SIST EN 17488:2021

(Main)Conservation of cultural heritage - Procedure for the analytical evaluation to select cleaning methods for porous inorganic materials used in cultural heritage

Conservation of cultural heritage - Procedure for the analytical evaluation to select cleaning methods for porous inorganic materials used in cultural heritage

This document gives the test methodology for evaluation of both harmfulness and effectiveness of a cleaning method as applied to porous inorganic materials. Mural paintings and polychromy are excluded.

Evaluation includes the use of on-site analyses and/or laboratory studies.

The evaluation of the potential harm has a higher priority than the effectiveness in order to prevent overcleaning. It is important that cleaning is always at the minimum level deemed effective and that it respects the original surface and finishes. Overcleaning is a term used to indicate that irreversible damage has been done by the unnecessary removal of materials, which are part of the value of the object.

This document applies to:

a) Part A: all methods of cleaning, which have characteristics of parameterization and reproducibility (see EN 17138).

b) Part B: all new methods that are under development.

This document applies to evaluate the optimum methods for cleaning and the optimization of the parameters of the selected cleaning process.

Erhaltung des kulturellen Erbes - Methodologie für die analytische Prüfung zur Auswahl von Reinigungsverfahren von porösen anorganischen Objekten des kulturellen Erbes

Dieses Dokument enthält das Prüfverfahren zur Bewertung der Schädlichkeit sowie der Wirksamkeit eines Reinigungsverfahrens, das auf porösen anorganischen Materialien angewendet wird. Wandmalereien und Polychromie sind hiervon ausgenommen.

Die Bewertung umfasst die Durchführung von Analysen vor Ort und/oder Untersuchungen im Labor.

Die Bewertung des möglichen Schadens hat eine höhere Priorität als die Wirksamkeit, um eine Überreinigung zu vermeiden. Es ist wichtig, dass die Reinigung stets auf dem niedrigsten Niveau erfolgt, das als wirksam erachtet wird, und dass sie unter Berücksichtigung der ursprünglichen Oberfläche und Beschichtungen erfolgt. Überreinigung ist ein Begriff, der darauf hinweist, dass durch die unnötige Entfernung von Materialien, die zum Wert des Objekts beitragen, irreversible Schäden entstanden sind.

Dieses Dokument gilt für:

a) Teil A: alle Reinigungsverfahren, die Merkmale der Parametrisierung und Reproduzierbarkeit aufweisen (siehe EN 17138);

b) Teil B: alle neuartigen Verfahren, die sich in der Entwicklung befinden.

Dieses Dokument dient der Bewertung der optimalen Reinigungsverfahren und der Optimierung der Parameter von ausgewählten Reinigungsprozessen.

Conservation du patrimoine culturel - Procédure pour l'évaluation analytique et le choix des méthodes de nettoyage des matériaux inorganiques poreux dans les bâtiments d'intérêt patrimonial

Le présent document présente la méthodologie d'essai utilisée pour l'évaluation de la dangerosité et de l'efficacité d'une méthode de nettoyage appliquée aux matériaux inorganiques poreux. Les peintures murales et la polychromie sont exclues.

L'évaluation inclut l'utilisation d'analyses sur site et/ou d'études en laboratoire.

Afin d'éviter tout nettoyage excessif, l'évaluation du dommage potentiel est prioritaire sur l'efficacité. Il est important que le nettoyage soit effectué au niveau minimal jugé efficace et qu'il respecte la surface d'origine et les couches de finition. Le nettoyage excessif est un terme utilisé pour indiquer qu'un dommage irréversible a été causé par l'élimination non nécessaire de matériaux constitutifs de la valeur du bien.

Le présent document s'applique à :

a) Partie A : toutes les méthodes de nettoyage présentant des caractéristiques de paramétrage et de reproductibilité (voir l'EN 17138) ;

b) Partie B : toutes les nouvelles méthodes en cours de développement.

Le présent document s'applique à l'évaluation des meilleures méthodes de nettoyage ainsi que l'optimisation des paramètres du processus de nettoyage choisi.

Ohranjanje kulturne dediščine - Postopek za analitično vrednotenje pri izbiri metod za čiščenje poroznih anorganskih materialov, uporabljenih pri tej kulturni dediščini

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Aug-2020

- Publication Date

- 22-Jul-2021

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 21-Jul-2021

- Due Date

- 25-Sep-2021

- Completion Date

- 23-Jul-2021

Overview

EN 17488:2021 - published by CEN - defines an analytical procedure to select and optimize cleaning methods for porous inorganic materials used in cultural heritage (mural paintings and polychromy are excluded). The standard prescribes a risk‑aware, evidence‑based workflow combining on‑site investigations and laboratory testing to evaluate both the potential harmfulness and the effectiveness of cleaning methods. Priority is given to preventing irreversible damage (overcleaning): the least invasive method that achieves the required result should be chosen and parameterized.

