SIST-TS CEN/TS 19102:2024

(Main)Design of tensioned membrane structures

Design of tensioned membrane structures

1.1 Scope of CEN/TS 19102

(1) This document applies to the design of buildings and structural works, made of structural membrane material. It provides guidance for the design of tensioned membrane structures, either mechanically or pneumatically tensioned at a defined prestress level.

NOTE 1 Membrane materials comprise structural fabrics, coated structural fabrics and foils.

NOTE 2 For elements of tensile surface structures not governed by this Technical Specification (for example made of steel, aluminium, wood or other structural materials), see relevant Eurocode parts.

(2) This document is concerned with the requirements for resistance, serviceability and durability of tensioned membrane structures, as given in EN 1990.

NOTE 1 The safety criteria follow EN 1990 and will consider specific limit states for tensioned membrane structures.

NOTE 2 Specific requirements concerning seismic design are not considered.

(3) Design and verification in this document is based on limit state design in conjunction with the partial factor method.

NOTE Special attention goes to the action of prestress, snow, wind and rain action on membrane structures and the combined effect of wind and rain or snow.

(4) This document covers analysis methodologies appropriate for tensioned membrane structures, from analytical to full numerical simulation methods.

(5) This document considers connections between membrane materials and between membrane materials and others.

(6) This document is applicable for hybrid membrane structures integrating different kinds of load bearing behaviour (tension, compression, bending, inflation…), in a way that the structural membrane shares loadbearing capacity with other structural elements made of different materials.

NOTE The term ‘hybrid structure’ refers to this combined structural behaviour or use of materials.

1.2 Assumptions

(1) The assumptions of EN 1990 apply to this document.

(2) This document is intended to be used in conjunction with EN 1990, the EN 1991 series, the EN 1993 series, the EN 1999 series, ENs, EADs and ETAs for construction products relevant to tensioned membrane structures.

Bemessung von vorgespannten Membrantragwerken

1.1 Anwendungsbereich von CEN/TS 19102

(1) Dieses Dokument ist anwendbar für die Bemessung und Konstruktion von Hochbauten und Tragwerken aus tragenden Membranwerkstoffen. Es enthält Hinweise zur Bemessung und Konstruktion von vorgespannten Membrantragwerken mit entweder mechanischer oder pneumatischer Vorspannung mit festgelegtem Wert.

ANMERKUNG 1 Membranwerkstoffe umfassen tragende Gewebe, beschichtete tragende Gewebe und Folien.

ANMERKUNG 2 Zu Bauelementen von Flächenzugtragwerken, die nicht Gegenstand dieses Dokuments sind (z. B. aus Stahl, Aluminium, Holz oder anderen Werkstoffen), siehe die maßgebenden Eurocode-Teile.

(2) Dieses Dokument behandelt die Anforderungen an Widerstand, Gebrauchstauglichkeit und Dauerhaftigkeit von vorgespannten Membrantragwerken, wie sie in EN 1990 angegeben sind.

ANMERKUNG 1 Die Sicherheitskriterien folgen EN 1990 und berücksichtigen spezifische Grenzzustände für vorgespannte Membrantragwerke.

ANMERKUNG 2 Besondere Anforderungen an die Bemessung gegen Erdbeben werden nicht berücksichtigt.

(3) Bemessung und Nachweis in diesem Dokument beruhen auf der Bemessung nach Grenzzuständen in Verbindung mit dem Verfahren mit Teilsicherheitsbeiwerten.

ANMERKUNG Besonderes Augenmerk gilt der Einwirkung von Vorspannung, Schnee, Wind und Regen auf Membrantragwerke sowie der kombinierten Auswirkung von Wind und Regen oder Schnee.

(4) Dieses Dokument behandelt für vorgespannte Membrantragwerke geeignete Berechnungsmethodologien von analytischen bis hin zu vollständig numerischen Simulationsverfahren.

(5) Dieses Dokument berücksichtigt Verbindungen von Membranwerkstoffen untereinander sowie mit anderen Werkstoffen.

(6) Dieses Dokument ist anwendbar für Hybridmembrantragwerke, die verschiedene Arten des Tragverhaltens (Zug, Druck, Biegung, Luftstützung usw.) so einschließen, dass sich die tragende Membran die Tragkraft mit anderen Tragwerkselementen aus unterschiedlichen Werkstoffen teilt.

ANMERKUNG Der Begriff „Hybridtragwerk“ bezieht sich auf diese(s) kombinierte Tragverhalten oder Verwendung von Werkstoffen.

1.2 Voraussetzungen

(1) Die Annahmen nach EN 1990 gelten für dieses Dokument.

(2) Dieses Dokument ist zur Anwendung in Zusammenhang mit EN 1990, der EN 1991-Reihe, der EN 1993 Reihe, der EN 1999-Reihe, EN, EAD und ETA für Bauprodukte, die für vorgespannte Membrantragwerke maßgebend sind, vorgesehen.

Conception et calcul des structures en membrane tendue

Projektiranje nateznih membranskih konstrukcij

(1) Ta dokument se uporablja za projektiranje stavb in konstrukcijskih objektov iz konstrukcijskega membranskega

materiala. Podaja smernice za projektiranje nateznih membranskih konstrukcij, ki so lahko mehansko ali

pnevmatsko napete na določeno raven prednapetosti.

OPOMBA 1: Membranski materiali so sestavljeni iz konstrukcijske tkanine, prevlečene konstrukcijske tkanine in folij.

OPOMBA 2: Za elemente nateznih površinskih konstrukcij, ki jih ne ureja ta tehnična specifikacija (npr. izdelanih iz jekla, aluminija, lesa ali drugih konstrukcijskih materialov), glej ustrezne dele Evrokoda.

(2) Ta dokument obravnava zahteve za odpornost, uporabnost in trajnost

nateznih membranskih konstrukcij, kot so podane v standardu EN 1990.

OPOMBA 1: Varnostna merila so skladna s standardom EN 1990 in bodo upoštevala posebna mejna stanja za natezne membranske konstrukcije.

OPOMBA 2: Posebne zahteve v zvezi s protipotresnim projektiranjem niso obravnavane.

(3) Projektiranje in potrjevanje v tem dokumentu temeljita na projektiranju po mejnih stanjih skupaj z metodo

delnih faktorjev.

OPOMBA: Posebna pozornost je namenjena vplivom prednapetostnih sil, snega, vetra in dežja na membranske konstrukcije in skupni vpliv vetra in dežja ali snega.

(4) Ta dokument zajema ustrezne metodologije za analizo nateznih membranskih konstrukcij, vse od analitičnih metod do metod povsem numeričnih simulacij.

(5) Ta dokument obravnava povezave med membranskimi materiali ter med membranskimi

in drugimi materiali.

(6) Ta dokument se uporablja za hibridne membranske konstrukcije z obnašanjem pri

obremenitvi (napetost, stiskanja, upogibanje, napihovanje itd.) na način, da konstrukcijska membrana

skupaj z drugimi konstrukcijskimi elementi, izdelanimi iz različnih materialov, prav tako zagotavlja nosilnost.

OPOMBA: Izraz »hibridna konstrukcija« se nanaša na to kombinirano konstrukcijsko obnašanje ali uporabo materialov.

General Information

- Status

- Published

- Public Enquiry End Date

- 18-Jul-2023

- Publication Date

- 11-Feb-2024

- Technical Committee

- KON - Structures

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 19-Dec-2023

- Due Date

- 23-Feb-2024

- Completion Date

- 12-Feb-2024

Overview

CEN/TS 19102:2023 - "Design of tensioned membrane structures" - is a CEN Technical Specification that provides guidance for the structural design, verification and detailing of buildings and structural works made from structural membrane materials (fabrics, coated fabrics and foils). It covers mechanically and pneumatically tensioned membranes at defined prestress levels and addresses resistance, serviceability and durability in accordance with EN 1990. The document complements Eurocodes and product standards used for membrane projects.

