SIST-TP CEN/TR 1459-6:2015

(Main)Rough-terrain trucks - Safety requirements and verification - Part 6: Application of EN ISO 13849-1 to slewing and non-slewing variable-reach rough-terrain truck

Rough-terrain trucks - Safety requirements and verification - Part 6: Application of EN ISO 13849-1 to slewing and non-slewing variable-reach rough-terrain truck

This Technical Report describes the risk assessment methodology followed to determine the Performance Level required (PLr), as defined in EN ISO 13849-1:2008, for specific safety related parts of control system (SRP/CS) of rough-terrain variable-reach trucks covered by prEN 1459-1, EN 1459-2 and EN 1459-3.

This Technical Report does not apply to SRP/CS that includes no electrical/electronic components.

NOTE It is the intention of CEN TC150 WG2 to use the same methodology to develop future standards (e.g. further parts of EN 1459).

Chariots tout-terrain - Prescriptions de sécurité et vérification - Partie 6: Application de l'EN ISO 13849-1 aux chariots tout-terrain à portée variable rotatifs et non-rotatifs

Vozila za talni transport - Terenska vozila - Varnostne zahteve in preverjanje - 6. del: Uporaba EN ISO 13849-1 za terenska vozila z vrtljivim in nevrtljivim mehanizmom za dviganje s spremenljivim dosegom

To tehnično poročilo opisuje metodologijo za oceno tveganja, ki se uporablja za določitev zahtevane ravni delovanja (PLr), kot je določena v standardu EN ISO 13849-1:2008, za posebne z varnostjo povezane dele krmilnih sistemov (SRP/CS) vozil za talni transport z mehanizmom za dviganje s spremenljivim dosegom, ki jih zajemajo standardi prEN 1459-1, prEN 1459-2 in prEN 1459-3.

To tehnično poročilo se ne uporablja za z varnostjo povezane dele krmilnih sistemov, ki nimajo električnih/elektronskih sestavnih delov.

OPOMBA: Cilj CEN TC150 WG2 je uporabljati enake metode za razvoj prihodnjih standardov (npr. nadaljnji deli standarda EN 1459).

General Information

- Status

- Published

- Public Enquiry End Date

- 07-Jun-2015

- Publication Date

- 05-Oct-2015

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 17-Sep-2015

- Due Date

- 22-Nov-2015

- Completion Date

- 06-Oct-2015

Overview

SIST-TP CEN/TR 1459-6:2015 is a Technical Report that explains how to apply EN ISO 13849-1:2008 to slewing and non-slewing variable-reach rough-terrain trucks. Its primary aim is to document the risk assessment methodology used to determine the Performance Level required (PLr) for safety-related parts of control systems (SRP/CS) referenced in prEN 1459‑1, EN 1459‑2 and EN 1459‑3. The report clarifies rationale and procedures for establishing minimum PLs for electrical/electronic SRP/CS (it does not apply where SRP/CS contain no electrical/electronic components).

Key topics and technical requirements

- Risk assessment methodology: Step‑by‑step approach for identifying hazards, estimating and evaluating risk, and deriving required PLr for SRP/CS.

- Risk assessment process elements:

- Determination of machine limits and operating conditions

- Hazard identification (aligned with EN ISO 12100 principles)

- Risk estimation and evaluation for different persons (operator, co‑worker, bystander)

- Performance Level determination: Use of EN ISO 13849‑1 criteria to translate risk priority into required PL for control functions.

- Risk Priority Number (RPN) approach: Numerical weighting and mapping of RPNs to Performance Levels (informative annexes provide the weighting and conversion guidance).

- Extensive annex material: Informative annexes include hazard lists, RPN numerical tables, PL correlation tables and comprehensive risk estimation examples covering many operating scenarios.

Practical applications

- Design and validation of SRP/CS: OEMs and system integrators can use the methodology to justify the required safety architecture and diagnostic measures for electrical/electronic control components.

- Type‑C standard implementation: Enables consistent application of EN ISO 13849‑1 within the EN 1459 series for variable‑reach rough‑terrain trucks.

- Conformity and verification: Useful for safety engineers, notified bodies and test laboratories performing verification, certification or conformity assessments against EN 1459 parts.

- Standards development: The methodology is intended as a template for future EN 1459 parts and can be reused by other technical committees developing machine‑specific standards.

Who should use this standard

- Manufacturers of rough‑terrain trucks and attachments

- Functional safety engineers and control system designers

- Certification bodies, test labs and safety assessors

- Standards committees drafting machine‑specific PL requirements

Related standards

- EN ISO 13849‑1:2008 (Safety of machinery - Safety‑related parts of control systems - Performance levels)

- EN ISO 12100 (general principles for hazard identification and risk assessment)

- prEN 1459‑1, EN 1459‑2, EN 1459‑3 (parts of the EN 1459 series on variable‑reach rough‑terrain trucks)

Keywords: rough‑terrain trucks, variable‑reach, slewing, EN ISO 13849‑1, Performance Level, SRP/CS, risk assessment, EN 1459.

Frequently Asked Questions

SIST-TP CEN/TR 1459-6:2015 is a technical report published by the Slovenian Institute for Standardization (SIST). Its full title is "Rough-terrain trucks - Safety requirements and verification - Part 6: Application of EN ISO 13849-1 to slewing and non-slewing variable-reach rough-terrain truck". This standard covers: This Technical Report describes the risk assessment methodology followed to determine the Performance Level required (PLr), as defined in EN ISO 13849-1:2008, for specific safety related parts of control system (SRP/CS) of rough-terrain variable-reach trucks covered by prEN 1459-1, EN 1459-2 and EN 1459-3. This Technical Report does not apply to SRP/CS that includes no electrical/electronic components. NOTE It is the intention of CEN TC150 WG2 to use the same methodology to develop future standards (e.g. further parts of EN 1459).

