SIST EN 267:2020

(Main)Forced draught burners for liquid fuels

Forced draught burners for liquid fuels

This European Standard specifies the terminology, the general requirements for the construction and operation of forced draught oil burners and also the provision of control and safety devices, and the test procedure for these burners.

This European Standard applies to forced draught oil burners supplied with:

- fuel based on first raffinates and their mixtures with biogenous liquid fuels having a viscosity at the burner inlet of 1,6 mm2/s (cSt) up to 6 mm2/s (cSt) at 20 °C, and

- higher boiling petroleum based first raffinates (viscosity greater than 6 mm2/s), that require preheating for proper atomization.

This European Standard is applicable to:

- single burners fitted to a single combustion chamber;

- single burners fitted to an appliance with additional requirements;

NOTE When additional requirements apply which are not identified or specified in this standard, the specification of the required safety measures and/or protective devices and compliance with them is outside the scope of this standard.

- single-fuel and dual-fuel burners when operating on oil only;

- the oil function of dual-fuel burners designed to operate simultaneously on gaseous and liquid fuels.

This European Standard deals with all significant machine hazards, hazardous situations and events relevant to burners, when they are used as intended and under conditions of misuse which are reasonably foreseeable, see Annex J.

This European Standard also deals with the additional requirements for the burners in the scope with pressurized parts and/or firing pressurized bodies, see Annex K.

This European Standard specifies the requirements to ensure the safety during commissioning, start-up, operation, shut-down and maintenance.

This European Standard deals also with forced draught burners intended to be used with biogenous liquid fuels, mixtures.

This European Standard deals also with burners and their equipment to increase the total appliance efficiency, see Annex M.

Gebläsebrenner für flüssige Brennstoffe

In diesem Dokument sind die Terminologie für und die allgemeinen Anforderungen an die Konstruktion und den Betrieb von Ölgebläsebrennern und die Ausrüstung mit Steuerungs- und Sicherheitseinrichtungen festgelegt sowie das Prüfverfahren für diese Brenner.

Dieses Dokument ist auf Ölgebläsebrenner anwendbar, die vorgesehen sind für:

- Brennstoff auf Basis von Erstraffinaten und deren Gemischen mit biogenen flüssigen Brennstoffen, deren Viskosität am Brennereintritt bei 20 °C 1,6 mm2/s (cSt) bis zu 6 mm2/s (cSt) beträgt; und

- höher siedende Erst-Raffinate auf Erdölbasis (Viskosität größer als 6 mm2/s), die für eine ordnungsgemäße Zerstäubung vorgewärmt werden müssen.

Dieses Dokument ist anwendbar für:

- Einzelbrenner angebaut an einem einzigen Feuerraum;

- Einzelbrenner angebaut an ein Gerät, das zusätzliche Anforderungen aufweist;

ANMERKUNG Wenn zusätzliche Anforderungen angewendet werden, welche nicht in dieser Norm identifiziert oder festgelegt werden, dann liegt die Spezifikation der erforderlichen Sicherheitsmaßnahmen und/oder Schutzeinrichtungen und die Konformität mit diesen Anforderungen außerhalb des Anwendungsbereichs dieser Norm.

- Ein- und Zweistoffbrenner, wenn sie nur mit Öl betrieben werden;

- den Ölbetrieb von Zweistoffbrennern, die für den gleichzeitigen Betrieb mit flüssigen und gasförmigen Brennstoffen ausgelegt sind; für letztere gelten auch die Anforderungen von EN 676.

Das vorliegende Dokument behandelt sämtliche signifikanten maschinenbezogenen Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse im Hinblick auf Brenner, wenn diese bestimmungsgemäß sowie unter nicht bestimmungsgemäßen Bedingungen verwendet werden, die vernünftigerweise vorhersehbar sind, siehe Anhang J.

Dieses Dokument behandelt darüber hinaus die zusätzlichen Anforderungen für Brenner im Anwendungsbereich mit druckbeaufschlagten Teilen und/oder für Brenner, die Druckgeräte befeuern, siehe Anhang K.

Dieses Dokument legt die Anforderungen fest, die für die Sicherheit während Inbetriebnahme, Anlauf, Betrieb und Abschaltung sowie Wartung erforderlich sind.

Dieses Dokument behandelt auch Gebläsebrenner, die für die Verwendung mit biogenen flüssigen Brennstoffen und Brennstoffgemischen vorgesehen sind.

Dieses Dokument behandelt auch Brenner und deren Ausrüstung für die Steigerung der Gesamt-Geräteeffizienz der Anlage; siehe Anhang M.

Brûleurs automatiques à air soufflé pour combustibles liquides

La présente Norme européenne spécifie la terminologie, les exigences générales concernant la conception et le fonctionnement des brûleurs à fioul à air soufflé et également les dispositions concernant les dispositifs de régulation et de sécurité ainsi que la procédure d'essai concernant ces brûleurs.

La présente Norme européenne s'applique aux brûleurs à fioul à air soufflé alimentés par :

- du combustible à base de premiers raffinats et leurs mélanges avec des combustibles liquides biogènes présentant une viscosité à l'entrée du brûleur comprise entre 1,6 mm2/s (cSt) et 6 mm2/s (cSt) à 20 °C et ;

- des premiers raffinats à base de pétrole à point d'ébullition élevé (viscosité supérieure à 6 mm2/s), qui nécessitent un préchauffage pour une atomisation appropriée.