Key topics and technical requirements

- Scope and structure

- Applies to: Part A - parameterized, reproducible cleaning methods (see EN 17138); Part B - new methods under development.

- Emphasis on trials, monitoring and optimisation of cleaning parameters.

- Risk-first evaluation

- Harmfulness (short‑ and long‑term risks) is assessed before effectiveness to avoid irreversible loss of historic material or alteration of substrate properties.

- On‑site investigations

- Non‑invasive observations: portable digital microscopes, raking light, UV‑induced fluorescence, stereo microscopy.

- Field analyses: colour measurement, portable XRF, portable FTIR, surface ion analysis.

- Water absorption tests: pipe method, contact‑sponge, water‑drop tests.

- Laboratory analyses

- Sampling and sample preparation protocols for trial areas.

- Microscopy and microanalysis: transmitted/reflective light microscopy (TLOM/RLOM), SEM/ESEM with EDS.

- Spectroscopy: FTIR, micro‑FTIR, Raman for molecular identification.

- Surface morphology and roughness (reference to ISO 25178).

- Wet chemical analysis of aqueous extracts where chemical cleaning is used.

- Trial area management and reporting

- Localization, delimitation and numbering of trial areas, definition of referenced cleaned area, and comprehensive test reports (measurements before/after cleaning).

- Compatibility and conservation context

- Cleaning actions must be assessed for compatibility with substrate and project conservation strategy (links to EN 15898, EN 16853, EN 16085, EN 16095).

Practical applications and users

Who benefits from EN 17488:2021:

- Conservators and conservation scientists selecting or validating cleaning protocols for stone, mortar, brick and other porous inorganic substrates.

- Restoration contractors and heritage managers needing documented, reproducible cleaning trials.

- Analytical laboratories performing microscopy, spectroscopy and wet chemical analyses for conservation projects.

- Institutions and public bodies that require standardized evaluation to justify interventions and minimize risk.

Practical uses:

- Designing trial areas and monitoring regimes before large‑scale cleaning.

- Comparing new cleaning technologies against established, parameterized methods.

- Documenting evidence to support minimally invasive cleaning decisions and to prevent overcleaning.

Related standards

- EN 17138 - Specifications for cleaning methods (parameterization and reproducibility)

- EN 15898 - Compatibility definition for materials in conservation

- EN 16853, EN 16085, EN 16095 - Conservation process and condition reporting

Keywords: EN 17488:2021, conservation of cultural heritage, cleaning methods, porous inorganic materials, analytical evaluation, trial areas, overcleaning, portable XRF, FTIR, SEM, conservation standards.

Frequently Asked Questions

SIST EN 17488:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Conservation of cultural heritage - Procedure for the analytical evaluation to select cleaning methods for porous inorganic materials used in cultural heritage". This standard covers: This document gives the test methodology for evaluation of both harmfulness and effectiveness of a cleaning method as applied to porous inorganic materials. Mural paintings and polychromy are excluded. Evaluation includes the use of on-site analyses and/or laboratory studies. The evaluation of the potential harm has a higher priority than the effectiveness in order to prevent overcleaning. It is important that cleaning is always at the minimum level deemed effective and that it respects the original surface and finishes. Overcleaning is a term used to indicate that irreversible damage has been done by the unnecessary removal of materials, which are part of the value of the object. This document applies to: a) Part A: all methods of cleaning, which have characteristics of parameterization and reproducibility (see EN 17138). b) Part B: all new methods that are under development. This document applies to evaluate the optimum methods for cleaning and the optimization of the parameters of the selected cleaning process.

This document gives the test methodology for evaluation of both harmfulness and effectiveness of a cleaning method as applied to porous inorganic materials. Mural paintings and polychromy are excluded. Evaluation includes the use of on-site analyses and/or laboratory studies. The evaluation of the potential harm has a higher priority than the effectiveness in order to prevent overcleaning. It is important that cleaning is always at the minimum level deemed effective and that it respects the original surface and finishes. Overcleaning is a term used to indicate that irreversible damage has been done by the unnecessary removal of materials, which are part of the value of the object. This document applies to: a) Part A: all methods of cleaning, which have characteristics of parameterization and reproducibility (see EN 17138). b) Part B: all new methods that are under development. This document applies to evaluate the optimum methods for cleaning and the optimization of the parameters of the selected cleaning process.