This Technical Report describes the risk assessment methodology followed to determine the Performance Level required (PLr), as defined in EN ISO 13849-1:2008, for specific safety related parts of control system (SRP/CS) of rough-terrain variable-reach trucks covered by prEN 1459-1, EN 1459-2 and EN 1459-3. This Technical Report does not apply to SRP/CS that includes no electrical/electronic components. NOTE It is the intention of CEN TC150 WG2 to use the same methodology to develop future standards (e.g. further parts of EN 1459).

SIST-TP CEN/TR 1459-6:2015 is classified under the following ICS (International Classification for Standards) categories: 53.060 - Industrial trucks. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST-TP CEN/TR 1459-6:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2015

Vozila za talni transport - Terenska vozila - Varnostne zahteve in preverjanje - 6.

del: Uporaba EN ISO 13849-1 za terenska vozila z vrtljivim in nevrtljivim

mehanizmom za dviganje s spremenljivim dosegom

Rough-terrain trucks - Safety requirements and verification - Part 6: Application of EN

ISO 13849-1 to slewing and non-slewing variable-reach rough-terrain truck

Ta slovenski standard je istoveten z: CEN/TR 1459-6:2015

ICS:

53.060 Industrijski tovornjaki Industrial trucks

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL REPORT

CEN/TR 1459-6

RAPPORT TECHNIQUE

TECHNISCHER BERICHT

August 2015

ICS 53.060

English Version

Rough-terrain trucks - Safety requirements and verification –

Part 6: Application of EN ISO 13849-1 to slewing and non-

slewing variable-reach rough-terrain truck

This Technical Report was approved by CEN on 6 July 2015. It has been drawn up by the Technical Committee CEN/TC 150.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United

Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2015 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 1459-6:2015 E

worldwide for CEN national Members.

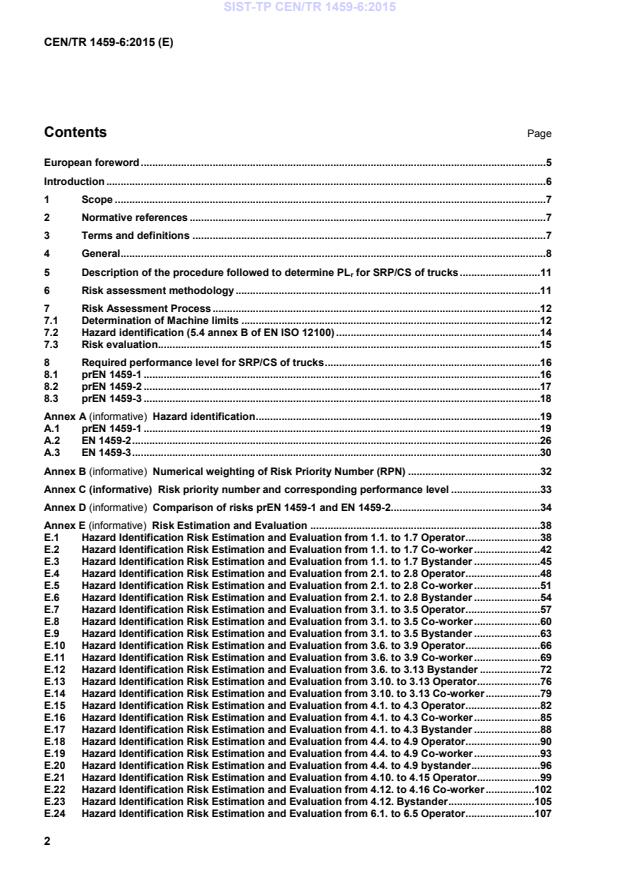

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 General . 8

5 Description of the procedure followed to determine PL for SRP/CS of trucks .11

r

6 Risk assessment methodology .11

7 Risk Assessment Process .12

7.1 Determination of Machine limits .12

7.2 Hazard identification (5.4 annex B of EN ISO 12100) .14

7.3 Risk evaluation.15

8 Required performance level for SRP/CS of trucks .16

8.1 prEN 1459-1 .16

8.2 prEN 1459-2 .17

8.3 prEN 1459-3 .18

Annex A (informative) Hazard identification .19

A.1 prEN 1459-1 .19

A.2 EN 1459-2 .26

A.3 EN 1459-3 .30

Annex B (informative) Numerical weighting of Risk Priority Number (RPN) .32

Annex C (informative) Risk priority number and corresponding performance level .33

Annex D (informative) Comparison of risks prEN 1459-1 and EN 1459-2.34

Annex E (informative) Risk Estimation and Evaluation .38

E.1 Hazard Identification Risk Estimation and Evaluation from 1.1. to 1.7 Operator .38

E.2 Hazard Identification Risk Estimation and Evaluation from 1.1. to 1.7 Co-worker .42

E.3 Hazard Identification Risk Estimation and Evaluation from 1.1. to 1.7 Bystander .45

E.4 Hazard Identification Risk Estimation and Evaluation from 2.1. to 2.8 Operator .48

E.5 Hazard Identification Risk Estimation and Evaluation from 2.1. to 2.8 Co-worker .51

E.6 Hazard Identification Risk Estimation and Evaluation from 2.1. to 2.8 Bystander .54

