oSIST prEN IEC 61058-1-2:2026

(Main)Switches for appliances - Part 1-2: Requirements for electronic switches

Switches for appliances - Part 1-2: Requirements for electronic switches

Geräteschalter - Teil 1-2: Anforderungen an elektronische Schalter

Interrupteurs pour appareils - Partie 1-2: Exigences relatives aux interrupteurs électroniques

Stikala za aparate - 1-2. del: Zahteve za konstrukcije elektronskih stikal

General Information

- Status

- Not Published

- Public Enquiry End Date

- 04-Feb-2026

- Technical Committee

- EPR - Electrical accessories

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 18-Nov-2025

- Due Date

- 07-Apr-2026

Relations

- Effective Date

- 02-Sep-2025

- Effective Date

- 06-Aug-2024

Overview

The oSIST prEN IEC 61058-1-2:2026 standard, titled Switches for appliances - Part 1-2: Requirements for electronic switches, is published by the European Committee for Electrotechnical Standardization (CLC). This document sets forth detailed requirements and testing procedures for electronic switching devices used in appliances. It serves as a subsidiary to the general requirements outlined in IEC 61058-1, focusing specifically on the unique needs and challenges of electronic switches.

This international standard aims to ensure the reliability, safety, and performance consistency of electronic switches in household and industrial appliances, addressing critical aspects such as electrical endurance, mechanical strength, protection against electric shock, and electromagnetic compatibility (EMC).

The standard is intended for manufacturers, testing laboratories, and regulatory bodies involved with the design, production, and certification of switches incorporated into electrical appliances.

Key Topics

Scope and Application

This standard applies solely to electronic switching devices and supplements the general requirements of IEC 61058-1 for appliance switches.Testing Protocols

Detailed testing specifications are included, covering:- Electrical endurance testing to verify switch reliability under rated load conditions.

- Mechanical strength assessments to confirm physical durability.

- Protection against ingress of solid foreign objects and water.

- Insulation resistance, dielectric strength, and temperature-rise tests.

- Abnormal operation and fault condition evaluations, including overload, short-circuit scenarios, and forced cooling failure.

Safety and Performance Requirements

- Protection against electric shock and provisions for earthing.

- Marking, documentation, and classification requirements.

- Compliance with electromagnetic compatibility (EMC) to avoid interference in electrical environments.

- Fire hazard prevention measures and resistance to rusting.

Standardization and Conformity

The document follows rigorous international IEC procedures and collaborates with ISO for harmonized terminology and standardization. It also addresses intellectual property considerations, such as relevant patent rights.

Applications

The oSIST prEN IEC 61058-1-2:2026 standard is critical for the development and certification of electronic switches used in a broad range of electrical appliances, including but not limited to:

- Household appliances (e.g., refrigerators, washing machines, ovens)

- Industrial and commercial equipment requiring reliable electronic switching components.

- Consumer electronics integrating electronic switch controls.

- Any appliance designs that demand strict compliance with electrical safety and operational reliability standards.

By conforming to this standard, manufacturers can enhance product safety, improve functional longevity, and meet international market access requirements. Testing laboratories benefit from comprehensive guidelines ensuring consistent evaluation and certification of electronic switches.

Related Standards

IEC 61058-1 - Switches for appliances - Part 1: General requirements: Forms the base standard for appliance switches, with prEN IEC 61058-1-2 adding supplemental electronic switch-specific guidance.

IEC 61058 parts 2 - Provide additional requirements for particular kinds of switches beyond electronic types.

ISO/IEC Directives - Provide procedural rules and guidance for the development of IEC and ISO standards, ensuring harmonization and consistent documentation practices.

IEC 60950 / IEC 62368 - Standards related to safety of electronic equipment may overlap with switch safety considerations.

EMC Standards (e.g., IEC 61000 series) - Cover electromagnetic compatibility related to appliance operation and interference.

Keywords: electronic switches standard, IEC 61058-1-2, appliance switches safety, electronic switch testing, electrical endurance, appliance switch requirements, IEC electrotechnical standards, switch protection requirements, electromagnetic compatibility electronic switches, appliance safety standards.

