SIST EN 15999-2:2025

(Main)Conservation of cultural heritage - Guidelines for design of showcases for exhibition and preservation of objects - Part 2: Technical aspects

Conservation of cultural heritage - Guidelines for design of showcases for exhibition and preservation of objects - Part 2: Technical aspects

This document classifies properties of passive showcases of cultural heritage objects for better preservation. It applies to most uses of the showcase: showcases for so called permanent or temporary exhibitions, historical or modular showcases, showcases in uncontrolled ambient environment, etc. It specifies how the performance of the showcase for the safe and secure display - as derived from needs identified during the risk assessment approach described in EN 15999-1:2025 - can be technically assessed by using classified properties.

Aspects of active showcases (those using electricity to directly condition their microclimates) and anoxic showcases (those containing inert atmospheres instead of air) are mentioned in this document, but their properties are not defined, nor classified.

Erhaltung des kulturellen Erbes - Leitfaden für die Konstruktion von Schauvitrinen zur Ausstellung und Erhaltung von Objekten - Teil 2: Technische Aspekte

Dieses Dokument klassifiziert die Eigenschaften passiver Schauvitrinen für Objekte des kulturellen Erbes für eine bessere Erhaltung. Es ist anwendbar für die meisten Anwendungen von Schauvitrinen: Vitrinen für sogenannte dauerhafte oder temporäre Ausstellungen, historische oder modulare Schauvitrinen, Schauvitrinen in unkontrollierter Umgebung usw. Es legt fest, wie die Leistungsfähigkeit der Schauvitrine hinsichtlich der sicheren und geschützten Ausstellung – entsprechend den im Rahmen der in EN 15999 1:2025 beschriebenen Risikobewertung bestimmten Erfordernissen – durch Anwendung der klassifizierten Eigenschaften technisch bewertet werden kann.

In diesem Dokument werden Aspekte aktiver Schauvitrinen (jene, die zur Regulierung ihres Mikroklimas elektrischen Strom nutzen) und anoxische Schauvitrinen (jene, die inerte Atmosphären statt Luft nutzen) genannt, ihre Eigenschaften werden jedoch weder festgelegt noch klassifiziert.

Conservation du patrimoine culturel - Lignes directrices pour la conception de vitrines destinées à exposer et préserver des biens culturels - Partie 2 : Aspects techniques

Le présent document classe les propriétés des vitrines passives destinées aux biens du patrimoine culturel pour une meilleure conservation. Il s'applique à la plupart des utilisations de la vitrine : vitrines pour des expositions dites permanentes ou temporaires, vitrines historiques ou modulaires, vitrines dans un milieu ambiant non contrôlé, etc. Il spécifie comment les performances de la vitrine, pour une exposition sûre et sécurisée, telles que déterminées à partir des besoins identifiés lors de l'approche d'appréciation du risque décrite dans l'EN 15999-1:2025, peuvent être techniquement évaluées en utilisant des propriétés classifiées.

Les aspects relatifs aux vitrines actives (c'est-à-dire celles qui utilisent l'électricité pour conditionner directement leurs microclimats) et aux vitrines anoxiques (c'est-à-dire celles qui contiennent des atmosphères inertes plutôt que de l'air) sont mentionnés dans le présent document, mais leurs propriétés ne sont ni définies ni classées.

Ohranjanje kulturne dediščine - Smernice za načrtovanje vitrin za razstavljanje in hrambo predmetov - 2. del: Tehnični vidiki

Ta dokument razvršča lastnosti pasivnih vitrin za boljšo hrambo predmetov kulturne dediščine. Uporablja se za večino vrst vitrin: vitrine za tako imenovane stalne ali začasne razstave, zgodovinske ali modularne vitrine, vitrine v nenadzorovanem okolju itd. Opredeljuje, kako je mogoče z uporabo razvrščenih lastnosti tehnično oceniti delovanje vitrine, da se zagotovi varno razstavljanje – kot izhaja iz potreb, ugotovljenih med oceno tveganja, opisano v standardu EN 15999-1:2025. V tem dokumentu so omenjeni vidiki aktivnih vitrin (tistih, ki za ustvarjanje mikroklime uporabljajo elektriko) in anoksičnih vitrin (tistih, ki namesto zraka vsebujejo inertno atmosfero), vendar njihove lastnosti niso opredeljene niti razvrščene.

General Information

- Status

- Published

- Public Enquiry End Date

- 02-May-2023

- Publication Date

- 20-Jul-2025

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 18-Jul-2025

- Due Date

- 22-Sep-2025

- Completion Date

- 21-Jul-2025

Overview

EN 15999-2:2025 - "Conservation of cultural heritage - Guidelines for design of showcases for exhibition and preservation of objects - Part 2: Technical aspects" (CEN) specifies how to classify and assess the technical performance of passive showcases used to display and preserve cultural heritage. It complements the risk assessment approach in EN 15999-1:2025 and applies to permanent and temporary exhibitions, historical or modular showcases, and showcases in uncontrolled ambient environments. Active (electrically conditioned) and anoxic (inert atmosphere) showcases are mentioned but not classified.

Key topics

- Airtightness & Air Exchange Rate (AER): Defines AER categories (from low airtightness AER ≥ 5 day−1 to high airtightness AER < 0.4 day−1) and explains how airtightness affects moisture exchange, pollutant ingress, and the effectiveness of humidity buffering.

