SIST EN 60099-4:2004/oprAB:2005

(Main)Surge arresters -- Part 4: Metal-oxide surge arresters without gaps for a.c. systems

Surge arresters -- Part 4: Metal-oxide surge arresters without gaps for a.c. systems

Work merged into 37/324/FDIS (pr=16386) * Standstill maintained

Überspannungsableiter -- Teil 4: Metalloxidableiter ohne Funkenstrecken für Wechselspannungsnetze

Parafoudres -- Partie 4: Parafoudres à oxyde métallique sans éclateurs pour réseaux à courant alternatif

Prenapetostni odvodniki - 4. del: Kovinsko-oksidni prenapetostni odvodniki brez iskrišč za sisteme z izmenično napetostjo

General Information

- Status

- Withdrawn

- Withdrawal Date

- 31-Dec-2006

- Technical Committee

- POD - Surge aresters

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 01-Jan-2007

- Due Date

- 01-Jan-2007

- Completion Date

- 01-Jan-2007

Relations

- Effective Date

- 07-Jun-2022

- Effective Date

- 01-Jan-2007

Overview

EN 60099-4:2004/prAB (CLC) - Amendment 1-f3 to IEC 60099-4 Ed.2.0 - covers metal‑oxide surge arresters without gaps for a.c. systems with particular focus on the short‑circuit test procedures and acceptance criteria. This amendment (originally an IEC committee draft for vote) clarifies test preparation, classification of arrester designs, initiation methods for short‑circuit current, asymmetry requirements, and evaluation criteria (mechanical projection and fire behaviour). Work has been merged into project 37/324/FDIS (pr=16386); the document was maintained as a draft during the circulated process.

Key topics and technical requirements

- Design classification: two design families are defined for short‑circuit testing:

- Design A - arrester with a continuous internal gas channel filling ≥ 50% of the internal non‑active volume (typical: porcelain or hollow composite housings).

- Design B - solid design with no or < 50% enclosed gas volume (typical: polymer‑housed units directly over MO resistors).

- Short‑circuit test scope: tests demonstrate that failure does not cause violent shattering of the housing. Tests use four short‑circuit current levels and supply frequency between 48 Hz and 62 Hz.

- Initiation methods:

- Fuse‑wire method (in contact with MO resistors, located in/near gas channel) for many Design A cases.

- Pre‑failing (electrical overloading) adopted as the preferred compromise for many Design B polymer housings to simulate realistic failure modes.

- Fuse wire sizing guidance: typical diameters ~0.2–0.5 mm, with special cases up to 1.5 mm to aid arc establishment.

- Asymmetry factor: full asymmetry requirement retained for Design A; for Design B the standard allows skipping the asymmetry factor because full‑length tests under symmetrical current are considered more representative.

- Test evaluation:

- Circle radius enlarged by 20% versus older criteria to reduce false failures from non‑violent part projection.

- Allowance of projected parts up to 60 g each (harmonised with internal‑arc substation standards).

- Self‑extinguishing: arrester must self‑extinguish open flames within 2 minutes; time between pre‑failing and short‑circuit limited to ≤ 15 minutes as a practical compromise.

Applications and who uses it

- Surge arrester manufacturers - design validation, type testing, conformity claims.

- High‑power test laboratories - test preparation, current initiation methods, and reporting.

- Utilities and substation designers - selection and specification of arresters for safety and fault‑containment.

- Certification bodies and test houses - compliance assessment against short‑circuit and safety criteria.

- R&D and design engineers - assessing housing materials (porcelain vs polymer), pressure‑relief design, and MO resistor homogeneity.

Related standards and references

- IEC 60099‑4 Ed.2 (base standard for MO surge arresters)

- IEC 62271‑200:2003 (metal‑enclosed substations - internal arc considerations)

- Future IEC 61330 (prefabricated substation internal arc)

- CIGRÉ report A3‑105 (test experiences & IEC review)

Keywords: surge arresters, metal‑oxide arresters, MO arresters, short‑circuit test, asymmetry factor, fuse wire, Design A, Design B, IEC 60099‑4, CLC.