Frequently Asked Questions

oSIST prEN IEC 61058-1-2:2026 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Switches for appliances - Part 1-2: Requirements for electronic switches". This standard covers: Switches for appliances - Part 1-2: Requirements for electronic switches

Switches for appliances - Part 1-2: Requirements for electronic switches

oSIST prEN IEC 61058-1-2:2026 is classified under the following ICS (International Classification for Standards) categories: 29.120.40 - Switches. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN IEC 61058-1-2:2026 has the following relationships with other standards: It is inter standard links to SIST EN 61058-1-2:2017/AC:2019, SIST EN 61058-1-2:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN IEC 61058-1-2:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Stikala za aparate - 1-2. del: Zahteve za konstrukcije elektronskih stikal

Switches for appliances - Part 1-2: Requirements for electronic switches

Geräteschalter - Teil 1-2: Anforderungen an elektronische Schalter

Interrupteurs pour appareils - Partie 1-2: Exigences relatives aux interrupteurs

électroniques

Ta slovenski standard je istoveten z: prEN IEC 61058-1-2:2025

ICS:

29.120.40 Stikala Switches

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

23J/496/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 61058-1-2 ED2

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2025-11-14 2026-02-06

SUPERSEDES DOCUMENTS:

23J/488/CD, 23J/492/CC

IEC SC 23J : SWITCHES FOR APPLIANCES

SECRETARIAT: SECRETARY:

Germany Mr Axel Klingberg

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

SC 23B,SC 23G,SC 23H,TC 116

ASPECTS CONCERNED:

Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft

for Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of

which they are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some

Countries” clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is

the final stage for submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Switches for appliances - Part 1-2: Requirements for electronic switches

PROPOSED STABILITY DATE: 2029

NOTE FROM TC/SC OFFICERS:

download this electronic file, to make a copy and to print out the content for the sole purpose of preparing National

Committee positions. You may not copy or "mirror" the file or printed version of the document, o r any part of it, for

any other purpose without permission in writing from IEC.

