined

by ISO 15076-1.

Tag = 51126 (C7B6 H)

Type = SHORT

Count = 1

Default = value of RenderingIntent from header of embedded ICC profile or media relative

colorimetric, if no profile is embedded.

Allowed values:

0 = Perceptual

1 = Media relative colorimetric

2 = Saturation

3 = ICC absolute colorimetric

5.2.2.2 UseBlackPtComp

This field is used to indicate whether or not black point compensation should be used for colour

conversion as defined by ISO 18619.

Tag = 51127 (C7B7 H)

Type = SHORT

8 © ISO 2014 – All rights reserved

Count = 1

Default = off

Allowed values:

0 = black point compensation shall not be used

1 = black point compensation shall be used

5.2.2.3 OutputIntentProfileURL

This field is used to encode the URL of an ICC profile that should be used as the destination profile

when converting to CMYK. When this tag is used, only profiles from the ICC profile registry should be

referenced. This tag shall not be used when the OutputIntentProfile tag is used.

Tag = 51128 (C7B8 H)

Type = ASCII

Count = length

5.2.2.4 OutputIntentProfile

If this tag is used, the output intent profile for the reference printing condition is embedded in the file.

This tag shall not be used when the OutputIntentProfileURL tag is used.

Tag = 51129 (C7B9 H)

Type = UNDEFINED (treated as 8-bit bytes)

Count = size of embedded ICC profile in bytes

Offset = the file offset, in bytes, to the beginning of the ICC profile

If this tag is used, the output intent profile specified in OutputIntentProfileDescription is embedded in

the file. Like all IFD entry values, the embedded profile data shall begin on a 2-byte boundary, so the