Key topics and technical requirements

- Design approach: Limit state design using the partial factor method, aligned with EN 1990 principles.

- Actions and combinations: Special emphasis on prestress, snow, wind, rain and combined effects (wind + rain/snow), and ponding behaviour.

- Material guidance: Requirements for fabrics, coated fabrics and foils (including ETFE, PES‑PVC, glass‑PTFE as referenced in annexes) and connection devices.

- Structural analysis: From analytical methods to full numerical simulation, and specific guidance for pneumatic (inflated) structures and patterning.

- Limit states: Ultimate Limit States (ULS) and Serviceability Limit States (SLS) including deflection, wrinkling, tear control, long‑term prestress maintenance and durability.

- Connections and details: Criteria for irreversible/reversible connections, membrane edges, corners and field supports.

- Durability & testing: Annexes for modification factors, test procedures (uniaxial/biaxial, creep, hysteresis), crease‑sensitive fabrics and foil testing.

- Safety & management: Informative annexes on fire provisions, fire performance, and technical management measures covering quality control, production, erection and maintenance.

- Scope limits: Seismic design is not considered in this TS; for non‑membrane elements (steel, aluminium, concrete) refer to relevant Eurocode parts.

Practical applications and users

Who uses CEN/TS 19102:2023:

- Structural and façade engineers designing tensile roofs, canopies, atria, pavilions and ETFE cushion systems.

- Architects and design teams integrating lightweight membrane forms.

- Manufacturers and fabricators specifying material tests, panel patterning and connection systems.

- Contractors and installers following erection, prestressing and quality control measures.

- Testing laboratories and certification bodies applying test methods and modification factors.

Typical applications include tensioned fabric roofs, hybrid membrane structures (membrane combined with other load‑bearing elements), pneumatic enclosures and transparent foil façades.

Related standards and keywords

- Related Eurocodes: EN 1990, EN 1991 series, EN 1993, EN 1999.

- Relevant product standards, EADs and ETAs for membrane construction products.

- SEO keywords: CEN/TS 19102:2023, design of tensioned membrane structures, tensile membrane design, ETFE foil, structural fabrics, limit state design, membrane connections, ponding, prestress.

Frequently Asked Questions

SIST-TS CEN/TS 19102:2024 is a technical specification published by the Slovenian Institute for Standardization (SIST). Its full title is "Design of tensioned membrane structures". This standard covers: 1.1 Scope of CEN/TS 19102 (1) This document applies to the design of buildings and structural works, made of structural membrane material. It provides guidance for the design of tensioned membrane structures, either mechanically or pneumatically tensioned at a defined prestress level. NOTE 1 Membrane materials comprise structural fabrics, coated structural fabrics and foils. NOTE 2 For elements of tensile surface structures not governed by this Technical Specification (for example made of steel, aluminium, wood or other structural materials), see relevant Eurocode parts. (2) This document is concerned with the requirements for resistance, serviceability and durability of tensioned membrane structures, as given in EN 1990. NOTE 1 The safety criteria follow EN 1990 and will consider specific limit states for tensioned membrane structures. NOTE 2 Specific requirements concerning seismic design are not considered. (3) Design and verification in this document is based on limit state design in conjunction with the partial factor method. NOTE Special attention goes to the action of prestress, snow, wind and rain action on membrane structures and the combined effect of wind and rain or snow. (4) This document covers analysis methodologies appropriate for tensioned membrane structures, from analytical to full numerical simulation methods. (5) This document considers connections between membrane materials and between membrane materials and others. (6) This document is applicable for hybrid membrane structures integrating different kinds of load bearing behaviour (tension, compression, bending, inflation…), in a way that the structural membrane shares loadbearing capacity with other structural elements made of different materials. NOTE The term ‘hybrid structure’ refers to this combined structural behaviour or use of materials. 1.2 Assumptions (1) The assumptions of EN 1990 apply to this document. (2) This document is intended to be used in conjunction with EN 1990, the EN 1991 series, the EN 1993 series, the EN 1999 series, ENs, EADs and ETAs for construction products relevant to tensioned membrane structures.

1.1 Scope of CEN/TS 19102 (1) This document applies to the design of buildings and structural works, made of structural membrane material. It provides guidance for the design of tensioned membrane structures, either mechanically or pneumatically tensioned at a defined prestress level. NOTE 1 Membrane materials comprise structural fabrics, coated structural fabrics and foils. NOTE 2 For elements of tensile surface structures not governed by this Technical Specification (for example made of steel, aluminium, wood or other structural materials), see relevant Eurocode parts. (2) This document is concerned with the requirements for resistance, serviceability and durability of tensioned membrane structures, as given in EN 1990. NOTE 1 The safety criteria follow EN 1990 and will consider specific limit states for tensioned membrane structures. NOTE 2 Specific requirements concerning seismic design are not considered. (3) Design and verification in this document is based on limit state design in conjunction with the partial factor method. NOTE Special attention goes to the action of prestress, snow, wind and rain action on membrane structures and the combined effect of wind and rain or snow. (4) This document covers analysis methodologies appropriate for tensioned membrane structures, from analytical to full numerical simulation methods. (5) This document considers connections between membrane materials and between membrane materials and others. (6) This document is applicable for hybrid membrane structures integrating different kinds of load bearing behaviour (tension, compression, bending, inflation…), in a way that the structural membrane shares loadbearing capacity with other structural elements made of different materials. NOTE The term ‘hybrid structure’ refers to this combined structural behaviour or use of materials. 1.2 Assumptions (1) The assumptions of EN 1990 apply to this document. (2) This document is intended to be used in conjunction with EN 1990, the EN 1991 series, the EN 1993 series, the EN 1999 series, ENs, EADs and ETAs for construction products relevant to tensioned membrane structures.

SIST-TS CEN/TS 19102:2024 is classified under the following ICS (International Classification for Standards) categories: 91.080.99 - Other structures. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST-TS CEN/TS 19102:2024 is associated with the following European legislation: Standardization Mandates: M/515. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST-TS CEN/TS 19102:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2024

Projektiranje nateznih membranskih konstrucij

Design of tensioned membrane structures

Bemessung von vorgespannten Membrantragwerken

Conception et calcul des structures en membrane tendue

Ta slovenski standard je istoveten z: CEN/TS 19102:2023

ICS:

91.080.99 Druge konstrukcije Other structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TS 19102

TECHNICAL SPECIFICATION

SPÉCIFICATION TECHNIQUE

November 2023

TECHNISCHE SPEZIFIKATION

ICS 91.080.99

English Version

Design of tensioned membrane structures

Conception et calcul des structures en membrane Bemessung von vorgespannten Membrantragwerken

tendue

This Technical Specification (CEN/TS) was approved by CEN on 24 August 2023 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to

submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS

available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in

parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 19102:2023 E

worldwide for CEN national Members.

