SIST EN 13766:2019+A1:2020

(Main)Thermoplastic multi-layer (non-vulcanized) hoses and hose assemblies for the transfer of liquid petroleum gas and liquefied natural gas - Specification

Thermoplastic multi-layer (non-vulcanized) hoses and hose assemblies for the transfer of liquid petroleum gas and liquefied natural gas - Specification

This document specifies requirements for two types of thermoplastic multi-layer (non-vulcanized) transfer hoses and hose assemblies for carrying liquefied petroleum gas and liquefied natural gas. Each type is subdivided into two classes, one for onshore duties, and the other for offshore.

This document is applicable for hose sizes from 25 mm to 250 mm, working pressures from 10,5 bar to 25 bar and operating temperatures from - 196 °C to + 45 °C.

NOTE Offshore LNG hose assemblies are also specified in EN 1474-2 [1].

Thermoplastische, mehrlagige (nicht vulkanisierte) Schläuche und Schlauchleitungen für die Förderung von Flüssiggas und verflüssigtem Erdgas - Spezifikation

Diese Europäische Norm legt Anforderungen für zwei Typen thermoplastischer, mehrlagiger (nicht vernetzter) Schläuche und Schlauchleitungen zur Förderung von Flüssiggas und verflüssigtem Erdgas fest. Jeder Typ ist unterteilt in zwei Klassen, eine für den Betrieb an Land und die andere für den Betrieb auf See.

Diese Europäische Norm ist anwendbar für Schlauchgrößen von 25 mm bis 250 mm, Betriebsdrücke von 10,5 bar bis 25 bar und Betriebstemperaturen von −196 °C bis +45 °C.

ANMERKUNG Schlauchleitungen für den Betrieb auf See für den Transport von verflüssigtem Erdgas werden in EN 1474-2 beschrieben.

WARNUNG - Personen, die diese Europäische Norm anwenden, sollten mit der üblichen Laborpraxis vertraut sein.

Diese Norm erhebt nicht den Anspruch, auf alle eventuell vorhandenen Sicherheitsprobleme hinzuweisen, die mit der Anwendung verbunden sind. Es liegt in der Verantwortung des Anwenders, entsprechende Gesundheits- und Sicherheitsregeln festzulegen und Übereinstimmungen mit irgendwelchen nationalen Richtlinien sicherzustellen.

Tuyaux et flexibles en thermoplastique multicouches (non vulcanisés) utilisés pour le dépotage de gaz pétrolier liquide et gaz naturel liquifié - Spécification

La présente Norme européenne spécifie des exigences pour deux types de tuyaux et flexibles en thermoplastique multicouches (non vulcanisés) utilisés pour le dépotage de gaz pétrolier liquide et de gaz naturel liquéfié. Chaque type est subdivisé en deux classes, une pour les applications à quai et l’autre pour les applications au large.

La présente Norme européenne est applicable aux tuyaux de dimensions comprises entre 25 mm et 250 mm, pour des pressions de service comprises entre 10,5 bar et 25 bar et des températures d’utilisation comprises entre - 196 °C et + 45 °C.

NOTE Les flexibles utilisés pour le transfert marin du gaz naturel liquéfié (GNL) sont aussi spécifiés dans l’EN 1474-2.

AVERTISSEMENT - Il convient que l’utilisateur de la présente Norme européenne connaisse bien les pratiques courantes de laboratoire. La présente norme n’a pas pour but de traiter tous les problèmes de sécurité qui sont, le cas échéant, liés à son utilisation. Il incombe à l’utilisateur d’établir des pratiques appropriées en matière d’hygiène et de sécurité, et de s’assurer de la conformité à la réglementation nationale en vigueur.