IEC CDV 61058-1-2 © IEC 2025

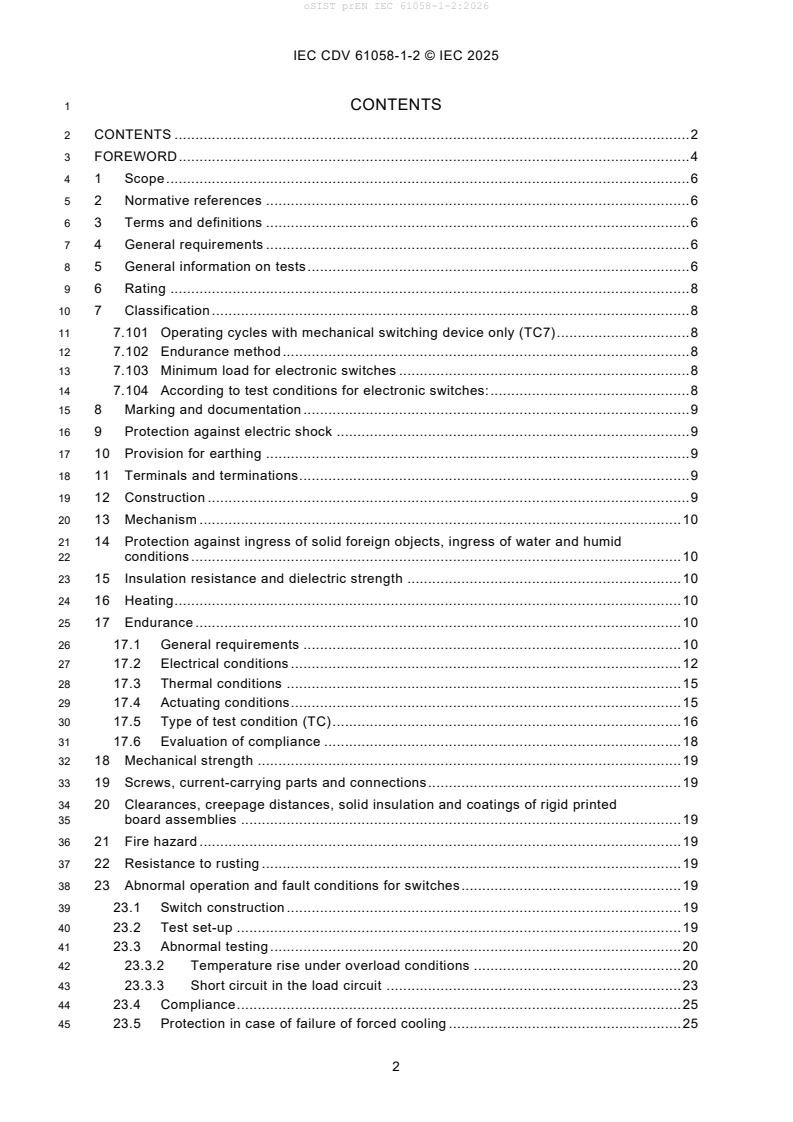

1 CONTENTS

2 CONTENTS . 2

3 FOREWORD . 4

4 1 Scope . 6

5 2 Normative references . 6

6 3 Terms and definitions . 6

7 4 General requirements . 6

8 5 General information on tests . 6

9 6 Rating . 8

10 7 Classification . 8

11 7.101 Operating cycles with mechanical switching device only (TC7). 8

12 7.102 Endurance method . 8

13 7.103 Minimum load for electronic switches . 8

14 7.104 According to test conditions for electronic switches: . 8

15 8 Marking and documentation . 9

16 9 Protection against electric shock . 9

17 10 Provision for earthing . 9

18 11 Terminals and terminations. 9

19 12 Construction . 9

20 13 Mechanism . 10

21 14 Protection against ingress of solid foreign objects, ingress of water and humid

22 conditions . 10

23 15 Insulation resistance and dielectric strength . 10

24 16 Heating . 10

25 17 Endurance . 10

26 17.1 General requirements . 10

27 17.2 Electrical conditions . 12

28 17.3 Thermal conditions . 15

29 17.4 Actuating conditions . 15

30 17.5 Type of test condition (TC) . 16

31 17.6 Evaluation of compliance . 18

32 18 Mechanical strength . 19

33 19 Screws, current-carrying parts and connections . 19

34 20 Clearances, creepage distances, solid insulation and coatings of rigid printed

35 board assemblies . 19

36 21 Fire hazard . 19

37 22 Resistance to rusting . 19

38 23 Abnormal operation and fault conditions for switches. 19

39 23.1 Switch construction . 19

40 23.2 Test set-up . 19

41 23.3 Abnormal testing . 20

42 23.3.2 Temperature rise under overload conditions . 20

43 23.3.3 Short circuit in the load circuit . 23

44 23.4 Compliance . 25

45 23.5 Protection in case of failure of forced cooling . 25

IEC CDV 61058-1-2 © IEC 2025

46 24 Components for switches . 25

47 25 EMC requirements . 26

48 Bibliography . 27

50 Table 1 – Test specimens . 6

51 Table 2 – Switch information and the loads placed in groups . 9

52 Table 3 – Electrical endurance tests for electronic switches . 11

53 Table 4 – Test loads for electrical endurance tests for a.c. circuits . 13

54 Table 5 – Test loads for electrical endurance tests for d.c. circuits . 14

55 Table 6 – Switch operating conditions . 16

56 Table 7 – .

57 Table 8 – Permissible temperature . 23

IEC CDV 61058-1-2 © IEC 2025

59 INTERNATIONAL ELECTROTECHNICAL COMMISSION

60 ____________

62 Switches for appliances - Part 1-2:

63 Requirements for electronic switches

65 FOREWORD

66 a) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

67 all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

68 co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

69 in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical

70 Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

71 preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt

72 with may participate in this preparatory work. International, governmental and non-governmental organizations

73 liaising with the IEC also participate in this preparation. IEC collaborates closely with the International

74 Organization for Standardization (ISO) in accordance with conditions determined by agreement between the two

75 organizations.

76 b) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

77 consensus of opinion on the relevant subjects since each technical committee has representation from all

78 interested IEC National Committees.

79 c) IEC Publications have the form of recommendations for international use and are accepted by IEC National

80 Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

81 Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

82 misinterpretation by any end user.

83 d) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

84 transparently to the maximum extent possible in their national and regional publications. Any divergence between

85 any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

86 e) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

87 assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

88 services carried out by independent certification bodies.

89 f) All users should ensure that they have the latest edition of this publication.