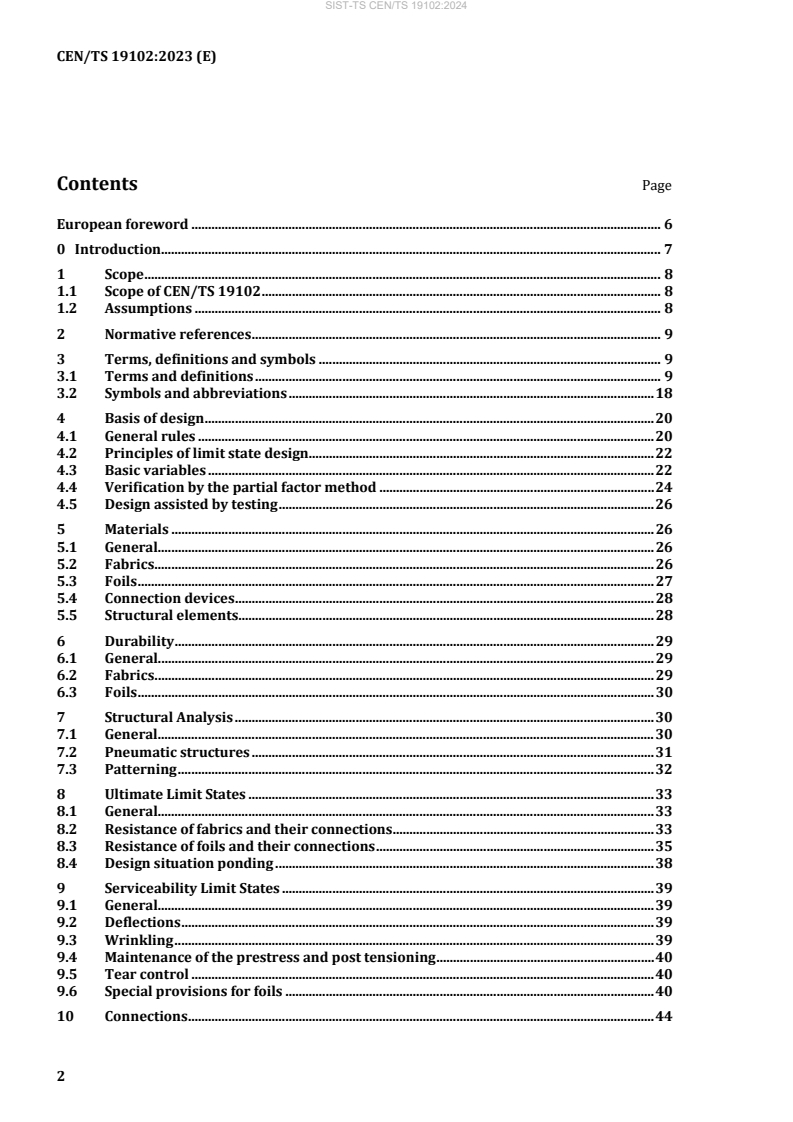

Contents Page

European foreword . 6

0 Introduction. 7

1 Scope . 8

1.1 Scope of CEN/TS 19102 . 8

1.2 Assumptions . 8

2 Normative references . 9

3 Terms, definitions and symbols . 9

3.1 Terms and definitions . 9

3.2 Symbols and abbreviations . 18

4 Basis of design . 20

4.1 General rules . 20

4.2 Principles of limit state design . 22

4.3 Basic variables . 22

4.4 Verification by the partial factor method . 24

4.5 Design assisted by testing . 26

5 Materials . 26

5.1 General. 26

5.2 Fabrics . 26

5.3 Foils . 27

5.4 Connection devices . 28

5.5 Structural elements . 28

6 Durability . 29

6.1 General. 29

6.2 Fabrics . 29

6.3 Foils . 30

7 Structural Analysis . 30

7.1 General. 30

7.2 Pneumatic structures . 31

7.3 Patterning . 32

8 Ultimate Limit States . 33

8.1 General. 33

8.2 Resistance of fabrics and their connections . 33

8.3 Resistance of foils and their connections . 35

8.4 Design situation ponding . 38

9 Serviceability Limit States . 39

9.1 General. 39

9.2 Deflections . 39

9.3 Wrinkling . 39

9.4 Maintenance of the prestress and post tensioning . 40

9.5 Tear control . 40

9.6 Special provisions for foils . 40

10 Connections . 44

10.1 Introduction . 44

10.2 Irreversible membrane connections . 46

10.3 Reversible membrane connections . 48

10.4 Membrane edges . 50

10.5 Corners . 52

10.6 Field supports . 54

10.7 Further connection devices . 54

Annex A (informative) Classification of structural membranes . 55

A.1 Use of this Annex . 55

A.2 Scope and field of application . 55

A.3 General framework . 55

A.4 Strength classification for PES-PVC . 55

A.5 Tensile strength classification for glass-PTFE . 56

A.6 Typical Strength values for ETFE foil . 57

Annex B (normative) Procedures for determination of modification factors . 58

B.1 Use of this Annex . 58

B.2 Scope and field of application . 58

B.3 General determination of modification factors . 58

B.4 Modification factor considering modified temperature . 58

B.5 Modification factor considering permanent load . 60

B.6 Modification factor considering long-term load . 62

B.7 Modification factor considering ageing . 62

B.8 Modification factor considering biaxial stress states . 62

B.9 Modification factor considering panel size . 62

Annex C (informative) Modification factors . 63

C.1 Use of this Annex . 63

C.2 Scope and field of application . 63

C.3 Typical modification factors for PES-PVC membrane . 63

C.4 Typical modification factors for glass-PTFE membrane . 64

C.5 Typical Modification factors for ETFE foil membrane for ULS verification . 64

C.6 Typical Modification factors for ETFE foil membrane for SLS verification . 65

Annex D (informative) Test procedures considering crease folds sensitive fabrics. 66

D.1 Use of this Annex . 66

D.2 Scope and field of application . 66

D.3 Running double crease fold . 67

D.4 Over-loop rolling . 68

Annex E (informative) Test procedures to determine foil properties . 70

E.1 Use of this Annex . 70

E.2 Scope and field of application . 70

E.3 Biaxial creep tests for foils . 70

E.4 Biaxial hysteresis load tests for foils . 72

E.5 Evaluation of the biaxial tests according to E.4 . 74

Annex F (informative) Special provisions with regards to fire . 77

F.1 Use of this Annex . 77

F.2 Scope and field of application . 77

Annex G (informative) Fire performance of membrane structures exposed to fire . 78

G.1 Safety assessment of membrane structures exposed to fire . 78

Annex H (informative) Technical management measures for the implementation of

membrane structures . 79

H.1 Use of this Annex . 79

H.2 Scope and field of application . 79

H.3 Choice of technical management measures . 79

H.4 Design quality. 79

H.5 Design checking . 79

H.6 Execution quality . 79

H.7 Inspection during execution . 80

H.8 Technical management measures . 80

H.9 Continuous quality control of base materials production . 81

H.10 Initial type testing of membrane panels . 82

H.11 Continuous quality control of membrane panel production . 83

H.12 Technical documents and workshop planning . 86

H.13 Acquisition of the membrane material . 88

H.14 Inspection before packing . 89

H.15 Folding, packaging and transportation . 89

H.16 Erection . 90

H.17 Installation . 91

H.18 Handling of crease fold impacts . 92

Annex I (normative) Structural foils – Determination of tensile properties under uniaxial

stress states . 93

I.1 Use of this Annex . 93

I.2 Scope and field of application . 93

I.3 Terms and definitions . 93

I.4 Principle . 93

I.5 Apparatus . 93

I.6 Test specimens . 94

I.7 Number of test specimens . 94

I.8 Test procedure . 94

I.9 Evaluation and representation of test results . 97

I.10 Precision . 97

I.11 Evaluation of tests . 97

I.12 Test report . 97

Annex J (normative) Structural coated fabrics – Determination of tensile properties under

uniaxial stress states . 98

J.1 Use of this Annex . 98

J.2 Scope and field of application . 98

J.3 Test specimen preparation . 98

J.4 Test procedure . 99

J.5 Tests at temperatures different from room temperature . 99

J.6 Evaluation of tests . 100

Bibliography . 101

European foreword

This document (CEN/TS 19102:2023) has been prepared by Technical Committee CEN/TC 250

“Structural Eurocodes”, the secretariat of which is held by BSI. CEN/TC 250 is responsible for all

Structural Eurocodes and has been assigned responsibility for structural and geotechnical design matters

by CEN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This Technical Specification has been prepared under Mandate M/515 issued to CEN by the European

Commission and the European Free Trade Association.