SIST EN 17488:2021 is classified under the following ICS (International Classification for Standards) categories: 97.195 - Items of art and handicrafts. Cultural property and heritage. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17488:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2021

Ohranjanje kulturne dediščine - Postopek za analitično vrednotenje pri izbiri

metod za čiščenje poroznih anorganskih materialov, uporabljenih pri tej kulturni

dediščini

Conservation of cultural heritage - Procedure for the analytical evaluation to select

cleaning methods for porous inorganic materials used in cultural heritage

Erhaltung des kulturellen Erbes - Methodologie für die analytische Prüfung zur Auswahl

von Reinigungsverfahren von porösen anorganischen Objekten des kulturellen Erbes

Conservation du patrimoine culturel - Procédure pour l'évaluation analytique et le choix

des méthodes de nettoyage des matériaux inorganiques poreux dans les bâtiments

d'intérêt patrimonial

Ta slovenski standard je istoveten z: EN 17488:2021

ICS:

97.195 Umetniški in obrtniški izdelki. Items of art and handicrafts.

Kulturne dobrine in kulturna Cultural property and

dediščina heritage

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17488

EUROPEAN STANDARD

NORME EUROPÉENNE

June 2021

EUROPÄISCHE NORM

ICS 97.195

English Version

Conservation of cultural heritage - Procedure for the

analytical evaluation to select cleaning methods for porous

inorganic materials used in cultural heritage

Conservation du patrimoine culturel - Procédure pour Erhaltung des kulturellen Erbes - Methodologie für die

l'évaluation analytique et le choix des méthodes de analytische Prüfung zur Auswahl von

nettoyage des matériaux inorganiques poreux dans les Reinigungsverfahren von porösen anorganischen

bâtiments d'intérêt patrimonial Objekten des kulturellen Erbes

This European Standard was approved by CEN on 23 May 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17488:2021 E

worldwide for CEN national Members.