E.7 Hazard Identification Risk Estimation and Evaluation from 3.1. to 3.5 Operator .57

E.8 Hazard Identification Risk Estimation and Evaluation from 3.1. to 3.5 Co-worker .60

E.9 Hazard Identification Risk Estimation and Evaluation from 3.1. to 3.5 Bystander .63

E.10 Hazard Identification Risk Estimation and Evaluation from 3.6. to 3.9 Operator .66

E.11 Hazard Identification Risk Estimation and Evaluation from 3.6. to 3.9 Co-worker .69

E.12 Hazard Identification Risk Estimation and Evaluation from 3.6. to 3.13 Bystander .72

E.13 Hazard Identification Risk Estimation and Evaluation from 3.10. to 3.13 Operator .76

E.14 Hazard Identification Risk Estimation and Evaluation from 3.10. to 3.13 Co-worker .79

E.15 Hazard Identification Risk Estimation and Evaluation from 4.1. to 4.3 Operator .82

E.16 Hazard Identification Risk Estimation and Evaluation from 4.1. to 4.3 Co-worker .85

E.17 Hazard Identification Risk Estimation and Evaluation from 4.1. to 4.3 Bystander .88

E.18 Hazard Identification Risk Estimation and Evaluation from 4.4. to 4.9 Operator .90

E.19 Hazard Identification Risk Estimation and Evaluation from 4.4. to 4.9 Co-worker .93

E.20 Hazard Identification Risk Estimation and Evaluation from 4.4. to 4.9 bystander .96

E.21 Hazard Identification Risk Estimation and Evaluation from 4.10. to 4.15 Operator .99

E.22 Hazard Identification Risk Estimation and Evaluation from 4.12. to 4.16 Co-worker .102

E.23 Hazard Identification Risk Estimation and Evaluation from 4.12. Bystander .105

E.24 Hazard Identification Risk Estimation and Evaluation from 6.1. to 6.5 Operator .107

E.25 Hazard Identification Risk Estimation and Evaluation from 6.1. to 6.5 Co-worker . 110

E.26 Hazard Identification Risk Estimation and Evaluation from 6.4. to 6.9 Bystander . 113

E.27 Hazard Identification Risk Estimation and Evaluation from 6.6. to 6.10 Operator . 116

E.28 Hazard Identification Risk Estimation and Evaluation from 6.6. to 6.10 Co-worker . 119

E.29 Hazard Identification Risk Estimation and Evaluation from 6.10. to 6.15 Bystander . 122

E.30 Hazard Identification Risk Estimation and Evaluation from 6.11. to 6.14 Operator . 125

E.31 Hazard Identification Risk Estimation and Evaluation from 6.11. to 6.14 Co-worker . 128

E.32 Hazard Identification Risk Estimation and Evaluation from 6.15. to 6.18 Operator . 131

E.33 Hazard Identification Risk Estimation and Evaluation from 6.15. to 6.18 Co-worker . 134

E.34 Hazard Identification Risk Estimation and Evaluation from 7.1. to 7.10 Operator . 137

E.35 Hazard Identification Risk Estimation and Evaluation from 7.1. to 7.5 Co-worker . 140

E.36 Hazard Identification Risk Estimation and Evaluation from 7.1. to 7.8 Bystander . 143

E.37 Hazard Identification Risk Estimation and Evaluation from 7.6. to 7.10 Co-worker . 146

E.38 Hazard Identification Risk Estimation and Evaluation from 8.1. to 8.7 Operator . 149

E.39 Hazard Identification Risk Estimation and Evaluation from 8.1. to 8.4 Co-worker . 152

E.40 Hazard Identification Risk Estimation and Evaluation from 8.2. to 8.5 Bystander . 155

E.41 Hazard Identification Risk Estimation and Evaluation from 8.8 to 8.12 Operator . 158

E.42 Hazard Identification Risk Estimation and Evaluation from 8.5. to 8.8 Co-worker . 161

E.43 Hazard Identification Risk Estimation and Evaluation from 8.9. to 8.12 Co-worker . 164

E.44 Hazard Identification Risk Estimation and Evaluation from 9.1. to 9.6 Co-worker . 167

E.45 Hazard Identification Risk Estimation and Evaluation from 9.1. to 9.4 Bystander . 170

E.46 Hazard Identification Risk Estimation and Evaluation 10.2 Operator . 173

E.47 Hazard Identification Risk Estimation and Evaluation from 10.1 to 10.2 Co-worker . 174

E.48 Hazard Identification Risk Estimation and Evaluation 10.2 Bystander . 177

E.49 Hazard Identification Risk Estimation and Evaluation from 18.1 to 18.4 Operator . 180

E.50 Hazard Identification Risk Estimation and Evaluation from 18.13 to 18.17 Co-worker . 183

E.51 Hazard Identification Risk Estimation and Evaluation from 18.13 to 18.21 Bystander . 186

E.52 Hazard Identification Risk Estimation and Evaluation from 18.4 to 18.8 Operator . 189

E.53 Hazard Identification Risk Estimation and Evaluation from 18.18 to 18.22 Co-worker . 192

E.54 Hazard Identification Risk Estimation and Evaluation from 18.9 to 18.12 Operator . 195

E.55 Hazard Identification Risk Estimation and Evaluation from 18.13 to 18.16 Operator . 198

E.56 Hazard Identification Risk Estimation and Evaluation from 19.1 to 19.4 Operator . 201

E.57 Hazard Identification Risk Estimation and Evaluation from 19.9 to 19.13 Co-worker . 204

