SIST EN 17530:2022+A1:2025

(Main)Railway applications - Interior glazing for rail vehicles

Railway applications - Interior glazing for rail vehicles

This document specifies the functional, performance, and quality requirements for the interior glazing of rail vehicles including type testing, routine testing, and inspection methods for high speed rail, heavy rail, urban rail vehicles including metro and tram applications.

This document is also applicable for tram vehicles.

Determination of the size, shape, orientation and position of interior glazing is outside the scope of this document.

This document does not specify requirements for the interfaces between the interior glazing and the vehicle. Accordingly, this document does not address issues relating to installation and structural integrity.

This document does not apply to interior glazing with a surface less than 0,02 m2 and also emergency device casings (e.g. cover sheets for emergency hammers, passenger alarm systems, etc).

This document does not apply to materials other than glazing materials.

For safety reasons, where the use of a specific type of glazing is specified that is not covered by this document (e.g. bullet proof glazing, fire proof glazing, etc.), this document does not apply.

Bahnanwendungen - Innenverglasung für Schienenfahrzeuge

!Dieses Dokument legt die funktionellen, Leistungs- und Qualitätsanforderungen für die Innenverglasung von Schienenfahrzeugen fest, einschließlich Typprüfungen, Serienprüfungen und Untersuchungsverfahren für Hochgeschwindigkeitsfahrzeuge, Vollbahnbahnfahrzeuge und Fahrzeuge städtischer Schienenbahnen einschließlich U Bahn- und Straßenbahnanwendungen.

Dieses Dokument ist auch für Straßenbahnfahrzeuge anwendbar."

Die Bestimmung von Größe, Form, Ausrichtung und Position von Innenverglasung fällt nicht in den Anwendungsbereich dieses Dokuments.

Dieses Dokument legt keine Anforderungen für die Schnittstellen zwischen der Innenverglasung und dem Fahrzeug fest. Folglich behandelt dieses Dokument keine Themen des Einbaus und der Struktureigenschaften.

Dieses Dokument ist nicht für Innenverglasung mit einer Oberfläche von weniger als 0,02 m2 und Noteinrichtungsgehäusen (z. B. Abdeckungen von Nothämmern, Fahrgastalarmsystemen usw.) anzuwenden.

!Dieses Dokument ist nicht für andere Materialien als Verglasungswerkstoffe anzuwenden.

Wenn aus Gründen der Sicherheit eine bestimmte Glasart erforderlich ist, die nicht in diesem Dokument behandelt wird (z. B. durchschusshemmende Verglasung oder Brandschutzverglasung), ist dieses Dokument nicht anwendbar."

Applications ferroviaires - Vitrage intérieur pour véhicules ferroviaires

!Le présent document spécifie les exigences fonctionnelles, de performance et de qualité du vitrage intérieur des véhicules ferroviaires, notamment les essais de type, les essais de série et les méthodes d'examen pour les applications de train à grande vitesse, de train lourd, et les trains urbains, dont les métros et les tramways.

Ce document s'applique également aux tramways."

La détermination des dimensions, de la forme, de l'orientation et de la position du vitrage intérieur ne relève pas du domaine d'application de la présente norme.

Le présent document ne spécifie pas les exigences relatives aux interfaces entre le vitrage intérieur et le véhicule. Par conséquent, le présent document ne traite pas des questions relatives à l'installation et à l'intégrité structurelle.

Le présent document ne s'applique pas au vitrage intérieur d'une surface inférieure à 0,02 m2 ni aux boîtiers des dispositifs de secours (par exemple, surface vitrée de marteaux brise-vitre, de systèmes d'alarme voyageurs, etc.).

!Le présent document ne s'applique pas aux matériaux autres que les matériaux de vitrage."

!Pour des raisons de sécurité, lorsque l’utilisation d'un type de vitrage particulier est spécifiée et n'est pas couverte par le présent document (par exemple, vitrage pare-balles, vitrage coupe-feu, etc.), ce dernier ne s'applique pas."

Železniške naprave - Notranja zasteklitev za železniška vozila (vključno z dopolnilom A1)

Ta dokument določa zahteve glede funkcionalnosti, učinkovitosti in kakovosti za notranjo zasteklitev železniških vozil, vključno s tipskim preskušanjem, rutinskim preskušanjem in metodami nadzora za železniška vozila visoke hitrosti, težka železniška vozila in vozila v mestnem železniškem prometu, vključno z metroji in tramvaji.

