SIST EN 17038-4:2024

(Main)Pumps - Methods of qualification of the Energy Efficiency Index for rotodynamic pump units - Part 4: Testing and calculation of energy efficiency index (EEI) of submersible multistage pump units

Pumps - Methods of qualification of the Energy Efficiency Index for rotodynamic pump units - Part 4: Testing and calculation of energy efficiency index (EEI) of submersible multistage pump units

This document specifies methods and procedures for testing, calculating, and determining the Energy Efficiency Index (EEI) of submersible multistage pump units.

Pumpen - Methoden zur Qualifikation des Energieeffizienzindexes für Kreiselpumpen - Teil 4: Prüfung und Berechnung des Energieeffizienzindexes (EEI) mehrstufiger Tauchmotorpumpenaggregate

Dieses Dokument legt Methoden und Verfahren zur Prüfung, Berechnung und Bestimmung des Energieeffizienzindex (EEI) von mehrstufigen Tauchmotorpumpenaggregaten fest.

Pompes - Méthodes de qualification de l'indice de rendement des groupes motopompes rotodynamiques - Partie 4 : Essais et calcul de l'indice de rendement énergétique (EEI) pour les unités de pompage submersibles des forages

Le présent document spécifie les méthodes et modes opératoires d'essai, de calcul et de détermination de l'indice d'efficacité énergétique (EEI) des groupes motopompes submersibles multi-étagés.

Črpalke - Metode za opredelitev indeksa energijske učinkovitosti centrifugalnih črpalk - 4. del: Preskušanje in računanje indeksa energijske učinkovitosti (IEE) večstopenjskih potopnih črpalk

Ta dokument določa metode in postopke za preskušanje, računanje in določanje indeksa energijske

učinkovitosti (EEI) potopnih večstopenjskih črpalk.

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Oct-2021

- Publication Date

- 07-Jan-2024

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 03-Jan-2024

- Due Date

- 09-Mar-2024

- Completion Date

- 08-Jan-2024

Overview

EN 17038-4:2023 (CEN) specifies methods for testing and calculating the Energy Efficiency Index (EEI) of submersible multistage pump units. It is Part 4 of a series for rotodynamic pump units and covers both experimental measurement procedures and a semi-analytical model (SAM) to determine average electric power input and the reference power used to compute the non-dimensional EEI. The standard targets submersible multistage water pump units (nominal outer diameters 2.5″–6″ / 63.5–152.4 mm, nominal flow > 1.75 m3/h) designed for operation immersed in clean water at temperatures up to 90 °C.

Key Topics

- Scope and definitions: clear definitions for submersible multistage pump, submersible borehole motor, PDS (Power Drive System), CDM (Complete Drive Module / frequency converter), clean water and test conditions.

- Reference operating profiles: prescribed reference flow–time profiles and pressure control curves used to represent typical part‑load and variable operation for EEI calculation.

- Test procedures: detailed measurement steps, instrumentation requirements, uncertainty treatment, determination of Q100% and H100% and reference load points for laboratory testing.

- Semi‑analytical model (SAM): numerical model for predicting average electric power input when direct measurement is impractical; includes pump, motor and PDS (CDM + motor) interaction models.

- Power drive systems (PDS): procedures to model and test units with variable speed drives (VSD/CDM), and to evaluate converter‑fed motor efficiencies.

- Corrections and tolerances: rules for adjusting measured values for deviations in flow and head, and for reporting average and reference power inputs.

- Annexes: input data generation for component models, experimental determination of thrust bearing friction losses, and guidance for RCDM data use.

Applications

- Manufacturers: product design optimization, performance verification and energy‑efficiency claims for submersible multistage pump units.

- Test laboratories: standardized procedures for EEI measurement and reporting, ensuring comparability across tests.

- Specifiers and purchasers: objective EEI values to compare pump options for borehole, well and deep‑well applications.

- Regulators and energy programs: supporting Ecodesign compliance, energy labelling and procurement criteria based on EEI.

- Consultants and asset managers: lifecycle energy-performance assessment (note: EEI is an index for comparison and does not replace full lifetime energy cost analysis).

Related standards (if applicable)

- EN 17038-1:2019 - General requirements for EEI methodology

- EN 17038-2:2019 - EEI of single pump units

- EN 16480:2021 - Minimum required efficiency and MEI

- EN ISO 9906:2012, EN 60034 series - relevant hydraulic and motor test standards

Keywords: EN 17038-4:2023, EEI, Energy Efficiency Index, submersible multistage pump units, testing, semi-analytical model, PDS, CDM, rotodynamic pumps, CEN.

Frequently Asked Questions

SIST EN 17038-4:2024 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Pumps - Methods of qualification of the Energy Efficiency Index for rotodynamic pump units - Part 4: Testing and calculation of energy efficiency index (EEI) of submersible multistage pump units". This standard covers: This document specifies methods and procedures for testing, calculating, and determining the Energy Efficiency Index (EEI) of submersible multistage pump units.

This document specifies methods and procedures for testing, calculating, and determining the Energy Efficiency Index (EEI) of submersible multistage pump units.

SIST EN 17038-4:2024 is classified under the following ICS (International Classification for Standards) categories: 23.080 - Pumps; 27.015 - Energy efficiency. Energy conservation in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17038-4:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2024

Črpalke - Metode za opredelitev indeksa energijske učinkovitosti centrifugalnih

črpalk - 4. del: Preskušanje in računanje indeksa energijske učinkovitosti (IEE)

Pumps - Methods of qualification of the Energy Efficiency Index for rotodynamic pump

units - Part 4: Testing and calculation of energy efficiency index (EEI) of submersible

multistage pump units

Pumpen - Methoden zur Qualifikation des Energieeffizienzindexes für Kreiselpumpen -

Teil 4: Prüfung und Berechnung des Energieeffizienzindexes (EEI) mehrstufiger

Tauchmotorpumpenaggregate

Pompes - Méthodes de qualification de l'indice de rendement des groupes motopompes

rotodynamiques - Partie 4 : Essais et calcul de l'indice de rendement énergétique (EEI)

pour les unités de pompage submersibles des forages

Ta slovenski standard je istoveten z: EN 17038-4:2023

ICS:

23.080 Črpalke Pumps

27.015 Energijska učinkovitost. Energy efficiency. Energy

Ohranjanje energije na conservation in general

splošno

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17038-4

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2023

EUROPÄISCHE NORM

ICS 23.080

English Version

Pumps - Methods of qualification of the Energy Efficiency

Index for rotodynamic pump units - Part 4: Testing and

calculation of energy efficiency index (EEI) of submersible

multistage pump units

Pompes - Méthodes de qualification de l'indice de Pumpen - Methoden zur Qualifikation des

rendement des groupes motopompes rotodynamiques Energieeffizienzindexes für Kreiselpumpen - Teil 4:

- Partie 4 : Essais et calcul de l'indice de rendement Prüfung und Berechnung des Energieeffizienzindexes

énergétique (EEI) pour les unités de pompage (EEI) mehrstufiger Tauchmotorpumpenaggregate

submersibles des forages

This European Standard was approved by CEN on 29 October 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17038-4:2023 E

worldwide for CEN national Members.