This Technical Specification has been drafted to be used in conjunction with relevant execution, material,

product and test standards, and to identify requirements for execution, materials, products and testing

that are relied upon by the Eurocodes.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

0 Introduction

0.1 Introduction to CEN/TS 19102

This document for the design of tensioned membrane structures, which was prepared in line with the

Eurocodes, is intended for use by designers, clients, manufacturers, constructors, relevant authorities (in

exercising their duties in accordance with national or international regulations), educators, software

developers, and committees drafting standards for related product, testing and execution standards.

NOTE Some aspects of design are most appropriately specified by relevant authorities or, where not specified,

can be agreed on a project-specific basis between relevant parties such as designers and clients. The Eurocodes

identify such aspects making explicit reference to relevant authorities and relevant parties.

0.2 Verbal forms used in the Eurocodes

The verb “shall” expresses a requirement strictly to be followed and from which no deviation is permitted

in order to comply with the Eurocodes.

The verb “should” expresses a highly recommended choice or course of action. Subject to national

regulation and/or any relevant contractual provisions, alternative approaches could be used/adopted

where technically justified.

The verb “may” expresses a course of action permissible within the limits of the Eurocodes.

The verb “can” expresses possibility and capability; it is used for statements of fact and clarification of

concepts.

0.3 National Annex for CEN/TS 19102

This document gives values within notes indicating where national choices can be made. Therefore, a

national document implementing CEN/TS 19102 can have a National Annex containing all Nationally

Determined Parameters to be used for the assessment of buildings and civil engineering works in the

relevant country.

When not given in the National Annex, the national choice shall be the default choice specified in the

relevant Technical Specification.

The national choice can be specified by a relevant authority.

When no choice is given in the Technical Specification, in the National Annex, or by a relevant authority,

the national choice can be agreed for a specific project by appropriate parties.

National choice is allowed in CEN/TS 19102 through the following clauses:

4.3.1.2(3) 4.4.3.2(1) 8.2.1(3) 8.3.1(3)

9.2.1(1) 9.6.1(3) C.3 C.4

C.5 C.6

National choice is allowed in CEN/TS 19102 on the application of the following informative annexes:

Annex A Annex H

The National Annex can contain, directly or by reference, non-contradictory complementary information

for ease of implementation, provided it does not alter any provisions of the Eurocodes.

1 Scope

1.1 Scope of CEN/TS 19102

(1) This document applies to the design of buildings and structural works, made of structural membrane

material. It provides guidance for the design of tensioned membrane structures, either mechanically or

pneumatically tensioned at a defined prestress level.

NOTE 1 Membrane materials comprise structural fabrics, coated structural fabrics and foils.

NOTE 2 For elements of tensile surface structures not governed by this Technical Specification (for example

made of steel, aluminium, wood or other structural materials), see relevant Eurocode parts.

(2) This document is concerned with the requirements for resistance, serviceability and durability of

tensioned membrane structures, as given in EN 1990.

NOTE 1 The safety criteria follow EN 1990 and will consider specific limit states for tensioned membrane

structures.

NOTE 2 Specific requirements concerning seismic design are not considered.

(3) Design and verification in this document is based on limit state design in conjunction with the partial

factor method.

NOTE Special attention goes to the action of prestress, snow, wind and rain action on membrane structures

and the combined effect of wind and rain or snow.

(4) This document covers analysis methodologies appropriate for tensioned membrane structures, from

analytical to full numerical simulation methods.

(5) This document considers connections between membrane materials and between membrane

materials and others.

(6) This document is applicable for hybrid membrane structures integrating different kinds of load

bearing behaviour (tension, compression, bending, inflation…), in a way that the structural membrane

shares loadbearing capacity with other structural elements made of different materials.

NOTE The term ‘hybrid structure’ refers to this combined structural behaviour or use of materials.

1.2 Assumptions

(1) The assumptions of EN 1990 apply to this document.

(2) This document is intended to be used in conjunction with EN 1990, the EN 1991 series, the EN 1993

series, the EN 1999 series, ENs, EADs and ETAs for construction products relevant to tensioned

membrane structures.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

NOTE See the Bibliography for a list of other documents cited that are not normative references, including

those referenced as recommendations (i.e. in ‘should’ clauses), permissions (‘may’ clauses), possibilities ('can'

clauses), and in notes.

EN 1990:2023, Eurocode — Basis of structural and geotechnical design

EN 1991 (all parts), Eurocode 1 — Actions on structures

EN 1993 (all parts), Eurocode 3 — Design of steel structures

EN 1999 (all parts), Eurocode 9 — Design of aluminium structures

EN ISO 527-1:2019, Plastics — Determination of tensile properties — Part 1: General principles (ISO 527-

1:2019)

EN ISO 527-3:2018, Plastics — Determination of tensile properties — Part 3: Test conditions for films and

sheets (ISO 527-3:2018)

EN ISO 1421:2016, Rubber- or plastics-coated fabrics — Determination of tensile strength and elongation

at break (ISO 1421:2016)

EN ISO 13934-1, Textiles — Tensile properties of fabrics — Part 1: Determination of maximum force and

elongation at maximum force using the strip method (ISO 13934-1)

3 Terms, definitions and symbols

For the purposes of this document, the terms and definitions given in EN 1990 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1 Terms and definitions

3.1.1

anchor

device used to secure a membrane or cable to a support, usually buried in the ground, so installed as to

provide a firm point of attachment for resisting uplift

3.1.2

biaxial

stress state with stress along two orthogonal axes simultaneously

3.1.3

boundary cable

cable at the edge or termination of the membrane

3.1.4

cable

flexible linear or curvilinear element acting in tension

Note 1 to entry: A cable can be a wire rope, strand or web.

3.1.5

cable fitting

any accessory used as an attachment to, or support for, a cable

3.1.6

cable pocket

method of wrapping the membrane around a cable at a boundary condition

3.1.7

clamped connection

connection made by a series of shaped, overlapping plates that are clamped together by bolting

3.1.8

coated fabric

fabric with an adherent layer of polymeric material on one or both sides, the coated product remaining

flexible

[SOURCE: ISO 472:2013, 2.152]

3.1.9

compensation

reduction in size of a cutting pattern, so that during installation the panel elongates to achieve an initial

nominal prestress

[SOURCE: EN 17117-2:2021, 3.2]

3.1.10

compensation value

amount by which the dimensions of the pattern geometry is reduced by compensation

Note 1 to entry: The compensation value is expressed as a percentage of length in the direction to be compensated.

[SOURCE: EN 17117-2:2021, 3.3]

3.1.11

connection

location at which two or more elements meet, e.g. two structural membrane panels or a structural

membrane and the supporting structure; for design purposes, it is the assembly of the basic components

required to represent the behaviour during the transfer of the relevant internal forces and moments at

the connection

[SOURCE: EN 1993-1-8:— , 3.1.3, modified to clarify the possible contribution of the structural

membrane]

Under preparation. Stage at the time of publication: FprEN 1993-1-8:2023.

3.1.12

cutting pattern

two-dimensional geometry developed from a pattern to be cut out of an individual piece of membrane

Note 1 to entry: The pattern refers to a seam layout-based subdivision of the three-dimensional surface.

[SOURCE: EN 17117-2:2021, 3.4, modified – “coated fabric” replaced by “membrane”]

3.1.13

decompensation

partial or complete reduction of compensation

Note 1 to entry: Decompensation may be applied to ease the installation process, typically in the vicinity of

boundaries.

Note 2 to entry: Typical application of compensation and decompensation to a piece of membrane is depicted in

Figure 3.1.