E.58 Hazard Identification Risk Estimation and Evaluation from 19.10 to 19.13 Bystander . 207

E.59 Hazard Identification Risk Estimation and Evaluation from 19.5 to 19.16 Operator . 210

E.60 Hazard Identification Risk Estimation and Evaluation from 19.17 to 19.20 Operator . 213

E.61 Hazard Identification Risk Estimation and Evaluation from 20.1 to 20.5 Operator . 216

E.62 Hazard Identification Risk Estimation and Evaluation from 20.1 to 20.5 Co-worker . 219

E.63 Hazard Identification Risk Estimation and Evaluation from 20.1 to 20.5 Bystander . 222

E.64 Hazard Identification Risk Estimation and Evaluation from 20.6 to 20.10 Operator . 225

E.65 Hazard Identification Risk Estimation and Evaluation from 20.6 to 20.10 Co-worker . 228

E.66 Hazard Identification Risk Estimation and Evaluation from 20.6 to 20.10 Bystander . 231

E.67 Hazard Identification Risk Estimation and Evaluation from 20.11 to 20.15 Operator . 234

E.68 Hazard Identification Risk Estimation and Evaluation from 20.11 to 20.15 Co-worker . 237

E.69 Hazard Identification Risk Estimation and Evaluation from 20.11 to 20.15 Bystander . 240

E.70 Hazard Identification Risk Estimation and Evaluation from 21.1 to 21.5 Operator . 243

E.71 Hazard Identification Risk Estimation and Evaluation from 21.1 to 21.4 Co-worker . 246

E.72 Hazard Identification Risk Estimation and Evaluation from 21.1 to 21.3 Bystander . 249

E.73 Hazard Identification Risk Estimation and Evaluation from 21.6 to 21.9 Operator . 252

E.74 Hazard Identification Risk Estimation and Evaluation from 21.5 to 21.9 Co-worker . 255

E.75 Hazard Identification Risk Estimation and Evaluation from 21.4 to 21.6 Bystander . 258

E.76 Hazard Identification Risk Estimation and Evaluation from 22a.1 to 22a.5 Operator . 261

E.77 Hazard Identification Risk Estimation and Evaluation from 22a.1 to 22a.5 Co-worker . 264

E.78 Hazard Identification Risk Estimation and Evaluation from 22a.1 to 22a.4 Bystander . 267

E.79 Hazard Identification Risk Estimation and Evaluation from 22a.6 to 22a.10 Operator . 270

E.80 Hazard Identification Risk Estimation and Evaluation from 22a.6 to 22a.10 Co-worker . 273

E.81 Hazard Identification Risk Estimation and Evaluation from 22a.7 to 22a.10 Bystander . 276

E.82 Hazard Identification Risk Estimation and Evaluation from 22b.1 to 22b.4 Operator . 279

E.83 Hazard Identification Risk Estimation and Evaluation from 22b.1 to 22b.4 Co-worker . 282

E.84 Hazard Identification Risk Estimation and Evaluation from 22b.7 to 22b.9 Bystander . 285

E.85 Hazard Identification Risk Estimation and Evaluation from 22b.5 to 22b.8 Operator . 288

E.86 Hazard Identification Risk Estimation and Evaluation from 22b.5 to 22b.8 Co-worker.291

E.87 Hazard Identification Risk Estimation and Evaluation from 22b.10 to 22b.12 Bystander .294

E.88 Hazard Identification Risk Estimation and Evaluation from 22b.9 to 22b.12 Operator .297

E.89 Hazard Identification Risk Estimation and Evaluation from 22b.9 to 22b.13 Co-worker.300

E.90 Hazard Identification Risk Estimation and Evaluation from 22b.13 to 22b.15 Operator .303

E.91 Hazard Identification Risk Estimation and Evaluation from 22b.14 to 22b.18 Co-worker .306

E.92 Hazard Identification Risk Estimation and Evaluation from 22b.16 to 22b.18 Operator .309

E.93 Hazard Identification Risk Estimation and Evaluation from 22c.1 to 22c.3 Operator.312

E.94 Hazard Identification Risk Estimation and Evaluation from 22c.1 to 22c.3 Co-worker .315

E.95 Hazard Identification Risk Estimation and Evaluation from 22c.3 to 22c.4 Bystander .318

E.96 Hazard Identification Risk Estimation and Evaluation from 22c.4 to 22c.6 Operator.321

E.97 Hazard Identification Risk Estimation and Evaluation from 22c.4 to 22c.6 Co-worker .324

E.98 Hazard Identification Risk Estimation and Evaluation from 22d.1 to 22d.6 Operator .327

E.99 Hazard Identification Risk Estimation and Evaluation from 22d.1 to 22d.6 Co-worker.330

E.100 Hazard Identification Risk Estimation and Evaluation from 22d.3 to 22d.4 Bystander .333

Bibliography .342

European foreword

This document (CEN/TR 1459-6:2015) has been prepared by Technical Committee CEN/TC 150 “Industrial

Trucks - Safety”, the secretariat of which is held by BSI.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights.

EN 1459 consists of the following parts, under the general title Rough-terrain trucks — Safety requirements

and verification:

— Part 1: Variable-reach trucks

— Part 2: Slewing variable-reach trucks

— Part 3: Interface between the variable-reach truck and the work platform

— Part 4: Additional requirements for variable reach trucks handling freely suspended loads

— Part 5: Additional requirements for attachments and attachment interface

— Part 6: Application of EN ISO 13849-1 to slewing and non-slewing variable-reach rough-terrain trucks

Introduction

This Technical Report has been prepared to explain the rationale used to determine the minimum required

Performance Levels for rough terrain variable reach trucks as listed in EN 1459 series.