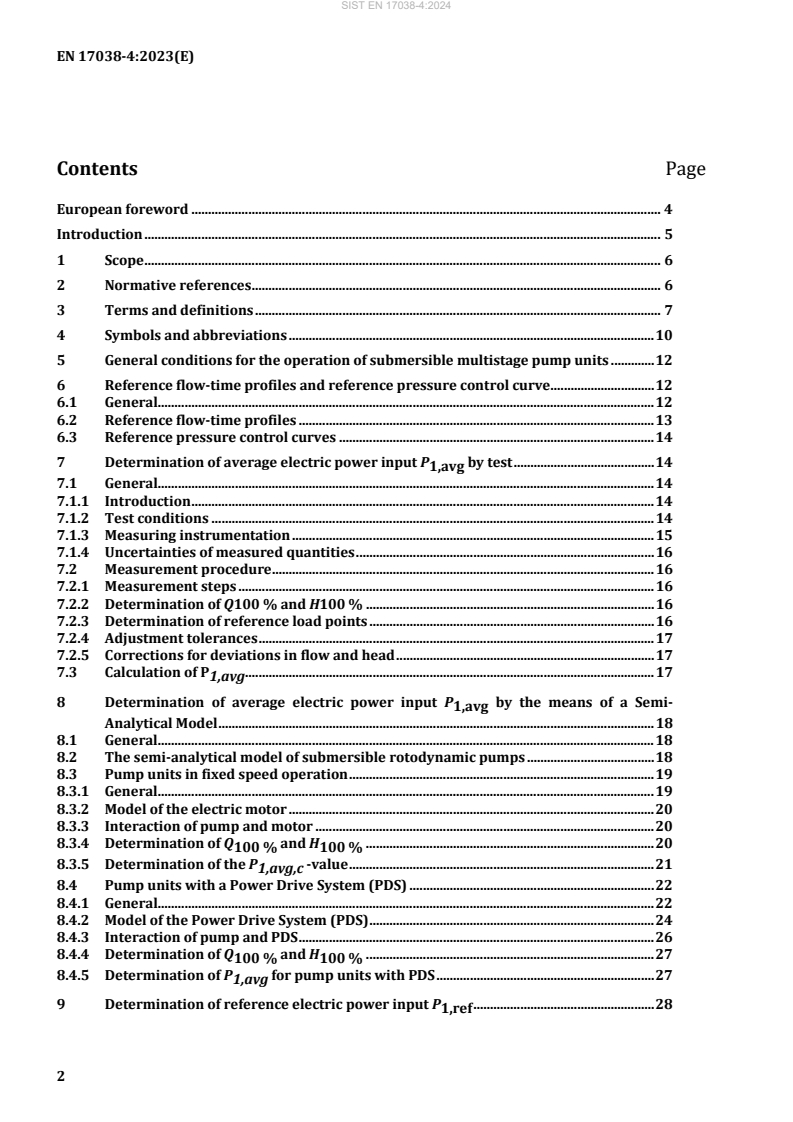

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Symbols and abbreviations . 10

5 General conditions for the operation of submersible multistage pump units . 12

6 Reference flow-time profiles and reference pressure control curve . 12

6.1 General. 12

6.2 Reference flow-time profiles . 13

6.3 Reference pressure control curves . 14

7 Determination of average electric power input P by test . 14

1,avg

7.1 General. 14

7.1.1 Introduction . 14

7.1.2 Test conditions . 14

7.1.3 Measuring instrumentation . 15

7.1.4 Uncertainties of measured quantities . 16

7.2 Measurement procedure . 16

7.2.1 Measurement steps . 16

7.2.2 Determination of Q100 % and H100 % . 16

7.2.3 Determination of reference load points . 16

7.2.4 Adjustment tolerances . 17

7.2.5 Corrections for deviations in flow and head . 17

7.3 Calculation of P . 17

1,avg

8 Determination of average electric power input P by the means of a Semi-

1,avg

Analytical Model . 18

8.1 General. 18

8.2 The semi-analytical model of submersible rotodynamic pumps . 18

8.3 Pump units in fixed speed operation . 19

8.3.1 General. 19

8.3.2 Model of the electric motor . 20

8.3.3 Interaction of pump and motor . 20

8.3.4 Determination of Q and H . 20

100 % 100 %

8.3.5 Determination of the P -value . 21

1,avg,c

8.4 Pump units with a Power Drive System (PDS) . 22

8.4.1 General. 22

8.4.2 Model of the Power Drive System (PDS) . 24

8.4.3 Interaction of pump and PDS . 26

8.4.4 Determination of Q and H . 27

100 % 100 %

8.4.5 Determination of P for pump units with PDS . 27

1,avg

9 Determination of reference electric power input P . 28

1,ref

10 Calculation of Energy Efficiency Index (EEI) . 31

Annex A (informative) Generation of input data for the models of components of a

submersible multistage pump unit . 32

A.1 General . 32

A.2 Input data for the model of a submersible rotodynamic pump . 32

A.3 Input data for the model of a submersible grid fed motor . 33

A.4 Input data for the model of a PDS consisting of submersible motor and CDM . 33

Annex B (informative) Experimental Determination of thrust bearing friction losses . 35

Annex C (informative) Determination of EEI values using data for RCDMs . 36

Bibliography . 37

European foreword

This document (EN 17038-4:2023) has been prepared by Technical Committee CEN/TC 197 “Pumps”,

the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2024, and conflicting national standards shall be

withdrawn at the latest by March 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is the fourth part of a series of standards describing a methodology to evaluate energy

efficiency performance of submersible multistage pump units, comprising a rotodynamic pump part and

a submersible motor which is either directly fed from the grid or combined with a frequency converter

(CDM) to form a Power Drive System (PDS). For consistency purposes with other referred standards,

CDM is used in this document. VSD, for variable speed drive, is the term used in Ecodesign regulations.

Rotodynamic pump and motor are designed with outer diameters and special design features that enable

to install them in boreholes and operate them completely surrounded by the pumped liquid. The

methodology is based on a non-dimensional numerical value called Energy Efficiency Index (EEI). An EEI

value allows the comparison of different configurations by one common indicator. Physical influences

such as size and stage number of the incorporated rotodynamic pump, unit part-load operation, motor-

efficiency characteristic and frequency converter influence are implemented into this metric.

Specific requirements for testing and a calculation method for EEI, the so called semi-analytical model

(SAM) of submersible multistage pump units, specific flow-time profiles and reference pressure control

curves are given in this document.

EEI is an index to rate submersible multistage pump units according to their energy efficiency but does

not replace the need to do a life-time cost analysis regarding energy consumption over the lifetime of the

submersible multistage pump unit.

1 Scope

This document specifies methods and procedures for testing, calculating, and determining the Energy

Efficiency Index (EEI) of submersible multistage pump units.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 16480:2021, Pumps — Rotodynamic pumps — Minimum required efficiency of rotodynamic water

pumps and determination of Minimum Efficiency Index (MEI)

EN 17038-1:2019, Pumps - Methods of qualification and verification of the Energy Efficiency Index for

rotodynamic pump units - Part 1: General requirements and procedures for testing and calculation of Energy

Efficiency Index (EEI)

EN 17038-2:2019, Pumps — Methods of qualification and verification of the energy efficiency index for

rotodynamic pump units — Part 2: Testing and calculation of energy efficiency index (EEI) of single pump

units

EN ISO 9906:2012, Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3 (ISO

9906:2012)

EN ISO 17769-1:2012, Liquid pumps and installation - General terms, definitions, quantities, letter symbols

and units - Part 1: Liquid pumps (ISO 17769-1:2012)

EN 60034-1:2017, Rotating electrical machines — Part 1: Rating and performance (IEC 60034-1:2010)

EN 60034-2-1:2014, Rotating electrical machines - Part 2-1: Standard methods for determining losses and

efficiency from tests (excluding machines for traction vehicles) (IEC 60034 2 1:2014)

EN IEC 60034-2-3:2020, Rotating electrical machines - Part 2-3: Specific test methods for determining

losses and efficiency of converter-fed AC motors (IEC 60034 2020)

EN IEC 60038:2011/prA1:2020, {fragment 1}, Standard voltages for LVDC supply and LVDC equipment

(Proposed horizontal standard)

EN IEC 60038:2011/prA1:2020, {fragment 2}, Standard voltages for AC supply and AC equipment

(Proposed horizontal standard)

EN IEC 60038:2011/prA1:2020, {fragment 3}, Standard voltages for DC and AC traction systems (Proposed

horizontal standard)

EN 61800-9-2:2017, Adjustable speed electrical power drive systems - Part 9-2: Ecodesign for power drive

systems, motor starters, power electronics and their driven applications - Energy efficiency indicators for

power drive systems and motor starters (IEC 61800 9 2:2017)

As impacted by EN 17038-2:2019/AC:2020.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 17769-1:2012 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

submersible multistage water pump unit

submersible multistage water pump unit is composition of submersible multistage pump and

submersible borehole motor with or without Variable Speed Drive (VSD)

3.2

submersible borehole motor

electric motor designed to be operated submersed at operating temperatures not below 0 °C and not

above 40 °C

3.3

submersible multistage pump

MSS

multistage (i > 1) rotodynamic water pump with a nominal outer diameter from 2,5″ (63,5 mm) up to 6″

(152,4 mm) designed to be operated submersed, at operating temperatures within a range of 0 °C and

90 °C, with a nominal flow rate > 1,75 m /h

3.4

clean water

water with a maximum non-absorbent free solid content of 0,25 kg/m , and with a maximum dissolved

solid content of 50 kg/m , provided that the total gas content of the water does not exceed the saturation

volume

Note 1 to entry: Any additives that are needed to avoid water freezing down to – 10 °C shall not be considered.