Plastomerne večslojne (nevulkanizirane) cevi in cevni priključki za pretok utekočinjenega naftnega plina in utekočinjenega zemeljskega plina - Specifikacija

General Information

- Status

- Published

- Publication Date

- 14-May-2020

- Technical Committee

- IPMA - Polimer materials and products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 12-May-2020

- Due Date

- 17-Jul-2020

- Completion Date

- 15-May-2020

Relations

- Effective Date

- 12-Feb-2020

- Effective Date

- 12-Feb-2020

Overview

EN 13766:2018+A1:2020 (CEN) specifies requirements for thermoplastic multi‑layer (non‑vulcanized) hoses and hose assemblies used to transfer liquefied petroleum gas (LPG) and liquefied natural gas (LNG). The standard covers two hose types, each subdivided into Class A (onshore) and Class B (offshore) variants, and applies to hose internal diameters from 25 mm to 250 mm, working pressures from 10.5 bar to 25 bar, and operating temperatures from ‑196 °C to +45 °C.

Key topics and technical requirements

- Classification: Type and class definitions with pressure and temperature ranges (see Table 1 of the standard). Type 1 typically covers -50 °C to +45 °C; Type 2 covers cryogenic service down to -196 °C.

- Materials & construction: Multi‑ply thermoplastic films and fabrics combined to provide a complete seal, plus internal and external stainless steel wire helixes. Specified stainless grades include EN 10088‑3 grades such as 1.4306, 1.4401, 1.4404 and 1.4436 (varies by class).

- Dimensional requirements: Internal diameter tolerances and minimum bend radii (25–250 mm sizes with specific radii listed in Table 2).

- Performance & testing: Mandatory proof, burst and hydrostatic tests (EN ISO 1402); crush recovery (Annex A); ozone resistance (EN ISO 7326); low‑temperature flexibility and stiffness (EN ISO 10619‑1/2); electrical continuity (EN ISO 8031); thermal ageing (Annex B); flammability (Annex G).

- End fittings & assemblies: Material and construction requirements for fittings and ferrules, fitting security and leak tightness tests (Annexes C, E, F).

- Quality control: Type, routine and batch testing regimes, marking and traceability requirements (Clause 10, Annexes H and I).

Applications and who uses this standard

- Applications: Ship‑to‑shore transfer, terminals, bunkering, LNG/LPG truck/rail loading and offloading, onshore terminals and offshore platforms where thermoplastic transfer hoses are used, including cryogenic service.

- Users: Hose and hose‑assembly manufacturers, terminal and port operators, offshore installation engineers, procurement and QA teams, test laboratories, certification bodies and regulatory authorities involved in LPG/LNG handling.

Related standards

- EN 1474‑2 (offshore LNG hose assemblies) - noted in EN 13766.

- Referenced test standards: EN ISO 1402, EN ISO 8031, EN ISO 10619‑1/2, EN ISO 7326, EN ISO 4671, EN ISO 527‑1, etc., for specific test methods.

EN 13766:2018+A1:2020 is essential for ensuring safe, compliant thermoplastic hose systems for LPG/LNG transfer, providing manufacturers and operators with clear construction, performance and testing criteria for both onshore and offshore service.

Frequently Asked Questions

SIST EN 13766:2019+A1:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Thermoplastic multi-layer (non-vulcanized) hoses and hose assemblies for the transfer of liquid petroleum gas and liquefied natural gas - Specification". This standard covers: This document specifies requirements for two types of thermoplastic multi-layer (non-vulcanized) transfer hoses and hose assemblies for carrying liquefied petroleum gas and liquefied natural gas. Each type is subdivided into two classes, one for onshore duties, and the other for offshore. This document is applicable for hose sizes from 25 mm to 250 mm, working pressures from 10,5 bar to 25 bar and operating temperatures from - 196 °C to + 45 °C. NOTE Offshore LNG hose assemblies are also specified in EN 1474-2 [1].

This document specifies requirements for two types of thermoplastic multi-layer (non-vulcanized) transfer hoses and hose assemblies for carrying liquefied petroleum gas and liquefied natural gas. Each type is subdivided into two classes, one for onshore duties, and the other for offshore. This document is applicable for hose sizes from 25 mm to 250 mm, working pressures from 10,5 bar to 25 bar and operating temperatures from - 196 °C to + 45 °C. NOTE Offshore LNG hose assemblies are also specified in EN 1474-2 [1].