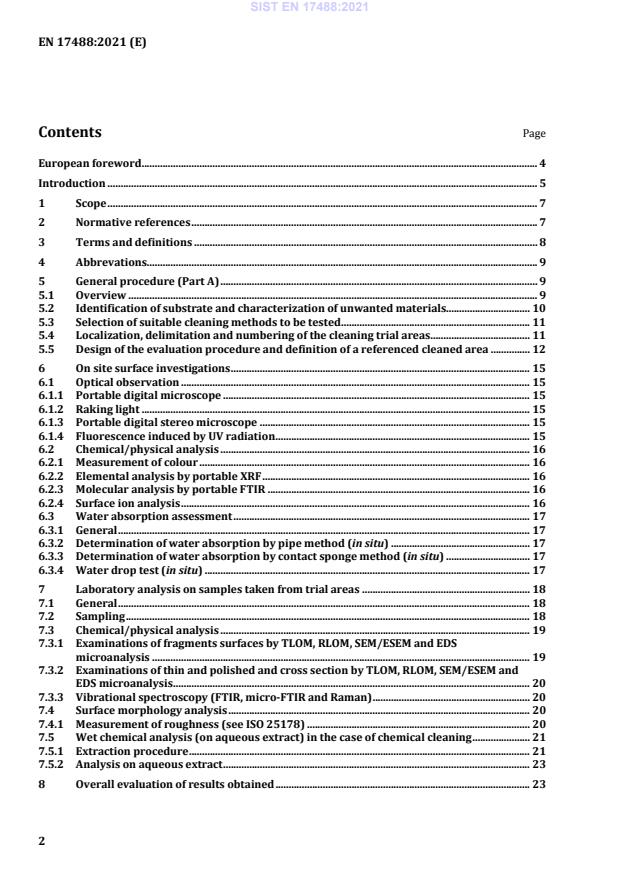

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Abbrevations. 9

5 General procedure (Part A) . 9

5.1 Overview . 9

5.2 Identification of substrate and characterization of unwanted materials. 10

5.3 Selection of suitable cleaning methods to be tested . 11

5.4 Localization, delimitation and numbering of the cleaning trial areas . 11

5.5 Design of the evaluation procedure and definition of a referenced cleaned area . 12

6 On site surface investigations . 15

6.1 Optical observation . 15

6.1.1 Portable digital microscope . 15

6.1.2 Raking light . 15

6.1.3 Portable digital stereo microscope . 15

6.1.4 Fluorescence induced by UV radiation . 15

6.2 Chemical/physical analysis . 16

6.2.1 Measurement of colour . 16

6.2.2 Elemental analysis by portable XRF . 16

6.2.3 Molecular analysis by portable FTIR . 16

6.2.4 Surface ion analysis . 16

6.3 Water absorption assessment . 17

6.3.1 General . 17

6.3.2 Determination of water absorption by pipe method (in situ) . 17

6.3.3 Determination of water absorption by contact sponge method (in situ) . 17

6.3.4 Water drop test (in situ) . 17

7 Laboratory analysis on samples taken from trial areas . 18

7.1 General . 18

7.2 Sampling . 18

7.3 Chemical/physical analysis . 19

7.3.1 Examinations of fragments surfaces by TLOM, RLOM, SEM/ESEM and EDS

microanalysis . 19

7.3.2 Examinations of thin and polished and cross section by TLOM, RLOM, SEM/ESEM and

EDS microanalysis . 20

7.3.3 Vibrational spectroscopy (FTIR, micro-FTIR and Raman) . 20

7.4 Surface morphology analysis . 20

7.4.1 Measurement of roughness (see ISO 25178) . 20

7.5 Wet chemical analysis (on aqueous extract) in the case of chemical cleaning . 21

7.5.1 Extraction procedure . 21

7.5.2 Analysis on aqueous extract . 23

8 Overall evaluation of results obtained . 23

9 Analytical procedure for testing methods under development on specimens of

analogous material (Part B). 24

9.1 General procedure . 24

9.2 Preparation of test specimens . 26

9.2.1 Number and dimensions of test specimens . 26

9.2.2 Pre-conditioning of test specimens . 27

9.3 Evaluation process of the cleaning method(s) under test . 27

9.4 Test analysis on specimens before and after the application of cleaning methods . 27

9.4.1 General . 27

9.4.2 Determination of water absorption by capillarity . 27

9.4.3 Colour measurement of surfaces . 28

9.4.4 Observation of the surfaces by the stereo microscope . 28

9.4.5 Determination of mass variation . 28

9.4.6 Thin and polished cross sections analysis by TLOM, RLOM, SEM/ESEM-EDS . 28

9.4.7 Thin and polished cross sections analysis by TLOM, RLOM, SEM/ESEM-EDS on

fragments of surfaces . 29

9.4.8 Cleaning application . 29

9.5 Analysis of aqueous extract for chemical cleaning . 30

9.6 Test report . 30

9.6.1 General information . 30

9.6.2 Results of measurements on specimens . 30

Annex A (normative) Examples of trial applications . 33

Annex B (informative) Test carried out, findings, inference . 38

Annex C (informative) Specifications to be reported for different cleaning methods (see

EN 17138:2018) . 48

Bibliography . 52

European foreword

This document (EN 17488:2021) has been prepared by Technical Committee CEN/TC 346 “Conservation

of Cultural Heritage”, the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by December 2021, and conflicting national standards shall

be withdrawn at the latest by December 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

Cleaning is the removal of unwanted material from an object surface or near-surface.

A cultural heritage object is irreplaceable and while cleaning is undertaken for object conservation, its

effects are irreversible. Failure to consider and address the technical problems which can arise during

cleaning may cause irrevocable damage to an object. Cultural heritage should be cleaned using the least

disruptive/invasive procedure possible in order to best preserve it.

Furthermore, an inadequate or inappropriate intervention may cause, or increase, future deterioration

processes or eliminate materials which are undocumented or which would allow a greater understanding

of the history of an object.

The actions required for cleaning involve a degree of risk for the object and therefore demand extreme

caution. The chosen methods for cleaning should not be harmful to the object, the operator, the

surroundings /environment, or users of the site.

Cleaning operation needs to take into account the compatibility definition (EN 15898) as the “extent to

which one material can be used with another material without putting significance or stability at risk”.

Extending the definition of compatibility to the cleaning action a “compatibility analysis” should therefore

ascertain how cleaning actions (in terms of effectiveness and harmfulness) would impact on the

significance and stability of the heritage object.

A successful cleaning strategy needs to adher to the strategy for the whole conservation-project in

accordance with the conservation-process and the condition report (EN 16853, EN 16085 and EN 16095)

and requires careful consideration of a number of aspects which include but are not limited to:

— the significance of the object;

— the aim of the cleaning;

— a clear definition of the nature of the materials to be removed and the rationale;

— context and sensitivity of the object to be evaluated (for example presence of polychrome and gilt

surfaces);

— condition of the substrate, which may result in greater risk of harm during testing;

— form of the substrate (flat or carved surface).

These factors may exclude the use of one or more cleaning methods, which would be unsuitable.

This document takes into account the extreme variability of both the constituent materials and the

conditions of the object, prescribing a procedure of analytical tests and comparing the extent of possible

damage, which may result from each cleaning method tested.

“Harmfulness” indicates the level of risk of the variety of unwanted changes, which may appear not only

in short-term but also in long-term after cleaning.

This may include the deterioration of the substrate, the change of porosity or surface roughness, the

release of residual substances and formation of stains, which are not compatible with the material and or

which could interfere with future conservation intervention.

The potential harmfulness of a cleaning method may be greater when it is applied to a deteriorated

material.

Evaluation of effectiveness and potential harmfulness of cleaning methods need to be carried out on site

by establishing a “trial area” as a preliminary step before any extensive work is started.

The process of cleaning requires careful evaluation throughout the work. This is initiated at the primary

evaluation through the execution of trials and continues with the monitoring and optimization during the

selected process. Trials aim to identify the method(s) of cleaning which produce an acceptable result at

minimum risk to the object. Even an extensive sampling procedure may fail to identify all the conditions

which exist on a cultural object therefore ongoing evaluation of the cleaning and the effects on the

substrate are vital. If necessary, cleaning needs to be halted to re-appraise the methods used or to

undertake further testing where areas of increased sensitivity or uncertainty are uncovered. This

document identifies the means by which cleaning methods may be selected and evaluated as part of

conservation interventions.