3.5

clean cold water

−6 2

clean water to be used for pump testing, with a maximum kinematic viscosity of 1,5 × 10 m /s, a

maximum density of 1 050 kg/m and a maximum temperature of 40 °C

3.6

fixed-speed pump unit

pump unit without a variable speed drive (VSD)

3.7

variable-speed pump unit

pump unit equipped with an VSD

3.8

complete drive module

CDM

variable speed drive

VSD

electronic power converter connected between the electric supply and a motor as well as extensions such

as protection devices, transformers and auxiliaries (according to EN 61800-2)

Note 1 to entry: This term is defined in EN 61800-2.

3.9

power drive system

PDS

combination of CDM and motor

3.10

check-valve

non-return valve

Note 1 to entry: Such a valve is often integrated in submersible multistage pump units.

3.11

constant flow

slight variation of the flow rate around the nominal value

Note 1 to entry: Caused by secondary influences from the process as, for example, the (moderately) varying level

of liquid in reservoirs, etc. The variation of flow rate occurs typically within the range which is covered by the

definition and determination of the Minimum Efficiency Index (MEI) of the pump (see EN 16480), and which is from

0,75 Q to 1,1 Q .

100 % 100 %

3.12

variable flow

widely varying flow rate

Note 1 to entry: Typically, at considerable fractions of the total operating time, the actual demand for pump flow

rate Q and pump head H is much lower than the values at the operating point of maximum flow rate which is

demanded by the application.

3.13

suction pressure

pressure at the inlet of a submersible multistage pump

Note 1 to entry: All pressures are gauge pressures (relative to the ambient pressure).

3.14

discharge pressure

pressure at the outlet of a submersible multistage pump

3.15

total head

overall energy in any section

Note 1 to entry: The total head is given by:

pU

xx

Hz=+ + (1)

xx

ρ××gg2

where

z is the height of the centre of the cross-section above the reference plane;

p is the gauge pressure related to the centre of the cross-section;

U is the flow velocity.

Note 2 to entry: The absolute total head in any section is given by:

pp U

xxamb

Hz=++ +

x(abs) x

ρρ××g gg2

3.16

hydraulic power

arithmetic product of the flow Q and the head H, and a constant a per Formula (2):

P = ρ⋅ Q⋅⋅gH (2)

hyd

where

P is the hydraulic power [W];

hyd

Q is the flow [m /s];

H is the total head [m];

g gravitational constant 9,81 m/s ;

ρ is the density of fluid [kg/m ].

3.17

electric power input P

electric power supplied:

— to the motor in the case of a (grid fed) fixed speed pump unit;

— to the CDM in the case of a variable speed pump unit

3.18

pump unit efficiency

ratio of hydraulic power P and electric power input P

hyd

3.19

pump unit best efficiency point

Q /H

BEP,unit BEP,unit

flow-head-point where the pump unit runs at its best unit efficiency point and at maximum operation

3.20

reference flow rate, Q

100%

flow per time unit [m /h] at the Best Efficiency Point (BEP) of the pump unit

3.21

reference head, H

100%

total head [m] at the Best Efficiency Point (BEP) of the pump unit

3.22

control curve

functional dependency of the demanded head H vs. the delivered flow rate Q in the form of a non-

dimensional correlation H/H = f (Q/Q )

100% 100%

3.23

reference control curve

pre-defined functional dependency H/H = f (Q/Q ) for standardised measurements and

100% 100%

calculations of average power input P

1, avg

3.24

flow-time profile

relation between flow rate intervals and relative operation time pattern of percentiles of time where the

pump unit runs at a given flow rate

3.25

Minimum Efficiency Index (MEI)

dimensionless number for the energy efficiency of pumps

Note 1 to entry: This term is defined in EN 16480:2021.

4 Symbols and abbreviations

For the purpose of this document, the symbols and units given in Table 1 apply.

Table 1 — Symbols and units

Symbol Designation Unit

g Gravitational constant m/s

H (Total) head m

H (Total) head at best efficiency point of a pump m

BEP,unit

H (Total differential) head at m

BEP,N

H Geodetic head m

geo

Symbol Designation Unit

H Head loss caused by a check-valve m

L,cv

H Measured head m

meas

H Reference head m

ref

H Head loss of the supplied hydraulic system m

resistance

H Head at BEP of the pump unit m

100 %

i Stage number of multistage pumps -

i Consecutive number of load points [-]

k Number of supporting points [-]

K Constant in Formula (3) 2 5 2 5

s /m or h /m

n Rotational speed -1

min

n Nominal rotational speed of a pump -1

N,PU min

n Specific speed of a pump -1

s min

N Total number of load points [-]

p Pressure bar (g)

p Suction pressure bar (g)

s

p Discharge pressure bar (g)

d

P Electric power input W, kW

P Reference value of electric power input W, kW

1,ref

P Measured electric power input W, kW

1,meas

P Mechanical power transmitted by the motor to the W, kW

hydraulic pump part

P Shaft power output of the calibrated submersible W, kW

2,calibrated

borehole motor without axial thrust load

P Power loss W, kW

L

PL,PDS Relative losses of the PDS in relation to the rated power of W, kW

the motor

Q Flow rate m /h

Q m /h

Flow rate at best efficiency point of a pump unit

BEP,unit

Q m /h

BEP,N

Flow rate at specific load point ?????

Q Reference flow rate m /h

ref

Q Flow rate from test m /h

test

Symbol Designation Unit

Q Flow rate at BEP of the pump unit m /h

100 %

s Slip of rotational motor speed [-] or %

t Time s; min; h

T Torque N⋅m

η Efficiency [-] or %

ρ Density 3

kg/m

5 General conditions for the operation of submersible multistage pump units

In the majority of applications, submersible multistage pump units are installed and operated in

boreholes. In these cases, the hydraulic circuit connected to the pump unit is an open loop system with

predominant geodetic head H . The resistance curve that determines the operating points of the pump

geo

unit is of the type given by Formula (3):

H H+⋅KQ (3)

resis tan ce geo

where typically the head loss caused by friction losses in the piping K⋅Q is much smaller than the

geodetic head H .

geo

Depending on the individual application, the range of flow rate demand may be rather small (“constant

flow”) or rather wide (“variable flow”).

Especially in the case of remarkably varying demand for delivered flow rate, it is advantageous (in respect

to energy consumption) to operate the pump unit at variable speed. This mode of operation requires a

variable speed driven pump. In other cases, it may be adequate to operate the pump unit at fixed speed,

i.e. to feed the electric motor directly by the grid.

6 Reference flow-time profiles and reference pressure control curve

6.1 General

According to the two different modes of operation (constant or variable flow), two different reference

flow-time profiles are relevant (see 6.3) that lead to two different numerical values of EEI. These values

are designated as EEI (concerning the constant flow operation mode) and EEI (concerning the variable

C V

flow operation mode).