- Environmental protection: Guidance on reducing risks from humidity, temperature, pollutants (VOCs), particulates, UV/IR radiation and pests.

- Humidity buffering vs. humidity control: Distinguishes passive buffering strategies from active humidity control and discusses implications for preservation.

- Pollution management: Use of sorbents, strategies when pollution originates inside the showcase, and material emission testing (see Annex H).

- Security & safety: Physical resistance against theft, electronic security interfaces, structural stability, fire resistance and resistance to splashing water.

- Relocation and maintenance: Requirements for disassembly, transport and marking to maintain performance over time.

- Measurement & testing methods: Practical procedures and informative annexes covering tracer gas decay and constant-pressure AER measurements, leak detection, hygrometric half-time calculations, and certified safety showcase testing.

Applications and users

This standard is intended for:

- Museum and heritage professionals (end-users) specifying showcase performance for object display or loan agreements.

- Designers and manufacturers of showcases who need to classify and verify technical performance.

- Contracting authorities and conservators writing procurement documents or technical briefs.

- Independent experts and testing laboratories performing AER measurements, emission testing, or certification (referenced: EN ISO/IEC 17025). Practical uses include defining procurement requirements, setting acceptance criteria after installation, selecting appropriate buffering/sorbent strategies, and preparing risk-based conservation plans.

Related standards

- EN 15999-1:2025 - General requirements and risk assessment approach

- EN 15898:2019 - Terms for conservation of cultural heritage

- Test and safety references listed in the normative annexes (e.g., EN 410, EN 50131, EN IEC 60332 series)

Keywords: EN 15999-2:2025, conservation of cultural heritage, showcases, airtightness, air exchange rate, humidity buffering, VOCs, museum display, showcase design, risk assessment.

Frequently Asked Questions

SIST EN 15999-2:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Conservation of cultural heritage - Guidelines for design of showcases for exhibition and preservation of objects - Part 2: Technical aspects". This standard covers: This document classifies properties of passive showcases of cultural heritage objects for better preservation. It applies to most uses of the showcase: showcases for so called permanent or temporary exhibitions, historical or modular showcases, showcases in uncontrolled ambient environment, etc. It specifies how the performance of the showcase for the safe and secure display - as derived from needs identified during the risk assessment approach described in EN 15999-1:2025 - can be technically assessed by using classified properties. Aspects of active showcases (those using electricity to directly condition their microclimates) and anoxic showcases (those containing inert atmospheres instead of air) are mentioned in this document, but their properties are not defined, nor classified.

This document classifies properties of passive showcases of cultural heritage objects for better preservation. It applies to most uses of the showcase: showcases for so called permanent or temporary exhibitions, historical or modular showcases, showcases in uncontrolled ambient environment, etc. It specifies how the performance of the showcase for the safe and secure display - as derived from needs identified during the risk assessment approach described in EN 15999-1:2025 - can be technically assessed by using classified properties. Aspects of active showcases (those using electricity to directly condition their microclimates) and anoxic showcases (those containing inert atmospheres instead of air) are mentioned in this document, but their properties are not defined, nor classified.

SIST EN 15999-2:2025 is classified under the following ICS (International Classification for Standards) categories: 97.195 - Items of art and handicrafts. Cultural property and heritage. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15999-2:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2025

Ohranjanje kulturne dediščine - Smernice za načrtovanje vitrin za razstavljanje in

hrambo predmetov - 2. del: Tehnični vidiki

Conservation of cultural heritage - Guidelines for design of showcases for exhibition and

preservation of objects - Part 2: Technical aspects

Erhaltung des kulturellen Erbes - Leitfaden für die Konstruktion von Schauvitrinen zur

Ausstellung und Erhaltung von Objekten - Teil 2: Technische Aspekte

Conservation du patrimoine culturel - Lignes directrices pour la conception de vitrines

destinées à exposer et préserver des biens culturels - Partie 2 : Aspects techniques

Ta slovenski standard je istoveten z: EN 15999-2:2025

ICS:

97.195 Umetniški in obrtniški izdelki. Items of art and handicrafts.

Kulturne dobrine in kulturna Cultural property and

dediščina heritage

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15999-2

EUROPEAN STANDARD

NORME EUROPÉENNE

June 2025

EUROPÄISCHE NORM

ICS 97.195

English Version

Conservation of cultural heritage - Guidelines for design of

showcases for exhibition and preservation of objects - Part

2: Technical aspects

Conservation du patrimoine culturel - Lignes Erhaltung des kulturellen Erbes - Leitfaden für die

directrices pour la conception de vitrines destinées à Konstruktion von Schauvitrinen zur Ausstellung und

exposer et préserver des biens culturels - Partie 2 : Erhaltung von Objekten - Teil 2: Technische Aspekte

Aspects techniques

This European Standard was approved by CEN on 21 April 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15999-2:2025 E

worldwide for CEN national Members.