SIST EN 13766:2019+A1:2020 is classified under the following ICS (International Classification for Standards) categories: 23.040.70 - Hoses and hose assemblies; 75.200 - Petroleum products and natural gas handling equipment; 83.140.30 - Plastics pipes and fittings for non fluid use. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13766:2019+A1:2020 has the following relationships with other standards: It is inter standard links to SIST EN 13766:2019, SIST EN 13766:2019/oprA1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13766:2019+A1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2020

Plastomerne večslojne (nevulkanizirane) cevi in cevni priključki za pretok

utekočinjenega naftnega plina in utekočinjenega zemeljskega plina - Specifikacija

Thermoplastic multi-layer (non-vulcanized) hoses and hose assemblies for the transfer of

liquid petroleum gas and liquefied natural gas - Specification

Thermoplastische, mehrlagige (nicht vulkanisierte) Schläuche und Schlauchleitungen für

die Förderung von Flüssiggas und verflüssigtem Erdgas - Spezifikation

Tuyaux et flexibles en thermoplastique multicouches (non vulcanisés) utilisés pour le

dépotage de gaz pétrolier liquide et gaz naturel liquifié - Spécification

Ta slovenski standard je istoveten z: EN 13766:2018+A1:2020

ICS:

75.200 Oprema za skladiščenje Petroleum products and

nafte, naftnih proizvodov in natural gas handling

zemeljskega plina equipment

83.140.30 Polimerne cevi in fitingi za Plastics pipes and fittings for

snovi, ki niso tekočine non fluid use

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13766:2018+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2020

EUROPÄISCHE NORM

ICS 23.040.70 Supersedes EN 13766:2018

English Version

Thermoplastic multi-layer (non-vulcanized) hoses and

hose assemblies for the transfer of liquid petroleum gas

and liquefied natural gas - Specification

Tuyaux et flexibles en thermoplastique multicouches Thermoplastische, mehrlagige (nicht vulkanisierte)

(non vulcanisés) utilisés pour le dépotage de gaz Schläuche und Schlauchleitungen für die Förderung

pétrolier liquide et gaz naturel liquifié - Spécification von Flüssiggas und verflüssigtem Erdgas -

Spezifikation

This European Standard was approved by CEN on 9 November 2018 and includes Amendment 1 approved by CEN on 24

February 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13766:2018+A1:2020 E

worldwide for CEN national Members.