La présente Norme européenne peut être appliquée à :

- des brûleurs individuels montés sur une seule chambre de combustion ;

- des brûleurs individuels montés sur un appareil présentant des exigences supplémentaires ;

NOTE Si des exigences supplémentaires non identifiées ou spécifiées dans la présente norme s'appliquent, la spécification des mesures de sécurité et/ou des dispositifs de protection requis et leur respect ne relèvent pas du domaine d'application de la présente norme.

- des brûleurs mono et bicombustible lorsqu'ils fonctionnent avec du fioul uniquement ;

- la fonction fioul des brûleurs biocombustibles conçus pour fonctionner simultanément avec des combustibles gazeux et liquides.

La présente Norme européenne traite de tous les risques significatifs des machines, des situations et des événements dangereux liés aux brûleurs, lorsque ces derniers sont utilisés comme prévu et dans des conditions anormales qui peuvent être raisonnablement prévues ; voir l'Annexe J.

La présente Norme européenne traite également des exigences supplémentaires concernant les brûleurs relevant du domaine d'application et comportant des parties sous pression et/ou installés sur des corps de chauffe fonctionnant sous pression ; voir l'Annexe K.

La présente Norme européenne spécifie les exigences à satisfaire pour garantir la sécurité au cours d'une mise en service, d'un démarrage, d'un fonctionnement, d'un arrêt et d'une maintenance.

La présente Norme européenne traite aussi des brûleurs à air soufflé destinés à être utilisés avec des combustibles liquides biogènes et des mélanges des liquides biogènes.

La présente Norme européenne traite également des équipements de brûleurs destinés à augmenter le rendement total de l'appareil ; voir l'Annexe M.

Ventilatorski gorilniki za tekoča goriva

General Information

- Status

- Published

- Public Enquiry End Date

- 28-Feb-2017

- Publication Date

- 06-Apr-2020

- Technical Committee

- OGS - Heating for buildings

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Apr-2020

- Due Date

- 06-Jun-2020

- Completion Date

- 07-Apr-2020

Relations

- Effective Date

- 01-May-2020

Overview

SIST EN 267:2020 - Forced draught burners for liquid fuels - is the European Type C standard specifying terminology, construction, operation, control and safety device requirements, and test procedures for forced-draught oil burners. It applies to burners using first raffinates and their mixtures with biogenous liquid fuels (viscosity 1.6–6 mm2/s at 20 °C) and to higher-boiling petroleum raffinates that require preheating for atomization. The standard covers single burners (including burners fitted to appliances), single- and dual-fuel burners when operating on oil, and the oil function of burners designed to operate simultaneously on gaseous and liquid fuels.

Key topics and technical requirements

- Terminology and classification specific to forced draught oil burners and burner heads.

- Construction and equipment requirements to ensure safe, reliable operation and proper atomization of liquid fuels.

- Control and safety devices: required sequencing, ignition, flame monitoring, air proving and emergency functions for safe start-up, operation, shut‑down and maintenance.

- Fuel viscosity and preheating: scope explicitly defines acceptable fuel types and the need for preheating for viscosities > 6 mm2/s.

- Testing procedures and test rigs: detailed test room/rig set-up, measuring equipment and test programs to verify combustion performance and safety functions.

- Combustion product quality and emissions: measurement and calculation methods for CO, NOx and unburned hydrocarbons (see Annexes B and D).

- Machine safety and risk assessment: hazards, foreseeable misuse and protective measures (Annex J); additional rules for pressurized parts or bodies (Annex K).

- Electrical interfaces and safety: harmonized with EN 60204-1 and EMC/LVD requirements (Annex L).

- Efficiency improvement options: equipment and measures to increase appliance efficiency (Annex M).

- Marking, labelling and documentation for installation, adjustment, maintenance and operation.

Practical applications - who uses this standard

SIST EN 267:2020 is essential for:

- Burner and appliance manufacturers designing or certifying forced draught oil burners.

- Test laboratories and conformity assessors performing safety and performance testing.

- System integrators, boiler installers and maintenance teams ensuring correct installation, commissioning and servicing.

- Regulators and procurement officers specifying compliant equipment for commercial and industrial heating, process heating and boiler plants.

- Product designers and R&D teams working with liquid fuels including bio-blends needing preheating or specific atomization.

Related standards (selected)

- EN 676 - Forced draught burners for gaseous fuels

- EN 298 - Automatic burner control systems

- EN 60204-1 - Electrical equipment of machines

- EN 746-2 - Industrial thermal process equipment (installation guidance)

SIST EN 267:2020 helps ensure safe, testable, and efficient burner design and operation for liquid-fuel applications across residential, commercial and industrial contexts.

Frequently Asked Questions

SIST EN 267:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Forced draught burners for liquid fuels". This standard covers: This European Standard specifies the terminology, the general requirements for the construction and operation of forced draught oil burners and also the provision of control and safety devices, and the test procedure for these burners. This European Standard applies to forced draught oil burners supplied with: - fuel based on first raffinates and their mixtures with biogenous liquid fuels having a viscosity at the burner inlet of 1,6 mm2/s (cSt) up to 6 mm2/s (cSt) at 20 °C, and - higher boiling petroleum based first raffinates (viscosity greater than 6 mm2/s), that require preheating for proper atomization. This European Standard is applicable to: - single burners fitted to a single combustion chamber; - single burners fitted to an appliance with additional requirements; NOTE When additional requirements apply which are not identified or specified in this standard, the specification of the required safety measures and/or protective devices and compliance with them is outside the scope of this standard. - single-fuel and dual-fuel burners when operating on oil only; - the oil function of dual-fuel burners designed to operate simultaneously on gaseous and liquid fuels. This European Standard deals with all significant machine hazards, hazardous situations and events relevant to burners, when they are used as intended and under conditions of misuse which are reasonably foreseeable, see Annex J. This European Standard also deals with the additional requirements for the burners in the scope with pressurized parts and/or firing pressurized bodies, see Annex K. This European Standard specifies the requirements to ensure the safety during commissioning, start-up, operation, shut-down and maintenance. This European Standard deals also with forced draught burners intended to be used with biogenous liquid fuels, mixtures. This European Standard deals also with burners and their equipment to increase the total appliance efficiency, see Annex M.