Ta dokument se uporablja tudi za tramvajska vozila.

Določanje velikosti, oblike, usmerjenosti in položaja notranje zasteklitve ne spada na področje uporabe tega dokumenta.

Ta dokument ne določa zahtev za vmesnike med notranjo zasteklitvijo in vozilom. Skladno s tem ta dokument ne obravnava vprašanj v zvezi z montažo in konstrukcijsko celovitostjo.

Ta dokument se ne uporablja za notranjo zasteklitev, katere površina je manjša od 0,02 m2, ali za ohišja naprav za uporabo v sili (npr. zaščitno steklo za kladiva za nujne primere, potniški alarmni sistemi itd.).

Ta dokument se ne uporablja za materiale, ki niso namenjeni za zasteklitev.

Iz varnostnih razlogov se ta dokument ne uporablja, če je določena uporaba posebne vrste zasteklitve, ki ni zajeta v tem dokumentu (npr. neprebojna zasteklitev, ognjevarna zasteklitev itd.).

General Information

- Status

- Published

- Publication Date

- 08-Jan-2025

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Jan-2025

- Due Date

- 13-Mar-2025

- Completion Date

- 09-Jan-2025

Relations

- Effective Date

- 01-Mar-2025

- Consolidates

SIST EN 17530:2022/kFprA1:2024 - Railway applications - Interior glazing for rail vehicles - Effective Date

- 01-Mar-2025

Overview

EN 17530:2022+A1:2024 is a CEN European standard that defines functional, performance and quality requirements for interior glazing in rail vehicles. It covers type testing, routine testing and inspection methods for glazing used in high-speed rail, heavy rail, urban rail (including metro and tram) applications. The standard applies to glazing materials (monolithic and laminated) but excludes very small items (surface < 0.02 m2), emergency device casings, non‑glazing materials and specialised safety glazing such as bullet‑proof or fire‑proof types.

Key topics and technical requirements

- Scope & exclusions: Interior glazing only; sizing/positioning, interface design and structural installation are outside scope. Special safety glazing types are not covered.

- Glazing types defined: Monolithic glass, laminated glass, toughened glass and mirror panels are described with reference to product standards.

- Dimensions & tolerances: Nominal thickness, width/length tolerances and flatness requirements reference EN 12150 and EN ISO 12543-5.

- Visual & optical requirements: Appearance defect classification, visual inspection procedures, optical distortion and transmittance testing (where required by technical specification).

- Mechanical performance: Impact resistance tests (hard object and optional soft body), fragmentation behaviour and fragmentation testing.

- Durability / ageing: Tests for laminated glass resistance to UV, high temperature and humidity.

- Testing regime:

- Type tests for design validation (dimensions, appearance, optical, transmittance, hard/soft impact, fragmentation, ageing).

- Routine tests during production (dimensions, appearance, optical distortion as applicable).

- Marking, storage and edge finishing: Requirements for marking of panels, storage of finished glazing and edge finishing standards for both monolithic and laminated products.

- Normative procedures & annexes: Includes test sample specifications and a summary of testing requirements.

Applications and who uses it

EN 17530 is used by:

- Glazing manufacturers to design and validate interior glazing components for trains, trams and metros.

- Vehicle designers and system integrators setting component specifications and procurement requirements.

- Testing laboratories performing type and routine tests to demonstrate compliance.

- Operators, maintenance and quality assurance teams ensuring delivered glazing meets optical, visual and mechanical standards. Typical applications include partition screens, draught screens, balustrade/banister infill panels, gangway glazing and display cover glazing inside rail vehicles.

Related standards

Key referenced standards include:

- EN 12150-1 (toughened glass), EN ISO 12543-5 (laminated glass), EN 15152 (windscreens), EN 45545 (fire protection), ISO 3538 (optical test methods) and ISO 3917 (ageing/weathering tests).

Keywords: EN 17530, interior glazing, rail vehicles, railway glazing standard, CEN, type testing, routine testing, impact resistance, laminated glass, monolithic glass.