Unwanted interactions may arise from different substrate and cleaning method combinations. Some

features of a given substrate may cause it to be particularly damaged depending on the method and

circumstances of its use. These specific combinations will increase likelihood of damage. In some

circumstances the synergistic effects can be easily predicted, e.g. a salt-laden wall masonry may be

seriously affected by a water-based method, even if we know that generally this cleaning method is gentle

and of low aggressiveness. The assessment of the synergistic effects should take into consideration that

damage may emerge after some considerable elapsed time.

The initial assessment for a building or similar immovable object will take place on site with non-invasive

systems. If necessary, it may be followed by appropriate micro-invasive or invasive laboratory analysis

(Figure 1, Table 1).

As there are many different cleaning methods and the results can vary greatly it is necessary to carefully

evaluate any proposed technique/system before trial and subsequent application. Reference to standard

EN 17138 is required to undertake this.

Cleaning methods considered in EN 17138 were divided into four categories: Water cleaning, mechanical

cleaning, physical cleaning and chemical cleaning. Each method requires different considerations in order

to select the most appropriate investigations.

Assessment of harmfulness for chemical cleaning methods needs additional investigation with respect to

the possible interactions between the chemicals and the products to be removed, notably the formation

of by-products which could be harmful for the substrate. As a consequence, the procedure for chemical

cleaning will follow a different pathway (Figures 2 and 6, Table 1).

The document is composed of two parts:

a) General procedure (Part A) to be applied when the evaluation of the effects of cleaning of a cultural

heritage object surface is needed.

b) Analytical procedure (Part B) for testing cleaning methods under development on specimens of

analogous material similarly decayed.

Cleaning methods and materials, which are under development should not be evaluated on cultural

heritage objects surface but they should be tested according to the analytical procedure described in

part B.

1 Scope

This document gives the test methodology for evaluation of both harmfulness and effectiveness of a

cleaning method as applied to porous inorganic materials. Mural paintings and polychromy are excluded.

Evaluation includes the use of on-site analyses and/or laboratory studies.

The evaluation of the potential harm has a higher priority than the effectiveness in order to prevent

overcleaning. It is important that cleaning is always at the minimum level deemed effective and that it

respects the original surface and finishes. Overcleaning is a term used to indicate that irreversible damage

has been done by the unnecessary removal of materials, which are part of the value of the object.

This document applies to:

a) Part A: all methods of cleaning, which have characteristics of parameterization and reproducibility

(see EN 17138).

b) Part B: all new methods that are under development.

This document applies to evaluate the optimum methods for cleaning and the optimization of the

parameters of the selected cleaning process.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 15801, Conservation of cultural property - Test methods - Determination of water absorption by

capillarity

EN 15886, Conservation of cultural property - Test methods - Colour measurement of surfaces

EN 16095, Conservation of cultural property - Condition recording for movable cultural heritage

EN 16096, Conservation of cultural property - Condition survey and report of built cultural heritage

EN 16302, Conservation of cultural heritage - Test methods - Measurement of water absorption by pipe

method

EN 16455, Conservation of cultural heritage - Extraction and determination of soluble salts in natural stone

and related materials used in and from cultural heritage

EN 16515:2015, Conservation of Cultural Heritage - Guidelines to characterize natural stone used in

cultural heritage

EN 17138:2018, Conservation of Cultural Heritage - Methods and materials for cleaning porous inorganic

materials

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

cleaning effectiveness

ability to remove unwanted material

3.2

harmfulness

any undesired change in the substrate to be cleaned, except the removal of the unwanted material

3.3

invasive analysis

requires the removal of powder or of a fragment from the surface or from the bulk of the object

3.4

micro-invasive analysis

no visible damage on the surface

Note 1 to entry: A small amount of material is collected (1 mg or less).

3.5

non-invasive analysis

contact between object surface and apparatus used for measurements is avoided; no material is removed

from the object

3.6

sample

portion of material, ideally representative, removed from the cultural property for scientific investigation

[SOURCE: EN 16085:2012, 3.2]

3.7

specimen

part considered representative of the material constituting an object

Note 1 to entry: The specimen can have different origins and can be taken from:

— materials similar to those constituting the object under study (e.g. stone quarries);

— reference materials, for instance, specifically prepared comparative materials;

— available materials from the object.

Note 2 to entry: The number and dimension of the specimens can be different depending on difficulties

encountered in sampling the required amount of material.

[SOURCE: EN 15886:2010, 3.11]

3.8

trial area

location where the cleaning method under evaluation is tested

3.9

unwanted material

substances to be removed indicated by the conservation plan

4 Abbrevations

The following list of analytical techniques is considered:

4.1 UVF: Fluorescence induced by Ultraviolet Radiation

4.2 pXRF: Portable X Ray Fluorescence

4.3 TLOM: Transmitted Light Optical Microscopy

4.4 RLOM: Reflected Light Optical Microscopy

4.5 UVOM: Ultraviolet Optical Microscopy

4.6 ESEM/SEM: Environmental Scanning Electron Microscopy/Scanning Electron Microscopy

4.7 WDS: Wavelength Dispersive Spectroscopy

4.8 EDS: Energy Dispersive Spectroscopy

4.9 FTIR: Fourier Transform Infrared Spectroscopy

4.10 Raman: Raman Spectroscopy

4.11 IC: Ion Chromatography

4.12 pH-m: pH measurement

4.13 WDT: Water Drop Test

5 General procedure (Part A)

5.1 Overview

Before starting to evaluate cleaning methods, a condition survey and a condition report are needed in

accordance with standards EN 16095 and EN 16096.