This European Standard specifies the terminology, the general requirements for the construction and operation of forced draught oil burners and also the provision of control and safety devices, and the test procedure for these burners. This European Standard applies to forced draught oil burners supplied with: - fuel based on first raffinates and their mixtures with biogenous liquid fuels having a viscosity at the burner inlet of 1,6 mm2/s (cSt) up to 6 mm2/s (cSt) at 20 °C, and - higher boiling petroleum based first raffinates (viscosity greater than 6 mm2/s), that require preheating for proper atomization. This European Standard is applicable to: - single burners fitted to a single combustion chamber; - single burners fitted to an appliance with additional requirements; NOTE When additional requirements apply which are not identified or specified in this standard, the specification of the required safety measures and/or protective devices and compliance with them is outside the scope of this standard. - single-fuel and dual-fuel burners when operating on oil only; - the oil function of dual-fuel burners designed to operate simultaneously on gaseous and liquid fuels. This European Standard deals with all significant machine hazards, hazardous situations and events relevant to burners, when they are used as intended and under conditions of misuse which are reasonably foreseeable, see Annex J. This European Standard also deals with the additional requirements for the burners in the scope with pressurized parts and/or firing pressurized bodies, see Annex K. This European Standard specifies the requirements to ensure the safety during commissioning, start-up, operation, shut-down and maintenance. This European Standard deals also with forced draught burners intended to be used with biogenous liquid fuels, mixtures. This European Standard deals also with burners and their equipment to increase the total appliance efficiency, see Annex M.

SIST EN 267:2020 is classified under the following ICS (International Classification for Standards) categories: 27.060.10 - Liquid and solid fuel burners. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 267:2020 has the following relationships with other standards: It is inter standard links to SIST EN 267:2010+A1:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 267:2020 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/68/EU, 2019-01-2272, 811/2013, 813/2013, 97/23/EC, TP173; Standardization Mandates: M/071, M/535. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 267:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2020

Nadomešča:

SIST EN 267:2010+A1:2012

Ventilatorski gorilniki za tekoča goriva

Forced draught burners for liquid fuels

Gebläsebrenner für flüssige Brennstoffe

Brûleurs automatiques à air soufflé pour combustibles liquides

Ta slovenski standard je istoveten z: EN 267:2020

ICS:

27.060.10 Gorilniki na tekoče in trdo Liquid and solid fuel burners

gorivo

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 267

EUROPEAN STANDARD

NORME EUROPÉENNE

January 2020

EUROPÄISCHE NORM

ICS 27.060.10 Supersedes EN 267:2009+A1:2011

English Version

Forced draught burners for liquid fuels

Brûleurs à air soufflé pour combustibles liquides Gebläsebrenner für flüssige Brennstoffe

This European Standard was approved by CEN on 8 October 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 267:2020 E

worldwide for CEN national Members.