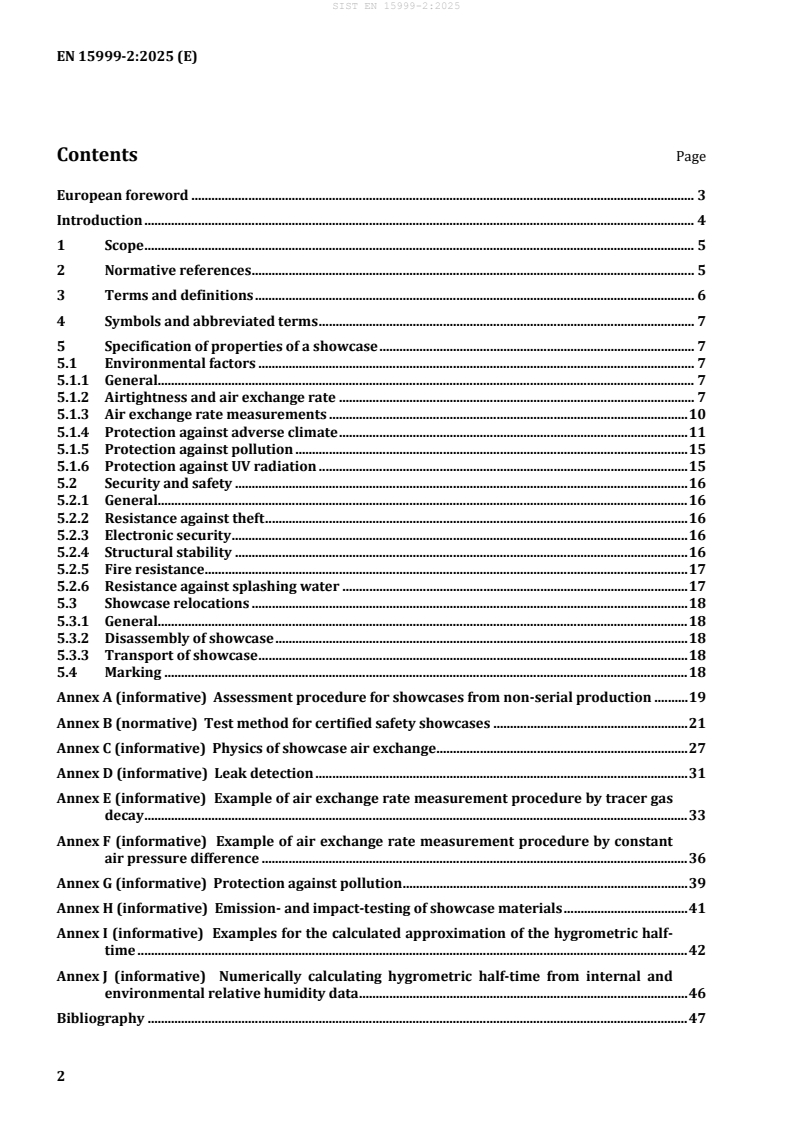

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols and abbreviated terms . 7

5 Specification of properties of a showcase . 7

5.1 Environmental factors . 7

5.1.1 General. 7

5.1.2 Airtightness and air exchange rate . 7

5.1.3 Air exchange rate measurements . 10

5.1.4 Protection against adverse climate . 11

5.1.5 Protection against pollution . 15

5.1.6 Protection against UV radiation . 15

5.2 Security and safety . 16

5.2.1 General. 16

5.2.2 Resistance against theft . 16

5.2.3 Electronic security . 16

5.2.4 Structural stability . 16

5.2.5 Fire resistance . 17

5.2.6 Resistance against splashing water . 17

5.3 Showcase relocations . 18

5.3.1 General. 18

5.3.2 Disassembly of showcase . 18

5.3.3 Transport of showcase . 18

5.4 Marking . 18

Annex A (informative) Assessment procedure for showcases from non-serial production . 19

Annex B (normative) Test method for certified safety showcases . 21

Annex C (informative) Physics of showcase air exchange . 27

Annex D (informative) Leak detection . 31

Annex E (informative) Example of air exchange rate measurement procedure by tracer gas

decay . 33

Annex F (informative) Example of air exchange rate measurement procedure by constant

air pressure difference . 36

Annex G (informative) Protection against pollution . 39

Annex H (informative) Emission- and impact-testing of showcase materials . 41

Annex I (informative) Examples for the calculated approximation of the hygrometric half-

time . 42

Annex J (informative) Numerically calculating hygrometric half-time from internal and

environmental relative humidity data . 46

Bibliography . 47

European foreword

This document (EN 15999-2:2025) has been prepared by Technical Committee CEN/TC 346

“Conservation of cultural heritage”, the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by December 2025, and conflicting national standards

shall be withdrawn at the latest by December 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

EN 15999 consists of the following parts, under the general title “Conservation of cultural heritage —

Guidelines for design of showcases for exhibition and preservation of objects”:

— Part 1: General requirements

— Part 2: Technical aspects

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

Introduction

A key objective of a showcase is to display objects of cultural heritage while acceptably reducing their

conservation risks. Conservation risks include total loss, physical damage, chemical and biological

deterioration (e.g. by accidents, theft, vandalism, natural disasters, humidity, temperature, dust,

pollutants, light, pests).

This document addresses stakeholders who are engaged in projects that involve showcases and who

are expected to understand the properties of a showcase, such as end-users, designers, manufacturers,

and contracting authorities who are in charge of the cultural institutions.