[SOURCE: EN 17117-2:2021, 3.5, modified – “coated fabric” replaced by “membrane” in Note 2 to entry]

Key

1 final geometry when stressed with nominal prestress

2 geometry compensated, unstressed

3 geometry decompensated, unstressed

4 half of the pattern compensation measure in warp

5 half of the pattern compensation measure in fill

Figure 3.1 — Typical application of compensation and decompensation to a piece of membrane

3.1.14

European Technical Product Specification

— European Product Standard (EN),

— or a European Technical Assessment (ETA) based on a European Assessment Document (EAD),

— or a transparent and reproducible assessment that complies with all requirements of the relevant

EAD

3.1.15

eyelet

metal ring used to reinforce a small round hole in the membrane for threading a lace, string or rope

through

3.1.16

external structure

structural elements of the construction, to which the membrane structure is connected, which carry

vertical and horizontal loads from the membrane structure down to the foundations of the construction

Note 1 to entry: The external structure is out of the scope of this document.

3.1.17

extrusion direction

extrusion direction (or machine direction), abbreviated as “ED” (or “MD”), is the direction of extrusion of

a foil, corresponding with the longitudinal direction of a rolled-up sheet

3.1.18

fabric

sheet material produced from yarn or roving by a weaving process

3.1.19

fill

weft

all wires running crosswise of the cloth as woven

[SOURCE: ISO 2395:1990, 3.2.22]

3.1.20

foil

film

unsupported film with uniform thickness

[SOURCE: CEN ISO/TS 80004-11:2020, 3.1.4]

Note 1 to entry: Strictly the term foil refers to a metallic membrane. However, it is now the most commonly used

term for all isotropic structural plastic membranes including ETFE foils.

3.1.21

form found shape

equilibrium shape of the membrane depending on the geometry of the boundaries and the ratio of

prestress in the main structural directions

3.1.22

hem

edge of a membrane panel folded and stitched or welded or both

3.1.23

high point

commonly used expression for a radially patterned conical structure with elevated mid-ring

3.1.24

initial type testing

initial tests performed to determine the strength of seams and edge connections that can be achieved

3.1.25

installation

erecting the membrane structure on site

3.1.26

keder

encased cable edge treatment for membrane surfaces, either used in conjunction with grooved profile

extrusions or with plates, for connecting to rigid boundaries, corner plates and boundary cables

3.1.27

manufacture

converting the membrane material into a panel ready to be installed

3.1.28

material production

production of the membrane (base) material in the form of a roll

3.1.29

membrane material (base material)

thin, sheet-like material to create tensile surface structures, comprising structural fabrics, coated

structural fabrics and foils

3.1.30

nominal prestress

input data of prestress prescribed during the form finding and structural analysis, and part of the

structural design

[SOURCE: EN 17117-2:2021, 3.10]

3.1.31

numerical model

numerical representation of a physical model

3.1.32

panel

final three-dimensional assembly of pieces of membrane, cut according to the cutting pattern, ready to

be installed on site

[SOURCE: EN 17117-2:2021, 3.8, modified – “coated fabric” replaced by “membrane”]

Note 1 to entry: An architectural tensioned envelope may be made of more than one panel.

Note 2 to entry: A panel made of pieces of membrane is depicted in Figure 3.2.

(a) (b)

Figure 3.2 — Example of a panel assembled of pieces of membrane:

(a) Pieces of membrane, cut according to the cutting pattern, (b) panel

3.1.33

piece of membrane

two-dimensional piece cut from a roll of membrane

[SOURCE: EN 17117-2:2021, 3.9, modified – “coated fabric” replaced by “membrane”]

3.1.34

ponding

accumulation of water or snow in flat or reversed areas

3.1.35

prestress

effect of prestressing process, namely, internal forces in the sections and the deformation of the structure

[SOURCE: EN 1992-1-1:2023, 3.1.64]

3.1.36

primary structure

stable structural system conceived to hold up the structural membrane

Note 1 to entry: This term is only used in the context of stability.

3.1.37

seam

connection of two or more pieces of membrane material, typically welded, stitched or glued

3.1.38

seam layout

definition of location and direction of seams over the surface of an architectural tensioned envelope

[SOURCE: EN 17117-2:2021, 3.12]

3.1.39

secondary structure

is only stable if connected to a primary structure (or an adjacent building), it can consist of the following

components: membrane, clamping profile, corner fittings, boundary cable/rope, ridge cable/rope, valley

cable/rope, pendulum supports, pendulum rods, hinged masts, supporting cables/ropes, “air supports”,

back cables/ropes, etc.

Note 1 to entry: Consider as example a four-point sail with four masts and back cables/ropes. All above-ground

components form the secondary structure, while the foundations form the primary structure. But if the top points

of the four masts are connected (e.g. with cables), only the membrane, the corner fittings and the boundary cables

form the secondary structure, since the rest remains standing without these components and thus forms the

primary structure.

Note 2 to entry: This term is only used in the context of stability.

3.1.40

structural membrane

tensioned membrane

tensile membrane

surface structure, carrying the loads by in-plane tension, attached to the supporting structure

3.1.41

supporting structure

membrane supporting structure

assembly of structural members (poles, cables, arches etc.), which carries the structural membrane and

resist loads that this structure is subjected to

a) b)

Key Key

A, B, C, D, E fixing points to the external structure A, B, C, D fixing points to the external structure

1 structural membrane 1, 2 supporting structure with fixing lines to the external

structures

2 membrane supporting structure (pole)

3 structural membrane

Figure 3.3 — Examples of supporting structures: (a) Fixing points to the external structure, (b)

Fixing lines to the external structure

Note 1 to entry: A membrane structure always ends at fixing points or fixing lines to foundations or to external

structures (e.g. adjacent walls). Elements (e.g. beams, columns, etc.), which are not structurally needed for the

membrane structure, are out of the scope of this document. Foreseeable deviations such as deflections, shortenings,

or elongations of the elements of the external structure should be communicated to the designer of the membrane

structure, so that these can be taken into account in the design.

3.1.42

tensioned membrane structure

membrane structure

tensile surface structure

combination of the structural membrane and its supporting structure

3.1.43

textile

woven fabric, knitted fabric, etc., formed by the interlocking of fibres and yarns having a certain cohesion

Note 1 to entry: Textiles often include certain types of non-woven fabrics.

[SOURCE: ISO 16373-3:2014, 2.1]

3.1.44

transversal direction

direction transverse to the extrusion direction, abbreviated as “TD”, of a foil, corresponding with the

width of a rolled-up sheet

3.1.45

turnbuckle

device composed of a doubly threaded cylinder commonly used to provide length adjustment of a cable

3.1.46

uniaxial

stress state with stress along one axis only

3.1.47

warp

all wires running lengthwise in the cloth as woven

[SOURCE: ISO 9044:2016, 3.4]

3.1.48

welding

means of connecting coated membrane or foil materials by a melting process like through hot air, hot

edge, hot bar, High Frequency or Ultra Sonic technology

3.1.49

work hardening

strengthening of a polymer, combined with plastic strain

Note 1 to entry: Within the scope of this document the strengthening of foil material like ETFE is meant, caused by

a single or multiple loading.