The initial assessment for a building or similar immovable object should take place on site with non-

invasive systems. Successively, if necessary, it may be followed by appropriate micro-invasive or invasive

laboratory analysis (Figure 1, Table 1).

To facilitate the analytical evaluation of cleaning methods in each individual case the following systematic

procedure is proposed. It consists of a number of consecutive stages as described in the flow chart of

Figure 1. Due to the wide variability of each individual case, the whole sequence proposed shall be case

specific and is up to the responsibility of the professional in charge.

Evaluation procedures depend also on time available and resources (budget and staff). In all cases, the

outcome should be the best possible one for the object.

Figure 1 — Flow chart of the procedure for cleaning evaluation

5.2 Identification of substrate and characterization of unwanted materials

The chemical, mineralogical and the micro-structural characteristics of the material constituting the

object shall be known or preliminarily identified (EN 16515) as well as the extent, nature and thickness

of the unwanted materials to be removed.

The layer of unwanted materials and the altered surface of substrate shall be distinguished from each

other at the investigation stage, so that the required degree of cleaning can be determined (see

EN 17138:2018, 5.2).

The preliminary investigations using non-invasive systems should be carried out on a defined trial area

selected as representative of the main surface material composition and cleaning problem.

The main non-invasive systems to be considered are:

a) portable microscope for optical observations;

b) portable XRF equipment for the identification of chemical elements;

c) portable fluorescence induced by UV radiation equipment for the identification of fluorescent

compounds;

d) portable FTIR spectrometer especially in the presence of organic materials.

For laboratory investigations the procedure reported in EN 16515 (examination of specimens under

stereo-microscope, petrographic examination, mineralogical analysis by X-ray diffraction XRD,

examination by SEM/ESEM, chemical analysis) shall be performed.

The identification of organic components, not considered in EN 16515, shall be performed by FTIR

spectroscopy and when necessary by GC-MS (gas chromatography and mass spectrometry).

5.3 Selection of suitable cleaning methods to be tested

As some cleaning methods are inappropriate where painted finishes are present, their presence or

absence shall be established before any evaluation is started.

After the identification of the substrate and of the composition of unwanted materials a selection of

suitable cleaning methods, according to the results obtained, is carried out on the “trial area”.

For the application of this document the following cleaning method categories are considered (see

EN 17138):

a) water cleaning (restricted to the following: nebulous spray or intermittent mist spray, water spray

at low pressure, steam cleaning, aqueous poultices or packs with absorbent material);

b) mechanical cleaning (restricted to the following: micro blasting, wet jet micro blasting, cryogenic

cleaning);

c) chemical cleaning (application of organic solvents, application of acidic or alkaline solutions,

application of chelating agents, application of surfactants, gel cleaning, application of ion exchange

resins);

d) physical cleaning (laser cleaning);

e) those cleaning methods not adjustable by changing physical known parameters (such as cleaning

with a lancet or a brush) are excluded by the present standard.

5.4 Localization, delimitation and numbering of the cleaning trial areas

Trial areas should be selected in order to be representative of the whole (constituting materials, surfaces

and materials to be removed); if possible, trial areas should be unobtrusive. The trial areas should be the

minimum size possible, taking into account the selected cleaning method, the significance of the object

and the evaluation procedure, while still being representative.

The trial area(s) selection process should also take into account:

— the decay patterns, the type of substrate and the nature of unwanted material;

— the object size;

— the number of trial test required;

— the location where the impact of cleaning trials has the least detriment to the significance of the

object, in case the trial should over-clean or otherwise damage an area;

— further optimization of the parameters of the selected cleaning process.

The description of trial areas selection and procedure is reported in Annex A, which is normative.

5.5 Design of the evaluation procedure and definition of a referenced cleaned area

The evaluation procedure is based on the investigations which are described in Clauses 6 and 7, which

shall be carried out before and after cleaning respectively. The tests are also used to establish the level of

cleaning that needs to be achieved and the actual level that can be achieved.

A flow chart of observations and analyses is reported in Figure 2 and Table 1.

The whole sequence reported is the ideal pathway for evaluation of potential harmfulness and

effectiveness of cleaning methods tested in the trial areas. The adaptation of the procedure depends on

specific features of the case (or object) under evaluation and is the responsibility of the professional in

charge. Any variation shall be specified in the test report.