In the constant flow mode of operation, the operating points for the determination of EEI are defined to

C

be the values of the flow rate Q according to the corresponding reference flow-time profile (see 6.3) and

the values of pump head H according to the Q-H curve of the actual pump unit at constant (grid) frequency.

Insofar, this Q-H curve stands for the reference pressure control curve for EEI .

C

On the other hand, in the variable flow mode of operation the reference pressure control curve for EEI

V

is based on the assumption of a constant pump head H which is independent of the delivered flow rate Q

and is equal to H (see 6.3).

100 %

When putting submersible multistage pump units into service an appropriate value of EEI shall be made

available. The EEI shall be for constant flow (EEI ) and/or variable flow (EEI ) according to the demand

C V

of the application in which the pump unit is put into service or for which the pump unit is specified, when

=

placed on the market. The corresponding flow-time profiles and pressure control curves are given in

Table 2.

Table 2 — Reference flow-time profiles and reference pressure control curves for submersible

multistage pump units

Mode Reference Reference Applicable Q/H Applicable

flow-time pressure test points EEI

profile

control curve

Demand of Type of

application pump unit

M1 constant fixed speed constant Q-H curve of on Q/H curve of EEI

C

flow flow the pump unit the pump unit

(Table 3)

M2 variable flow fixed speed variable Formula (4) on Q-H curve of EEI

V

flow the pump unit

(Table 4)

M3 constant variable constant Q-H curve of on Q-H curve of EEI

C

flow speed flow the pump unit the pump unit

(Table 3) (measured at

fixed speed)

M4 variable flow variable variable Formula (4) Q/H points de- EEI

V

speed flow fined by

(Table 4) Formula (4)

M5 constant variable variable Formula (4) Q/H points de- EEI

V

flow, varying speed flow fined by

head (Table 4) Formula (4)

6.2 Reference flow-time profiles

The reference flow-time profile for constant flow operation is specified by the values given in Table 3.

Table 3 — Reference flow-time profile for constant flow operation

Flow Q in % of Q

75 100 110

100 %

Time Δt in % of total operating time 25 50 25

The reference flow-time profile for variable flow operation is specified in Table 4.

Table 4 — Reference flow-time profile for variable flow operation

Flow Q in % of Q

100 %

25 50 75 100

10 40 40 10

Time Δt in % of total operating time

NOTE 1 Q is defined in 3.20.

100 %

NOTE 2 The time fractions of total operating time that are specified in Tables 3 and 4 as values to be used for the

determination of EEI are based on comprehensive experience of manufacturers of submersible pumps in respect to

typical applications and operational conditions of their products.

6.3 Reference pressure control curves

In the case of the variable flow demand (modes M2 and M4), the reference control curve shall be defined

by Formula (4):

H H or H /%H 100

ii100% 100%

(4)

In the case of the constant flow operation mode (modes M1 and M3), the reference control curve is the Q-

H curve of the actual pump unit applied to define Q H (see 7.2.2 and 8.3.4).

100 %, 100 %

In the case of the constant flow and varying head demand (mode M5), the reference control curve shall be

defined by Formula (4).

NOTE H is defined in 3.21.

100 %

7 Determination of average electric power input P by test

1,avg

7.1 General

7.1.1 Introduction

This clause specifies performance tests and evaluations on submersible multistage pump units.

Such tests shall provide the necessary information on the actual performance values of tested

submersible multistage pump units needed for the calculation of the EEI-value according to its definition

given in EN 17038-1:2019, Clause 4.

All provisions for the test concerning the submersible multistage pump unit (taken as “black box” and

treated as a pump unit as those covered by EN 17038-2:2019) shall be in accordance with

EN ISO 9906:2012, grade 2. The exception for power of 10 kW and below (as allowed for the application

of EN ISO 9906:2012 on acceptance tests) shall not be valid.

All provisions for the test concerning electric motors that are part of the submersible multistage pump

unit and are fed directly from an electric grid shall be in accordance with EN 60034-2-1:2014.

All provisions for the test concerning a Power Drive System which is part of the submersible multistage

pump unit shall be in accordance with EN 61800-9-2:2017.

7.1.2 Test conditions

Tests shall be carried out with clean cold water.

The duration of the test shall be considered to obtain repeatable results. Especially run-in of bearings and

sealings and warming-up effects of the electric and electronic components of the unit shall be considered.

NOTE 1 Run-in effects can take up to 24 h of operating time.

The electric power supply of the test installation shall fulfil the requirements as specified in

EN 60034-1:2017. This requires the following:

— the voltage shall be in accordance with EN 60038, 7.2, and EN 60034-1;

— the frequency shall be within ± 0,3 % of the rated frequency during measurements;

— the testing requires thermal stabilization, the fluid-temperature shall be in the range 10 °C to 30 °C;

— the change in the motor temperature over time shall be smaller than 1 K/30 min;

==

— a cooling flow according to the corresponding flow velocity shall be ensured, e.g. by applying a

cooling shroud.

The tests should be conducted under conditions where cavitation does not affect the performance of the

pump.

All measurements shall be performed under hydraulic and thermal steady-state conditions (see

EN ISO 9906:2012, EN 60034-2-1:2014, EN IEC 60034-2-3:2020 and EN 61800-9-2:2017).

For Case 1 in 7.2.3 (motor fed by an electric supply with constant frequency), the electric power supply

of the test installation shall fulfil the requirements as specified in EN 60034-1:2017. This requires that:

— the maximum motor cable length shall be 10 m.

For Case 2 in 7.2.3 (PDS, i.e. motor combined with and fed by a CDM), the following requirements shall

be fulfilled in accordance to EN 61800-9-2:

— pump units equipped with a PDS shall be measured with a screened cable between CDM and motor

of a maximum length of 10 m;

— the measurements shall be done when the PDS is thermally stable (the temperature gradient shall be

maximal 2 K per hour);

— if a frequency converter is used, the filter between motor and frequency converter are recommended

to be disabled.

NOTE 2 Filters between motor and frequency converter are used to overcome impedances due to longer cable

lengths.

7.1.3 Measuring instrumentation

For the test procedures described in 7.2, measuring instrumentation is needed for the determination of:

— the flow rate Q;

— the head H;

— the electric power input P .

Since instrument accuracy is generally expressed as a percentage of full scale, the range of the

instruments chosen shall be as small as suitable to the maximum of the measured values.

The maximum observed values should be in the upper third of the instrument range.

The measuring equipment needed to determine the flow rate Q and the head H shall be selected in

accordance with EN ISO 9906:2012.

NOTE Detailed information is given in EN ISO 9906:2012, A.1.

For the determination of the electric power input P in case 1 in 7.2.3 (motor directly fed by the electric

grid) the electric input power P is determined based on input voltages U and input currents I. All

requirements concerning the instrumentation for the measurements of P shall be fulfilled according to

EN 60034-2-1:2014.

For the determination of the electric power input P in case 2 in 7.2.3 (motor combined with and fed by

a CDM), the electric input power P shall be measured according to “input-output measurement method”

in EN 61800-9-2:2017. All requirements concerning the instrumentation for the measurement of P shall

be fulfilled according to EN 61800-9-2:2017.

7.1.4 Uncertainties of measured quantities

The total measurement uncertainties of the flow rate Q, the pump head H and the electric power P result

from the combined effects of the measurement device uncertainty and of the random uncertainty and can

be determined as described in EN 17038-1:2019, Annex D. The random uncertainty can be reduced by

increasing the number of readings of a measured quantity at the same operating condition (i.e. load point)

of the test submersible multistage pump unit.

For tests done by a company which is responsible for the qualification of submersible multistage pump

units (see EN 17038-1:2019, Clause 5), it is advisable to achieve total measurement uncertainties as small

as possible, i.e. smaller than the maximum permissible values specified by standards.

7.2 Measurement procedure

7.2.1 Measurement steps

The measurement procedure consists of the following steps which are explained in detail in 7.2.2 to 7.2.5

and in 7.3.