3.1.50

wrinkle

local buckling deformation of a membrane under compressive stresses

3.2 Symbols and abbreviations

3.2.1 Latin uppercase symbols

E Young’s modulus

P Pressure

R Design value of the resistance

d

Characteristic value of the resistance

R

k

T Temperature

V Volume

V Coefficient of variation

x

3.2.2 Latin lowercase symbols

f Characteristic foil stress in the considered direction in the framework of the SLS verification

E

f Design membrane stress in the considered direction

Ed

f Characteristic ( = 5 % fractile) elastic limit of a foil in the framework of the SLS verification

el23

determined from in a uniaxial short-term tensile test at T = 23 °C

f Characteristic ( = 5 % fractile) tensile strength of a membrane or connection in a uniaxial

k23

short-term tensile test at T = 23 °C

f Stress limit of a foil in the framework of the SLS verification

str23

f Characteristic tensile strength of a foil or a foil connection in the framework of the SLS

R

verification

f Design tensile strength of a membrane or a membrane connection

Rd

f Characteristic tensile strength of a foil or a foil connection related to the specific SLS design

R,mod

situation

f Design tensile strength of a foil or a foil connection related to the specific design situation

Rd,mod

f Characteristic ( = 5 % fractile) tensile strength of a foil in a uniaxial short-term tensile test at

u23

T = 23 °C

f Characteristic ( = 5 % fractile) tensile strength of a foil connection in a uniaxial short-term

uw23

tensile test at T = 23 °C

k Modification factor taking into account separate specific effects influencing the membrane

properties in specific design situations

3.2.3 Greek lowercase symbols

ß Reliability index

Irreversible strain

ε

irr

residual strain after a relaxation time

ε

res

strain when elongation has stopped in a creep test

ε

sat

γ Shear angle

γ Partial factor for a material property

m

γ Partial factor for a material property, also accounting for model uncertainties and

M

dimensional variations

γ Partial factor for material

M0

γ Partial factor for connections

M1

γ Partial factor for material in the SLS verification

M,ser

Partial factor associated with the uncertainty of the resistance model

γ

Rd

ν Poisson’s ratio

φ Spreading angle in a cable pocket

3.2.4 Abbreviations

CC Consequence class

Cl. Clause

D Dimension

EXC Execution class

EPDM Ethylene propylene diene (monomer) rubber

ETFE Ethylene-tetrafluoroethylene

FEP Fluorinated Ethylene Propylene

PES Polyester

PET Polyethylene terephthalate

PFA Tetrafluoroethylene perfluoroalkoxy vinyl ether copolymer

PP Polypropylene

PTFE Polytetrafluoroethylene

PVC Polyvinylchlori

...

SLOVENSKI STANDARD

01-marec-2024

Projektiranje nateznih membranskih konstrukcij

Design of tensioned membrane structures

Bemessung von vorgespannten Membrantragwerken

Conception et calcul des structures en membrane tendue

Ta slovenski standard je istoveten z: CEN/TS 19102:2023

ICS:

91.080.99 Druge konstrukcije Other structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TS 19102

TECHNICAL SPECIFICATION

SPÉCIFICATION TECHNIQUE

November 2023

TECHNISCHE SPEZIFIKATION

ICS 91.080.99

English Version

Design of tensioned membrane structures

Conception et calcul des structures en membrane Bemessung von vorgespannten Membrantragwerken

tendue

This Technical Specification (CEN/TS) was approved by CEN on 24 August 2023 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to

submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS

available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in

parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 19102:2023 E

worldwide for CEN national Members.

Contents Page

European foreword . 6

0 Introduction. 7

1 Scope . 8

1.1 Scope of CEN/TS 19102 . 8

1.2 Assumptions . 8

2 Normative references . 9

3 Terms, definitions and symbols . 9

3.1 Terms and definitions . 9

3.2 Symbols and abbreviations . 18

4 Basis of design . 20

4.1 General rules . 20

4.2 Principles of limit state design . 22

4.3 Basic variables . 22

4.4 Verification by the partial factor method . 24

4.5 Design assisted by testing . 26

5 Materials . 26

5.1 General. 26

5.2 Fabrics . 26

5.3 Foils . 27

5.4 Connection devices . 28

5.5 Structural elements . 28

6 Durability . 29

6.1 General. 29

6.2 Fabrics . 29

6.3 Foils . 30

7 Structural Analysis . 30

7.1 General. 30

7.2 Pneumatic structures . 31

7.3 Patterning . 32

8 Ultimate Limit States . 33

8.1 General. 33

8.2 Resistance of fabrics and their connections . 33

8.3 Resistance of foils and their connections . 35

8.4 Design situation ponding . 38

9 Serviceability Limit States . 39

9.1 General. 39

9.2 Deflections . 39

9.3 Wrinkling . 39

9.4 Maintenance of the prestress and post tensioning . 40

9.5 Tear control . 40

9.6 Special provisions for foils . 40

10 Connections . 44

10.1 Introduction . 44

10.2 Irreversible membrane connections . 46

10.3 Reversible membrane connections . 48

10.4 Membrane edges . 50

10.5 Corners . 52

10.6 Field supports . 54

10.7 Further connection devices . 54

Annex A (informative) Classification of structural membranes . 55

A.1 Use of this Annex . 55

A.2 Scope and field of application . 55

A.3 General framework . 55

A.4 Strength classification for PES-PVC . 55

A.5 Tensile strength classification for glass-PTFE . 56

A.6 Typical Strength values for ETFE foil . 57

Annex B (normative) Procedures for determination of modification factors . 58

B.1 Use of this Annex . 58

B.2 Scope and field of application . 58

B.3 General determination of modification factors . 58

B.4 Modification factor considering modified temperature . 58

B.5 Modification factor considering permanent load . 60

B.6 Modification factor considering long-term load . 62

B.7 Modification factor considering ageing . 62

B.8 Modification factor considering biaxial stress states . 62

B.9 Modification factor considering panel size . 62

Annex C (informative) Modification factors . 63

C.1 Use of this Annex . 63

C.2 Scope and field of application . 63

C.3 Typical modification factors for PES-PVC membrane . 63

C.4 Typical modification factors for glass-PTFE membrane . 64

C.5 Typical Modification factors for ETFE foil membrane for ULS verification . 64

C.6 Typical Modification factors for ETFE foil membrane for SLS verification . 65

Annex D (informative) Test procedures considering crease folds sensitive fabrics. 66

D.1 Use of this Annex . 66

D.2 Scope and field of application . 66

D.3 Running double crease fold . 67

D.4 Over-loop rolling . 68

Annex E (informative) Test procedures to determine foil properties . 70

E.1 Use of this Annex . 70

E.2 Scope and field of application . 70

E.3 Biaxial creep tests for foils . 70

E.4 Biaxial hysteresis load tests for foils . 72

E.5 Evaluation of the biaxial tests according to E.4 . 74

Annex F (informative) Special provisions with regards to fire . 77

F.1 Use of this Annex . 77

F.2 Scope and field of application . 77

Annex G (informative) Fire performance of membrane structures exposed to fire . 78

G.1 Safety assessment of membrane structures exposed to fire . 78

Annex H (informative) Technical management measures for the implementation of

membrane structures . 79

H.1 Use of this Annex . 79

H.2 Scope and field of application . 79

H.3 Choice of technical management measures . 79

H.4 Design quality. 79

H.5 Design checking . 79

H.6 Execution quality . 79

H.7 Inspection during execution . 80

H.8 Technical management measures . 80

H.9 Continuous quality control of base materials production . 81

H.10 Initial type testing of membrane panels . 82

H.11 Continuous quality control of membrane panel production . 83

H.12 Technical documents and workshop planning . 86

H.13 Acquisition of the membrane material . 88

H.14 Inspection before packing . 89

H.15 Folding, packaging and transportation . 89

H.16 Erection . 90

H.17 Installation . 91

H.18 Handling of crease fold impacts . 92

Annex I (normative) Structural foils – Determination of tensile properties under uniaxial

stress states . 93

I.1 Use of this Annex . 93

I.2 Scope and field of application . 93

I.3 Terms and definitions . 93

I.4 Principle . 93

I.5 Apparatus . 93

I.6 Test specimens . 94

I.7 Number of test specimens . 94

I.8 Test procedure . 94

I.9 Evaluation and representation of test results . 97

I.10 Precision . 97

I.11 Evaluation of tests . 97

I.12 Test report . 97

Annex J (normative) Structural coated fabrics – Determination of tensile properties under

uniaxial stress states . 98

J.1 Use of this Annex . 98

J.2 Scope and field of application . 98

J.3 Test specimen preparation . 98

J.4 Test procedure . 99

J.5 Tests at temperatures different from room temperature . 99

J.6 Evaluation of tests . 100

Bibliography . 101

European foreword

This document (CEN/TS 19102:2023) has been prepared by Technical Committee CEN/TC 250

“Structural Eurocodes”, the secretariat of which is held by BSI. CEN/TC 250 is responsible for all

Structural Eurocodes and has been assigned responsibility for structural and geotechnical design matters

by CEN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This Technical Specification has been prepared under Mandate M/515 issued to CEN by the European

Commission and the European Free Trade Association.