Frequently Asked Questions

SIST EN 60099-4:2004/oprAB:2005 is a amendment published by the Slovenian Institute for Standardization (SIST). Its full title is "Surge arresters -- Part 4: Metal-oxide surge arresters without gaps for a.c. systems". This standard covers: Work merged into 37/324/FDIS (pr=16386) * Standstill maintained

Work merged into 37/324/FDIS (pr=16386) * Standstill maintained

SIST EN 60099-4:2004/oprAB:2005 is classified under the following ICS (International Classification for Standards) categories: 29.120.50 - Fuses and other overcurrent protection devices; 29.240.10 - Substations. Surge arresters. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 60099-4:2004/oprAB:2005 has the following relationships with other standards: It is inter standard links to SIST EN 60099-4:2005; is excused to SIST EN 60099-4:2005/A1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 60099-4:2004/oprAB:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

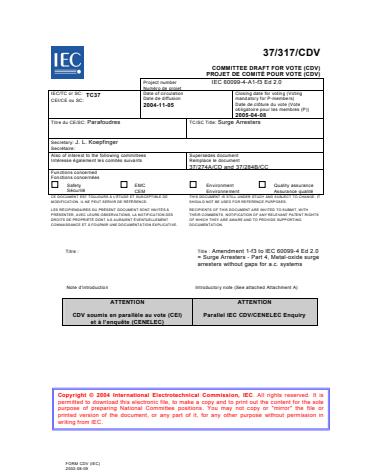

37/317/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJET DE COMITÉ POUR VOTE (CDV)

Project number IEC 60099-4-A1-f3 Ed 2.0

Numéro de projet

IEC/TC or SC: Date of circulation Closing date for voting (Voting

TC37

Date de diffusion mandatory for P-members)

CEI/CE ou SC:

Date de clôture du vote (Vote

2004-11-05

obligatoire pour les membres (P))

2005-04-08

Titre du CE/SC: Parafoudres TC/SC Title: Surge Arresters

Secretary: J. L. Koepfinger

Secrétaire:

Also of interest to the following committees Supersedes document

Intéresse également les comités suivants Remplace le document

37/274A/CD and 37/284B/CC

Functions concerned

Fonctions concernées

Safety EMC Environment Quality assurance

Sécurité

CEM Environnement Assurance qualité

CE DOCUMENT EST TOUJOURS À L'ÉTUDE ET SUSCEPTIBLE DE THIS DOCUMENT IS STILL UNDER STUDY AND SUBJECT TO CHANGE. IT

MODIFICATION. IL NE PEUT SERVIR DE RÉFÉRENCE. SHOULD NOT BE USED FOR REFERENCE PURPOSES.

LES RÉCIPIENDAIRES DU PRÉSENT DOCUMENT SONT INVITÉS À RECIPIENTS OF THIS DOCUMENT ARE INVITED TO SUBMIT, WITH

PRÉSENTER, AVEC LEURS OBSERVATIONS, LA NOTIFICATION DES THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS

DROITS DE PROPRIÉTÉ DONT ILS AURAIENT ÉVENTUELLEMENT OF WHICH THEY ARE AWARE AND TO PROVIDE SUPPORTING

CONNAISSANCE ET À FOURNIR UNE DOCUMENTATION EXPLICATIVE. DOCUMENTATION.

Titre : Title : Amendment 1-f3 to IEC 60099-4 Ed 2.0

= Surge Arresters - Part 4, Metal-oxide surge

arresters without gaps for a.c. systems

Note d'introduction Introductory note (See attached Attachment A)

ATTENTION ATTENTION

CDV soumis en parallèle au vote (CEI) Parallel IEC CDV/CENELEC Enquiry

et à l’enquête (CENELEC)

permitted to download this electronic file, to make a copy and to print out the content for the sole

purpose of preparing National Committee positions. You may not copy or "mirror" the file or

printed version of the document, or any part of it, for any other purpose without permission in

writing from IEC.