1) Run in effects may affect the power input of a submersible multistage pump unit during its initial

operation. In order to ensure a representative power input, a run in of the submersible multistage

pump unit for up to 24 h is necessary. It is recommended to operate the submersible multistage

pump unit at maximum speed and at different flows.

2) To ensure a proper cooling during measurement, information about cooling of the submersible

multistage pump unit provided by the manufacturer shall be applied.

3) Determine the 100 % point at best unit efficiency (Q , H ) as described in 7.2.2.

100 % 100 %

4) Concerning the measurements to determine P the following steps in 7.2.3 up to 7.3 shall be

1,avg

carried out.

5) Calculate the average input power consumption P as described in 7.3 using the measured values

1,avg

of P .

1,corr,i

7.2.2 Determination of Q100 % and H100 %

The best efficiency point of the pump unit and the corresponding values of Q and H shall be

100 % 100 %

determined according to EN 17038-2:2019, 5.2.2.

7.2.3 Determination of reference load points

The relevant values of the flow rate Q at the reference load points shall be calculated by Formula (5):

ref,i

1 𝑄𝑄

𝑄𝑄 = ⋅� � ⋅𝑄𝑄 (5)

𝑟𝑟𝑟𝑟𝑟𝑟,𝑖𝑖 100%

100 𝑄𝑄

100%,𝑖𝑖

where the values (Q/Q ) in [%] which correspond to the N load points of the reference flow-time

100 %, i

profile are taken from Table 3 or Table 4, respectively.

In respect to the head H at the test load points different cases shall be distinguished:

— Case 1, Fixed speed operation:

The electric motor of the pump unit is fed by a constant stator frequency and, therefore, can only be

operated at (nearly) constant rotational speed n. In this case only the pump flow rate Q can be

controlled during the test. The flow rate Q shall be adjusted to the various values of the reference

flow-time profile according to Formula (5) while the head H generated by the pump is given by the

Q-H curve of the pump at constant motor stator frequency. Besides the electric power input P , the

actual values of the pump flow rate Q and head H shall be measured and documented.

— Case 2, Variable speed operation:

The pump unit shall be operated at variable rotational speed along the reference pressure control

curve specified by Formula (4), i.e. H = H . In the test, the flow rate Q shall be adjusted to

ref,i 100 %

the various values according to Formula (5). The pump head H shall be adjusted to the values

according to the reference pressure control curve.

7.2.4 Adjustment tolerances

For each load point, the flow rate Q which is adjusted and measured shall not deviate from the

meas,i

values Q according to the reference flow-time profile by more than ± 3 % or ± 0,1 m /h, whichever is

ref,i

the largest absolute value.

In the case of variable speed operation the measured value H shall not deviate more than ± 5 %

meas,i

or ± 0,2 m, whichever is the largest absolute value, from the values H according to the reference

ref,i

pressure control curve.

7.2.5 Corrections for deviations in flow and head

In tests, the adjusted flow rates Q and pressures H can deviate from the exact values of Q ,

meas,i meas,i ref,i

H defined by the reference pressure control curve specified in 6.3. Within the limits defined in 7.2.4,

ref,i

the measured power input P shall be corrected to the value P by the Formula (6):

1,meas,i 1,corr,i

HQ

ref,,i ref i

PP= ⋅⋅

11,,corr i ,meas,i

HQ

meas,,i meas i

(6)

7.3 Calculation of P

1,avg

To determine the weighted averaged electric power input P , the following steps shall be performed:

1,avg

1) Measure the electric power input P as described in 7.2.1 for all values of the relative flow Q/Q

1 100 %

defined by the respective reference flow-time profile (see Table 3 or 4).

2) Calculate the weighted average of the electric power P by Formula (7):

1,avg

iN=

∆t

PP⋅

11,avg ∑ ,,corr i

i

i=1

(7)

=

where

N = 3 for P

1,avg,c

N = 4 for P .

1,avg,v

3) Using the values of P or P the respective EEI or EEI can be determined according to

1,avg,c 1,avg,v c v

Clauses 9 and 10.

8 Determination of average electric power input P by the means of a Semi-

1,avg

Analytical Model

8.1 General

Instead of determining the Energy Efficiency Index (EEI or EEI , later called EEI value) by performing

V C

tests on complete pump units, their EEI value can be determined by mathematical calculations based on

a so-called Semi-Analytical Model (SAM) of the pump unit.

In this document, a model is called semi-analytical if the mathematical correlations (i.e. equations)

describe the performance in a principal form which reflects the underlying physical processes and

influences, but needs a limited number of data (at so-called supporting points) which result from tests on

the separate components.

As input to the semi-analytical models of the components serve performance quantities and

characteristics that are documented by their manufacturer(s). For a type of pump unit, i.e. a number of

identical pump units of the same configuration, these data describe the mean performance quantities

x of the pump unit size only within a band x ± t . These total tolerances t of the

mean mean x,totx x,tot

performance quantities result from manufacturing performance tolerances t as well as from

x,man

measurement uncertainties e .

x

NOTE 1 Methods to determine the mean values are described in EN 16480.

Furthermore, by applying the mathematical models and the method of SAM the accuracy of the resulting

EEI values is additionally dependent on model uncertainties.

The accumulated effects of tolerances and uncertainties on the total tolerance of EEI values determined

by application of the semi-analytical model(s) are treated in EN 17038-2:2019, D.4.3.

Basic principles of a SAM method applied to pump units are given in EN 17038-2:2019, 6.1. Alternatively,

mathematical models delivering at least the same accuracy of EEI values are permitted.

NOTE 2 For example alternative mathematical models are permitted where the technology of components is not

covered in this document or other mathematical (part-)models are available.

8.2 The semi-analytical model of submersible rotodynamic pumps

The semi-analytical model of submersible rotodynamic pumps that are components of submersible

multistage pump units in the scope of this document is identical to the semi-analytical model of pumps

that are components of single pump units in the scope of EN 17038-2:2019. This pump model is described

in detail in EN 17038-2:2019, 6.2.

It needs as input data supporting points in the form of pairs (Q;H) and (Q;P ) at n = n , respectively,

2 N,PU

that result from tests and evaluations on the respective pump size and shall represent mean values of the

size. Generally, a suitable number k of supporting points shall be used to determine corresponding “best-

fit” functions:

— the number of supporting operating points should at least be k = 5;

— the supporting operating points shall cover at least the range of relative flow rate

0,1 ≤ (Q/Q ) ≤ 1,1.

BEP;PU

Usually, the axial thrust bearing of submersible multistage pump units is integrated in the motor part.

Nevertheless, the shaft power P described by the model of the rotodynamic pump shall include the

friction loss of the axial bearing. A method to determine approximately P including the axial bearing

friction loss is described in Annex B.

NOTE The method to generate additional supporting points for the pump model on the basis of the so-called

“MEI-points” which is described in EN 17038-2:2019, Annex B, is not applicable to submersible multistage pumps

because the underlying statistical evaluations and experimental validations were only done for pumps of the types

ESOB, ESCC, ESCCi and MS-V and H.

If testing with a calibrated motor is not possible a fixed losses of 0.5 % of the pump input power shall be

added, to represent the axial bearing losses caused on the motor.

8.3 Pump units in fixed speed operation

8.3.1 General

The method to determine EEI and/or EEI of submersible multistage pump units operated at fixed speed

c v

is identical to that one described in EN 17038-2:2019, 6.3. Insofar, it is directly applicable to submersible

multistage pump units with a submersible asynchronous cage-induction electric motor. The method is

applicable in spite of the fact that design and constructional features of motors of submersible multistage

pump units show typical differences to standard dry motors in respect to diameter to length ratio,

winding etc. The relevant asynchronous submersible motors are of one of the following types:

1. water filled, encapsulated;

2. water filled, rewindable;

3. oil filled, rewindable;

4. dry motor.

The rotor space of type 1. is filled with liquid, and the motors of the types 2. and 3. are totally filled with

liquid, including the windings.