The proposed categories and classifying of technical aspects of the showcases for conservation, safety

and security, use and management of the showcase should facilitate the dialogue between the

stakeholder and can be used in the procurement phase or in the operating phase; e.g. to define

showcase properties for objects on loan.

While recognizing that aesthetics of showcases are very important, the present document emphasizes

functional design of the showcase, the practical needs of the user and the requirements of the objects

for better preservation.

1 Scope

This document classifies properties of passive showcases of cultural heritage objects for better

preservation. It applies to most uses of the showcase: showcases for so called permanent or temporary

exhibitions, historical or modular showcases, showcases in uncontrolled ambient environment, etc. It

specifies how the performance of the showcase for the safe and secure display - as derived from needs

identified during the risk assessment approach described in EN 15999-1:2025 - can be technically

assessed by using classified properties.

Aspects of active showcases (those using electricity to directly condition their microclimates) and

anoxic showcases (those containing inert atmospheres instead of air) are mentioned in this document,

but their properties are not defined, nor classified.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 410, Glass in building — Determination of luminous and solar characteristics of glazing

EN 1023-3, Office furniture — Screens — Part 3: Test methods

EN 1630:2021, Pedestrian doorsets, windows, curtain walling, grilles and shutters — Burglar

resistance — Test method for the determination of resistance to manual burglary attempts

EN 15898:2019, Conservation of cultural heritage — Main general terms and definitions

EN 50131 (all parts), Alarm systems — Intrusion and hold-up systems

EN 60529, Degrees of protection provided by enclosures (IP Code)

EN ISO/IEC 17025:2017, General requirements for the competence of testing and calibration laboratories

(ISO/IEC 17025:2017)

EN IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions — Part 1-2: Test for

vertical flame propagation for a single insulated wire or cable — Procedure for 1 kW pre-mixed flame

(IEC 60332-1-2)

EN IEC 60332-3-24, Tests on electric and optical fibre cables under fire conditions — Part 3-24: Test for

vertical flame spread of vertically-mounted bunched wires or cables — Category C (IEC 60332-3-24)

ISO 20653:2023, Road vehicles — Degrees of protection (IP code) — Protection of electrical equipment

against foreign objects, water and access

ISO 21348:2007, Space environment (natural and artificial) — Process for determining solar irradiances

EN 15999-1:2025, Conservation of cultural heritage — Guidelines for design of showcases for exhibition

and preservation of objects — Part 1: General requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 15898:2019 and in

EN 15999-1:2025 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

airtightness

capacity of an envelope to limit the entrance or escape of air or other gas

3.2

end-user

person with assigned responsibility for cultural heritage on display in showcases or for the showcases

themselves

3.3

environment

physical, chemical and biological conditions surrounding the showcase

3.4

humidity buffering

smoothing of the peaks and troughs in relative humidity, whilst not changing the average relative

humidity

3.5

humidity control

maintaining a relative humidity value different from the average relative humidity value of the

environment (3.3)

3.6

independent expert

competent person who has the necessary training, knowledge, experience, expertise and skills,

sufficient to complete their allotted task

3.7

pollution sorbent

material that captures some specific gaseous pollutants to reduce their concentration

3.8

relative humidity

ratio of the actual vapour pressure to the saturation vapour pressure

[SOURCE: EN 15757:2010, 3.9]

3.9

volatile organic compound

VOC

organic molecule with a high vapour pressure at room temperature, including VVOC (very volatile

organic compound) and SVOC (semi volatile organic compound)

Note 1 to entry: VOCs can be found in construction materials and might be responsible for odour or considered

as air pollutants.

3.10

security personnel

those people in the organisation that have been assigned security related duties

Note 1 to entry: These people may or may not be employees of the organization.

[SOURCE: ISO 28001:2007, 3.22, modified, “in the supply chain” deleted]

4 Symbols and abbreviated terms

AER air exchange rate

RH relative humidity

T temperature

VOC volatile organic

compound

UV ultraviolet

IR infrared

−1 divided by

5 Specification of properties of a showcase

5.1 Environmental factors

5.1.1 General

Showcases can enhance the physical protection of objects from environmental risks arising from

incorrect humidity and temperature, pollutants, pests, from UV to IR radiation.

5.1.2 Airtightness and air exchange rate

The protective capacity of the showcase against the environmental factors listed below is mainly

determined by its airtightness. This allows it to:

— limit entry of gaseous pollutants present in the showcase's environment, e.g. external use of

corrosive cleaning products, outdoor gaseous pollutants;

— reduce water vapour exchanges and improve microclimate control. Moisture exchange due to low

airtightness limits the effectiveness and useful lifetimes of added moisture sorbent. It also

decreases hygrometric control of buffering showcases, which rely on high loading of moisture

sorbent in conjunction with higher airtightness;

— limit entry of particulate matter present in the room coming from indoor and outdoor sources

(e.g. smoke, dust, sporae, pest eggs) that deposit on objects or infest them, and to decrease cleaning

frequency of showcase interior.

When pollution comes from a source inside the showcase (e.g. an object releasing VOCs), and objects

made of vulnerable materials are present, higher airtightness is unfavourable for object preservation.

Intentional leaks (vents) should be created using natural or forced ventilation, or a material able to

absorb and retain the pollution should be added.

