SIST EN 13367:2005+A1:2008

(Main)Ceramic machines - Safety - Transfer platforms and cars

Ceramic machines - Safety - Transfer platforms and cars

This European Standard applies for the design, installation and commissioning of transfer platforms and cars and ancillary devices for the process related transport of ceramic material on rails. The rails, which are considered to be horizontal and the movement of vehicles in equipment and machinery connected with the process related transport such as kilns, dryers, collector scaffolds, machinery for loading and unloading are also covered.

1.2 This European Standard deals with all significant hazards, hazardous situations and events relevant to transfer platforms and cars, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). Noise is not a significant hazard. This document deals with the preventive measures to minimise these hazards which can arise during commissioning, the operation and maintenance.

1.3 This European Standard is not applicable to:

1.3.1 Kilns and dryers (see EN 746-1:1997), machinery for setting and dehacking of heavy clay and refractory, products and machinery for loading and unloading of fine clay tiles;

1.3.2 Retrial, packaging and storage of finished products;

1.3.3 Transport of cars with not rail mounted equipment e.g. with driverless trucks (see EN 1525:1997);

1.3.4 Transfer platforms and cars which are driven by human power.

1.4 This European Standard is not applicable to transfer platforms and cars and ancillary devices which are manufactured before the date of publication of this European Standard by CEN.

Keramikmaschinen - Sicherheit - Schiebebühnen und Wagen

Machines de la céramique - Sécurité - Chariots et wagons de transfert

1.1 La présente Norme européenne s’applique à la conception, l’installation et la mise en service des chariots et wagons de transfert ainsi que des dispositifs auxiliaires sur rails pour le transport, lié au procédé, des matériaux céramiques. Elle couvre également les rails, considérés comme étant horizontaux, ainsi que le mouvement des véhicules dans les équipements et les machines associés au transport lié au procédé, tels que fours, séchoirs, structures de chargement, machines de chargement et de déchargement.

1.2 La présente Norme européenne traite de tous les phénomènes dangereux, situations dangereuses et événements dangereux significatifs liés aux chariots et wagons de transfert, lorsqu’ils sont utilisés normalement et dans les conditions prévues par le constructeur (voir Article 4). Le bruit n’est pas un phénomène dangereux significatif. Le présent document traite des mesures préventives permettant de minimiser les risques susceptibles de survenir au cours des phases de mise en service, de fonctionnement et de maintenance.

1.3 La présente Norme européenne ne s’applique pas :

1.3.1 aux fours et aux séchoirs (voir EN 746-1:1997), aux machines destinées à l’empilage et au dépilage des produits en terre cuite et des produits réfractaires ainsi qu’aux machines destinées au chargement et au déchargement des carreaux en argile fine ;

1.3.2 à la révision, à l’emballage et au stockage des produits finis ;

1.3.3 au transport de wagons avec équipement non monté sur rails, tels que les chariots sans conducteur (voir EN 1525:1997) ;

1.3.4 aux wagons et chariots à propulsion humaine.

1.4 La présente Norme européenne ne s’applique pas aux wagons de transfert, chariots et dispositifs auxiliaires construits avant la date de publication du présent document par le CEN.

Stroji za keramiko - Varnost - Prenosne mize in vozila

This European Standard applies for the design, installation and Ta evropski standard velja za načrtovanje, vgradnjo in prevzem prenosnih miz in vozil ter pomožnih pripomočkov za postopek, povezan s transportom keramičnega materiala po tirih. Zajeti so tudi vodoravni tiri in premikanje vozil v opremi in mehanizaciji, povezano s transportom, ki se nanaša na postopek, kot so žgalne peči, sušilniki, zbiralni odri ter stroji za natovarjanje in raztovarjanje. Ta evropski standard obravnava vse velike nevarnosti, nevarna situacije in primere, pomembne za prenosne mize in vozila, kadar se uporabljajo v skladu z namembnostjo in pod pogoji, kot jih je predvidel proizvajalec (glej Klavzulo 4). Hrup ni velika nevarnost. Ta dokument obravnava preprečevalne ukrepe za zmanjševanje nevarnosti, ki se lahko pojavijo med prevzemom, delovanjem in vzdrževanjem. Ta evropski standard ne velja za: žgalne peči in sušilnike (glej EN 746-1:1997), stroje za postavljanje in razstavljanje opek in proti vročini odpornih snovi, proizvode in stroje za natovarjanje in raztovarjanje keramičnih ploščic; ponovno preskušanje, pakiranje in shranjevanje končnih izdelkov; transport vozil z netirno opremo, npr. s tovornjaki brez voznika (glej EN 1525:1997); prenosne mize in vozila na človeški pogon.