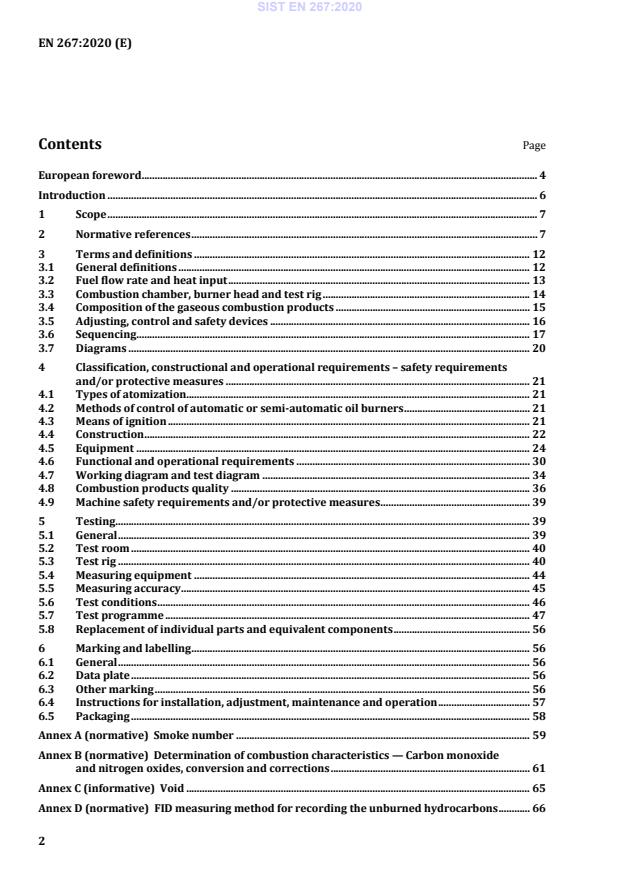

Contents Page

European foreword . 4

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 12

3.1 General definitions . 12

3.2 Fuel flow rate and heat input . 13

3.3 Combustion chamber, burner head and test rig . 14

3.4 Composition of the gaseous combustion products . 15

3.5 Adjusting, control and safety devices . 16

3.6 Sequencing . 17

3.7 Diagrams . 20

4 Classification, constructional and operational requirements – safety requirements

and/or protective measures . 21

4.1 Types of atomization . 21

4.2 Methods of control of automatic or semi-automatic oil burners . 21

4.3 Means of ignition . 21

4.4 Construction . 22

4.5 Equipment . 24

4.6 Functional and operational requirements . 30

4.7 Working diagram and test diagram . 34

4.8 Combustion products quality . 36

4.9 Machine safety requirements and/or protective measures . 39

5 Testing . 39

5.1 General . 39

5.2 Test room . 40

5.3 Test rig . 40

5.4 Measuring equipment . 44

5.5 Measuring accuracy . 45

5.6 Test conditions . 46

5.7 Test programme . 47

5.8 Replacement of individual parts and equivalent components . 56

6 Marking and labelling . 56

6.1 General . 56

6.2 Data plate . 56

6.3 Other marking . 56

6.4 Instructions for installation, adjustment, maintenance and operation . 57

6.5 Packaging . 58

Annex A (normative) Smoke number . 59

Annex B (normative) Determination of combustion characteristics — Carbon monoxide

and nitrogen oxides, conversion and corrections . 61

Annex C (informative) Void . 65

Annex D (normative) FID measuring method for recording the unburned hydrocarbons . 66

Annex E (informative) Conformity evaluation . 67

Annex F (informative) Examples for equipping of burners . 70

Annex G (informative) Other fuels . 74

Annex H (informative) Specific additional requirements and limitations for use of EN 267

burners for industrial applications. 75

Annex I (informative) Check of the air proving device . 76

Annex J (normative) Machine related hazards - additional safety requirements and/or

protective measures . 77

Annex K (normative) Additional requirements for burners with pressurized parts and

burners firing pressurized bodies as defined in the Pressure Equipment Directive

(PED) 2014/68/EU . 82

Annex L (normative) Electrical requirements – modifications to EN 60204-1 . 90

Annex M (normative) Equipment to increase the efficiency of the burner - boiler

installation . 105

Annex N (informative) Electrical interfaces for burners. 106

Annex O (informative) Environmental checklist EN 267 . 111

Annex P (informative) Guide for the applicability of the different standards on electrical

safety . 113

Annex Q (informative) Verification procedures for market surveillance purposes (ErP) . 115

Annex ZA (informative) Relationship between this European Standard and the ecodesign

requirements of Commission Regulation (EU) No 813/2013 aimed to be covered . 116

Bibliography . 117

European foreword

This document (EN 267:2020) has been prepared by Technical Committee CEN/TC 47 “Atomizing oil

burners and their components - Function - Safety - Testing”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by July 2020, and conflicting national standards shall be

withdrawn at the latest by January 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 267:2009+A1:2011.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directives.

For relationship with EU Directives, see informative Annex ZA, which are integral parts of this

document.

Compared to EN 267:2009+A1:2011 the following fundamental changes have been made:

— based on ISO 22968 where different to EN 267:2009+A1:2011 such as:

— flow rate from 100 kg/h to 30 kg/h requires a second valve, where the 30 kg/h are replaced by

400 kW;

— update of definitions;

— electrical interfaces for burners;

— modification:

— test and working diagram NO emission calculation;

X

— replacement of EN 50156-1:2004 by EN 60204-1 to include international available

requirements for the electrical safety of machines; see Annex L with editorial allocation in

Annex K;

— Annex J is adapted to the new ISO EN 12100 which is substituting EN 1050 which is currently

referenced to in Table J.1;

— mass flow rate is changed into heat input;

— new functions / requirements:

— remote reset;

— environmental aspects (environmental check list);

— increase of burner efficiency;

— terminology for burner load control;

— NO mean value for evaluating the NO classes;

X X

— implementing new requirements to comply with the 2013/813 (ErP);

— requiring of a risk assessment as required by EU directive 2014/35/EU for LVD and EU

Directive 2014/30/EU for EMC.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

This document is primarily intended for forced draught oil burners having a combustion air fan,

operated with liquid fuels, and intended to be marketed as a complete assembly.

Forced draught oil burners according to this document are also used in industrial applications. The

safety principles are the same as for forced draught oil burners used for household/commercial

applications. Industrial forced draught oil burners however need to operate safely in their industrial

environment and the risks involved can differ from those for household applications. These industrial

forced draught oil burners can be characterized by the ability to withstand industrial environmental

influences, like moisture, high temperature, electrical and magnetic phenomena, vibrations, etc.

Special requirements for forced draught burners for industrial premises are given in the form of notes

and identified by “industrial application”.

Further information and application limitations for forced draught burners, which are used for

industrial application, are given in informative Annex H.

Principal requirements for installation of oil burners for industrial thermal processing are covered by

EN 746-2.

This document is a type C standard as stated in EN ISO 12100.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document.

When provisions of this type C standard are different from those which are stated in type A or B

standards, the provisions of this type C standard take precedence over the provisions of the other

standard, for machines that have been designed and built according to the provisions of this type C

standard.

1 Scope

This document specifies the terminology, the general requirements for the construction and operation

of forced draught oil burners and also the provision of control and safety devices, and the test

procedure for these burners.

This document applies to forced draught oil burners supplied with:

— fuel based on first raffinates and their mixtures with biogenous liquid fuels having a viscosity at the

2 2

burner inlet of 1,6 mm /s (cSt) up to 6 mm /s (cSt) at 20 °C, and

— higher boiling petroleum based first raffinates (viscosity greater than 6 mm /s), that require

preheating for proper atomization.