Investigation and interpretation of results shall be performed by professional(s) (e.g. conservation or

material scientists, conservators/restorers) with appropriate competencies.

For most projects this will require a multidisciplinary approach.

The evaluation should be carried out before and soon after the cleaning operation. Monitoring over time

is also possible, taking into account that decay, particulate deposition and several other phenomena can

complicate the interpretation of results strictly referable to cleaning.

For some special cleaning methods an evaluation is also possible in real time during cleaning, such as the

case for Laser Cleaning.

The trial area showing the most suitable result according to all the partners, taking into account the

results of the evaluation (in situ and/or in the laboratory) should be preserved.

This area should be used as the visual reference of the expected cleaning result during all the cleaning

campaign.

Figure 2 — Flow chart of observations and analysis related to cleaning methods

Table 1 — Observations and analysis in relation to the different cleaning categories

Water Mechanical Chemical

a

cleaning /physical

cleaning

cleaning

6 On site surface investigations

6.1 Optical observation

6.1.1 Portable digital microscope X X X

6.1.2 Raking light X X X

6.1.3 Portable digital stereo microscope X X X

6.1.4 Fluorescence induced by UV radiation X X X

6.2 Chemical/physical analysis

6.2.1 Measurement of colour X X X

6.2.2 Elemental analysis by portable XRF X X X

6.2.3 Molecular analysis by portable FTIR X X X

6.2.4 Surface ion analysis X X X

6.3 Water absorption assessment X X X

6.3.2 Determination of water absorption by X X X

pipe method

6.3.3 Determination of water absorption by X X X

contact sponge method

6.3.4 Water drop test X X X

7 Laboratory analysis on samples

7.3.1 TLOM, RLOM and SEM/ESEM-EDS on X X X

fragments

7.3.2 TLOM, RLOM and SEM/ESEM-EDS on thin X X X

cross section

7.3.3 Vibrational spectroscopy (FTIR, micro- X X X

FTIR and Raman)

7.4 Surface morphology analysis (roughness) X X X

7.5 Wet chemical analysis (on aqueous

extract)

7.5.2.2 Specific conductivity measurement X X

7.5.2.3 pH measurement X X

7.5.2.4 Ion content measurement X X

a

Chemical cleaning is considered separately from the other methods due to the potential for

deleterious reactions between chemicals and the unwanted materials to be removed.

Some significant examples of potential drawbacks or side effects are listed below:

i) water cleaning can affect variations in distribution and concentrations of soluble salts (if present);

ii) mechanical cleaning can affect the roughness of the surface with possible change in colour,

appearance and the water absorption behaviour;

iii) physical cleaning can cause discolouration of the surface;

iv) chemical cleaning can affect variations of pH, conductivity and concentrations of soluble salts.

Chemical cleaning methods, which provoke the formation of harmful by-products (e.g. soluble salts

residues, acidic substances etc.), shall generally be avoided.

In particular some of the chemicals mentioned in EN 17138 shall be carefully monitored during in situ

trial tests. We refer to:

a) strong alkaline and acid compounds, which were used in the past but are not commonly currently

used for cultural heritage objects. Substances in the pH range between 5,5 and 8,0 are commonly

used. A notable exception to this regard is the use of ammonium carbonate or bicarbonate (at pH

between 8 and 10), which have been successfully used for many years particularly on limestones and

marbles affected by gypsum formation crusts and on surfaces affected by proteinaceous residues,

oily and greasy materials;

b) chelating agents used at the right pH (between 6 and 10) can be very selective, very effective and

generally not harmful. In the case of painted surfaces pH shall not be above 8, which is the critical

threshold limit for the dissolution of some of the most common pigments;

+

c) strong acid cationic resins release H which can affect calcareous-based materials;

−

d) strong basic anionic resins release OH , which can affect pigments sensitive to an alkaline

environment.

As a consequence of the previous considerations for chemical cleaning it is of importance to monitor any

change of pH and by-product formation as a result of the selected cleaning process.

In addition to the common tests for each of the cleaning methods (water, mechanical and physical

cleaning) an aqueous extract should be obtained and the following measurements shall be carried out on

it:

i) pH;

ii) specific conductivity;

iii) qualitative and quantitative analyses of soluble salts.

6 On site surface investigations

6.1 Optical observation

6.1.1 Portable digital microscope

With the help of a portable digital microscope, it is possible to observe the surface (stone, mortars,

painting layers, finishes) and the decay products. This pre-test could help to optimize sampling. It also

assists in assessment of the results of the cleaning tests and how the different systems affect the surface

morphology, in the preliminary studies and during the development of the restoration works. It is

possible to use several magnifications and specific lights (visible, ultraviolet) to characterize different

surfaces and identify also residues and overpaints.

Acquisition of digital images shall be obtained in order to document the surface condition and also close

observation of residues.