General Information

- Status

- Published

- Publication Date

- 14-Oct-2008

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 13-Oct-2008

- Due Date

- 18-Dec-2008

- Completion Date

- 15-Oct-2008

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 01-Dec-2008

- Corrected By

SIST EN 13367:2005+A1:2008/AC:2010 - Ceramic machines - Safety - Transfer platforms and cars - Effective Date

- 01-Feb-2010

Overview

EN 13367:2005+A1:2008 - published by CEN - is the European safety standard for ceramic machines specifically covering the design, installation and commissioning of transfer platforms and cars and their ancillary devices used for process‑related transport of ceramic material on rails. It applies to rail‑mounted vehicles (e.g., drying cars, kiln cars, finger cars), transfer platforms that move cars transverse to tracks, and connected equipment such as push/pull devices, turntables and brakes. The standard addresses significant hazards during commissioning, operation and maintenance (noise is explicitly not treated as a significant hazard) and supports the Essential Requirements of EU machinery directives.

Key topics and requirements

- Scope and exclusions: Applies to process‑related transport on horizontal rails; excludes certain kilns/dryers, packaging/storage, non‑rail transport (e.g., driverless trucks), human‑powered transfer platforms, and equipment manufactured before publication.

- Risk identification: Lists significant hazards (crushing, impact, trapping, electrical contact, unexpected start‑up, ergonomic issues) and requires preventive measures based on risk assessment.

- Safety requirements / protective measures: Addresses guarding, interlocking, braking and shock‑absorbing arrangements, stopping devices, hold‑to‑run and emergency stop principles, prevention of rope entanglement, measures to avoid overturning of finger cars, and safe positioning of controls.

- Control and automation: Covers safety‑related parts of control systems, verification of safety functions, and specific considerations for automatically controlled plants (e.g., maintenance control stations vs operating control stations).

- Verification and documentation: Specifies verification of safety measures, marking, and required information for use (instruction handbooks, maintenance and commissioning instructions).

- Informative annexes: Include drawings, examples (e.g., captive devices to prevent overturning, measures for tunnel kilns), and relationships to EU directives.

Practical applications and users

- Intended for: machine designers, manufacturers, safety engineers, plant installers, commissioning teams, maintenance personnel, and conformity assessors involved in ceramic production lines.

- Use cases: Ensuring safe design and integration of transfer platforms/cars with kilns, dryers and loading/unloading machinery; preparing technical documentation for CE conformity; developing operating and maintenance procedures; performing risk assessments and verification testing.

Related standards (selection)

- EN ISO 12100 (machine safety - basic concepts)

- EN 60204‑1 (electrical equipment of machines)

- EN 1037, EN 1088, EN 61496 series (interlocks, electro‑sensitive protective equipment)

- EN 349, EN 999, EN 1760 (gap/approach/pressure sensitive devices)

EN 13367 is essential for safe, standards‑compliant rail‑mounted transport systems in the ceramic industry and helps organizations manage mechanical, electrical and procedural risks in process‑related material handling.