Airtightness of showcases generally decreases with time due to ageing and wear of sealing materials

(e.g. joints, adhesives, door-gasketas) and misalignment of the showcase with its closures (e.g. for

display space, technical compartments) and its joints due to deformation of glass and metal sheets.

Showcase airtightness is quantifiable by the air exchange rate (AER). Categories of AER and showcase

performance affected by the air exchange rate are indicated in Table 1. Different classes of AER are

−1

characterized by different levels of airtightness from low airtightness (AER ≥ 5 day ) to high

−1

airtightness (AER < 0,4 day ).

Table 1 — Class labels according to AER with indicative capacity to maintain a suitable

environment

Class AER Capacity to buffer Capacity to maintain internal Capacity to Pollutant

−1

Label against external hygrometric conditions (RH) provide protection accumulation

[day ]

(RH) fluctuation against the ingress from off-gassing

b

showcase

of pollutants

materials and/or

objects

Passive control Active control

AE 0 ≥ 5,0 Can significantly no Yes with high

Slight. Some Least build-up

reduce daily, but capacity protection offered

not weekly, systems against external

fluctuations with pollution, but not

very large amounts recommended

of moisture

a

sorbent

AE 1 < 5,0 to Can significantly will struggle to Yes Some. Between most Very low risk of

3,0 reduce weekly, but control RH stringent build-up

not monthly, depending on recommended levels

fluctuations with room (in rooms with low

large amounts of environment pollution

a

background values)

moisture sorbent

up to ~25 %

protection

compared to the

environment

AE 2 < 3,0 to Can significantly can struggle for Yes Good. Between most Low risk of buid-

1,0 reduce monthly, part of the year, stringent up

but not seasonal depending on recommended levels

up to ~50 %

variations with environment

medium amounts protection

of moisture compared to the

a

environment

sorbent

Class AER Capacity to buffer Capacity to maintain internal Capacity to Pollutant

−1

Label against external hygrometric conditions (RH) provide protection accumulation

[day ]

(RH) fluctuation against the ingress from off-gassing

b

showcase

of pollutants

materials and/or

objects

Passive control Active control

AE 3 < 1,0 to Can significantly can work for Suitable with Very good. Large Moderate risk of

0,4 reduce monthly, most most control showcases, and/or build-up

and most seasonal environments systems for with hard and

variations with most situations smooth materials

medium amounts (e.g. glass and

of moisture aluminium), cannot

a

satisfy most

sorbent

stringent

recommended levels

AE 4 < 0,4 to can significantly Yes Yes Very good. Nearly High risk of build-

reduce monthly, always satisfy most

0,1 up

and seasonal stringent

variations with recommended

medium amount of levels. Large

a

showcases in

moisture sorbent

naturally ventilated

buildings or in

conditioned

buildings with

insufficient chemical

filtering in urban

environments,

cannot satisfy most

stringent levels

AE 5 < 0,1 unlikely to be Yes Yes Excellent. Very few Highest risk of

required for RH showcases need this build-up

buffering or low AER

control, except in

most extreme

situations with low

amount of

a

moisture sorbent

a 3 3

Very high loading of moisture sorbent: e.g. 10 kg/m ; high loading of moisture sorbent: e.g. 6 kg/ m ; medium loading of

3 3

moisture sorbent: e.g. 3 kg/ m ; low loading of moisture sorbent: e.g. 1 to 2 kg/ m .

b

Protection levels are based on showcases placed in indoor environment.

Active climate conditioning systems can offer an alternative. However, the risk of technical failure

should be considered. The performance of many active systems is very temperature dependent.

Experience has shown that the showcase air exchange rate influences active conditioning (see Table 1).

Many manufacturers give indicative showcase volumes and air exchange rates that a certain active

climate conditioning unit will work with and requirements for space around the unit, which should be

adhered to. Humidifiers and dehumidifiers have large capacities and can successfully condition large

showcases with high air exchange rates. If both humidifiers and dehumidifiers are used together,

correct settings on the control sensor are essential. Mixing chambers can be used for smoothening RH

fluctuations induced by humidifiers and dehumidifiers units that run alternately. It comprises a space

between the display volume and humidifier or dehumidifier units. For greater effect, a mixing chamber

is possibly equipped with moisture sorbent. Several units based on Peltier coolers and water reservoirs

are available. Many have limited dehumidification capacity and can struggle at high room RH or high

temperatures.

5.1.3 Air exchange rate measurements

Two methods adapted from building measurement standards are suitable for measuring showcase air

exchange rates. They measure:

— tracer gas concentrations;

— air pressure differences.

Measuring showcase airtightness to estimate protection against the environmental factors outlined in

the previous section (see 5.1.2) is typically achievable with the tracer gas decay method. This is because

it measures air exchanges resulting from the complex interplay between the construction of the

showcase, and a variety of environmental contributions that often vary over time (see Annex C). As a

consequence, air exchange rates measured by tracer gas decay vary according to the changing ambient

environmental conditions. For this reason, tests running over periods longer than one day are

recommended to obtain an average air exchange rate; arriving at results representative of the

exhibition conditions. See Annex E for an example of air exchange rate measurement procedure by

tracer gas decay.