It is intended to provide solid basis to the Performance Level Required (PL ) required for the Safety Related

r

Part of Control System (SRP/CS) referred to in prEN 1459-1, EN 1459-2 and EN 1459-3. The PL have been

r

defined by using approaches from appropriate standards for safety of machinery and proven general

principles for design.

The methodology described in this Technical Report may be used by other Technical Committees to assess

the risk and determine PL for machines covered by other type C-standards.

r

1 Scope

This Technical Report describes the risk assessment methodology followed to determine the

Performance Level required (PL), as defined in EN ISO 13849-1:2008, for specific safety related

r

parts of control system (SRP/CS) of rough-terrain variable-reach trucks covered by prEN 1459-1,

EN 1459-2 and EN 1459-3.

This Technical Report does not apply to SRP/CS that includes no electrical/electronic components.

NOTE It is the intention of CEN TC150 WG2 to use the same methodology to develop future standards (e.g.

further parts of EN 1459).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

prEN 1459-1:2015, Rough-terrain trucks — Safety requirements and verification — Part 1: Variable-

reach trucks

EN 1459-2:2015 Rough-terrain trucks — Safety requirements and verification — Part 2: Slewing

variable-reach trucks

EN 1459-3:2015 Rough-terrain trucks — Safety requirements and verification — Part 3: Interface

between the variable-reach truck and the work platform

EN ISO 12100:2010 Safety of machinery — General principles for design — Risk assessment and

risk reduction (ISO 12100:2010)

EN ISO 13849-1:2008 Safety of machinery — Safety-related parts of control systems — Part 1:

General principles for design (ISO 13849-1:2006)

ISO/TR 14121-2:2012 Safety of machinery — Risk assessment — Part 2: Practical guidance and

examples of methods

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100, prEN 1459-

1:2015, EN 1459-2:2015 and EN 1459-3:2015 and the following apply.

3.1

operator

competent person who controls the operation of the truck

3.2

co-worker

trained person who is working in the vicinity of the truck but not in control of the truck

3.3

by-stander

untrained person who is in the vicinity of the truck and not involved in the job site activity

4 General

It is intended that this document be read in conjunction with the corresponding Parts -1, -2 and -3 of

this standard (EN 1459).

EN ISO 13849-1 applies to the safety related parts of control system including the design of software,

regardless of the type of technology and energy used (electrical, electronic, hydraulic, pneumatic,

mechanical, etc.), for all kinds of machinery.

For safety functions that comprise mechanical parts only, no specific performance level is necessary.

There are many control systems fitted to trucks but not all will be subject to the requirements of EN

ISO 13849-1.

EN ISO 13849-1 is relevant for cases where a risk assessment according to EN ISO 12100 has

initiated a risk reduction measure that relies on a safety-related control system. In those cases the

safety-related control system has to perform a safety function. The application of EN ISO 13849-1 is

restricted to those cases only (see figures 1 and 2).

Systems may be subject to specific requirements in other standards e.g ISO 6292 - Powered

industrial trucks and tractors — Brake performance and component strength.

Interrelation with ISO 13849-1 in case risk

reduction/protective measures are

connected with the control system

a

The first time the question is asked, it is answered by the result of the initial risk assessment.

Figure 1 — Process flow chart

Safety control system

Risk assessment in accordance

performance level selection

Determination of need to

with EN ISO 12100 (including

determined by risk assessment

meet EN ISO 13849

the elements below)

– Refer to Annex E

END

RISK

SEVE

is a

PROBABILITY OF

RITY

Funct

OCCORRUNCE of

related

OF

ion

that harm

NO

to the HARM

of

Exposure of

consid

person(s) to the

ered

that

Risk reduction

hazard

hazard

can

a

process for the

result

hazard:

The occurrence of

from

Does the

a hazardous event 1 by intrinsic

the

b

protective

design

YES

consid

measure

2 by safeguards

ered

selected

3 by information

The possibility of avoiding c

hazar

depend on a

for use (see ISO

or limiting the harm

d

control

12100-1:2003,

d

Figure 4)

e

Figure 2 — Abbreviated EN ISO 12100/EN ISO 13849-1 process drawing distinction between risk assessment and control system performance

selection

and

5 Description of the procedure followed to determine PL for SRP/CS of

r

trucks

The first stage of meeting EN ISO 13849-1 is to take the risk assessment/risk reduction output from

following EN ISO 12100 and to check whether the protective measure selected depends on the

control system.

In order to perform the EN ISO 12100 assessment correctly for trucks with respect to EN ISO 13849-1

compliance, any existing control system which has been added / modified for achieving safety should

be disregarded at a first stage so that the risk they are addressing can be understood. This is

important to get the correct inputs if the system is later determined as SRP/CS and requires a PL to

r

be determined.