For these motor types (as for all asynchronous cage-induction motors), the rotational speed n is slightly

smaller than the synchronous speed n which corresponds to the grid frequency. The difference

sync

between synchronous speed and actual rotational speed (described as the so-called slip s as fraction of

the synchronous speed) is dependent on the motor type and size and additionally on the motor load. The

method takes into account the small variations of the rotational speed of the pump unit with the varying

pump shaft power and shaft torque.

NOTE The method ca

...

SLOVENSKI STANDARD

01-februar-2024

Črpalke - Metode za opredelitev indeksa energijske učinkovitosti centrifugalnih

črpalk - 4. del: Preskušanje in računanje indeksa energijske učinkovitosti (IEE)

večstopenjskih potopnih črpalk

Pumps - Methods of qualification of the Energy Efficiency Index for rotodynamic pump

units - Part 4: Testing and calculation of energy efficiency index (EEI) of submersible

multistage pump units

Pumpen - Methoden zur Qualifikation des Energieeffizienzindexes für Kreiselpumpen -

Teil 4: Prüfung und Berechnung des Energieeffizienzindexes (EEI) mehrstufiger

Tauchmotorpumpenaggregate

Pompes - Méthodes de qualification de l'indice de rendement des groupes motopompes

rotodynamiques - Partie 4 : Essais et calcul de l'indice de rendement énergétique (EEI)

pour les unités de pompage submersibles des forages

Ta slovenski standard je istoveten z: EN 17038-4:2023

ICS:

23.080 Črpalke Pumps

27.015 Energijska učinkovitost. Energy efficiency. Energy

Ohranjanje energije na conservation in general

splošno

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17038-4

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2023

EUROPÄISCHE NORM

ICS 23.080

English Version

Pumps - Methods of qualification of the Energy Efficiency

Index for rotodynamic pump units - Part 4: Testing and

calculation of energy efficiency index (EEI) of submersible

multistage pump units

Pompes - Méthodes de qualification de l'indice de Pumpen - Methoden zur Qualifikation des

rendement des groupes motopompes rotodynamiques Energieeffizienzindexes für Kreiselpumpen - Teil 4:

- Partie 4 : Essais et calcul de l'indice de rendement Prüfung und Berechnung des Energieeffizienzindexes

énergétique (EEI) pour les unités de pompage (EEI) mehrstufiger Tauchmotorpumpenaggregate

submersibles des forages

This European Standard was approved by CEN on 29 October 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17038-4:2023 E

worldwide for CEN national Members.

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Symbols and abbreviations . 10

5 General conditions for the operation of submersible multistage pump units . 12

6 Reference flow-time profiles and reference pressure control curve . 12

6.1 General. 12

6.2 Reference flow-time profiles . 13

6.3 Reference pressure control curves . 14

7 Determination of average electric power input P by test . 14

1,avg

7.1 General. 14

7.1.1 Introduction . 14

7.1.2 Test conditions . 14

7.1.3 Measuring instrumentation . 15

7.1.4 Uncertainties of measured quantities . 16

7.2 Measurement procedure . 16

7.2.1 Measurement steps . 16

7.2.2 Determination of Q100 % and H100 % . 16

7.2.3 Determination of reference load points . 16

7.2.4 Adjustment tolerances . 17

7.2.5 Corrections for deviations in flow and head . 17

7.3 Calculation of P . 17

1,avg

8 Determination of average electric power input P by the means of a Semi-

1,avg

Analytical Model . 18

8.1 General. 18

8.2 The semi-analytical model of submersible rotodynamic pumps . 18

8.3 Pump units in fixed speed operation . 19

8.3.1 General. 19

8.3.2 Model of the electric motor . 20

8.3.3 Interaction of pump and motor . 20

8.3.4 Determination of Q and H . 20

100 % 100 %

8.3.5 Determination of the P -value . 21

1,avg,c

8.4 Pump units with a Power Drive System (PDS) . 22

8.4.1 General. 22

8.4.2 Model of the Power Drive System (PDS) . 24

8.4.3 Interaction of pump and PDS . 26

8.4.4 Determination of Q and H . 27

100 % 100 %

8.4.5 Determination of P for pump units with PDS . 27

1,avg

9 Determination of reference electric power input P . 28

1,ref

10 Calculation of Energy Efficiency Index (EEI) . 31

Annex A (informative) Generation of input data for the models of components of a

submersible multistage pump unit . 32

A.1 General . 32

A.2 Input data for the model of a submersible rotodynamic pump . 32

A.3 Input data for the model of a submersible grid fed motor . 33

A.4 Input data for the model of a PDS consisting of submersible motor and CDM . 33

Annex B (informative) Experimental Determination of thrust bearing friction losses . 35

Annex C (informative) Determination of EEI values using data for RCDMs . 36

Bibliography . 37

European foreword

This document (EN 17038-4:2023) has been prepared by Technical Committee CEN/TC 197 “Pumps”,

the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2024, and conflicting national standards shall be

withdrawn at the latest by March 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is the fourth part of a series of standards describing a methodology to evaluate energy

efficiency performance of submersible multistage pump units, comprising a rotodynamic pump part and

a submersible motor which is either directly fed from the grid or combined with a frequency converter

(CDM) to form a Power Drive System (PDS). For consistency purposes with other referred standards,

CDM is used in this document. VSD, for variable speed drive, is the term used in Ecodesign regulations.

Rotodynamic pump and motor are designed with outer diameters and special design features that enable

to install them in boreholes and operate them completely surrounded by the pumped liquid. The

methodology is based on a non-dimensional numerical value called Energy Efficiency Index (EEI). An EEI

value allows the comparison of different configurations by one common indicator. Physical influences

such as size and stage number of the incorporated rotodynamic pump, unit part-load operation, motor-

efficiency characteristic and frequency converter influence are implemented into this metric.

Specific requirements for testing and a calculation method for EEI, the so called semi-analytical model

(SAM) of submersible multistage pump units, specific flow-time profiles and reference pressure control

curves are given in this document.

EEI is an index to rate submersible multistage pump units according to their energy efficiency but does

not replace the need to do a life-time cost analysis regarding energy consumption over the lifetime of the

submersible multistage pump unit.

1 Scope

This document specifies methods and procedures for testing, calculating, and determining the Energy

Efficiency Index (EEI) of submersible multistage pump units.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 16480:2021, Pumps — Rotodynamic pumps — Minimum required efficiency of rotodynamic water

pumps and determination of Minimum Efficiency Index (MEI)

EN 17038-1:2019, Pumps - Methods of qualification and verification of the Energy Efficiency Index for

rotodynamic pump units - Part 1: General requirements and procedures for testing and calculation of Energy

Efficiency Index (EEI)

EN 17038-2:2019, Pumps — Methods of qualification and verification of the energy efficiency index for

rotodynamic pump units — Part 2: Testing and calculation of energy efficiency index (EEI) of single pump

units

EN ISO 9906:2012, Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3 (ISO

9906:2012)

EN ISO 17769-1:2012, Liquid pumps and installation - General terms, definitions, quantities, letter symbols

and units - Part 1: Liquid pumps (ISO 17769-1:2012)

EN 60034-1:2017, Rotating electrical machines — Part 1: Rating and performance (IEC 60034-1:2010)

EN 60034-2-1:2014, Rotating electrical machines - Part 2-1: Standard methods for determining losses and

efficiency from tests (excluding machines for traction vehicles) (IEC 60034 2 1:2014)

EN IEC 60034-2-3:2020, Rotating electrical machines - Part 2-3: Specific test methods for determining

losses and efficiency of converter-fed AC motors (IEC 60034 2020)

EN IEC 60038:2011/prA1:2020, {fragment 1}, Standard voltages for LVDC supply and LVDC equipment

(Proposed horizontal standard)

EN IEC 60038:2011/prA1:2020, {fragment 2}, Standard voltages for AC supply and AC equipment