This document is applicable to:

— single burners fitted to a single combustion chamber;

— single burners fitted to an appliance with additional requirements;

NOTE When additional requirements which are not identified or specified in this standard apply, the

specification of the required safety measures and/or protective devices and compliance with them is outside the

scope of this standard.

— single-fuel and dual-fuel burners when operating on oil only;

— the oil function of dual-fuel burners designed to operate simultaneously on liquid and gaseous

fuels, which, for the latter, the requirements of EN 676 also apply.

This document deals with all significant machine hazards, hazardous situations and events relevant to

burners, when they are used as intended and under conditions of misuse which are reasonably

foreseeable, see Annex J.

This document also deals with the additional requirements for the burners in the scope with

pressurized parts and/or firing pressurized bodies, see Annex K.

This document specifies the requirements to ensure the safety during commissioning, start-up,

operation, shut-down and maintenance.

This document deals also with forced draught burners intended to be used with biogenous liquid fuels,

mixtures.

This document deals also with burners and their equipment to increase the total appliance efficiency,

see Annex M.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 298:2012, Automatic burner control systems for burners and appliances burning gaseous or liquid

fuels

EN 676:2017, Forced draught burners for gaseous fuels

EN 1057:2006+A1:2010, Copper and copper alloys — Seamless, round copper tubes for water and gas in

sanitary and heating applications

EN 1092-1:2007+A1:2013, Flanges and their joints — Circular flanges for pipes, valves, fittings and

accessories, PN designated — Part 1: Steel flanges

EN 1092-2:1997, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 2: Cast iron flanges

EN 1092-3:2003, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 3: Copper alloy flanges

EN 1254-1, Copper and copper alloys — Plumbing fittings — Part 1: Fittings with ends for capillary

soldering or capillary brazing to copper tubes

EN 1254-4:1998, Copper and copper alloys — Plumbing fittings — Part 4: Fittings combining other end

connections with capillary or compression ends

EN 1854:2010, Pressure sensing devices for gas burners and gas burning appliances

EN 10204:2004, Metallic products — Types of inspection documents

EN 10220:2002, Seamless and welded steel tubes — Dimensions and masses per unit length

EN 10305-1:2016, Steel tubes for precision applications — Technical delivery conditions — Part 1:

Seamless cold drawn tubes

EN 10305-2:2016, Steel tubes for precision applications — Technical delivery conditions — Part 2:

Welded cold drawn tubes

EN 10305-3:2016, Steel tubes for precision applications — Technical delivery conditions — Part 3:

Welded cold sized tubes

EN 10305-4:2016, Steel tubes for precision applications — Technical delivery conditions — Part 4:

Seamless cold drawn tubes for hydraulic and pneumatic power systems

EN 10305-5:2016, Steel tubes for precision applications — Technical delivery conditions — Part 5:

Welded cold sized square and rectangular tubes

EN 10305-6:2016, Steel tubes for precision applications — Technical delivery conditions — Part 6:

Welded cold drawn tubes for hydraulic and pneumatic power systems

EN 13611:2015, Safety and control devices for burners and appliances burning gaseous and/or liquid

fuels — General requirements

EN 15035:2006, Heating boilers — Special requirements for oil fired room sealed units up to 70 kW

EN 15036-1:2006, Heating boilers — Test regulations for airborne noise emissions from heat generators

— Part 1: Airborne noise emissions from heat generators

EN 15456:2008, Heating boilers — Electrical power consumption for heat generators — System

boundaries - Measurements

EN 50156-1:2015, Electrical equipment for furnaces and ancillary equipment — Part 1: Requirements for

application design and installation

EN 50205:2002, Relays with forcibly guided (mechanically linked) contacts

EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements (IEC 60204-1:2005)

EN 60335-2-102:2016, Household and similar electrical appliances — Safety — Part 2-102: Particular

requirements for gas, oil and solid-fuel burning appliances having electrical connections (IEC 60335-2-

102:2004)

HD 60364-4-41:2007, Low-voltage electrical installations — Part 4-41: Protection for safety —

Protection against electric shock (IEC 60364-4-41:2005)

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 60664-1:2007, Insulation coordination for equipment within low-voltage systems — Part 1: Principles,

requirements and tests (IEC 60664-1:2007)

EN 60721-3-1:1997, Classification of environmental conditions — Part 3: Classification of groups of

environmental parameters and their severities — Section 1: Storage (IEC 60721-3-1:1997)

EN 60721-3-2:1997, Classification of environmental conditions — Part 3: Classification of groups of

environmental parameters and their severities — Section 2: Transportation (IEC 60721-3-2:1997)

EN 60721-3-3:1995, Classification of environmental conditions — Part 3: Classification of groups of

environmental parameters and their severities — Section 3: Stationary use at weatherprotected locations

(IEC 60721-3-3:1994)

EN 60730-1:2011, Automatic electrical controls for household and similar use — Part 1: General

requirements (IEC 60730-1:2010, modified)

EN 60730-2-5:2015, Automatic electrical controls — Part 2-5: Particular requirements for automatic

electrical burner control systems (IEC 60730-2-5:2013)

EN 60947-4-1:2010, Low-voltage switchgear and controlgear — Part 4-1: Contactors and motor-starters

— Electromechanical contactors and motor-starters (IEC 60947-4-1:2009)

EN 60947-2:2016, Low-voltage switchgear and controlgear — Part 2: Circuit-breakers (IEC

60947-2:2016)

EN 61000-4, Electromagnetic compatibility (EMC) — Testing and measurement techniques