The following key stages were applied to determine PL for SRP/CS:

r

a) Identify which functions of the truck involve SRP/CS and identify the relevant clauses in the

standard. Determine control systems (mechanical, hydraulic, pneumatic, electrical/electronic,

electro-mechanical, electro-hydraulic…) that are necessary for the truck to carry out its intended

function 8.2 and Annex A)

b) Determine the intended truck limits as per EN ISO 12100:2010 clause 5.3 (see 8.1)

c) Perform risk assessment in accordance with EN ISO 12100:2010 clauses 5.5 and 5.6 (see Annex

E)

d) Take into account any risk reduction measures (intrinsic design and safeguards) and re-assess

the system to determine if the intended risk reduction has been achieved at this point any existing

control systems that are known to be used/added/modified for achieving safety should be

considered as a risk reduction measure. (see 8.3, Annex E and EN ISO 12100:2010 clause 5.6)

e) Determine if the protective measure selected is dependent upon a control system (and is

therefore SRP/CS). If it is not the process ends here.

f) If the protective measure is dependent upon a control system, use the information from the EN

ISO 12100 Risk Assessment to determine the EN ISO 13849-1 performance level that applies to

that system (this should consider that other non-control system risk reduction measures intended

to be fitted are in-place) (see Annex E)

NOTE The integrity of control systems which are not subject to EN ISO 13849-1 are to be ensured by

following sound engineering practice and by following relevant technical requirements and standards as

applicable. EN ISO 13849-1 imposes an extra burden to SRP/CS due to the nature and importance of these in

providing safety to exposed persons.

6 Risk assessment methodology

EN ISO 12100 does not define a risk assessment method but does define the elements to be

considered. Users of the above standard are free to choose a risk assessment method and ISO/TR

14121-2 provides practical guidance and examples. It should be noted that the informative “Risk

Graph” as presented in EN ISO 13849-1 is not a risk assessment tool that fulfils the needs of EN ISO

12100 as it does not include the important component of “probability of occurrence”. It also offers

limited selection of exposure, possibility of avoidance or limiting harm and severity as compared to

other documented risk graphs (see for example ISO/TR 14121-2, A.4).

The risk graph in EN ISO 13849-1 is a tool to determine a PL but is not a risk assessment method,

r

this tool was used to determine risks associated with a press and therefore its value is limited in

relation to mobile machinery. See 8.3 for risk evaluation of trucks.

Document ISO/DTR 18670 Safety of machinery — How EN ISO 12100 relates to EN ISO 13849-1

gives more explanation on this point, for instance in clause 4.1 it’s written that:

“For the correct application of EN ISO 13849-1 basic input information resulting from the application of

the overall risk assessment and risk reduction process for the particular machine design is necessary.

Based on this input information the safety-related parts of the control system can be appropriately

designed according to EN ISO 13849-1. Information resulting from a detailed design of safety-related

parts of the control system relevant for its integration into the machine design has then to be

considered in the overall risk assessment and risk reduction process according to EN ISO 12100.”

“…Consequently all necessary input information for the selection of the PL (elements of risk values

r

for the considered hazardous situation) are available from the overall risk assessment and risk

reduction process according to EN ISO 12100.

Therefore a separate risk assessment for the application of EN ISO 13849-1 is not necessary. The

graph given in EN ISO 13849-1:2006, Figure A.1 is used only to select the PL for safety functions

r

and is not intended to be used as a risk estimation method for the overall machine according to EN

ISO 12100.”

1)

.

The risk evaluation used for trucks is based on the Kinney method machinery safety

7 Risk Assessment Process

7.1 Determination of Machine limits

The following limits of use for the trucks is determined first in accordance with ISO 14121 to assist

with the risk assessment.

a) Intended use:

Starting

Driving

Load handling

User stabilizers

Operation (right side window breakage)

Maintenance

Lifting of persons (only EN 1459-3)

b) Foreseeable misuse:

Overriding of LLMC-LLMI and other safety devices (not emergency situation)

Use of stabilizers to displace the machine

Improper use of forks and other attachments

1) Fine, W.T. 1971. Mathematical Evaluation for controlling Hazards, Journal of Safety Research.

Kinney, G & Wiruth A. 1976, Practical Risk Analysis for Safety management

Overload of the platform (only EN 1459-3)

Overriding of controls in normal operation condition (only EN 1459-3)

Use not integrated platform (only EN 1459-3)

c) Limit to the use of the machine by persons:

95% men

Mostly between 18-60 years, occasionally between 14-18 years and more than 60

Right hand operator (dominant hand usage)

Visual limits for placing loads (17-18 m), more for driving (visibility measured at 12 m

considered as the reaction time as per EN 15830)

Hearing limits (regularly checked and medically approved to operate the machine)

Physical size: 5-95 percentile of human size distribution

Strength: level for steering and braking in case of failure

level of training and experience of the operator: newcomers (not trained) and experienced

(rely too much on the experience, less prepared to adapt to new machine and devices).

Increased legal obligation for a training for the operator

experience or ability of the users

operators (refer to above)

maintenance persons

trainees

general public (they should not be entitled to operate machines if they are not

properly trained)

exposure of other persons

other operators

co-workers in the vicinity

non-employees and visitors in the vicinity including children (work site

supervisor’s responsibility)

d) Space limits

Range of movements (travelling, boom movement, stabilizers movement, cab and guards

movement)

Range of movements (boom movement, platform movement) (only EN 1459-3)

Space required to interact with the machine

For the operator

For maintenance people

Operator-machine interface

Machine power supply interface

e) Time limits

Life time of machine and/or components

Recommended service intervals

Stress due to job schedule (quickest way to carry out a task)

f) Other limits:

Exposure to animals and human reaction

Environmental

Minimum and maximum temperature

Indoor and outdoor usage

Weather (dry/wet/rain/snow/fog/direct sunlight/dust)

Ground conditions

Level of cleanness required of the machine and cleaning process

Characteristic of the material to be handled (not applicable to EN 1459-3)

human error/behaviour

human behaviour when faced with a failure or incident with the machine

7.2 Hazard identification (5.4 annex B of EN ISO 12100)

Annex A includes tables which were created to identify the clauses which include SRP/CS within

prEN 1459-1, EN 1459-2 and EN 1459-3 and therefore a PL

r

The hazard identification numbering corresponds to the references within the risk assessment spread

sheet.