Frequently Asked Questions

SIST EN 13367:2005+A1:2008 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Ceramic machines - Safety - Transfer platforms and cars". This standard covers: This European Standard applies for the design, installation and commissioning of transfer platforms and cars and ancillary devices for the process related transport of ceramic material on rails. The rails, which are considered to be horizontal and the movement of vehicles in equipment and machinery connected with the process related transport such as kilns, dryers, collector scaffolds, machinery for loading and unloading are also covered. 1.2 This European Standard deals with all significant hazards, hazardous situations and events relevant to transfer platforms and cars, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). Noise is not a significant hazard. This document deals with the preventive measures to minimise these hazards which can arise during commissioning, the operation and maintenance. 1.3 This European Standard is not applicable to: 1.3.1 Kilns and dryers (see EN 746-1:1997), machinery for setting and dehacking of heavy clay and refractory, products and machinery for loading and unloading of fine clay tiles; 1.3.2 Retrial, packaging and storage of finished products; 1.3.3 Transport of cars with not rail mounted equipment e.g. with driverless trucks (see EN 1525:1997); 1.3.4 Transfer platforms and cars which are driven by human power. 1.4 This European Standard is not applicable to transfer platforms and cars and ancillary devices which are manufactured before the date of publication of this European Standard by CEN.

This European Standard applies for the design, installation and commissioning of transfer platforms and cars and ancillary devices for the process related transport of ceramic material on rails. The rails, which are considered to be horizontal and the movement of vehicles in equipment and machinery connected with the process related transport such as kilns, dryers, collector scaffolds, machinery for loading and unloading are also covered. 1.2 This European Standard deals with all significant hazards, hazardous situations and events relevant to transfer platforms and cars, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). Noise is not a significant hazard. This document deals with the preventive measures to minimise these hazards which can arise during commissioning, the operation and maintenance. 1.3 This European Standard is not applicable to: 1.3.1 Kilns and dryers (see EN 746-1:1997), machinery for setting and dehacking of heavy clay and refractory, products and machinery for loading and unloading of fine clay tiles; 1.3.2 Retrial, packaging and storage of finished products; 1.3.3 Transport of cars with not rail mounted equipment e.g. with driverless trucks (see EN 1525:1997); 1.3.4 Transfer platforms and cars which are driven by human power. 1.4 This European Standard is not applicable to transfer platforms and cars and ancillary devices which are manufactured before the date of publication of this European Standard by CEN.

SIST EN 13367:2005+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 81.100 - Equipment for the glass and ceramics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13367:2005+A1:2008 has the following relationships with other standards: It is inter standard links to SIST EN 13367:2005, SIST EN 13367:2005+A1:2008/AC:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13367:2005+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13367:2005+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za keramiko - Varnost - Prenosne mize in vozilaKeramikmaschinen - Sicherheit - Schiebebühnen und WagenMachines de la céramique - Sécurité - Chariots et wagons de transfertCeramic machines - Safety - Transfer platforms and cars81.100Equipment for the glass and ceramics industriesICS:Ta slovenski standard je istoveten z:EN 13367:2005+A1:2008SIST EN 13367:2005+A1:2008en01-december-2008SIST EN 13367:2005+A1:2008SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13367:2005+A1

October 2008 ICS 81.100 Supersedes EN 13367:2005 English Version

Ceramic machines - Safety - Transfer platforms and cars

Machines de la céramique - Sécurité - Chariots et wagons de transfert

Keramikmaschinen - Sicherheit - Schiebebühnen und Wagen This European Standard was approved by CEN on 14 February 2005 and includes Amendment 1 approved by CEN on 25 August 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13367:2005+A1:2008: ESIST EN 13367:2005+A1:2008