EN 61000-4-13:2002, Electromagnetic compatibility (EMC) — Part 4-13: Testing and measurement

techniques — Harmonics and interharmonics including mains signalling at a.c. power port, low frequency

immunity tests (IEC 61000-4-13:2002)

EN 61310-1:2008, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for

visual, acoustic and tactile signals (IEC 61310-1:2007)

EN 61558-2-3:2010, Safety of transformers, reactors, power supply units and combinations thereof —

Part 2-3: Particular requirements and tests for ignition transformers for gas and oil burners (IEC 61558-2-

3:2010)

EN 61558-2-6:2009, Safety of transformers, reactors, power supply units and similar products for supply

voltages up to 1 100 V — Part 2-6: Particular requirements and tests for safety isolating transformers and

power supply units incorporating safety isolating transformers (IEC 61558-2-6:2009)

EN 61810-1:2015, Electromechanical elementary relays — Part 1: General and safety requirements (IEC

61810-1:2015)

EN 62061:2005, Safety of machinery — Functional safety of safety-related electrical, electronic and

programmable electronic control systems (IEC 62061:2005)

EN ISO 228-1:2003, Pipe threads where pressure-tight joints are not made on the threads — Part 1:

Dimensions, tolerances and designation (ISO 228-1:2000)

EN ISO 1127:1996, Stainless steel tubes — Dimensions, tolerances and conventional masses per unit

length (ISO 1127:1992)

EN ISO 3183:2012, Petroleum and natural gas industries — Steel pipe for pipeline transportation systems

(ISO 3183:2012)

EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 6806:2014, Rubber hoses and hose assemblies for use in oil burners — Specification (ISO

6806:2014)

EN ISO 9606-1:2013, Qualification testing of welders — Fusion welding — Part 1: Steels (ISO 9606-1:2012

including Cor 1:2012)

EN ISO 9606-2:2004, Qualification test of welders — Fusion welding — Part 2: Aluminium and aluminium

alloys (ISO 9606-2:2004)

EN ISO 9606-3:1999, Approval testing of welders — Fusion welding — Part 3: Copper and copper alloys

(ISO 9606-3:1999)

EN ISO 9606-4:1999, Approval testing of welders — Fusion welding — Part 4: Nickel and nickel alloys

(ISO 9606-4:1999)

EN ISO 9606-5:2000, Approval testing of welders — Fusion welding — Part 5: Titanium and titanium

alloys, zirconium and zirconium alloys (ISO 9606-5:2000)

EN ISO 11688-1:2009, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2015, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13857:2008, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2008)

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and

construction of fixed and movable guards (ISO 14120:2015)

EN ISO 15609-1:2004, Specification and qualification of welding procedures for metallic materials —

Welding procedure specification — Part 1: Arc welding (ISO 15609-1:2004)

EN ISO 15609-2:2001, Specification and qualification of welding procedures for metallic materials —

Welding procedure specification — Part 2: Gas welding (ISO 15609-2:2001)

EN ISO 15609-3:2004, Specification and qualification of welding procedures for metallic materials —

Welding procedures specification — Part 3: Electron beam welding (ISO 15609-3:2004)

EN ISO 15609-4:2009, Specification and qualification of welding procedures for metallic materials —

Welding procedure specification — Part 4: Laser beam welding (ISO 15609-4:2009)

EN ISO 15609-5:2011, Specification and qualification of welding procedures for metallic materials —

Welding procedure specification — Part 5: Resistance welding (ISO 15609-5:2011, Corrected version 2011-

12-01)

EN ISO 15612:2004, Specification and qualification of welding procedures for metallic materials —

Qualification by adoption of a standard welding procedure (ISO 15612:2004)

EN ISO 15614-7:2016, Specification and qualification of welding procedures for metallic materials —

Welding procedure test — Part 7: Overlay welding (ISO 15614-7:2016)

EN ISO 15614-11:2002, Specification and qualification of welding procedures for metallic materials —

Welding procedure test — Part 11: Electron and laser beam welding (ISO 15614-11:2002)

EN ISO 17672:2016, Brazing — Filler metals (ISO 17672:2016)

EN ISO 23553-1:2014, Safety and control devices for oil burners and oil-burning appliances — Particular

requirements — Part 1: Automatic and semi-automatic valves (ISO 23553-1:2014)

ISO 7-1:1994, Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions,

tolerances and designation

ISO 1129:1980, Steel tubes for boilers, superheaters and heat exchangers — Dimensions, tolerances and

conventional masses per unit length

ISO 8217:2017, Petroleum products — Fuels (class F) — Specifications of marine fuels

ISO 9329-1:1989, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 1:

Unalloyed steels with specified room temperature properties

ISO 9330-1:1990, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 1:

Unalloyed steel tubes with specified room temperature properties

ISO 9330-2:1997, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 2:

Electric resistance and induction welded unalloyed and alloyed steel tubes with specified elevated

temperature properties

ISO 9330-3:1997, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 3:

Electric resistance and induction welded unalloyed and alloyed steel tubes with specified low temperature

properties

ISO 9330-4:2000, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 4:

Submerged arc-welded unalloyed and alloyed steel tubes with specified elevated temperature properties

ISO 9330-5:2000, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 5:

Submerged arc-welded unalloyed and alloyed steel tubes with specified low temperature properties

ISO 9330-6:1997, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 6:

Longitudinally welded austenitic stainless steel tubes

ISO 23552-1:2007, Safety and control devices for gas and/or oil burners and gas and/or oil appliances —

Particular requirements — Part 1: Fuel/air ratio controls, electronic type

3 Terms and definitions

For the purposes of this document the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 General definitions

3.1.1

forced draught burner

burner in which the total air for combustion is supplied by means of a fan

3.1.2

automatic forced draught burner

forced draught burner that is fitted with an ignition, and automatic burner control system where the

ignition, flame monitoring and the on/off switching of the burner occurs automatically

Note 1 to entry: The heat input of the burner can be adjusted during operation either automatically or

manually.