Measuring the extent of showcase air exchange via gaps is typically achievable with air pressure

difference methods, e.g. air pressure difference decay, constant air pressure difference. With these

methods air exchange is measured under a consistently controlled test environment which dominates

over ambient environmental conditions. As a result, air exchange rates measured by air pressure

methods are less subject to changing ambient environmental conditions; according to the unchanging

construction/geometries of the showcase and its gaps. This high test repeatability stems from its

mechanically-induced air exchange, which also enable tests to be completed in minutes. See Annex F.

Before taking air exchange rate measurements, the objective/s shall be clearly defined. This can help to

choose the suitable measurement method/s; especially in terms of the test duration, equipment and

environmental conditions. Unless preliminary tests are being undertaken, showcases shall be tested as

part of their final assessment, with all features installed, e.g. security/lighting devices and wiring.

Sealing surfaces and seals on all openings should be cleaned, and openings properly shut with all locks

engaged.

The objectives can be to determine the:

— construction quality of showcases versus targets from specifications in procurement contracts with

showcase suppliers, or from ad hoc exhibition needs;

— lifetime/amount of sorbent needed for buffering RH (see also Annex G, G.2);

— lifetime/amount of sorbent needed for controlling RH to a limit/threshold (see also G.3);

— protection of objects from externally generated pollutants (see also G.2);

— accumulation of internally generated pollutants (see also G.4);

— venting of internally generated pollutants (see also G.4);

— remedial alterations to airtightness made during maintenance or retrofitting of door-gaskets,

hinges, joints, gas struts, vertical lift systems and joints resealing around lighting/cableruns, etc. on

existing showcases;

— alterations to airtightness made after relocating existing showcases;

— influences of ageing and wear on alterations to airtightness of existing showcases.

Active microclimate conditioning systems will interfere with accuracy of airtightness measurements, so

should be turned off and have any plumbing connections closed when performing the measurements.

Before or after taking air exchange rate measurements, searching for leaks may be appropriate

(see Annex D).

Further information can be found in the Annexes:

— the physics of showcase air exchange (Annex C);

— the influence of showcase design on air exchange (see EN 15999-1:2025, Annex B);

— Example of air exchange rate measurement procedure by tracer gas decay (Annex E);

— Example of air exchange rate measurement procedure by constant air pressure difference

(Annex F).

5.1.4 Protection against adverse climate

5.1.4.1 General

Showcases can be designed to provide appropriate climate conditions for the long term preservation of

objects. Relative humidity and temperature are the principal climate parameters, but air pollution shall

be considered for many objects as well. Relative humidity of air is linked to the air temperature. A

temperature increase of 1°C can make the relative humidity decrease about 2 % to 3 %.

NOTE An enthalpy-entropy chart, a so-called Mollier-diagram, can be consulted to determine such changes.

For example: the relative humidity in air with a temperature of 25 °C and a constant humidity mixing ratio

of 9,9 g/kg, will drop from 50 % to 47 % when the temperature rises to 26 °C.

Four different qualities of showcases are described below to control its microclimate performances:

— Hygrometric half-time (5.1.4.2);

— Buffering against external relative humidity fluctuations (5.1.4.3);

— Capacity to maintain internal hygrometric conditions (RH) (5.1.4.4); and

— Thermal performance (5.1.4.5).

Whilst humidity buffering (5.1.4.3), is suitable if the room average relative humidity is acceptable, there

are often occasions when it is desired to keep the showcase average relative humidity significantly

different to the room (5.1.4.4).

The targeted relative humidity conditions for an object are obtained by selecting a showcase with a

suitable hygrometric half-time (5.1.4.2) and corresponding replacement cycle of the moisture sorbent.

5.1.4.2 Hygrometric half-time

The capacity of a showcase to buffer against fluctuations in room relative humidity, or to maintain a

specific microclimate relative humidity, is most easily expressed as the hygrometric half-time. The

hygrometric half-time depends on two chief factors: (1) airtightness of the showcase envelope, and (2)

the type, amount (loading for the moisture sorbent) of buffering material in the display space and

technical compartment (see Annex I, Formula (I.1)).

NOTE Showcase construction, dressings, exhibit can also be hygroscopic.

A long hygrometric half-time signifies a large buffering capacity for RH fluctuations. The objectives for

installing a certain amount and type of suitably conditioned moisture sorbent are to:

— adjust the microclimate RH to the target interval;

— increase the duration that the target microclimate RH can be maintained.

Examples for the calculated approximation of the hygrometric half-time are given in Annex I.

The hygrometric half-time of an existing showcase can be calculated from internal and external relative

humidity data, see Annex J. When specifying existing showcases, the hygrometric half-time shall be

quoted. When specifying new showcases, the anticipated showcase air exchange rate, and the volume of

the technical compartment for moisture sorbent, shall both be quoted. These allow estimation of the

hygrometric half-time. Hygrometric half-times are expressed in the following categories given

in Table 2.

Table 2 — Categories of hygrometric half-time with some indicative uses

Class Label Hygrometric Example of use

half-time (the actual suitability is subject to environmental

climate parameters)

(days)

HH 6 ≥ 800 extreme climates: RH over 80 % for considerable

amount of time (any kind of castle or underground

building, as tunnels, mines, bunker, marine

environment)

HH 5 < 800 to 400 Seasonal variations of 50 % RH in the environment

HH 4 < 400 to 200 Seasonal variations of 40 % RH in the environment

HH 3 < 200 to 100 Seasonal variations of 30 % RH in the environment

HH 2 < 100 to 50 Seasonal variations of 20 % RH in the environment

HH 1 < 50 to 10 two-week maintenance or repair period for air

conditioning in many environments

HH 0 < 10 most favourable climates and air conditioned spaces

5.1.4.3 Buffering against external (RH) fluctuations

A high hygrometric half-time of a showcase indicates a high capacity to maintain a narrow relative

humidity range over a long time.