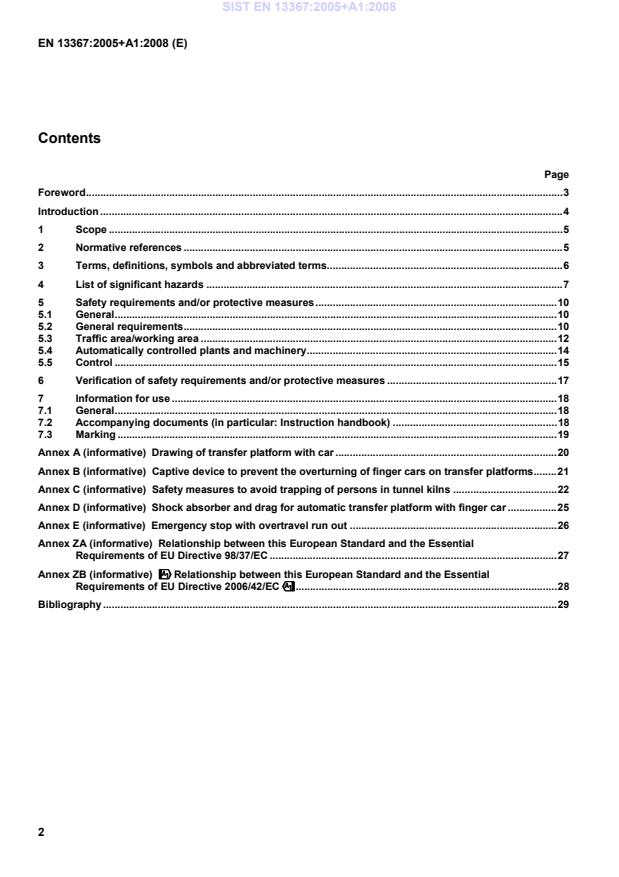

2 Contents Page Foreword.3 Introduction.4 1 Scope.5 2 Normative references.5 3 Terms, definitions, symbols and abbreviated terms.6 4 List of significant hazards.7 5 Safety requirements and/or protective measures.10 5.1 General.10 5.2 General requirements.10 5.3 Traffic area/working area.12 5.4 Automatically controlled plants and machinery.14 5.5 Control.15 6 Verification of safety requirements and/or protective measures.17 7 Information for use.18 7.1 General.18 7.2 Accompanying documents (in particular: Instruction handbook).18 7.3 Marking.19 Annex A (informative)

Drawing of transfer platform with car.20 Annex B (informative)

Captive device to prevent the overturning of finger cars on transfer platforms.21 Annex C (informative)

Safety measures to avoid trapping of persons in tunnel kilns.22 Annex D (informative)

Shock absorber and drag for automatic transfer platform with finger car.25 Annex E (informative)

Emergency stop with overtravel run out.26 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.27 Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential

Requirements of EU Directive 2006/42/EC"""".28 Bibliography.29

4 Introduction This European Standard is a type C standard as stated in EN ISO 12100-1:2003. The machinery concerned and the extent to which hazards, hazardous situations and events are covered is indicated in the scope of this European Standard. When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of the other standards, for machines that have been designed and built according to the provisions of this type C standard.

When compiling this European Standard it was assumed that: negotiations occur between the manufacturer and the user concerning especially the building components in relation to: static; sufficient free space (minimum gap) between vehicles and fixed parts of the building and between cars on adjoining rails; laying of tracks; local separation of the area of process related transport on rails and the machinery and equipment connected with it, e.g. for setting, dehacking, drying, burning, from other work stations and intended traffic routes; hazards of crushing between moving cars and fixed parts of machines for setting and loading or dehacking or unloading are covered by the preventive measures at these machines; the place of use is adequately lit; the existing ad hoc standards for components are applied; components without specific requirements are designed in accordance with usual engineering practice and calculation codes; components are kept in good repair and working order, so that the required characteristic remain despite wear; specifications have been met about interface with machinery and equipment connected with the process related transport with transfer platforms and cars such as kilns, dryers, machinery for setting, loading, dehacking, unloading; the design and working mode exclude an overload of cars. SIST EN 13367:2005+A1:2008