FORM CDV (IEC)

2002-08-09

60099-4-Amend 1/f3/Ed 2.0/CDV@IEC

-2-

Attachment A

Introduction

As a result of a decision during the IEC TC37 Kristiansand meeting in June 2000, the

short-circuit tests have become informative Annex O in 60099-4 Ed.1.2 and Annex N

in 60099-4 Ed. 2, respectively. As this situation is extremely unsatisfying, MT4

considered working on these tests as their main task.

More than 50% of time in all meetings was spent with discussion on short-circuit

testing in order to look at this from all possible views. A questionnaire to 51 high-

power labs worldwide was sent out that was answered by 18 labs and brought very

informative and helpful feedback.

Main reasons for missing international consensus so far

Many problems have risen in achieving a value of 2.5 for the "asymmetry factor" (i.e.

the ratio of first short-circuit current peak value to the r.m.s. value) on certain new

designs, which have become possible only by the use of polymeric housings. Designs

of concern are extremely tall arresters (unit length 2 m and above, which is not

possible with porcelain housings) and the various makes of polymer housed arresters

with housings directly applied onto the MO resistors, without any gas volume included

(designated as "Design B, Polymer Housed" arresters in the new short-circuit test

draft).

The first design requires very high testing voltages of 50 kV and more, which limits the

number of laboratories worldwide being able to run the short-circuit test close to only

one.

The problem with the other design mentioned is that the short-circuit current has

reasonably to be initiated by pre-failing (i.e. electrical overloading) and not by a fuse

wire, which would lead to too severe or to too simple test conditions, depending on

the location of the wire (within a drilled hole or along the outer surface of the MO

resistors). Pre-failing, however, usually does not result in the full asymmetry factor

and – in addition – poses problems with the test circuit, which must be able to provide

in succession a high pre-failing voltage (at limited current) and a high short-circuit

current. It also turned out to be a problem to re-ignite a short-circuit current arc if the

test sample was allowed to cool down after pre-failing.

All this had lead, for instance, to the compromise to allow tests at full voltage on

samples of only 20 kV rated voltage (see IEC 60099-4, Ed. 2, N.8.7.3), whereas it is

doubtful if these can really be representative for the short-circuit performance of a

high-voltage arrester of this design.

Thus four main concerns dominated the MT4 discussion over the past two years:

− classification of arrester designs (with/without enclosed gas volume, porcelain

housed, polymer housed)

− requirements on test currents (full asymmetry, no asymmetry)

− test procedure ("failure mode") (pre-failing, re-pre-failing, fuse wire method, fuse

wire position)

− test evaluation (diameter of test circle, weight of pieces outside the circle, self

extinguishing open flames)

60099-4-Amend 1/f3/Ed 2.0/CDV@IEC

-3-

MT4 now considers that satisfactory solutions have been found for all these problems.

Details are given below.

Classification of arrester designs

MT4 has defined two designs, designated as "Design A" and "Design B". They differ in

the relative volume of an enclosed gas channel that runs along the entire length of the

arrester.

In case of a breakdown/flashover in the gas channel, the arc will develop very quickly

over the entire length of the arrester. This may generate an intensive shock wave in

the gas channel, stressing the housing over its entire length and imposing high

requirements on pressure relief devices to open quickly. In case of a breakdown in the

solid material, the arc will develop more slowly.

"Design A" defines an arrester where the probability of a failure initiated in the gas

volume is much higher than in the solid material.

"Design B" defines a design with a higher probability of failure initiated in the solid

material.

There are also different considerations of porcelain and polymeric housings. All

porcelain housed arresters shall be tested in full length without any exception

because the brittleness of the material has to be taken into account, and in all cases

the fuse wire method is applied.