90 g) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

91 members of its technical committees and IEC National Committees for any personal injury, property damage or

92 other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

93 expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

94 Publications.

95 h) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

96 indispensable for the correct application of this publication.

97 i) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

98 patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

99 respect thereof. As of the date of publication of this document, IEC [had/had not] received notice of (a) patent(s),

100 which may be required to implement this document. However, implementers are cautioned that this may not

101 represent the latest information, which may be obtained from the patent database available at

102 https://patents.iec.ch. IEC shall not be held responsible for identifying any or all such patent rights.

103 IEC 61058-1-2 has been prepared by subcommittee 23J: Switches for appliances, of IEC

104 technical committee 23: Electrical accessories. It is an International Standard.

105 This XXX edition cancels and replaces the XXX edition published in [publication_date],

106 Amendment 1:[publication_date] and Amendment 2:[publication_date]. This edition constitutes

107 a technical revision.

108 This edition includes the following significant technical changes with respect to the previous

109 edition:

110 a) .;

111 The text of this International Standard is based on the following documents:

Draft Report on voting

XX/XX/FDIS XX/XX/RVD

IEC CDV 61058-1-2 © IEC 2025

112 Full information on the voting for its approval can be found in the report on voting indicated in

113 the above table.

114 The language used for the development of this International Standard is English [change

115 language if necessary].

116 A list of all parts in the IEC 61058 series, published under the general title Switches for

117 appliances, can be found on the IEC website.

118 In this standard, the following print types are used:

119 – test specifications: in italic type.

120 This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

121 accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

122 at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

123 described in greater detail at www.iec.ch/publications.

124 The committee has decided that the contents of this document will remain unchanged until the

125 stability date indicated on the IEC website under webstore.iec.ch in the data related to the

126 specific document. At this date, the document will be

127 • reconfirmed,

128 • withdrawn, or

129 • revised.

IEC CDV 61058-1-2 © IEC 2025

130 1 Scope

131 IEC 61058-1:—, Clause 1 is applicable with the following addition.

132 This part of IEC 61058 applies to electronic switching devices and shall be used in conjunction

133 with the general requirements of IEC 61058-1.

134 NOTE Additional requirements for particular switches may be found in the relevant part 2 of IEC 61058.

135 2 Normative references

136 The following documents are referred to in the text in such a way that some or all of their content

137 constitutes requirements of this document. For dated references, only the edition cited applies.

138 For undated references, the latest edition of the referenced document (including any

139 amendments) applies.

140 IEC 61058-1, Switches for appliances - Part 1: General requirements

141 3 Terms and definitions

142 For the purposes of this document, the terms and definitions given in IEC 61058-1:— apply.

143 ISO and IEC maintain terminology databases for use in standardization at the following

144 addresses:

145 • IEC Electropedia: available at https://www.electropedia.org/

146 • ISO Online browsing platform: available at https://www.iso.org/obp

147 4 General requirements

148 IEC 61058-1:—, Clause 4 is applicable.

149 5 General information on tests

150 IEC 61058-1:—, Clause 5 is applicable with the following addition.

151 Table 101 provides information on:

152 – The minimum number of specimens needed for each test.

153 – The minimum number of total specimens, when applicable tests are added, needed for each

154 evaluation.

155 – Additional specimens that may be required as a result of additional electrical rating, unique

156 construction or damage /breakage during testing.

157 Table 101 – Test specimens

Clause Description Minimum number of Notes

a

specimens for each test

Clause General information on tests - i ii b

Clause Rating 1 c

Clause Classification

IEC CDV 61058-1-2 © IEC 2025

Clause Description Minimum number of Notes

a

specimens for each test

Clause Marking and documentation

Clause Protection against electric shock

Clause Provision for earthing

Clause Terminals and terminations

Clause Construction

Clause Mechanism

14.1 Protection against ingress of solid foreign objects 1 d

14.2 Protection against ingress of water 1 d

14.3 to Protection against humid conditions 3 e,m

Clause Insulation resistance and dielectric strength

Clause Heating - 3 3 b,f,m

Clause Endurance - 3 3 b,f,m

Clause Mechanical strength 1 c

Clause Screws, current-carrying parts and connections 1 c

Clause Clearances, creepage distances, solid insulation and coatings 1 g,h

20 of rigid printed board assemblies

Clause Fire hazard 2 i,c

Clause Resistance to rusting 1 c

Clause Abnormal operation and fault conditions for switches 1 l

Clause Components for switches 3 j

Clause EMC requirements 1 k

IEC CDV 61058-1-2 © IEC 2025

Clause Description Minimum number of Notes

a

specimens for each test

a

Additional specimens may be required depending on the construction and declaration of the switch.