3.1.3

semi-automatic oil burner

burner that differs from the fully automatic burner only in that start-up of the burner is initiated

manually by the operating personnel and there is no automatic recycling after switching off the burner

3.1.4

dual-fuel burner

burner in which both gaseous and liquid fuels can be burnt either simultaneously or in succession

3.1.5

industrial application

forced draught burner utilization and operation in industrial environment

EXAMPLE industrial application in:

― the extraction,

― growth,

― refining,

― processing,

― production,

― manufacture, or

― preparation of materials, plants, livestock, animal products, food or artefacts.

3.2 Fuel flow rate and heat input

3.2.1

fuel flow rate

constant volume or mass of fuel consumed during a period of time

Note 1 to entry: Fuel flow rate is expressed in kilograms per hour (kg/h) as mass flow rate.

Note 2 to entry: Fuel flow rate is expressed in litre per hour (l/h) as volume flow rate.

3.2.1.1

maximum fuel flow rate

mass or volume of fuel consumed during a period of time at maximum heat input

3.2.1.2

minimum fuel flow rate

mass or volume of fuel consumed during a period of time at minimum heat input

3.2.2

heat input

Q

F

quantity of energy used in unit time corresponding to the volume or mass flow rates, the calorific value

used being either the net or gross calorific value

Note 1 to entry: Heat input is expressed in kilowatts (kW) and is calculated as fuel flow rate multiplied with the

net calorific value.

3.2.2.1

maximum heat input

Q

Fmax

highest value of the heat input given in the instructions

Note 1 to entry: Maximum heat input is expressed in kilowatts (kW).

3.2.2.2

minimum heat input

Q

Fmin

lowest value of the heat input given in the instructions

Note 1 to entry: Minimum heat input is expressed in kilowatts (kW).

3.2.2.3

start heat input

Q

s

input of the burner during start-up position as a ratio of the maximum heat input

Note 1 to entry: Start heat input is expressed in percent (%).

3.2.2.4

nominal heat input

Q

FN

value of the heat input given in the instructions

Note 1 to entry: Fixed heat input burners have a single nominal heat input.

Note 2 to entry: Range-rated burners can be adjusted between the maximum nominal heat input and the

minimum nominal heat input given in the instructions.

Note 3 to entry: Nominal heat input is expressed in kilowatts (kW).

3.3 Combustion chamber, burner head and test rig

3.3.1

combustion chamber

part of the appliance in which the combustion takes place

3.3.2

pressure in the combustion chamber

p

F

pressure or depression, relative to atmospheric pressure, prevailing in the combustion chamber

Note 1 to entry: Pressure in the combustion chamber is expressed in kilopascals (kPa).

3.3.3

length of the combustion chamber

l

distance between the face of the nozzle or the fuel outlet and the rear wall of the test flame tube or

combustion chamber

Note 1 to entry: Length of the combustion chamber is expressed in metres (m).

3.3.4

diameter of the combustion chamber

d

inner diameter of the combustion chamber around the flame tube of the burner

Note 1 to entry: The diameter of the combustion chamber is measured in metres (m).

3.3.5

burner head

mixing device consisting of an atomizing system and other components for the mixing of air and fuel

EXAMPLE Stabilizing disc.

3.3.6

burner flame tube

device which hosts the mixing device and the root of the flame

3.3.7

test flame tube

cylindrical part of the test rig where the combustion takes place

3.4 Composition of the gaseous combustion products

3.4.1

content of carbon dioxide (CO )

ratio of the volume of carbon dioxide to the total volume of dry gaseous products in which it is present

Note 1 to entry: The carbon dioxide content is expressed as a percentage volume fraction.

3.4.2

content of oxygen (O )

ratio of the volume of oxygen to the total volume of dry gaseous products in which it is present

Note 1 to entry: The oxygen content is expressed as a percentage volume fraction.

3.4.3

content of carbon monoxide (CO)

ratio of the volume of carbon monoxide to the total volume of dry gaseous products in which it is

present

Note 1 to entry: The carbon monoxide content is expressed as a volume fraction, in units of millilitres per cubic

metre (ml/m ) for measuring purposes and in milligrams per kilowatt hour (mg/kWh) related to inferior calorific

value (Hi) for calculation purposes and declaring values.

3.4.4

content of nitrogen oxides (NO )

x

ratio of the combined volume of nitrogen oxides to the total volume of dry gaseous products in which

they are present

Note 1 to entry: The nitrogen oxides content is expressed as a volume fraction, in units of millilitres per cubic

metre (ml/m ) for measuring purposes and in milligrams per kilowatt hour (mg/kWh) related to inferior calorific

value (Hi) for calculation purposes and declaring values.

3.4.5

content of unburned hydrocarbons

ratio of the volume of unburnt hydrocarbons to the total volume of wet combustion products in which

they are present on an air free basis

Note 1 to entry: It is expressed in millilitres per cubic metre (ml/m ), calculated as C3H8.

3.4.6

smoke number

sample reference, the shade of which is closest to that of the comparison scale

Note 1 to entry: See Annex A.