"Asymmetry factor"

Based on laboratory investigations, report A3-105 [1] of the CIGRÉ 2004 session

suggested skipping the asymmetry factor requirement for "Design B" arresters. This is

justified by the fact that a symmetrical current transfers more energy during the first 2

to 3 ms, the typical time of the housing to open for this design. Besides further

reasons that are mentioned in this report, one of the most important is that "Design B"

arresters can thus be tested in full length. Independent of the discussion if the

symmetrical current constitutes the most onerous stress or not (at least differences

will be marginal) this benefit countervails all possible trade-offs. There is consensus

within MT4 that a test at maybe only 95% of the most severe stress on the full arrester

is by far more meaningful than any test on a reduced 20-kV sample! Thus MT4

adopted this proposal for "Design B" arresters in the new short-circuit test draft.

For "Design A" arresters the asymmetry requirement was kept as it usually takes more

time than up to the first current peak until the arc has fully commutated to the outside

of the housing.

Test procedure ("failure mode")

There has been a lot of discussion over the last years if the short-circuit current

should be initiated by a fuse wire along the MO resistor surface, a fuse wire through a

drilled hole in the center of the MO resistors or by pre-failing (electrical overloading).

For porcelain housed arresters and polymer housed arresters with composite hollow

insulator ("Design A" arresters according to the new definition) it is mostly generally

agreed that the fuse wire in the gas volume along the surface of the resistor column

60099-4-Amend 1/f3/Ed 2.0/CDV@IEC

-4-

represents the most relevant failure scenario and at the same time the most severe

test condition as this design has mainly to prove its ability to handle the shock wave

caused by the internal arc.

For polymer housed arresters with housing directly applied onto the MO resistors

("Design B" arresters according to the new definition) it has often been claimed that

puncture of the MO resistors will not happen under overload conditions, but any proof

of this assertion is missing so far. It seems reasonable to assume that the better the

homogeneity of the MO material is the higher the probability of puncture anywhere in

the resistor (and thus also in or close to the center) will be. But there is no general

published knowledge about these dependencies. Improvement of the homogeneity is

a declared goal of MO development. It can thus not be taken for granted that even if

today many arresters do fail without puncture this will also be the case for future

designs.

A short-circuit test has to consider worst case scenarios. Thus a fuse wire along the

MO resistor surface can definitely not be accepted. On the other hand, a fuse wire

through holes drilled through the blocks is vice versa an obviously too harsh scenario,

as it can hardly be imagined that all MO resistors of a failing arrester will break by

puncture. It is therefore justified to specify the pre-failing method, which among the

alternatives mentioned above seems to be the most reasonable compromise with

regard to test severeness and realism, and it will automatically cover possible

influences of material homogeneity.

An exception had to be made only for porcelain housed arresters of "Design B", where

the pre-failing method could cause less severe test conditions (in case the arc

develops in the gas channel and not in the solid material as originally intended), a risk

that can be accepted for polymer housings but not for housings of brittle material.

Test evaluation

a) Parts allowed to be found outside the enclosure

Practice over decades has shown that in many cases one particular pass criterion of

the old "pressure relief test" was the reason for failing the short-circuit test, though the

arrester basically performed well. The requirement "no single part shall be found

outside the enclosure" is unrealistically hard, as very often parts of porcelain or MO

resistors just "jump" over the enclosure of the circle, without any dangerous kinetic

energy. This had just been taken into account in the short-circuit test of 60099-4, Ed.

2, Annex N, by allowing pieces of up to 10 g to be found outside the circle. This

requirement was again discussed in MT4, and the following is now specified:

- The diameter of the circle has been increased by 20 % compared with the old

requirement. Justification: it was observed in many cases that after non-violent

thermal breaking of the porcelain housing the active part, completely intact, fell down

such that its top end collided with the enclosure (which has a radius equal to the

arrester height according to the former requirements) and some parts of its top end

just jumped outside the enclosure. Though in these cases the short-circuit

performance was good, the arrester did not pass the test. In order to avoid this

conflict the radius of the enclosure was chosen to be 20% larger than the arrester

height.