b

Each electrical rating submitted to the testing of Clause 16 and Clause 17 requires an additional 3 specimens

(such as rating i = 3 specimens, rating ii = additional 3 specimens).

c

The specimen may be used for more than 1 test, if cumulative stress as a result of sequential testing is avoided.

When a specimen is damaged, a new specimen shall be used for the next test.

d

In general 1 specimen for ingress of solid foreign objects (dust), and 1 specimen for ingress of water. Specific

IP ratings (such as IP5x, IP6x and protection against water) require a special enclosure to be provided with

the switch specimen in order to complete the testing.

e

The same test specimens are used to complete the testing of 14.3 and Clause 15. The test are completed in

immediate sequence.

f

Heating and endurance is recommended to be tested on the same specimens. If declared, separate specimens

may be used when noted on the test record.

g

Three additional new specimens may be required according to Clause 20, for the test according to annex G.

h

For testing coatings on printed boards according to 20.6, the number of printed boards needed is determined

by the testing of IEC 60664-3.

i

For testing glow wire and ball pressure special test specimens according to 60695-2-11 and 60695-10-2,

respectively may be required.

j

The number of specimens for specific test and examination of Clause 24 is according to the individual

subclasses.

k

EMC testing may require additional specimens according to the EMC test program and switch construction.

l

Abnormal operation and fault conditions are generally destructive, typically the switch cannot be repaired and

reused for the next fault. Specially prepared specimens (such as with wires soldered to the internal circuit)

may be necessary in order to complete the testing. The total number of specimens depends on the switch

construction, for details see Clause 23.

m

This test is part of a sequence, and a new set of 3 specimens shall not be used except as permitted by 5.1.2.

158 6 Rating

159 IEC 61058-1:—, Clause 6 is applicable.

160 7 Classification

161 IEC 61058-1:—, Clause 7 is applicable with the following addition.

162 7.101 Operating cycles with mechanical switching device only (TC7)

163 7.102 Endurance method

164 7.102.1 Electrical endurance method “a” (Table 3)

165 7.102.2 Electrical endurance method “b” (Table 3)

166 7.103 Minimum load for electronic switches

167 7.104 According to test conditions for electronic switches:

168 7.104.1 Functional test conditions for electronic switches with thermal current or maximum

169 rated resistive current.

170 NOTE This test condition reflects the proper functioning of the switch. This test does not simulate the actual load

171 of the end application.

IEC CDV 61058-1-2 © IEC 2025

172 7.104.2 Simulated test conditions for electronic switches with type of load as classified in IEC

173 61058-1:—, 7.2.

174 NOTE This test condition reflects the proper functioning of the switch. It also simulates all conditions of the end

175 application.

176 7.104.3 Specific test conditions of end application for electronic switches, i.e. in or together

177 with the appliance and under the cooling conditions of the appliance.

178 8 Marking and documentation

179 IEC 61058-1:—, Clause 8 is applicable with the following addition.

180 IEC 61058-1:—,Table 3 is applicable with the addition of Table 2.

181 Table 102 – Switch information and the loads placed in groups

Characteristic Subclause Means of information

No Common type Unique type

reference CT reference UT

12.3 Thermal current if defined IEC 61058-1:—, Documentation Documentation

3.2.12

12.4 Number of cycles with electronic IEC 61058-1:—, Documentation Documentation

control failed (TC 7) 7.24

12.5 Endurance method “a” or “b” IEC 61058-1:—, Documentation Documentation

7.25

12.6 Minimum test load if required IEC 61058-1:—, Documentation Documentation

7.26

12.7 Test conditions functional or 7.104 Documentation Documentation

simulated

IEC 61058-1:—,

12.8 Cooling conditions Documentation Documentation

7.22

182 9 Protection against electric shock

183 IEC 61058-1:—, Clause 9 is applicable.

184 10 Provision for earthing

185 IEC 61058-1:—, Clause 10 is applicable.

186 11 Terminals and terminations

187 IEC 61058-1:—, Clause 11 is applicable with the following addition.

188 Compliance is checked according to TE2 in Clause 17. For electronic switches rated for less

189 than 1E4 cycles the TE2 test shall be performed on the complete switch.