(Proposed horizontal standard)

EN IEC 60038:2011/prA1:2020, {fragment 3}, Standard voltages for DC and AC traction systems (Proposed

horizontal standard)

EN 61800-9-2:2017, Adjustable speed electrical power drive systems - Part 9-2: Ecodesign for power drive

systems, motor starters, power electronics and their driven applications - Energy efficiency indicators for

power drive systems and motor starters (IEC 61800 9 2:2017)

As impacted by EN 17038-2:2019/AC:2020.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 17769-1:2012 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

submersible multistage water pump unit

submersible multistage water pump unit is composition of submersible multistage pump and

submersible borehole motor with or without Variable Speed Drive (VSD)

3.2

submersible borehole motor

electric motor designed to be operated submersed at operating temperatures not below 0 °C and not

above 40 °C

3.3

submersible multistage pump

MSS

multistage (i > 1) rotodynamic water pump with a nominal outer diameter from 2,5″ (63,5 mm) up to 6″

(152,4 mm) designed to be operated submersed, at operating temperatures within a range of 0 °C and

90 °C, with a nominal flow rate > 1,75 m /h

3.4

clean water

water with a maximum non-absorbent free solid content of 0,25 kg/m , and with a maximum dissolved

solid content of 50 kg/m , provided that the total gas content of the water does not exceed the saturation

volume

Note 1 to entry: Any additives that are needed to avoid water freezing down to – 10 °C shall not be considered.

3.5

clean cold water

−6 2

clean water to be used for pump testing, with a maximum kinematic viscosity of 1,5 × 10 m /s, a

maximum density of 1 050 kg/m and a maximum temperature of 40 °C

3.6

fixed-speed pump unit

pump unit without a variable speed drive (VSD)

3.7

variable-speed pump unit

pump unit equipped with an VSD

3.8

complete drive module

CDM

variable speed drive

VSD

electronic power converter connected between the electric supply and a motor as well as extensions such

as protection devices, transformers and auxiliaries (according to EN 61800-2)

Note 1 to entry: This term is defined in EN 61800-2.

3.9

power drive system

PDS

combination of CDM and motor

3.10

check-valve

non-return valve

Note 1 to entry: Such a valve is often integrated in submersible multistage pump units.

3.11

constant flow

slight variation of the flow rate around the nominal value

Note 1 to entry: Caused by secondary influences from the process as, for example, the (moderately) varying level

of liquid in reservoirs, etc. The variation of flow rate occurs typically within the range which is covered by the

definition and determination of the Minimum Efficiency Index (MEI) of the pump (see EN 16480), and which is from

0,75 Q to 1,1 Q .

100 % 100 %

3.12

variable flow

widely varying flow rate

Note 1 to entry: Typically, at considerable fractions of the total operating time, the actual demand for pump flow

rate Q and pump head H is much lower than the values at the operating point of maximum flow rate which is

demanded by the application.

3.13

suction pressure

pressure at the inlet of a submersible multistage pump

Note 1 to entry: All pressures are gauge pressures (relative to the ambient pressure).

3.14

discharge pressure

pressure at the outlet of a submersible multistage pump

3.15

total head

overall energy in any section

Note 1 to entry: The total head is given by:

pU

xx

Hz=+ + (1)

xx

ρ××gg2

where

z is the height of the centre of the cross-section above the reference plane;

p is the gauge pressure related to the centre of the cross-section;

U is the flow velocity.

Note 2 to entry: The absolute total head in any section is given by:

pp U

xxamb

Hz=++ +

x(abs) x

ρρ××g gg2

3.16

hydraulic power

arithmetic product of the flow Q and the head H, and a constant a per Formula (2):

P = ρ⋅ Q⋅⋅gH (2)

hyd

where

P is the hydraulic power [W];

hyd

Q is the flow [m /s];

H is the total head [m];

g gravitational constant 9,81 m/s ;

ρ is the density of fluid [kg/m ].

3.17

electric power input P

electric power supplied:

— to the motor in the case of a (grid fed) fixed speed pump unit;

— to the CDM in the case of a variable speed pump unit

3.18

pump unit efficiency

ratio of hydraulic power P and electric power input P

hyd

3.19

pump unit best efficiency point

Q /H

BEP,unit BEP,unit

flow-head-point where the pump unit runs at its best unit efficiency point and at maximum operation

3.20

reference flow rate, Q

100%

flow per time unit [m /h] at the Best Efficiency Point (BEP) of the pump unit

3.21

reference head, H

100%

total head [m] at the Best Efficiency Point (BEP) of the pump unit

3.22

control curve

functional dependency of the demanded head H vs. the delivered flow rate Q in the form of a non-

dimensional correlation H/H = f (Q/Q )

100% 100%

3.23

reference control curve

pre-defined functional dependency H/H = f (Q/Q ) for standardised measurements and

100% 100%

calculations of average power input P

1, avg

3.24

flow-time profile

relation between flow rate intervals and relative operation time pattern of percentiles of time where the

pump unit runs at a given flow rate

3.25

Minimum Efficiency Index (MEI)

dimensionless number for the energy efficiency of pumps

Note 1 to entry: This term is defined in EN 16480:2021.

4 Symbols and abbreviations

For the purpose of this document, the symbols and units given in Table 1 apply.

Table 1 — Symbols and units

Symbol Designation Unit

g Gravitational constant m/s

H (Total) head m

H (Total) head at best efficiency point of a pump m

BEP,unit

H (Total differential) head at m

BEP,N

H Geodetic head m

geo

Symbol Designation Unit

H Head loss caused by a check-valve m

L,cv

H Measured head m

meas

H Reference head m

ref

H Head loss of the supplied hydraulic system m

resistance

H Head at BEP of the pump unit m

100 %

i Stage number of multistage pumps -

i Consecutive number of load points [-]

k Number of supporting points [-]

K Constant in Formula (3) 2 5 2 5

s /m or h /m

n Rotational speed -1

min

n Nominal rotational speed of a pump -1

N,PU min

n Specific speed of a pump -1

s min

N Total number of load points [-]

p Pressure bar (g)

p Suction pressure bar (g)

s

p Discharge pressure bar (g)

d

P Electric power input W, kW

P Reference value of electric power input W, kW

1,ref

P Measured electric power input W, kW

1,meas

P Mechanical power transmitted by the motor to the W, kW

hydraulic pump part

P Shaft power output of the calibrated submersible W, kW

2,calibrated

borehole motor without axial thrust load

P Power loss W, kW

L

PL,PDS Relative losses of the PDS in relation to the rated power of W, kW

the motor

Q Flow rate m /h

Q m /h

Flow rate at best efficiency point of a pump unit

BEP,unit

Q m /h

BEP,N

Flow rate at specific load point ?????

Q Reference flow rate m /h

ref

Q Flow rate from test m /h

test

Symbol Designation Unit

Q Flow rate at BEP of the pump unit m /h

100 %

s Slip of rotational motor speed [-] or %

t Time s; min; h

T Torque N⋅m

η Efficiency [-] or %

ρ Density 3

kg/m

5 General conditions for the operation of submersible multistage pump units

In the majority of applications, submersible multistage pump units are installed and operated in

boreholes. In these cases, the hydraulic circuit connected to the pump unit is an open loop system with

predominant geodetic head H . The resistance curve that determines the operating points of the pump

geo

unit is of the type given by Formula (3):

H H+⋅KQ (3)

resis tan ce geo

where typically the head loss caused by friction losses in the piping K⋅Q is much smaller than the

geodetic head H .

geo

Depending on the individual application, the range of flow rate demand may be rather small (“constant

flow”) or rather wide (“variable flow”).

Especially in the case of remarkably varying demand for delivered flow rate, it is advantageous (in respect

to energy consumption) to operate the pump unit at variable speed. This mode of operation requires a

variable speed driven pump. In other cases, it may be adequate to operate the pump unit at fixed speed,

i.e. to feed the electric motor directly by the grid.