Frequently Asked Questions

SIST EN 17530:2022+A1:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Interior glazing for rail vehicles". This standard covers: This document specifies the functional, performance, and quality requirements for the interior glazing of rail vehicles including type testing, routine testing, and inspection methods for high speed rail, heavy rail, urban rail vehicles including metro and tram applications. This document is also applicable for tram vehicles. Determination of the size, shape, orientation and position of interior glazing is outside the scope of this document. This document does not specify requirements for the interfaces between the interior glazing and the vehicle. Accordingly, this document does not address issues relating to installation and structural integrity. This document does not apply to interior glazing with a surface less than 0,02 m2 and also emergency device casings (e.g. cover sheets for emergency hammers, passenger alarm systems, etc). This document does not apply to materials other than glazing materials. For safety reasons, where the use of a specific type of glazing is specified that is not covered by this document (e.g. bullet proof glazing, fire proof glazing, etc.), this document does not apply.

This document specifies the functional, performance, and quality requirements for the interior glazing of rail vehicles including type testing, routine testing, and inspection methods for high speed rail, heavy rail, urban rail vehicles including metro and tram applications. This document is also applicable for tram vehicles. Determination of the size, shape, orientation and position of interior glazing is outside the scope of this document. This document does not specify requirements for the interfaces between the interior glazing and the vehicle. Accordingly, this document does not address issues relating to installation and structural integrity. This document does not apply to interior glazing with a surface less than 0,02 m2 and also emergency device casings (e.g. cover sheets for emergency hammers, passenger alarm systems, etc). This document does not apply to materials other than glazing materials. For safety reasons, where the use of a specific type of glazing is specified that is not covered by this document (e.g. bullet proof glazing, fire proof glazing, etc.), this document does not apply.

SIST EN 17530:2022+A1:2025 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17530:2022+A1:2025 has the following relationships with other standards: It is inter standard links to SIST EN 17530:2022, SIST EN 17530:2022/kFprA1:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 17530:2022+A1:2025 is associated with the following European legislation: EU Directives/Regulations: 2016/797/EU; Standardization Mandates: M/591. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17530:2022+A1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2025

Železniške naprave - Notranja zasteklitev za železniška vozila (vključno z

dopolnilom A1)

Railway applications - Interior glazing for rail vehicles

Bahnanwendungen - Innenverglasung für Schienenfahrzeuge

Applications ferroviaires - Vitrage intérieur pour véhicules ferroviaires

Ta slovenski standard je istoveten z: EN 17530:2022+A1:2024

ICS:

45.060.01 Železniška vozila na splošno Railway rolling stock in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17530:2022+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2024

EUROPÄISCHE NORM

ICS 45.060.01 Supersedes EN 17530:2022

English Version

Railway applications - Interior glazing for rail vehicles

Applications ferroviaires - Vitrage intérieur pour Bahnanwendungen - Innenverglasung für

véhicules ferroviaires Schienenfahrzeuge

This European Standard was approved by CEN on 27 March 2022 and includes Amendment 1 approved by CEN on 2 September

2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17530:2022+A1:2024 E

worldwide for CEN national Members.