190 12 Construction

191 IEC 61058-1:—, Clause 12 is applicable.

IEC CDV 61058-1-2 © IEC 2025

192 13 Mechanism

193 IEC 61058-1:—, Clause 13 is applicable.

194 14 Protection against ingress of solid foreign objects, ingress of water and

195 humid conditions

196 IEC 61058-1:—, Clause 14 is applicable.

197 15 Insulation resistance and dielectric strength

198 IEC 61058-1:—, Clause 15 is applicable with the following addition.

199 – For electronic switches, the test is carried out across full disconnection and micro-

200 disconnection only on electronic switches with mechanical switching devices connected in

201 series with the semiconductor switching device.

202 – For electronic switches, the tests are not carried out across protective impedances and

203 poles interconnected by components.

204 16 Heating

205 IEC 61058-1:—, Clause 16 is applicable.

206 17 Endurance

207 17.1 General requirements

208 17.1.1 Switches shall withstand without excessive wear or other harmful effect the electrical,

209 thermal and mechanical stresses that occur in normal use.

210 17.1.2 Electronic switches are tested in an increasing TC order as specified in Table 103.

211 The test conditions are according to the following depending on their classification in 7.104.

212 – under functional test conditions according to 7.104.1 with thermal current or with maximum

213 rated resistive current, if no thermal current is declared, and without forced cooling;

214 – under simulated test conditions according to 7.104.2 and with type of load according to IEC

215 61058-1:—, 7.2 and under the cooling conditions classified in IEC 61058-1:—, 7.22 and with

216 test conditions as specified in Table 104 and Table 5;

217 – under specific test conditions of end application according to 7.104.3, in or together with the

218 appliance and under the cooling conditions of the appliance;

219 – under test conditions according to duty type according to IEC 61058-1:—, 7.18, the tests

220 may be performed in combination with simulated test conditions or specific test conditions

221 of the end application.

222 NOTE Additional mechanical operating means (for example, actuating member such as speed -limit settings for

223 electric tools) are ignored.

IEC CDV 61058-1-2 © IEC 2025

224 Table 103 – Electrical endurance tests for electronic switches

Type of electronic Test conditions

d

switch

Functional test (7.104.1) Simulated test (7.104.2) Specific test condition

of end application

(Table 104 and Table

(7.104.3)

105)

Complet Contacts Complet Contacts Complet Contacts

e switch only e switch only e switch only

b TL1 TC5, --- TL3 TC5, --- TL4 TC5, ---

SD withou

TC6, TC8 TC6, TC8 TC6, TC8

t electrical

TE1, TE3 TE1, TE3 TE1, TE3

contact(s)

SD with TL1 TC5, Serial a) TL1 a) Serial TL4 TC5, Serial

serial TC6, TC8 contact: TC5, contact: TC8 TE1, contact:

contact(s) TE1, TE3 TC6, TC8 TE3

TC1, TC4 TL3, TC1, TC7 with TL4

TE1, TE3

with TL2 TE1 TC4 TE1 to TE1 to TE3

to TE3 (SD TE3 (SD (SD short-

short- short- c

circuited)

c c

circuited) circuited)

b) TL3 b) Serial

TC5, contact:

TC6, TC8

TL3, TC1,

TE1, TE3

TC7 TE1 to

TE3 (SD

short-

c

circuited)

SD with TL1 TC5, Parallel TL3 TC5, Parallel TL4 TC5, Parallel

parallel TC6, TC8 contact: TC6, TC8 contact: TC8 TE1, contact:

contact(s) TE1, TE3 TE1, TE3 TE3

TC1, TC4 TL3, TC1, TC7 with TL4

with TL2 TE1 TC4 TE1 to TE3

to TE3 (SD (SD

TE1 to TE3

disconnected disconnected

) )

(SD

disconnected

)