- Parts of up to 60 g are allowed to be found outside the circle. Justification: the IEC 62271-

200:2003 for metal-enclosed substations and the future IEC 61330 for medium-voltage/low-

60099-4-Amend 1/f3/Ed 2.0/CDV@IEC

-5-

voltage prefabricated substations explicitly deal with internal arc testing with respect to the

safety of personnel and public in case of failures within such stations. Two levels of

accessibility have been adopted, where the accessibility B refers to stations that are directly

accessible to the public. Although these standards deal with the safety of persons and are,

therefore very restrictive concerning possibly arising danger, they permit projection of parts

out of the station up to a weight of 60 g each as compared to the value of 10 g specified in

IEC 60099-4, Ed. 2. Furthermore, it would be of advantage if all standards dealing with

similar parts of a power system specify similar requirements. MT4, therefore, decided that

the permitted value of 60 g per projected part is also adopted for the short-circuit testing of

surge arresters.

b) Ability to self extinguish open flames

As one of the requirements, the arrester shall be able to self extinguish open flames

within 2 minutes. The actual time interval between pre-failing and the short-circuit test

may influence this test result. It must be pointed out that the specified time interval of

≤ 15 minutes is a compromise, in order to enable as many high-power labs as

possible to run the short-circuit tests.

15 minutes are considered a well-balanced compromise, based on the feedback to the

questionnaire sent out to the high-power labs, but even this is a hard requirement to

many labs. The question if the 15 minutes may ensure that designs prone to catching

fire will always be inflamed cannot be finally answered until more test experience has

been gained. MT4 feels that further investigations on this issue should be performed

in the near future. This will take longer time, however, and should not be a reason to

further delay publication of a mandatory short-circuit test procedure.

Literature

[1] R.P.P. Smeets, H. Barts, W. A. van der Linden, L. Stenström

Modern ZnO Surges Arresters Under Short-Circuit Current Stresses: Test

Experiences and Critical Review of the IEC Standard

CIGRÉ 2004 Session, Report A3-105

60099-4-Amend 1/f3/Ed 2.0/CDV@IEC

-6-

The following material is to replace that in Clause 8.7 of 60099-4 Ed 2.0

8.7 Short-circuit tests

8.7.1 General

Arresters, for which a short-circuit rating is claimed by the manufacturer, shall be tested in

accordance with this sub-clause. The test shall be performed in order to show that an

arrester failure does not result in a violent shattering of the arrester housing, by testing each

arrester type with four values of short-circuit currents. If the arrester is equipped with some

other arrangement as a substitute for a conventional pressure relief device, this arrangement

shall be included in the test.

The frequency of the short-circuit test current supply shall be between 48 Hz and 62 Hz.

With respect to the short-circuit current performance it is important to distinguish

between 2 designs of surge arresters as follows:

• “Design A” arresters have a design in which a gas channel runs along the entire

length of the arrester unit and fills ≥ 50 % of the internal volume not occupied by

the internal active parts.

• “Design B” arresters are of a solid design with no enclosed volume of gas or

having an internal gas volume filling < 50 % of the internal volume not occupied by

the internal active parts.

NOTE 1: Typically, “Design A” arresters are porcelain housed arresters, or polymer housed arresters

with a composite hollow insulator which are equipped either with pressure relief devices, or

with prefabricated weak spots in the composite housing which burst or flip open at a

specified pressure, thereby decreasing the internal pressure.

Typically, “Design B” arresters do not have any pressure relief device and are of a solid

type with no enclosed volume of gas. If the resistors fail electrically, an arc is established

within the arrester. This arc causes heavy evaporation and possibly burning of the housing

and/or internal material. These arresters’ short-circuit performance is determined by their

ability to control the cracking or tearing open of the housing due to the arc effects, thereby

avoiding a violent shattering.

NOTE 2: "Active parts" in this context are the non-linear metal-oxide resistors and any metal spacers

directly in series with them.