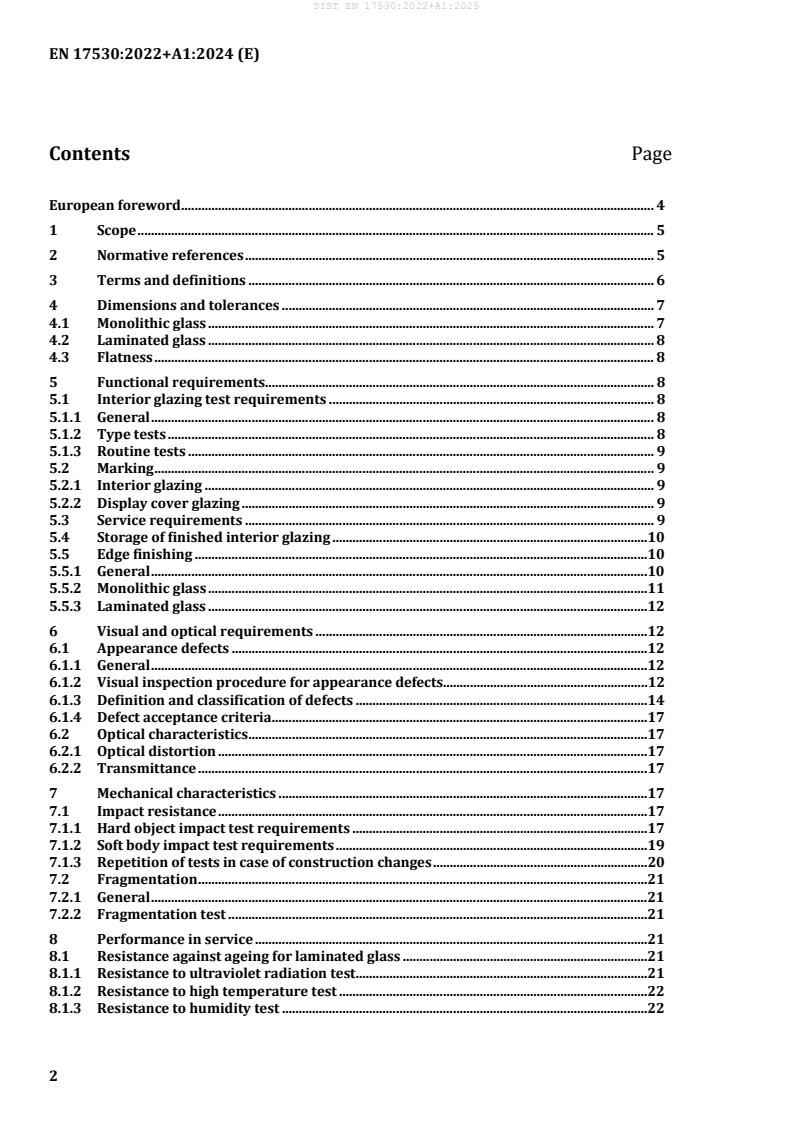

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Dimensions and tolerances . 7

4.1 Monolithic glass . 7

4.2 Laminated glass . 8

4.3 Flatness . 8

5 Functional requirements. 8

5.1 Interior glazing test requirements . 8

5.1.1 General . 8

5.1.2 Type tests . 8

5.1.3 Routine tests . 9

5.2 Marking . 9

5.2.1 Interior glazing . 9

5.2.2 Display cover glazing . 9

5.3 Service requirements . 9

5.4 Storage of finished interior glazing .10

5.5 Edge finishing .10

5.5.1 General .10

5.5.2 Monolithic glass .11

5.5.3 Laminated glass .12

6 Visual and optical requirements .12

6.1 Appearance defects .12

6.1.1 General .12

6.1.2 Visual inspection procedure for appearance defects.12

6.1.3 Definition and classification of defects .14

6.1.4 Defect acceptance criteria .17

6.2 Optical characteristics .17

6.2.1 Optical distortion .17

6.2.2 Transmittance .17

7 Mechanical characteristics .17

7.1 Impact resistance .17

7.1.1 Hard object impact test requirements .17

7.1.2 Soft body impact test requirements .19

7.1.3 Repetition of tests in case of construction changes .20

7.2 Fragmentation .21

7.2.1 General .21

7.2.2 Fragmentation test .21

8 Performance in service .21

8.1 Resistance against ageing for laminated glass .21

8.1.1 Resistance to ultraviolet radiation test .21

8.1.2 Resistance to high temperature test .22

8.1.3 Resistance to humidity test .22

Annex A (normative) Test samples (including mounting) . 23

A.1 Test sample properties . 23

A.2 Test sample for optical tests . 23

A.3 Test sample for mechanical tests . 23

A.4 Test sample for ageing tests . 23

Annex B (informative) Visual inspection procedure with a luminous board . 24

Annex C (normative) Summary of testing requirements . 26

Bibliography . 27

European foreword

This document (EN 17530:2022+A1:2024) has been prepared by Technical Committee CEN/TC 256

“Railway applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2025, and conflicting national standards shall be

withdrawn at the latest by June 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1, approved by CEN on 2 September 2024.

This document supersedes !EN 17530:2022".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

!This document specifies the functional, performance, and quality requirements for the interior glazing

of rail vehicles including type testing, routine testing, and inspection methods for high speed rail, heavy

rail, urban rail vehicles including metro and tram applications.

This document is also applicable for tram vehicles."

Determination of the size, shape, orientation and position of interior glazing is outside the scope of this

document.

This document does not specify requirements for the interfaces between the interior glazing and the

vehicle. Accordingly, this document does not address issues relating to installation and structural

integrity.