If a technical compartment is used for moisture sorbents, sufficient air exchange with the display

volume is essential and its installation adjacent to the display volume works best. Sufficient gaps for

moisture exchange between the technical compartment and the display volume are essential to support

the function of the moisture sorbent.

NOTE Experience has shown that 8 mm holes covering 25 % of the surface area of a fabric covered 2 mm

thick metal board work well [1]. For slots, a 20 mm gap width has been proposed [2].

If air exchange between the display volume and sorbent compartment is too slow, electric fans can be

used. However, their powering, maintenance and malfunction risks should be considered.

To achieve the required hygrometric half-time, the:

— volume of the technical compartment shall be large enough to accommodate the calculated amount

of moisture sorbent material (see 5.1.4.1);

— surface area of contact in the technical compartment shall be large enough to condition air being

exchanged with the display volume.

Table 3 gives the expected RH microclimate inside showcases for selected hygrometric half-times

related to annual RH intervals of the indoor environment.

Table 3 — Expected RH microclimate inside showcases for selected hygrometric half-times

related to annual RH intervals of the indoor environment

Hygrometric half- Environment seasonal interval

time of the showcase (minimum to maximum annual RH (%))

(in days) between 30 to 70 between 20 to 80 between 10 to 90

Expected showcase microclimate

(minimum to maximum RH (%))

800 50 50 50

400 50 50 to 51 50 to 52

200 50 to 52 49 to 52 49 to 53

100 49 to 53 48 to 54 48 to 55

50 47 to 55 46 to 57 45 to 59

10 35 to 63 29 to 68 23 to 72

The higher category is mainly useful for long-term relative humidity control when the room average is

far from the desired average relative humidity, see 5.1.4.4.

5.1.4.4 Capacity to maintain microclimate hygrometric conditions (RH)

A high hygrometric half-time of a showcase indicates a high capacity to maintain a relative humidity

microclimate over a long time. At the same time, the maintenance cycle for reconditioning the moisture

sorbent material will be long. If large numbers of showcases are in use the resources (human, technical

and financial) required for reconditioning the moisture sorbents shall be considered.

A relative humidity microclimate different from the room can be achieved by adding moisture sorbent

(previously conditioned to the desired level). With time, the showcase average will move toward the

room average relative humidity. This means the buffer material shall be replaced with new conditioned

buffer. Calculations are available to predict moisture sorbent material lifetime (see [3]). Essentially, the

lower the showcase air exchange rate is and the higher the amount of moisture sorbent material

present, the longer the replacement interval will be.

The duration required to recondition the moisture sorbent of a showcase depends on the hygrometric

half-time of the showcase, the room conditions and the target relative humidity.

Table 4 was generated with calculations extensively tested on 200 real monitored showcases in historic

buildings in the United Kingdom. The time values have been found to have errors of less than 5 %. The

hygrometric half-time is the indicator for the capacity of the showcase to maintain the RH microclimate.

The moisture sorbent will need replacing after the time-periods indicated in Table 4. The seasonal

relative humidity values can differ and influence the time-periods.

Table 4 — Illustration of how the hygrometric half-time influence the time period for replacing

of a moisture sorbent

Hygrometric half- Days to maintain the microclimate in Days to maintain the

time (days) a 40 % –60 % RH interval microclimate

(with moisture sorbent material conditioned below 30 % RH

to 50 % RH) (with moisture sorbent

material conditioned

a

to 5 % RH)

RH room interval RH room interval room at 80 % RH

between 20 % to 60 % between 60 % to 100 %

800 ~ 11 000 (30 years) 2 916 467

400 ~ 6 600 (18 years) 1 500 233

200 ~ 3 300 (9 years) 768 116

100 1 400 387 58

50 653 117 19

10 238 31 5

a

Source: [4]

5.1.4.5 Thermal performance

The performance of a showcase to control its microclimate can be very negatively impacted by heating;

either from internal heat sources or external irradiation producing a greenhouse effect. Possible

internal heat sources include waste heat from active climate control devices, light sources (including

LEDs) and other electronic devices. If they are present, the temperature should be measured at the

warmest point of the deck or backboard, with the heat source running for at least 30 min prior to the

measurement, or in the centre of the display volume. Results should be expressed as the maximum

temperature difference measured through a full day. The thermal performance of display space of a

showcase should be placed in the following bands (see Table 5).

Thermal performance of display space of a showcase already installed on site can also be classified

according to Table 5 by long-term temperature monitoring. The installation site of the showcase can

affect the temperature inside the showcase due to a possible green-house effect. Green-house effects

from natural light (even through blinds) will have a strong seasonal effect and results should be

expressed as the maximum temperature measured throughout a full year.