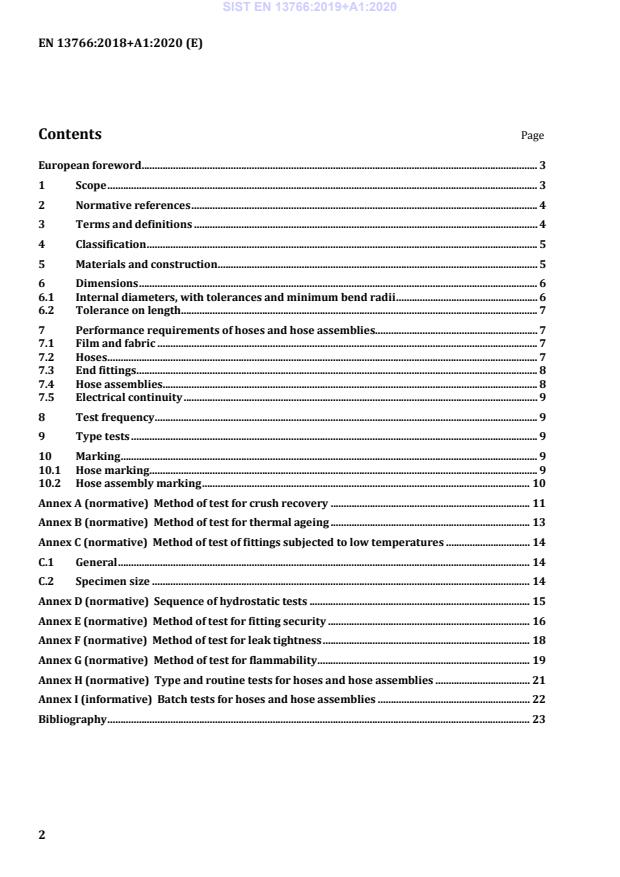

Contents Page

European foreword . 3

1 Scope . 3

2 Normative references . 4

3 Terms and definitions . 4

4 Classification . 5

5 Materials and construction . 5

6 Dimensions . 6

6.1 Internal diameters, with tolerances and minimum bend radii . 6

6.2 Tolerance on length. 7

7 Performance requirements of hoses and hose assemblies . 7

7.1 Film and fabric . 7

7.2 Hoses . 7

7.3 End fittings . 8

7.4 Hose assemblies. 8

7.5 Electrical continuity . 9

8 Test frequency . 9

9 Type tests . 9

10 Marking . 9

10.1 Hose marking . 9

10.2 Hose assembly marking . 10

Annex A (normative) Method of test for crush recovery . 11

Annex B (normative) Method of test for thermal ageing . 13

Annex C (normative) Method of test of fittings subjected to low temperatures . 14

C.1 General . 14

C.2 Specimen size . 14

Annex D (normative) Sequence of hydrostatic tests . 15

Annex E (normative) Method of test for fitting security . 16

Annex F (normative) Method of test for leak tightness . 18

Annex G (normative) Method of test for flammability . 19

Annex H (normative) Type and routine tests for hoses and hose assemblies . 21

Annex I (informative) Batch tests for hoses and hose assemblies . 22

Bibliography . 23

European foreword

This document (EN 13766:2018+A1:2020) has been prepared by Technical Committee CEN/TC 218 “Rubber

and plastics hoses and hose assemblies”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2020, and conflicting national standards shall

be withdrawn at the latest by November 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 24 February 2020.

This document supersedes !EN 13766:2018".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

The main changes compared to the previous version are as follows:

— the safety warning has been moved from the Scope to Clause 7 “Performance requirements of hoses and

hose assemblies”;

— the normative references (Clause 2) have been updated;

— the tolerances for the minimum working temperature in Table 1 “Pressure and temperature range” have

been removed;

— in Clause 5, “Materials and construction”, a requirement has been added that the manufacturer shall

establish that the materials used are suitable for the cryogenic liquids to be carried;

— the requirement for the electrical resistance between end fittings (Clause 7) has been modified;

— Clause 10 “Marking” has been updated;

— the title of Annex A has been changed to “Method of test for crush recovery” and tolerances for the test

force have been added;

— requirements have been added to Annex D “Sequence of hydrostatic tests”;

— in Annex E “Method of test for fitting security”, the wording concerning a “cycle” has been clarified and

the requirements for the end of the test after completion of 20 cycles have been rewritten;

— Annex G “Method of test for flammability” has been added;

— the requirements for type tests, routine tests and batch tests (Annexes H and I) have been updated;

— the document has been editorially revised.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia,

Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

1 Scope

This document specifies requirements for two types of thermoplastic multi-layer (non-vulcanized) transfer

hoses and hose assemblies for carrying liquefied petroleum gas and liquefied natural gas. Each type is

subdivided into two classes, one for onshore duties, and the other for offshore.

This document is applicable for hose sizes from 25 mm to 250 mm, working pressures from 10,5 bar to 25

bar and operating temperatures from –196 °C to +45 °C.

NOTE Offshore LNG hose assemblies are also specified in EN 1474-2 [1].

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 10088-3:2014, Stainless steels - Part 3: Technical delivery conditions for semi-finished products, bars, rods,

wire, sections and bright products of corrosion resisting steels for general purposes

EN ISO 148-1, Metallic materials - Charpy pendulum impact test - Part 1: Test method (ISO 148-1)

EN ISO 527-1, Plastics - Determination of tensile properties - Part 1: General principles (ISO 527-1)

EN ISO 1043-1, Plastics - Symbols and abbreviated terms - Part 1: Basic polymers and their special

characteristics (ISO 1043-1)

EN ISO 1402:2009, Rubber and plastics hoses and hose assemblies - Hydrostatic testing (ISO 1402)

EN ISO 4671, Rubber and plastics hoses and hose assemblies - Methods of measurement of the dimensions of

hoses and the lengths of hose assemblies (ISO 4671)