Depending on the type of arrester and test voltage, different requirements apply with

regard to number of test samples, initiation of short-circuit current, and amplitude of

the first short-circuit current peak. Table 1 shows a summary of these requirements

which are further explained in the following subclauses.

NOTE After agreement between the manufacturer and the purchaser the test procedure could

be modified to e.g. include a number of reclosing operations. For such special tests

the procedure and acceptance criteria should be agreed upon between the

manufacturer and the purchaser.

8.7.2 Preparation of the test samples

60099-4-Amend 1/f3/Ed 2.0/CDV@IEC

-7-

For the high-current tests the test samples shall be the longest arrester unit used for the

design with the highest rated voltage of that unit used for each different arrester design.

For the low current test the test sample shall be an arrester unit of any length with the highest

rated voltage of that unit used for each different arrester design.

NOTE Figure 1 shows different examples of arrester units.

In case a fuse wire is required the fuse wire material and size shall be selected so that the

wire will melt within the first 30 electrical degrees after the initiation of the test current.

NOTE In order to have melting of the fuse wire within the specified time limit and create

suitable condition for arc ignition, it is generally recommended to use a fuse wire of a

low resistance material (for example copper, aluminum or silver) with a diameter of

.

about 0,2 mm to 0,5 mm Higher fuse wire cross-sections are applicable to surge

arrester units prepared for higher short circuit test current. When there are problems in

initiating the arc a fuse wire of larger size, but with diameter not exceeding 1,5 mm,

may be used since it will help arc establishment. In such case a specially prepared

fuse wire, having larger cross section along most of the arrester height with a short

thinner section in the middle, may also help.

8.7.2.1 “Design A” arresters

The samples shall be prepared with means for conducting the required short-circuit

current by a fuse wire. The fuse wire shall be in direct contact with the MO resistors

and be positioned within or as close as possible to the gas channel, and shall

short-circuit the entire internal active part. The actual location of the fuse wire in the

test shall be reported in the test report.

No differences with regard to polymer housings or porcelain housings are made in the

preparation of the test samples. However, differences partly apply in the test procedure (see.

8.7.4.2). In this case, “Design A” arresters with polymeric sheds outside porcelain or other

hollow insulators, which are as brittle as ceramics, shall be considered and tested as

porcelain housed arresters.

8.7.2.2 “Design B” arresters

“Design B” arresters with polymeric sheds outside porcelain or other mechanically supporting

structures, which are as brittle as ceramics, shall be considered and tested as porcelain

housed arresters.

8.7.2.2.1 Polymer housed arresters

No special preparation is necessary; standard arrester units shall be used. The arrester units

shall be electrically pre-failed with a power frequency overvoltage. The overvoltage shall be

run on completely assembled test units. It is not allowed to open the arrester units between

pre-failing and the actual short-circuit current test.

The overvoltage given by the manufacturer shall be a voltage exceeding 1,15 times

U . The voltage shall cause the arrester to fail in a time within 5 +/- 3 minutes. The

c

resistors are considered to be failed when the voltage across the resistors falls below

10 % of the originally applied voltage. The short-circuit current of the pre-failing test

circuit shall not exceed 30 A.

The time between pre-failure and the rated short-circuit current test shall not exceed 15

minutes.

60099-4-Amend 1/f3/Ed 2.0/CDV@IEC

-8-

NOTE The pre-failure can be achieved by either applying a voltage source or a current

source to the samples.

VOLTAGE SOURCE METHOD: The initial current should typically be in the range 5

to 10 mA/cm . The short-circuit current should typically be between 1 A and 30 A.

The voltage source need not to be adjusted after the initial setting, although small

adjustments might be necessary in order to fail the resistors in the given time range.

CURRENT SOURCE METHOD: Typically a current density of around 15 mA/cm with

a variation of +/- 50%, will result in failure of the resistors in the given time range.

The short-circuit current shoul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...