This Technical Specification has been drafted to be used in conjunction with relevant execution, material,

product and test standards, and to identify requirements for execution, materials, products and testing

that are relied upon by the Eurocodes.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

0 Introduction

0.1 Introduction to CEN/TS 19102

This document for the design of tensioned membrane structures, which was prepared in line with the

Eurocodes, is intended for use by designers, clients, manufacturers, constructors, relevant authorities (in

exercising their duties in accordance with national or international regulations), educators, software

developers, and committees drafting standards for related product, testing and execution standards.

NOTE Some aspects of design are most appropriately specified by relevant authorities or, where not specified,

can be agreed on a project-specific basis between relevant parties such as designers and clients. The Eurocodes

identify such aspects making explicit reference to relevant authorities and relevant parties.

0.2 Verbal forms used in the Eurocodes

The verb “shall” expresses a requirement strictly to be followed and from which no deviation is permitted

in order to comply with the Eurocodes.

The verb “should” expresses a highly recommended choice or course of action. Subject to national

regulation and/or any relevant contractual provisions, alternative approaches could be used/adopted

where technically justified.

The verb “may” expresses a course of action permissible within the limits of the Eurocodes.

The verb “can” expresses possibility and capability; it is used for statements of fact and clarification of

concepts.

0.3 National Annex for CEN/TS 19102

This document gives values within notes indicating where national choices can be made. Therefore, a

national document implementing CEN/TS 19102 can have a National Annex containing all Nationally

Determined Parameters to be used for the assessment of buildings and civil engineering works in the

relevant country.

When not given in the National Annex, the national choice shall be the default choice specified in the

relevant Technical Specification.

The national choice can be specified by a relevant authority.

When no choice is given in the Technical Specification, in the National Annex, or by a relevant authority,

the national choice can be agreed for a specific project by appropriate parties.

National choice is allowed in CEN/TS 19102 through the following clauses:

4.3.1.2(3) 4.4.3.2(1) 8.2.1(3) 8.3.1(3)

9.2.1(1) 9.6.1(3) C.3 C.4

C.5 C.6

National choice is allowed in CEN/TS 19102 on the application of the following informative annexes:

Annex A Annex H

The National Annex can contain, directly or by reference, non-contradictory complementary information

for ease of implementation, provided it does not alter any provisions of the Eurocodes.

1 Scope

1.1 Scope of CEN/TS 19102

(1) This document applies to the design of buildings and structural works, made of structural membrane

material. It provides guidance for the design of tensioned membrane structures, either mechanically or

pneumatically tensioned at a defined prestress level.

NOTE 1 Membrane materials comprise structural fabrics, coated structural fabrics and foils.

NOTE 2 For elements of tensile surface structures not governed by this Technical Specification (for example

made of steel, aluminium, wood or other structural materials), see relevant Eurocode parts.

(2) This document is concerned with the requirements for resistance, serviceability and durability of

tensioned membrane structures, as given in EN 1990.

NOTE 1 The safety criteria follow EN 1990 and will consider specific limit states for tensioned membrane

structures.

NOTE 2 Specific requirements concerning seismic design are not considered.

(3) Design and verification in this document is based on limit state design in conjunction with the partial

factor method.

NOTE Special attention goes to the action of prestress, snow, wind and rain action on membrane structures

and the combined effect of wind and rain or snow.

(4) This document covers analysis methodologies appropriate for tensioned membrane structures, from

analytical to full numerical simulation methods.

(5) This document considers connections between membrane materials and between membrane

materials and others.

(6) This document is applicable for hybrid membrane structures integrating different kinds of load

bearing behaviour (tension, compression, bending, inflation…), in a way that the structural membrane

shares loadbearing capacity with other structural elements made of different materials.

NOTE The term ‘hybrid structure’ refers to this combined structural behaviour or use of materials.

1.2 Assumptions

(1) The assumptions of EN 1990 apply to this document.

(2) This document is intended to be used in conjunction with EN 1990, the EN 1991 series, the EN 1993

series, the EN 1999 series, ENs, EADs and ETAs for construction products relevant to tensioned

membrane structures.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

NOTE See the Bibliography for a list of other documents cited that are not normative references, including

those referenced as recommendations (i.e. in ‘should’ clauses), permissions (‘may’ clauses), possibilities ('can'

clauses), and in notes.

EN 1990:2023, Eurocode — Basis of structural and geotechnical design

EN 1991 (all parts), Eurocode 1 — Actions on structures

EN 1993 (all parts), Eurocode 3 — Design of steel structures

EN 1999 (all parts), Eurocode 9 — Design of aluminium structures

EN ISO 527-1:2019, Plastics — Determination of tensile properties — Part 1: General principles (ISO 527-

1:2019)

EN ISO 527-3:2018, Plastics — Determination of tensile properties — Part 3: Test conditions for films and

sheets (ISO 527-3:2018)

EN ISO 1421:2016, Rubber- or plastics-coated fabrics — Determination of tensile strength and elongation

at break (ISO 1421:2016)

EN ISO 13934-1, Textiles — Tensile properties of fabrics — Part 1: Determination of maximum force and

elongation at maximum force using the strip method (ISO 13934-1)

3 Terms, definitions and symbols

For the purposes of this document, the terms and definitions given in EN 1990 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1 Terms and definitions

3.1.1

anchor

device used to secure a membrane or cable to a support, usually buried in the ground, so installed as to

provide a firm point of attachment for resisting uplift

3.1.2

biaxial

stress state with stress along two orthogonal axes simultaneously

3.1.3

boundary cable

cable at the edge or termination of the membrane

3.1.4

cable

flexible linear or curvilinear element acting in tension

Note 1 to entry: A cable can be a wire rope, strand or web.

3.1.5

cable fitting

any accessory used as an attachment to, or support for, a cable

3.1.6

cable pocket

method of wrapping the membrane around a cable at a boundary condition

3.1.7

clamped connection

connection made by a series of shaped, overlapping plates that are clamped together by bolting

3.1.8

coated fabric

fabric with an adherent layer of polymeric material on one or both sides, the coated product remaining

flexible

[SOURCE: ISO 472:2013, 2.152]

3.1.9

compensation

reduction in size of a cutting pattern, so that during installation the panel elongates to achieve an initial

nominal prestress

[SOURCE: EN 17117-2:2021, 3.2]

3.1.10

compensation value

amount by which the dimensions of the pattern geometry is reduced by compensation

Note 1 to entry: The compensation value is expressed as a percentage of length in the direction to be compensated.

[SOURCE: EN 17117-2:2021, 3.3]

3.1.11

connection

location at which two or more elements meet, e.g. two structural membrane panels or a structural

membrane and the supporting structure; for design purposes, it is the assembly of the basic components

required to represent the behaviour during the transfer of the relevant internal forces and moments at

the connection

[SOURCE: EN 1993-1-8:— , 3.1.3, modified to clarify the possible contribution of the structural

membrane]

Under preparation. Stage at the time of publication: FprEN 1993-1-8:2023.

3.1.12

cutting pattern

two-dimensional geometry developed from a pattern to be cut out of an individual piece of membrane

Note 1 to entry: The pattern refers to a seam layout-based subdivision of the three-dimensional surface.