EN ISO 7326, Rubber and plastics hoses - Assessment of ozone resistance under static conditions (ISO 7326)

EN ISO 8031:2009, Rubber and plastics hoses and hose assemblies - Determination of electrical resistance and

conductivity (ISO 8031:2009)

EN ISO 8330:2014, Rubber and plastics hoses and hose assemblies - Vocabulary (ISO 8330:2014)

EN ISO 10619-1, Rubber and plastics hoses and tubing - Measurement of flexibility and stiffness - Part 1:

Bending tests at ambient temperature (ISO 10619-1)

!EN ISO 10619-2, Rubber and plastics hoses and tubing - Measurement of flexibility and stiffness - Part 2:

Bending tests at sub-ambient temperatures (ISO 10619-2)"

EN ISO 13934-1, Textiles - Tensile properties of fabrics - Part 1: Determination of maximum force and

elongation at maximum force using the strip method (ISO 13934-1)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 8330:2014 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Classification

Hoses shall be classified according to their usage, working pressure and working temperature range as given

in Table 1.

Table 1 — Pressure and temperature range

Classification

Pressure/temperature

a b a b

Class A Class B Class A Class B

Type 1 Type 1 Type 2 Type 2

Maximum working 25 20 13 10,5

pressure (bar)

Proof pressure (bar) 37,5 30 19,5 15,8

Minimum burst pressure 100 100 52 52,5

(bar)

Working temperature –50 to +45 –50 to +45 –196 to +45 –196 to +45

range (°C)

NOTE 1 1 bar = 0,1 MPa

NOTE 2 Due to pressurization during test and operations the temperature of the fluid could increase.

The indicated temperatures are measured at atmospheric pressure.

a

Class A is for use onshore.

b

Class B is for use offshore.

Upon agreement with the manufacturer, lower min. and/or higher max. temperatures are allowed

depending on the materials used and the compatibility at those temperatures with the fluid conveyed. Other

properties and requirements mentioned in the standard still have to be met.

5 Materials and construction

The manufacturer shall establish that the materials used are suitable for the cryogenic liquids to be carried.

Hoses shall be constructed as shown in Figure 1 and shall consist of the following:

a) Class A:

1) An internal wire helix of stainless steel conforming to EN 10088-3:2014, numbers 1.4306, 1.4401,

1.4404 or 1.4436;

2) A multi-ply wall of layers of films and fabrics made of thermoplastics that in combination give the

required properties specified in Table 1 and provide a complete seal;

3) An external wire helix of stainless steel conforming to EN 10088-3:2014, numbers 1.4306, 1.4401,

1.4404 or 1.4436.

b) Class B:

1) An internal wire helix of stainless steel conforming to EN 10088-3:2014, numbers 1.4401, 1.4404 or

1.4436;

2) A multi-ply wall of layers of films and fabrics made of thermoplastics that in combination give the

required properties specified in Table 1 and provide a complete seal;

3) An external wire helix of stainless steel conforming to EN 10088-3:2014, numbers 1.4401, 1.4404 or

1.4436.

By agreement between manufacturer and purchaser, the outer layer may have colour identification.

Key

1 internal wire

2 film

3 fabric

4 external wire

Figure 1 — Section of a typical thermoplastic multilayer hose

6 Dimensions

6.1 Internal diameters, with tolerances and minimum bend radii

When measured in accordance with EN ISO 4671, the values of the internal diameter of the hose shall

conform to Table 2. When tested by the method described in EN ISO 10619-1 the value of the minimum bend

radius shall be as given in Table 2. The hose shall show no sign of permanent deformation of the cross

section i.e. kinking.

Table 2 — Dimensions and minimum bend radius

Dimensions in millimetres

Internal diameter Tolerance Minimum bend radius

25 ±1 150

32 ±1 175

38 ±1 175

40 ±1 200

50 ±1 200

65 ±2 200

75 ±2 250

80 ±2 250

100 ±2 500

150 ±2 660

200 ±3 910

250 ±3 2 500

6.2 Tolerance on length

When

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...