Where information is strikethrough an explanation is given rather than deleting the information to

demonstrate the thought processes.

In Annex E, each line of the risk assessment is a breakdown of the task and hazardous events that

may occur.

NOTE 1 Indicators are not part of control system (SRP/CS) so are not addressed in this analysis.

NOTE 2 Tasks including setting, corrective maintenance (being realized at the factory or at the dealership

generally) are considered not applicable to the by-standers assessment because these are carried out by trained

personnel.

7.3 Risk evaluation

The complete risk evaluation and calculation is in Annex E.

The risk evaluation is based on the statistical / numerical method of calculating machinery safety first

developed by Kinney, G and Wiruth A. 1976, Practical Risk Analysis for Safety management.

The risk is calculated separately for the three pre-determined groups operator, co-worker and

bystander

The risk evaluation is made in two steps:

a) the first step (columns J-O initial assessment) assumes the truck has no safety device fitted or a

solution in place for risk reduction on the machine.

The risk priority number (RPN) is calculated using the following formula and the values in Annex B.

P x E x S x N = RPN

where:

P is the possibility/probability of avoiding the hazard or limiting the harm

E is the exposure (time and frequency) to the hazard

S is the severity of injury

N is the number of persons involved

To determine a performance level the highest RPN is used calculated from the three groups.

The values in Annex C determine the risk rating and where the risk assessment deems this is a safety

related part of the control system a corresponding performance level is given.

a) the second step considers the countermeasures within prEN 1459-1, EN 1459-2 or EN 1459-3

have been implemented fully and are working correctly (columns Q-V).

NOTE For the purpose of the residual risk assessment we have to consider the SRP/CS fitted as a

countermeasure is working and P=0.033 is considered the most appropriate value to enable closure of the risk

assessment.

8 Required performance level for SRP/CS of trucks

Tables 1, 2 and 3 identify performance levels required for the SRP/CS referenced to in prEN 1459-1,

EN 1459-2 and EN 1459-3. These PL are based upon generic risk assessment for the collective

r

trucks types with certain control system architecture and being used in the specified application. As

such the identified PL are presented for guidance and manufacturers shall verify that the respective

r

PL are in accordance with their own EN ISO 12100 risk assessments.

r

For electrical, electronic and software based circuits, corresponding Safety Integrity Levels (SILs)

according to EN 62061 may be used in accordance with Table 1 of PD ISO/TR 23849:2010 which is

replicated below.

ISO/TR 23849:2010 – Table 1:

Average Probability of a

Performance Level Dangerous Failure per Hour Safety integrity level (SIL)

(1/h)

-5 -4

a ≥ 10 to < 10 No special safety requirements

-6 -5

b ≥ 3 x 10 to < 10 1

-6 -6

c ≥ 10 to < 3 x 10 1

-7 -6

d ≥ 10 to < 10 2

-8 -7

e ≥ 10 to < 10 3

Where SILs and PLs are used in the same safety function, combination shall be in accordance with

7.1 and 7.3 of PD ISO/TR 23849: 2010.

8.1 prEN 1459-1

Table 1 — PL for variable-reach trucks

r

Ref

SRP/CS (clause of prEN 1459-1:2015) Performance level

No.

1 4.2.2 unintended movement PLb

2 4.2.3 uncontrolled motion PLb

3a 4.2.4.a) powered travel movement PLc

3b 4.2.4.b) powered travel movement PLb

3c 4.2.4.c) powered travel movement PLc

4a 4.2.5 non activation of the parking brake PLb

4b 4.5.5 Multi-function controls – 2nd para PLb

4c 4.7 stabilizing devices 2nd indent PLb

4d 4.7 stabilizing devices 4th paragraph PLb

6 4.5.1.1 multiple operating positions PLc

7 4.5.1.3 inadvertent activation PLb

8 4.5.4.2.1 control with detents PLb

9 4.5.4.2.2 boom float control PLc

10 4.7 stabilizing devices 1st indent PLb

NOTE This reference number in the first column of the table refers to Table A1.

8.2 prEN 1459-2

The comparison of clauses and risks against PL’s already determined for prEN 1459-1 is in Annex D

Table 2 — PL for slewing variable-reach trucks

r

Ref

SRP/CS (clause of EN 1459-2:2015) Performance level

No.

1 4.2.2 unintended movement PLb

2 4.2.3 uncontrolled motion PLb

3a 4.2.4.a) powered travel movement PLc

3b 4.2.4.b) powered travel movement PLb

3c 4.2.4.c) powered travel movement PLc

4a 4.2.5 non activation of the parking brake PLb

6 4.5.1.1 multiple operating positions PLc

7 4.5.1.3 inadvertent activation PLb

8 4.5.4.2.1 control with detents PLb

9 4.5.4.2.2 boom float control PLc

10 4.7 stabilizing devices 1st indent PLb

11 4.7 stabilizing devices 3rd indent PLc

20 4.5.1 f) means shall be provided to

prevent any possibility of powered

PLc

movements actuated by controls if the

operator is not at one operator’s position.

21 4.5.8. Axle oscillation locking PLb

22a 4.10.7.1.1 LLD General PLc

22b 4.10.7.1.1 LLD General (5th paragraph) PLc

PLc

22c 4.10.7.1.1 LLD General (6th paragraph)

PLc

22d

4.10.7.1.1 LLD General (7th paragraph)

NOTE This reference number in the first column of the table refers to Table A2.