6 prEN 61496-2:2004, Safety of machinery — Electro-sensitive protective equipment — Part 2: Particular requirements for equipment using active opto-electronic protective devices (AOPDs) (IEC 61496-2:1997) EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003) 3 Terms, definitions, symbols and abbreviated terms For the purposes of this European Standard, the terms and definitions given in EN ISO 12100-1:2003 and the following apply. 3.1 cars rail mounted vehicles e.g. drying cars, kiln cars, finger cars, container cars, frame cars for accumulating (see Annex A (informative)) 3.2 transfer platform rail mounted vehicle for the movement of cars transverse to direction of their tracks (see Annex A (informative)) NOTE The term vehicle comprises cars and transfer platforms. 3.3 ancillary devices equipment which is an essential part of a system of transfer platforms and cars such as pushing or pulling devices for cars, turntables, limit switches and their supports, brakes for cars without own drive 3.4 pushing or pulling devices means for power driven movement of cars without own drive by applying the moving force from outside e.g. by guided trolleys with catches. The drive is realised e.g. by ropes of motor driven winches, hydraulic cylinders, motor driven frictional wheels 3.5 turntables means to rotate cars around a vertical axis 3.6 process related transport movement of transfer platforms and cars in the course of different process operations of ceramic material such as drying, firing; accumulating is included 3.7 fixed parts objects able to produce high reaction force such as supporting pillars, cars on adjacent tracks 3.8 fixed low parts fixed parts, e.g. ancillary devices, not higher than 250 mm above floor level 3.9 mechanical stop structural or special component generally at the end of tracks for a rigid halt of vehicles 3.10 shock absorbers mechanical equipment at the end of tracks, which allows damped stops by turning kinetic energy into heat SIST EN 13367:2005+A1:2008

8 Table 1 — List of significant hazards Clause Hazards Danger zone/Dangerous item Preventive measures see clause 4.1 mechanical

4.1.1 crushing of the body between moving cars (and their loads) and fixed adjacent parts;

fixed parts: cars on adjacent tracks, building components, parts of equipment and machinery connected with the process related transport e.g. inlets of kilns and dryers between moving transfer platforms with or without (loaded) cars and fixed adjacent parts such as structures, kilns, cars on their respective tracks 5.3.1; 5.4.2; 5.5.3; 5.5.6; 7.2.5; 7.2.6; 7.2.8 4.1.2 crushing and impact between the front of cars (and their loads), the front of transfer platforms with or without cars (and their loads) and (low) fixed parts; fixed parts: e.g. walls, stationary or slower travelling cars on the same track; low fixed parts e.g.: brakes, centring devices, the floor with rail itself; (impact) by the front of cars or of transfer platforms (with their loads) 5.3.8.2 to 5.3.8.4; 5.4.1.3; 5.4.1.4; 5.4.1.7; 5.4.2; 5.5.3; 7.2.6; 7.2.11; 7.2.12 4.1.3 crushing of the body between finger cars rotating by turntables on transfer platforms and fixed parts of the platform, e.g. consoles (cabins) 5.3.1.3; 5.3.8.2 to 5.3.8.5; 5.4.2; 5.5.3; 5.5.6; 7.2.9 SIST EN 13367:2005+A1:2008

5.2.10; 5.3.5 4.1.7 drawing - in loose coils of ropes; rope take-up on winch drums, deflection and return pulleys 5.2.7; 5.2.8 4.1.8 trapping finger cars with ride on drivers in chamber dryers; automatically moved cars in confined space 5.3.8.8; 5.4.1.6; 5.4.2; 5.5.3; 5.5.6; 7.2.1.3 4.2 electrical direct contact of conductor wires or of cables with damaged insulation 5.2.5; 5.2.6; 7.2.16 4.3 by neglecting ergonomic principles

4.3.1 inadequate local lighting chamber dryers 5.2.4 4.3.2 inadequate design and location of manual con-trols (actuators) missing view over danger zones; dangerous position 5.3.8.3; 5.5.4.1; 5.5.4.2 4.4 unexpected start-up, overrun – malfunction by:

4.4.1 failure, disorder of the control system overrun by: hold-to run device, which fails to deliver a stop command when released by failure of limiting devices; non release of contactors; start-up: all machinery or parts of it 5.5.1; 5.3.9; 5.5.2; 5.5.7; 7.2.4; 7.2.15; 7.2.16 4.4.2 external influences local changes in rail gradient, kinetic en-ergy of the car or induced by other cars 5.2.2; 5.3.9; 7.2.4 4.4.3 errors made by the op-erator due to human behaviour misuse by untrained persons; erroneous start of machinery; manipulation 5.2.5; 5.3.8.5; 5.3.8.6; 5.3.9, 5.5.1; 5.5.3.6; 5.5.6; 7.2.4; 7.2.10; 7.2.15; 7.2.16 4.5 impossibility of stop-ping the machine in the best possible condi-tions braking, emergency stop, failure of operational stop 5.2.1; 5.5.2; 5.5.5, 7.2.9 4.6 break-up during opera-tion ropes, transfer platforms and cars 5.2.7; 5.2.9; 7.2.7 4.7 falling objects load of finger cars, unstable load on cars 5.3.8.7; 5.3.10; 7.2.3 4.8 overturning of machin-ery finger cars 5.2.3 4.9 slip, trip, fall of persons

4.9.1 trip of persons parts protruding the floor such as tracks, pushing or pulling devices, limit switches 5.3.2; 5.3.7 4.9.2 fall of persons operating stations on transfer platforms 5.3.8.9

10 5 Safety requirements and/or protective measures 5.1 General Machinery shall comply with the safety requirements and/or protective measures of Clause 5. In addition, transfer platforms, cars and ancillary devices shall be designed according to the principles of both parts of EN ISO 12100 for hazards relevant but not significant which are not dealt with by this document (e.g. sharp edges). For applications of EN 418:1992, EN 954-1:1996, EN 982:1996, EN 999:1998, EN 1037:1995, EN 1088:1995, EN 60204-1:1997 and due to complexity and variety of machinery covered, the manufacturer shall carry out an adequate risk assessment for the requirements thereof where choice is necessary. NOTE This specific risk assessment is part of the general risk assessment relating to the hazards not covered by this type C standard. 5.2 General requirements 5.2.1 Mechanical brakes Transfer platforms and cars with own drive, e.g. finger cars, shall be equipped with mechanical brakes to be able to be stopped and hold (immobilised) at any time even if there is a failure of the power supply. When transfer platforms and cars with own drive are controlled in the automatic mode, devices to brake and hold shall be self-acting, when the power supply fails. 5.2.2 Devices against unintended movement Devices shall be installed, which brake or stop unintended movement of cars without own drive caused by kinetic energy or by local falling gradient of the track: at rail ends in front of transfer platforms driving ways; where trip devices (see e.g. 5.3.1.2) or hold-to-run control devices (see 5.3.1.3) are provided to interrupt dangerous movements of cars at crushing points; in the working area of permanent setting and/or unloading stations, at which persons stand on the floor; on transfer platforms. Suitable devices are for example: brakes acting permanently from outside on the cars; back run mechanisms on tracks where cars are moved only in one direction. Devices operating in the positive mode shall be (additionally) installed: for immobilising finger cars with ride on drivers on transfer platforms (see 5.2.9.3), e.g. by self acting bolts; to prevent cars, which move in elevated position from running off from rail ends in front of transfer platform driving ways in multi level buffers, e.g. by self acting mechanical stops, which are only retracted by positive operation by means of the transfer platform, when the latter is correctly positioned to the respective track.

NOTE For immobilising cars in variable areas, where people stand on the floor for setting/unloading see 5.3.9. SIST EN 13367:2005+A1:2008

12 pushing or pulling devices are retracted, and cars without own drive are completely delivered or are positioned as intended on the platform and immobilised, and finger cars with ride on drivers are positioned as intended and immobilised in the positive mode e.g. by jumping of a bolt into a groove, and 5.2.9.4 Interlockings, which are used to comply with the requirements of 5.2.9.2 and 5.2.9.3 are in accordance with minimum category 1 of EN 954-1:1996. 5.2.10 Running wheels Wheels of all transfer platforms, finger cars and pushing or pulling devices, which are not safeguarded by design against access from all sides, shall be fitted with rail strikers on both sides of each wheel. NOTE Wheels of other cars than finger cars see 5.3.5. 5.3 Traffic area/working area 5.3.1 Avoidance of crushing of the body 5.3.1.1 A gap of minimum 0,5 m in accordance with EN 349:1993 shall be left to avoid the hazard of crushing of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...