6.1.2 Raking light

Light directed under a very small incidence angle (usually between 5 ° and 20 °) to the object surface

emphasizes its surface morphology and its relief variations. This observation provides information on

the initial condition of the surface (roughness, surface defects etc.) before cleaning tests and any changes

after the cleaning. The observations on target areas shall be photographed under any appropriate

magnification and lighting angle.

6.1.3 Portable digital stereo microscope

The stereo microscope surface observations before and after treatment shall be carried out on the

selected surface area of the object.

The observation points of the surfaces shall be the same before and after treatment. For each observation

point, at least a micro-photograph, shall be acquired including the scale for each magnification. A final

report shall contain qualitative assessments on any visible changes in the surface morphology

accompanied by photos of comparison of individual points of view.

Any type of morphological variation is indicative of a potential damage caused to the surface by the

cleaning method.

6.1.4 Fluorescence induced by UV radiation

This photographic technique is a non-invasive and portable method of analysis of objects of art. It is

usually used for identification of varnishes, protective treatments, binders and repainting, so it can be

very useful in assessing the efficacy of successive cleaning phases.

Ultraviolet fluorescence can be acquired by using the proper source(s) (UV emission around 365 nm) and

a camera equipped with filter able to cut reflected ultraviolet from the surface and environment. In

general, the fluorescence signal is not very intense and therefore the light in the environment should be

almost absent. For each area, at least one photograph before and after cleaning shall be acquired with the

same configuration.

6.2 Chemical/physical analysis

6.2.1 Measurement of colour

The colorimetric measurements are performed according to EN 15886. The surface to be measured

should, as far as practicable, be smooth and flat so as to exclude external light. Where no smooth, flat

areas are available, this shall be noted in the report.

The number and location of measurement points and their diameter shall be adapted to the object as to

obtain statistically representative values. Five measurements at arbitrary locations would be considered

the minimum, however more may be needed.

The measuring points shall be the same before and after treatment. If, following the cleaning, there are

areas with noticeable colour variations, which were not initially measured, they should be quantified and

identified in the photographic documentation.

A few examples of the use of this technique are listed as follows:

— changes in the lightness can be used for assessing the effectiveness of removal of black crusts or

carbonaceous black deposits from substrates light in colour;

— changes in hue could be an indicator of the presence of unwanted chemical reactions. These changes

can result from the reaction of cleaning product with the material to be removed or from the

mobilization of iron soluble compounds causing yellow or brown staining.

6.2.2 Elemental analysis by portable XRF

Portable X-ray fluorescence is an elemental technique able to detect elements on the surface or sub-

surfaces (depending on the matrices) and therefore can be used to trace elements that are characteristic

of material to be removed. This can be done by measuring the same area before and after the cleaning

test. Limitations of the technique shall be taken into account in the evaluation of the results: i) the error

in the detection of lighter elements and ii) the possible peaks overlap (i.e. sulphur in presence of lead or

titanium in presence of barium).

6.2.3 Molecular analysis by portable FTIR

Vibrational spectroscopic patterns can be recorded on a chosen area, before and after cleaning

operations. FTIR is especially indicated to detect the removal of organic layers, although it is of use in

other cases. In case of using a portable FTIR instrument, spectra will be recorded in reflectance mode.

Where the instrument is used on the scaffolding, it is crucial to ensure good stability and to avoid

vibrations to the instruments, which need to be focused precisely.

6.2.4 Surface ion analysis

Plasticized strips test with specific zones of reaction may be used, to detect ions derived from soluble

salts. Normally these are immersed in a solution to identify if a specific ion is present, and the strip

changes colour at varying grades according to the quantity of ions. In the latter case they can be used on

site by placing a wetted reagent strip directly against an efflorescence. Obviously, the result in this case

is qualitative not quantitative and relates only to the outer surface in contact with the strip. Each type of

strip test is sensitive to only one type of ion.

The sensitivity of the strip tests varies according to the type of ion; there is a marked variation in range

between one ion and another (e.g. sulphates 200 ppm to 1 600 ppm (mg/l); nitrates 10 ppm to 500 ppm).

Colorimetric kits (based on colorimetric comparison of a standard coloured scale) can also be used on

site, for their simplicity but require a sample collection. These are based on reactions that lead to the

formation of coloured compounds formed between each ion and its specific reagent. All the reagents and

equipment necessary for analysis are inside the kit together with the instructions for their use. In this

case the intensity of the colour indicates the amount of ions present in the solution and provides a colour

card against which to measure the sample.

6.3 Water absorption assessment

6.3.1 General

It could be important to evaluate the absorption property of the substrate by an appropriate method, as

water absorption, suitable to investigate whether a material surface is porous and absorbent, wettable

but impervious, or hydrophobic. Such properties depend on the substrate nature and condition, and also

on ancient treatments or deposits.

Three alternative methods for water absorption measurements are available (6.3.2, 6.3.3, 6.3.4).

The trial surface should be dry and it should not be exposed to direct solar light or rain. It is recommended

to record temperature (T) and relative humidity (RH) close to the test surface.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...