SD with TL1 TC5, Serial a) TL1 a) Serial TL4 TC5, Serial

serial and TC6, TC8 contact: TC5, contact: TC8 TE1, contact:

parallel TE1, TE3 TC6, TC8 TE3

TC1, TC4 TL3, TC1, TC7 with TL4

contact(s) TE1, TE3

with TL2 TE1 TC4 TE1 to TE1 to TE3

to TE3 (SD TE3 (SD (SD short-

short- short-

c

circuited)

c c

circuited) circuited)

b) TL3 b) Serial

TC5,

contact:

TC6, TC8

TL3, TC1,

TE1, TE3

TC7 TE1 to

TE3 (SD

short-

c

circuited)

Parallel a) and b) Parallel

Parallel

contact: contact:

contact:

TC1, TC4 TC7 with TL4

with TL2 TE1 TL3, TC1, TE1 to TE3

to TE3 (SD TC7 TE1 to (SD

disconnected TE3 (SD disconnected

) disconnected )

)

IEC CDV 61058-1-2 © IEC 2025

Type of electronic Test conditions

d

switch

Functional test (7.104.1) Simulated test (7.104.2) Specific test condition

of end application

(Table 104 and Table

(7.104.3)

105)

Complet Contacts Complet Contacts Complet Contacts

e switch only e switch only e switch only

a

TL :

type of test load

TL1 : thermal current or maximum rated resistive current, if no thermal current is declared

TL2 : maximum rated resistive current

TL3 : rated load (7.2)

TL4 : declared specific load (7.2.5)

TC : type of test condition:

TC1 : increased-voltage test (17.5.1)

TC4 : accelerated speed test (17.5.4)

TC5 : manual functional test (17.5.5)

TC6 : manual functional test at minimum load - optional (17.5.6)

TC7 : limited number of operation test (17.5.7)

TC8 : endurance test (17.5.8)

TE : Type of evaluation test:

TE1 : functional compliance (17.6.1)

TE2 : thermal compliance (17.6.2)

TE3 : insulating compliance (17.6.3)

a

Tests which are not in the normal test sequence of Table 3 (such as TC3 and TC9) may be added to the test

sequence when required for the rating. These test are to be added before the test cycling test condition.

Switch designs not covered by the four construction of Table 3, test method(s) most suitable to the switch design

shall be applied.

b

SD : semiconductor device

c

The short circuit shall be performed in a way to allow the terminals and contacts and other parts designed for

the maximum rated current to be loaded with the maximum test current.

d

For combinations of SD and mechanical contacts, where the function of the SD and the mechanical contacts

are independent of each other, the requirements of IEC 61058-1-1 apply for the mechanical contacts.

e

Testing shall be completed using either method “a” or method “b”. The same method shall be used for both

“complete switch” and the “contacts only” testing. Switches with series and parallel contacts test shall add the

parallel contact test with the same method “a” or ”b” used for the series contact test. Testing to both method

“a” and method “b” is not required.

225 17.2 Electrical conditions

226 The switch shall be loaded as specified in Table 103, and connected in accordance with the

227 test circuit in 61058-1: —, Table 2.

228 a) Where, in IEC 61058-1:—, Table 2, an auxiliary switch (A) is symbolized in the test circuit,

229 the tests for the two ON-positions of the specimen (S) are performed on two separate sets

230 of test samples. The connection to the test load to be performed for the two tests is

231 symbolized in IEC 61058-1:—, Table 2 by an auxiliary switch A.

232 b) Multiway switches are loaded according to 61058-1:2016, Table 1. The load for the other

233 switch positions is that resulting from the loads necessary to achieve the conditions

234 specified above.

235 c) For circuits according to IEC 61058-1:—, 7.2.7 for specific lamp load, the connection and

236 test load are as specified by the manufacturer using the maximum occurring inrush current

237 at room temperature. For a specific lamp load, it is recommended that the specimen be

IEC CDV 61058-1-2 © IEC 2025

238 operated with loads that are used in the field rather than with synthetic loads. Forced cooling

239 of the specific lamp load may be applied in order to ensure cold resistance for each

240 operating cycle and shorten the test time.

241 d) No electrical load is applied during the endurance tests for switches classified to IEC 61058 -

242 1:—, 7.2.6 with a rating of 20 mA or less.

243 e) For electronic switches, the test circuit shall be as shown in IEC 61058-1:—, Figure 16. The

244 declared

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...