3.4.7

excess air ratio

λ

ratio between the effectively introduced quantity of air and the theoretically required quantity of air

3.5 Adjusting, control and safety devices

3.5.1

flame detector device

device by which the presence of a flame is detected and signalled

Note 1 to entry: It can consist of a flame sensor, an amplifier and an element for signal transmission. These

parts, with the possible exception of the actual flame sensor, can be assembled in a single housing together with a

programming unit.

3.5.2

automatic burner control system

system which comprises at least a programming unit and all the elements of a flame detector device

Note 1 to entry: The various functions of an automatic burner control system can be in one or more housings.

3.5.3

programming unit

device that reacts to signals from control and safety devices, gives control commands, controls the start-

up sequence, supervises the burner operation and causes controlled shut-down, and if necessary safety

shut-down and non-volatile lock-out

Note 1 to entry: The programming unit follows a predetermined sequence of actions and always operates in

conjunction with a flame detector device.

3.5.4

safe-start check

procedure employing a protection circuit or circuits, to establish whether or not a fault in a safety

system or a flame simulating condition exists prior to start-up

3.5.5

controlled shut-down

process by which the power to the fuel shut-off valve(s) is removed based on the removed heat demand

3.5.6

non-volatile lock-out

safety shut-down condition of the system, such that a recycling can only be accomplished by a manual

reset of the system and by no other means

3.5.7

safety shut-down

process which is activated immediately following the response of a safety device or the detection of a

fault in the automatic burner control system and which puts the burner out of operation by immediately

removing the power to the fuel shut-off valve(s) and the ignition device

Note 1 to entry: Safety shut-down can also occur as a result of an interruption/decrease of the power supply.

3.5.8

safety shut-off device

device that automatically cuts off the fuel supply

3.5.9

ignition-restoration

process by which, following loss of flame signal, the ignition device will be switched on again without

total interruption of the fuel supply

3.5.10

recycling

process by which, after a safety shut-down, a full start-up sequence is automatically repeated

3.5.11

pressure switch

switch which compares the actual value of a pressure with the desired value, gives a signal when the

actual value exceeds or drops below the desired value and initiates the shut-off sequence

3.5.12

ignition device

means (flame, electrical ignition or other means) used to ignite the main burner, or the pilot burner if

applicable

3.5.13

remote reset

manual reset after a lock-out carried out from a location different from the safety related device

Note 1 to entry: The connection between the place of reset and the safety related device on the application can

be by electrical or electronic circuit. It complies with the single fault criterion.

3.6 Sequencing

3.6.1

pre-ignition time

period between the start of the ignition cycle and the release of the fuel

Note 1 to entry: Pre-ignition time is expressed in seconds (s).

3.6.2

safety time

t

s

duration of the maximum permissible time during which the automatic burner control system allows

the fuel to be released without there being a flame

Note 1 to entry: Safety time is expressed in seconds (s).

3.6.3

ignition safety time

first safety time

t

smax

time starting from the signal for release of the fuel and terminating at the moment at which the signal

for interrupting the fuel supply is given

Note 1 to entry: Ignition safety time is expressed in seconds (s).

3.6.4

safety time during operation

time starting at the moment the sensed flame is extinguished and ending at the moment the signal for

interrupting the fuel supply is given

Note 1 to entry: Safety time during operation is expressed in seconds (s).

3.6.5

purge time

period during which the combustion chamber is compulsorily ventilated without any fuel being

supplied

Note 1 to entry: Purge time is expressed in seconds (s).

3.6.6

pre-purge time

period during which purge takes place at the proven air rate prior to the energization of the ignition

device

Note 1 to entry: Pre-purge time is expressed in seconds (s).

3.6.7

post-purge time

period between any shut-down and the moment the fan is switched off

Note 1 to entry: Post-purge time is expressed in seconds (s).

3.6.8

total closing time

period that starts with the signal that the flame has been extinguished and ends with the shut-off valves

being closed

Note 1 to entry: The total closing time is expressed in seconds (s).

3.6.9

flame detector device

device by which the presence of a flame is detected and signalled (see Figure 1)

Note 1 to entry: Flame detector devices can consist of a flame sensor, an amplifier and a relay for signal

transmission. These parts, with the possible exception of the actual flame sensor, can be assembled in a single

housing together with a programming unit.

Key

1 automatic burner control system (see 3.5.2) 8 programming unit (see 3.5.3)

2 flame detector device (see 3.6.9) 9 shut-off valve (see 3.5.8)

3 flame 10 shut-off valve terminal

4 flame sensor (see 3.6.11) 11 flame signal (see 3.6.14)

5 amplifier 12 flame failure response time (see 3.6.12.1)

6 filter 13 sensed flame (see 3.6.13)

7 threshold

Figure 1 — Basic functional chain of a typical flame supervision

3.6.10

independent flame detector device

flame detector device which operates independent of the programming unit to provide the class C

control function (see Figure 2)

Note 1 to entry: Self-checking functions are incorporated in this type of flame detector device.

Key

1 independent flame detector device (see 3.6.10) 6 threshold

2 flame 7 flame signal (see 3.6.14)

3 flame sensor (see 3.6.11) 8 flame failure detection time (see 3.6.12.2)

4 amplifier 9 sensed flame (see 3.6.13)

5 filter

Figure 2 — Basic functional chain of an independent flame detector device

3.6.11

flame sensor

device which reacts to the presence of the flame by providing an output signal that is used for further

signal processing

3.6.12

time in case of flame failure

3.6.12.1

flame failure response time

FFRT

response time between the loss of a sensed flame and the resulting de-energizing of the shut-off valve

terminals

Note 1 to entry: FFRT may be referred to as “extinction safety time” in appliance standards.

3.6.12.2

flame

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...