Table 5 — Classification by maximum daily temperature difference ΔT in the showcase

max

compared to the environment

Class label ΔT (°C) Expected adverse effect

max

TP 0 > 4,0 dramatic impact on performance, showcase

protection is very likely to be compromised

TP 1 from > 2,0 to ≤ 4,0 impact on performance, AER will increase,

medium amounts of buffer can struggle

TP 2 from > 1,0 to ≤ 2,0 some impact on performance, AER will

increase, small amounts of buffer can struggle

TP 3 from > 0,5 to ≤ 1,0 little impact on performance

TP 4 ≤ 0,5 negligible impact on performance

5.1.5 Protection against pollution

5.1.5.1 General

Pollution in a showcase can originate from air exchanged with the environment or can be emitted from

internal sources. The balance between ingress of pollutants and their release by air exchange

determines the pollution level. Examples of typical situations are given in Annex G.

5.1.5.2 Protection against the ingress of pollutants

The protection against external air pollutants (gases, droplets, particles) is determined by the air

exchange rate of the showcase. The degree of protection can be categorized according to the six classes

indicated in Table 1.

5.1.5.3 Material emissions

An undesirable side effect of several materials and products used for constructing and decorating

showcases is that they emit pollutants. Showcases construction and decoration materials should be

selected with great care with regard to the emission behaviour. Preselected materials should be tested

for emissions and impacts to avoid damage of the objects on display (Annex H).

NOTE 1 High emitting materials are for example, wood-based materials, acetic acid containing sealants etc. For

more information about undesirable effects of several materials and products, see [5], [6], [7], [8], [9], [10].

NOTE 2 With increasing showcase tightness the risk of pollutant accumulation also rises (see Table 1).

5.1.5.4 Maintenance cycle for pollution sorbent

The maintenance procedures and lifetimes, as obtained e.g. by industrial capacity tests, as

described/recommended by manufacturers should be adhered to.

Critical impact levels of relevant air pollutants in the showcase as measured by relevant methods

(concentration in air or impact on dosimeters) can be determined.

Impact levels should be measured in regular intervals and the absorber then changed when the

measured level increases above the critical level.

For similar showcases, the amount of pollution sorbent needed to reach the same interval between its

changing will be proportional to the pollution sorbent exposed surface area and inversely proportional

to the showcase volume.

5.1.6 Protection against UV radiation

Ultraviolet (UV) radiation transmittance of glass shall be calculated according to EN 410 with the UVA

(from 315 nm to 400 nm) and UVB (from 280 nm to 315 nm) ranges defined in ISO 21348:2007.

NOTE In the museum context UV radiation is usually considered to include wavelengths up to 400 nm.

For the use in the showcase, the UV radiation protection properties can be categorized as follows:

— Class UV 0 – UV radiation absorbing properties are not specified;

— Class UV 1 – UV radiation transmittance of glass is lower than 1,0 %.

5.2 Security and safety

5.2.1 General

Showcases shall provide protection of objects from theft, burglary, vandalism, visitor damage, fire, etc.

Different levels of security and safety protection can be achieved through case design (water resistance,

physical stability) and building materials (fire resistance) or with added equipment (electronic

devices).

The security of a showcase is determined by a combination of the physical resistance and any

technological system such as an alarm. A good physical resistance prolongs the time that a perpetrator

needs to access the objects while electronic alarm systems built into the showcase can shorten the time

to trigger the intervention of security personnel.

5.2.2 Resistance against theft

Showcases from serial production can be qualified according to their resistance to burglary attacks by

practical attempts to overcome them in an attack test. Tool attack tests cannot be used for both non-

serial customized or existing showcases. In this case, an independent expert can evaluate the showcase

for its burglary resistance based on comparable showcases of the manufacturer and on the

requirements listed in Annex A.

Destructive laboratory tests can be used with known attack methods and tools. The resistance class for

the test showcase is determined from the type and duration of use of the tools used in a break-in

attempt (Annex B).

The fixing elements of the showcase shall not be accessible nor visible for visitors.

5.2.3 Electronic security

If the risk assessment for theft indicates a high risk, the provision or addition of an alarm system or

defence system shall be considered. The operation modes of the alarm and defence systems shall be

adjustable to suit the public opening/closure hours of the premises and shall be integrated into the

security concept of the entire premises.

Electronic alarm systems build into the showcase can shorten the time to trigger the intervention of

security personnel. Defence systems (such as fogging) can be used in confined rooms during closing

hours and serve to slow down the attack or escape of the perpetrator and by this prolonging the time

which is available to the security services to respond. All alarm systems shall comply with EN 50131 (all

parts). Hard wired monitored systems with a power back up are more reliable than any stand-alone

system.

5.2.4 Structural stability

Structural stability of a showcase is defined as the capability not to deform, collapse, dislodge or fall

over because of its intrinsic weight or applied loads over its lifetime. Structural stability shall be verified

by structural engineering calculations, experimentation or extensive experience given by the

manufacturer.

The structural stability of a showcase is determined by the following factors: its materials, assembly,

dimensions and weight distribution, and its surroundings.

Any showcase at risk of falling over should be fixed mechanically to the building. If mechanical fixings of

a free-standing showcase are not possible or inadequate, increasing the weight of the showcase base

can help. In doing so, the maximum distributed load on load-bearing structures of the gallery should be

taken into consideration. Such an evaluation shall also account for point loads of the showcase

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...