6 Reference flow-time profiles and reference pressure control curve

6.1 General

According to the two different modes of operation (constant or variable flow), two different reference

flow-time profiles are relevant (see 6.3) that lead to two different numerical values of EEI. These values

are designated as EEI (concerning the constant flow operation mode) and EEI (concerning the variable

C V

flow operation mode).

In the constant flow mode of operation, the operating points for the determination of EEI are defined to

C

be the values of the flow rate Q according to the corresponding reference flow-time profile (see 6.3) and

the values of pump head H according to the Q-H curve of the actual pump unit at constant (grid) frequency.

Insofar, this Q-H curve stands for the reference pressure control curve for EEI .

C

On the other hand, in the variable flow mode of operation the reference pressure control curve for EEI

V

is based on the assumption of a constant pump head H which is independent of the delivered flow rate Q

and is equal to H (see 6.3).

100 %

When putting submersible multistage pump units into service an appropriate value of EEI shall be made

available. The EEI shall be for constant flow (EEI ) and/or variable flow (EEI ) according to the demand

C V

of the application in which the pump unit is put into service or for which the pump unit is specified, when

=

placed on the market. The corresponding flow-time profiles and pressure control curves are given in

Table 2.

Table 2 — Reference flow-time profiles and reference pressure control curves for submersible

multistage pump units

Mode Reference Reference Applicable Q/H Applicable

flow-time pressure test points EEI

profile

control curve

Demand of Type of

application pump unit

M1 constant fixed speed constant Q-H curve of on Q/H curve of EEI

C

flow flow the pump unit the pump unit

(Table 3)

M2 variable flow fixed speed variable Formula (4) on Q-H curve of EEI

V

flow the pump unit

(Table 4)

M3 constant variable constant Q-H curve of on Q-H curve of EEI

C

flow speed flow the pump unit the pump unit

(Table 3) (measured at

fixed speed)

M4 variable flow variable variable Formula (4) Q/H points de- EEI

V

speed flow fined by

(Table 4) Formula (4)

M5 constant variable variable Formula (4) Q/H points de- EEI

V

flow, varying speed flow fined by

head (Table 4) Formula (4)

6.2 Reference flow-time profiles

The reference flow-time profile for constant flow operation is specified by the values given in Table 3.

Table 3 — Reference flow-time profile for constant flow operation

Flow Q in % of Q

75 100 110

100 %

Time Δt in % of total operating time 25 50 25

The reference flow-time profile for variable flow operation is specified in Table 4.

Table 4 — Reference flow-time profile for variable flow operation

Flow Q in % of Q

100 %

25 50 75 100

10 40 40 10

Time Δt in % of total operating time

NOTE 1 Q is defined in 3.20.

100 %

NOTE 2 The time fractions of total operating time that are specified in Tables 3 and 4 as values to be used for the

determination of EEI are based on comprehensive experience of manufacturers of submersible pumps in respect to

typical applications and operational conditions of their products.

6.3 Reference pressure control curves

In the case of the variable flow demand (modes M2 and M4), the reference control curve shall be defined

by Formula (4):

H H or H /%H 100

ii100% 100%

(4)

In the case of the constant flow operation mode (modes M1 and M3), the reference control curve is the Q-

H curve of the actual pump unit applied to define Q H (see 7.2.2 and 8.3.4).

100 %, 100 %

In the case of the constant flow and varying head demand (mode M5), the reference control curve shall be

defined by Formula (4).

NOTE H is defined in 3.21.

100 %

7 Determination of average electric power input P by test

1,avg

7.1 General

7.1.1 Introduction

This clause specifies performance tests and evaluations on submersible multistage pump units.

Such tests shall provide the necessary information on the actual performance values of tested

submersible multistage pump units needed for the calculation of the EEI-value according to its definition

given in EN 17038-1:2019, Clause 4.

All provisions for the test concerning the submersible multistage pump unit (taken as “black box” and

treated as a pump unit as those covered by EN 17038-2:2019) shall be in accordance with

EN ISO 9906:2012, grade 2. The exception for power of 10 kW and below (as allowed for the application

of EN ISO 9906:2012 on acceptance tests) shall not be valid.

All provisions for the test concerning electric motors that are part of the submersible multistage pump

unit and are fed directly from an electric grid shall be in accordance with EN 60034-2-1:2014.

All provisions for the test concerning a Power Drive System which is part of the submersible multistage

pump unit shall be in accordance with EN 61800-9-2:2017.

7.1.2 Test conditions

Tests shall be carried out with clean cold water.

The duration of the test shall be considered to obtain repeatable results. Especially run-in of bearings and

sealings and warming-up effects of the electric and electronic components of the unit shall be considered.

NOTE 1 Run-in effects can take up to 24 h of operating time.

The electric power supply of the test installation shall fulfil the requirements as specified in

EN 60034-1:2017. This requires the following:

— the voltage shall be in accordance with EN 60038, 7.2, and EN 60034-1;

— the frequency shall be within ± 0,3 % of the rated frequency during measurements;

— the testing requires thermal stabilization, the fluid-temperature shall be in the range 10 °C to 30 °C;

— the change in the motor temperature over time shall be smaller than 1 K/30 min;

==

— a cooling flow according to the corresponding flow velocity shall be ensured, e.g. by applying a

cooling shroud.

The tests should be conducted under conditions where cavitation does not affect the performance of the

pump.

All measurements shall be performed under hydraulic and thermal steady-state conditions (see

EN ISO 9906:2012, EN 60034-2-1:2014, EN IEC 60034-2-3:2020 and EN 61800-9-2:2017).

For Case 1 in 7.2.3 (motor fed by an electric supply with constant frequency), the electric power supply

of the test installation shall fulfil the requirements as specified in EN 60034-1:2017. This requires that:

— the maximum motor cable length shall be 10 m.

For Case 2 in 7.2.3 (PDS, i.e. motor combined with and fed by a CDM), the following requirements shall

be fulfilled in accordance to EN 61800-9-2:

— pump units equipped with a PDS shall be measured with a screened cable between CDM and motor

of a maximum length of 10 m;

— the measurements shall be done when the PDS is thermally stable (the temperature gradient shall be

maximal 2 K per hour);

— if a frequency converter is used, the filter between motor and frequency converter are recommended

to be disabled.

NOTE 2 Filters between motor and frequency converter are used to overcome impedances due to longer cable

lengths.

7.1.3 Measuring instrumentation

For the test procedures described in 7.2, measuring instrumentation is needed for the determination of:

— the flow rate Q;

— the head H;

— the electric power input P .

Since instrument accuracy is generally expressed as a percentage of full scale, the range of the

instruments chosen shall be as small as suitable to the maximum of the measured values.

The maximum observed values should be in the upper third of the instrument range.

The measuring equipment needed to determine the flow rate Q and the head H shall be selected in

accordance with EN ISO 9906:2012.

NOTE Detailed information is given in EN ISO 9906:2012, A.1.

For the determination of the electric power input P in case 1 in 7.2.3 (motor directly fed by the electric

grid) the electric input power P is determined based on input voltages U and input currents I. All

requirements concerning the instrumentation for the measurements of P shall be fulfilled according to

EN 60034-2-1:2014.

For the determination of the electric power input P in case 2 in 7.2.3 (motor combined with and fed by

a CDM), the electric input power P shall be measured according to “input-output measurement method”

in EN 61800-9-2:2017. All requirements concerning the instrumentation for the measurement of P shall

be fulfilled according to EN 61800-9-2:2017.

7.1.4 Uncertainties of measured quantities

The total measurement uncertainties of the flow rate Q, the pump head H and the electric power P result

from the combined effects of the measurement device uncertainty and of the random uncertainty and can

be determined as described in EN 17038-1:2019, Annex D. The random uncertainty can be reduced by

increasing the number of readings of a measured quantity at the same operating condition (i.e. load point)

of the test submersible multistage pump unit.

For tests done by a company which is responsible for the qualification of submersible multistage pump