This document does not apply to interior glazing with a surface less than 0,02 m and also emergency

device casings (e.g. cover sheets for emergency hammers, passenger alarm systems, etc).

!This document does not apply to materials other than glazing materials.

For safety reasons, where the use of a specific type of glazing is specified that is not covered by this

document (e.g. bullet proof glazing, fire proof glazing, etc.), this document does not apply."

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

!EN 572-2:2012, Glass in building - Basic soda lime silicate glass products - Part 2: Float glass

EN 12150-1:2015+A1:2019, Glass in building - Thermally toughened soda lime silicate safety glass - Part

1: Definition and description

EN 15152, Railway applications - Windscreens for trains

EN 16584-1, Railway applications - Design for PRM use - General requirements - Part 1: Contrast

EN 45545-1, Railway applications - Fire protection on railway vehicles - Part 1: General

EN 45545-2, Railway applications - Fire protection on railway vehicles - Part 2: Requirements for fire

behavior of materials and components

EN ISO 12543-5:2021, Glass in building - Laminated glass and laminated safety glass - Part 5: Dimensions

and edge finishing (ISO 12543-5:2021)

ISO 3538, Road vehicles — Safety glazing materials — Test methods for optical properties

ISO 3917:2016, Road vehicles — Safety glazing materials — Test methods for resistance to radiation, high

temperature, humidity, fire and simulated weathering

ISO 7892, Vertical building elements — Impact resistance tests — Impact bodies and general test

procedures"

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 15152, EN 45545-1 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

draught screen

glazing used to separate passenger areas from vestibules and doorways

3.2

gangway area glazing

glazing located at the articulated assembly allowing movement between rail vehicles

3.3

display

hardware device or system that shows text and/or graphical information to the user

[SOURCE: EN 16186-3:2016+A1:2018, 3.8, modified – Note 1 to entry has been deleted]

3.4

banister infill panel

glazing used to fill the space between the handrail and the stairs

3.5

balustrade

infill glazing protecting the edge of a stair, landing or floor that may otherwise be open to passengers

3.6

mirror

glazing material used for the purpose of reflecting images

3.7

monolithic glass

single layer of glass that is constructed from material that has a consistent thickness throughout

3.8

laminated glass

glazing material consisting of two or more layers of glass held together by one or more interlayers

[SOURCE: ISO 3536:2016, 2.3]

3.9

toughened glass

glazing material consisting of a single layer of glass which has been subjected to special thermal or

chemical treatment to increase its mechanical strength and to condition its fragmentation upon

shattering

[SOURCE: ISO 3536:2016, 2.2, modified – “Safety” has been deleted and “after shatter” has been replaced

by “upon shattering”]

3.10

technical specification

document describing specific parameters and/or product requirements as an addition to the

requirements of this document

[SOURCE EN 15551:2017, 3.16]

3.11

glazing

transparent item used for the interior of railway vehicles constructed from glazing material

3.12

glazing material

material that allows the transmission of light

3.13

partition screen

!glazing used to separate or partition different areas"

4 Dimensions and tolerances

4.1 Monolithic glass

The nominal thicknesses and thickness tolerances for a single sheet of glass are those given in the relevant

product standards (see EN 12150-1:2015+A1:2019, Clause 4). The thickness of a pane shall be

determined as for the basic product.

The measurement shall be taken at the centres of the 4 sides, and away from the area of any tong marks

(see Figure 1), which may be present.

The tolerance values applied to the width (B) and length (H) for monolithic glass are shown in Table 1.

Key

1 deformation

2 maximum of 20 mm

3 tong mark

4 100 mm radius maximum are of optical distortion

Figure 1 — Tong marks

Table 1 — Tolerances on width, B, and length, H

Nominal dimension of Tolerance (mm)

side,

nominal glass nominal glass

B or H

thickness, ≤ 6 thickness, > 6

(mm)

0 < B or H ≤ 500 ±1,5 ±2,0

500 < B or H ≤ 1 000 ±1,5 ±2,0

1 000 < B or H ≤ 1 500 ±2,0 ±2,5

1 500 < B or H ≤ 2 000 ±2,5 ±3,0

2 000 < B or H ≤ 3 000 ±3,0 ±4,0

> 3 000 ±4,0 ±5,0

4.2 Laminated glass

!Laminated glass shall comply with the requirements of offset d as defined in EN ISO 12543-5:2021,

Clause 4. This is dependent on the thickness of each panel according to Table 1 of this document.