8.3 prEN 1459-3

Table 3 — PL for trucks fitted with integrated personnel work platform

r

Ref

SRP/CS (clause of EN 1459-3:2015) Performance level

No.

18 4.2.2 Engagement of platform PLc

19 4.2.3 Disengagement of platform PLc

NOTE this reference number in the first column of the table refers to Table A3.

Annex A

(informative)

Hazard identification

A.1 prEN 1459-1

Areas of the Tasks

No. Paragraph of standard Hazardous event machinery

concerned

1 5.2.1 unauthorized The machine starts Mechanism and Start up

starting inadvertently function

setting

Note: 4.2.1 is covered by

Restart after unscheduled stop

4.2.2 and this is the

Fault finding/troubleshooting

reason why it isn’t

Corrective maintenance

addressed here

1 4.2.2 unintended The machine moves Mechanism and Start up

movement inadvertently after starting function/parts

setting

Environment

Restart after unscheduled stop

Fault finding/troubleshooting

Corrective maintenance

Recovery of operation from jam

Areas of the Tasks

No. Paragraph of standard Hazardous event machinery

concerned

2 4.2.3 uncontrolled motion The machine moves Mechanism and Start up

inadvertently from rest function

Note: the analysis is the setting

same of 4.2.2 Environment

Restart after unscheduled stop

Parts

all modes of operation (boom movement + rpm increase)

Fault finding/troubleshooting

Corrective maintenance

Recovery of operation from jam

3a 4.2.4 a) powered travel The machine moves when the Mechanism and Start up Note: the machine has already started up, not

movement operator is not at the primary function applicable.

operating position

Environment Setting

Parts Testing

Recovery of operation from jam Note: we considered not

applicable

Fault finding/troubleshooting Note: we considered not

applicable

all modes of operation (attachment functions and locking,

trailers connection, PTO operations)

preventive maintenance Note: we considered not applicable

Corrective maintenance

Stopping of the machine Note: we considered not applicable

Stopping the machine in case of emergency Note: we

considered not applicable

Areas of the Tasks

No. Paragraph of standard Hazardous event machinery

concerned

3b 4.2.4 b) powered travel Powered travel shall not occur Mechanism and Start up Note: the machine has already started up, covered

movement automatically when the function by 5.2.2 unintended movement.

operator returns to the normal

Environment Setting

operator’s position without an

Parts Testing

additional operation, e.g., by

Restart after unscheduled stop Note: the machine has

requiring resetting the direction

already started up, covered by 5.2.2 unintended movement

control.

all modes of operation (forward travelling, reverse travelling)

Corrective maintenance

3c 4.2.4 c) powered travel Application of the parking brake Mechanism and Start up

movement shall apply neutral travel function

Setting

control, except on trucks with

Environment

Testing

hydro-static transmission

Parts

Stopping of the machine

Stopping the machine in case of emergency Note: we

considered this already covered by “stopping of the

machine”

4a 4.2.5 non activation of Operator is not warned that the Mechanism and Setting

the parking brake parking brake is engaged. function

Testing (applicable to operator and co-worker only)

Parts

Stopping of the machine

4b 4.5.5 Multi-function Operator is not warned about Mechanism and Setting

nd

controls – 2 para mode of operation (dangerous function

Testing (applicable to operator and co-worker only)

movements)

Parts

Fault finding/troubleshooting (applicable to operator and co-

worker only)

All modes of operation

4c 4.7 stabilizing devices Bystanders hit by stabilizers Mechanism and Setting

nd

2 indent during travel mode function

Testing (applicable to operator and co-worker only)

Parts

All modes of operation

Areas of the Tasks

No. Paragraph of standard Hazardous event machinery

concerned

th

4d 4.7 stabilizing devices 4 Loss of stability Mechanism and Setting

paragraph function

Testing (applicable to operator and co-worker only)

Parts

All modes of operation

5.10.7.1 and 5.10.7.2 LLMI is not considered here

control panels and because it is covered by EN

control displays 15000.

Note: 5.10.7.1 and 5.10.7.2 are

too broad to be covered by the

analysis and these clauses

already give prescriptions

because they have got

standards references.

5 5.3.1 – 5.3.2 Brakes Note: Will be taken into Mechanism and Setting

account electrohydraulic function

Testing

brakes, if added to prEN 1459-

Environment

Stopping of the machine

Parts

Stopping the machine in case of emergency

Restart after unscheduled stop

recovery of operation from jam or blockage (towing)

preventive maintenance

Corrective maintenance

Areas of the Tasks

No. Paragraph of standard Hazardous event machinery

concerned

6a 4.5.1.1 multiple operating Uncontrolled load movement Mechanism and Setting

positions (the use of the function

Uncontrolled movement of Testing (daily checks)

controls at one

stabilizers, levelling, etc. Parts

all modes of operation (boom lifting, lowering, extending,

operator’s position shall

Note: application of man Environment retracting, fork tilting, attachment locking, attachment

preclude the use of the

platform is not considered here functions, stabilizers, leveling, steering, forward and reverse

controls at other

but in EN 1459-3 and in travelling)

operator’s positions)

EN 280.

start-up;

Stopping of the machine

Stopping the machine in case of emergency

Restart after unscheduled stop

Fault-finding/trouble-shooting (only operator and coworker)

Adverse weather conditions (e.g. lightning, wind, etc.) Note:

this is something that is not possible to control and we

cannot define a performance level for this.

7 4.5.1.3 inadvertent Uncontrolled load movement Mechanism and Testing (included in “all modes of operation” because it’s

activation (on

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...