Each panel shall be compliant with the requirements of 4.1 of this document."

4.3 Flatness

Flatness for monolithic glass shall be according to EN 12150-1:2015+A1:2019, 6.3.

Flatness for laminated glass shall be defined in technical specification, otherwise bow shall be less than

or equal to 2 mm/m.

5 Functional requirements

!Deleted subclause"

5.1 Interior glazing test requirements

5.1.1 General

NOTE A summary of tests is given in Annex C.

5.1.2 Type tests

The interior glazing design shall be validated by satisfactory completion of the assessments and tests for:

— dimensions (see Clause 4);

— appearance (see 6.1);

— optical distortion, if required in the technical specification (see 6.2.1);

— transmittance, if required in the technical specification (see 6.2.2);

— hard object impact (see 7.1.1);

— soft body test, if required in the technical specification (see 7.1.2);

— fragmentation (7.2) ;

— ageing (see 8.1).

5.1.3 Routine tests

Routine testing shall be undertaken during production on all interior glazing for:

— dimensions (see Clause 4);

— appearance (see 6.1);

— optical distortion, if required in the technical specification (see 6.2.1);

— fragmentation (see 7.2).

Periodicity shall be determined in the technical specification.

5.2 Marking

5.2.1 Interior glazing

The interior glazing shall have a permanent marking that contains, as a minimum, the following

information:

— name or logo of glazing supplier;

— date of manufacturing: month and the last two numerals of the year or a code by which this

information can be identified;

— type of glass used, e.g. L = laminated, T = toughened;

The marking shall be visible regardless of the installation method used.

The minimum height of characters shall be 4 mm.

The positioning and colour of the marking should be defined in the technical specification.

5.2.2 Display cover glazing

The glazing used for covering displays shall have a permanent marking that contains the following

information:

— date of manufacturing: month and the last two numerals of the year or a code by which this

information can be identified;

— optionally, name or logo of the glazing supplier, if it does not obscure the information provided.

5.3 Service requirements

Interior glazing shall comply with the requirements set out in EN 45545-2.

Interior glazing shall comply with the contrast requirements set out in EN 16584-1.

Interior glazing shall be designed to withstand normal operational conditions.

NOTE 1 The operational conditions include induced static and dynamic loads, the environmental conditions

include temperature and humidity.

NOTE 2 Typically, reference is made to EN 50125-1 temperature classes T1, T2 or T3.

Requirements for use in a specific environment that are in addition to the requirements set out in this

document shall form part of the technical specification.

Specific requirements for mirrors shall be set out in the technical specification.

!The mechanical strength of the interior glazing for the following elements shall comply with both load

cases defined below:"

— draught screen;

— partition wall/screen;

— saloon door;

— gangway area glazing;

— compartment doors;

Load case 1: a concentrated perpendicular load of 2,5 kN applied for 60 s over an area of 100 mm x

100 mm at the centre of the glass.

Load case 2: a pressure of 2,5 kPa applied for 60 s over its entire surface plus a concentrated

perpendicular load of 0,8 kN applied over an area of 100 mm x 100 mm at the centre of the glass.

The load cases may be assessed by calculation.

The requirements for mechanical strength of the interior glazing with its installation for the following

elements, shall be defined in the technical specification:

— luggage rack;

— luggage stack;

— compartment screens;

— banister infill panels;

— balustrade;

— display cabinet;

— technical cabinet;

— advertising frames.

5.4 Storage of finished interior glazing

Interior glazing should be stored in a well ventilated area, protected from the weather and out of direct

sunlight.

5.5 Edge finishing

5.5.1 General

All exposed glass edges shall be arrised or bevelled to give smooth edge profiles and corners.

5.5.2 Monolithic glass

Depending on the shaping mode that is used, the requirements of one of the Figures 2 to 3 should be

followed. If not shown in the technical specification, edge shaping is of the “Seamed Edge (SE)” type.

The dimension c of Figures 2a and 2b shall comply with the following requirements:

— if d < 6 mm: 0,3 mm ≤ c ≤ 2 mm;

— if d ≥ 6 mm: 0,3 mm ≤ c ≤ 2,5 mm.

Figure 2b — Smoothed edge referred to as

Figure 2a — Seamed Edges (SE)

Industrial Flat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...