[SOURCE: EN 17117-2:2021, 3.4, modified – “coated fabric” replaced by “membrane”]

3.1.13

decompensation

partial or complete reduction of compensation

Note 1 to entry: Decompensation may be applied to ease the installation process, typically in the vicinity of

boundaries.

Note 2 to entry: Typical application of compensation and decompensation to a piece of membrane is depicted in

Figure 3.1.

[SOURCE: EN 17117-2:2021, 3.5, modified – “coated fabric” replaced by “membrane” in Note 2 to entry]

Key

1 final geometry when stressed with nominal prestress

2 geometry compensated, unstressed

3 geometry decompensated, unstressed

4 half of the pattern compensation measure in warp

5 half of the pattern compensation measure in fill

Figure 3.1 — Typical application of compensation and decompensation to a piece of membrane

3.1.14

European Technical Product Specification

— European Product Standard (EN),

— or a European Technical Assessment (ETA) based on a European Assessment Document (EAD),

— or a transparent and reproducible assessment that complies with all requirements of the relevant

EAD

3.1.15

eyelet

metal ring used to reinforce a small round hole in the membrane for threading a lace, string or rope

through

3.1.16

external structure

structural elements of the construction, to which the membrane structure is connected, which carry

vertical and horizontal loads from the membrane structure down to the foundations of the construction

Note 1 to entry: The external structure is out of the scope of this document.

3.1.17

extrusion direction

extrusion direction (or machine direction), abbreviated as “ED” (or “MD”), is the direction of extrusion of

a foil, corresponding with the longitudinal direction of a rolled-up sheet

3.1.18

fabric

sheet material produced from yarn or roving by a weaving process

3.1.19

fill

weft

all wires running crosswise of the cloth as woven

[SOURCE: ISO 2395:1990, 3.2.22]

3.1.20

foil

film

unsupported film with uniform thickness

[SOURCE: CEN ISO/TS 80004-11:2020, 3.1.4]

Note 1 to entry: Strictly the term foil refers to a metallic membrane. However, it is now the most commonly used

term for all isotropic structural plastic membranes including ETFE foils.

3.1.21

form found shape

equilibrium shape of the membrane depending on the geometry of the boundaries and the ratio of

prestress in the main structural directions

3.1.22

hem

edge of a membrane panel folded and stitched or welded or both

3.1.23

high point

commonly used expression for a radially patterned conical structure with elevated mid-ring

3.1.24

initial type testing

initial tests performed to determine the strength of seams and edge connections that can be achieved

3.1.25

installation

erecting the membrane structure on site

3.1.26

keder

encased cable edge treatment for membrane surfaces, either used in conjunction with grooved profile

extrusions or with plates, for connecting to rigid boundaries, corner plates and boundary cables

3.1.27

manufacture

converting the membrane material into a panel ready to be installed

3.1.28

material production

production of the membrane (base) material in the form of a roll

3.1.29

membrane material (base material)

thin, sheet-like material to create tensile surface structures, comprising structural fabrics, coated

structural fabrics and foils

3.1.30

nominal prestress

input data of prestress prescribed during the form finding and structural analysis, and part of the

structural design

[SOURCE: EN 17117-2:2021, 3.10]

3.1.31

numerical model

numerical representation of a physical model

3.1.32

panel

final three-dimensional assembly of pieces of membrane, cut according to the cutting pattern, ready to

be installed on site

[SOURCE: EN 17117-2:2021, 3.8, modified – “coated fabric” replaced by “membrane”]

Note 1 to entry: An architectural tensioned envelope may be made of more than one panel.

Note 2 to entry: A panel made of pieces of membrane is depicted in Figure 3.2.

(a) (b)

Figure 3.2 — Example of a panel assembled of pieces of membrane:

(a) Pieces of membrane, cut according to the cutting pattern, (b) panel

3.1.33

piece of membrane

two-dimensional piece cut from a roll of membrane

[SOURCE: EN 17117-2:2021, 3.9, modified – “coated fabric” replaced by “membrane”]

3.1.34

ponding

accumulation of water or snow in flat or reversed areas

3.1.35

prestress

effect of prestressing process, namely, internal forces in the sections and the deformation of the structure

[SOURCE: EN 1992-1-1:2023, 3.1.64]

3.1.36

primary structure

stable structural system conceived to hold up the structural membrane

Note 1 to entry: This term is only used in the context of stability.

3.1.37

seam

connection of two or more pieces of membrane material, typically welded, stitched or glued

3.1.38

seam layout

definition of location and direction of seams over the surface of an architectural tensioned envelope

[SOURCE: EN 17117-2:2021, 3.12]

3.1.39

secondary structure

is only stable if connected to a primary structure (or an adjacent building), it can consist of the following

components: membrane, clamping profile, corner fittings, boundary cable/rope, ridge cable/rope, valley

cable/rope, pendulum supports, pendulum rods, hinged masts, supporting cables/ropes, “air supports”,

back cables/ropes, etc.

Note 1 to entry: Consider as example a four-point sail with four masts and back cables/ropes. All above-ground

components form the secondary structure, while the foundations form the primary structure. But if the top points

of the four masts are connected (e.g. with cables), only the membrane, the corner fittings and the boundary cables

form the secondary structure, since the rest remains standing without these components and thus forms the

primary structure.

Note 2 to entry: This term is only used in the context of stability.

3.1.40

structural membrane

tensioned membrane

tensile membrane

surface structure, carrying the loads by in-plane tension, attached to the supporting structure

3.1.41

supporting structure

membrane supporting structure

assembly of structural members (poles, cables, arches etc.), which carries the structural membrane and

resist loads that this structure is subjected to

a) b)

Key Key

A, B, C, D, E fixing points to the external structure A, B, C, D fixing points to the external structure

1 structural membrane 1, 2 supporting structure with fixing lines to the external

structures

2 membrane supporting structure (pole)

3 structural membrane

Figure 3.3 — Examples of supporting structures: (a) Fixing points to the external structure, (b)

Fixing lines to the external structure

Note 1 to entry: A membrane structure always ends at fixing points or fixing lines to foundations or to external

structures (e.g. adjacent walls). Elements (e.g. beams, columns, etc.), which are not structurally needed for the

membrane structure, are out of the scope of this document. Foreseeable deviations such as deflections, shortenings,

or elongations of the elements of the external structure should be communicated to the designer of the membrane

structure, so that these can be taken into account in the design.

3.1.42

tensioned membrane structure

membrane structure

tensile surface structure

combination of the structural membrane and its supporting structure

3.1.43

textile

woven fabric, knitted fabric, etc., formed by the interlocking of fibres and yarns having a certain cohesion

Note 1 to entry: Textiles often include certain types of non-woven fabrics.

[SOURCE: ISO 16373-3:2014, 2.1]

3.1.44

transversal direction

direction transverse to the extrusion direction, abbreviated as “TD”, of a foil, corresponding with the

width of a rolled-up sheet

3.1.45

turnbuckle

device composed of a doubly threaded cylinder commonly used to provide length adjustment of a cable

3.1.46

uniaxial

stress state with stress along one axis only

3.1.47

warp

all wires running lengthwise in the cloth as woven

[SOURCE: ISO 9044:2016, 3.4]

3.1.48

welding

means of connecting coated membrane or foil materials by a melting process like through hot air, hot

edge, hot bar, High Frequency or Ultra Sonic technology

3.1.49

work hardening

strengthening of a polymer, combined with plastic strain

Note 1 to entry: Within the scope of this document the strengthening of foil material like ETFE is meant, caused by

a single or multiple loading.

3.1.50

wrinkle

local buckling deformation of a membrane under compressive stresses

3.2 Symbols and abbreviations

3.2.1 Latin uppercase symbols

E Young’s modulus

P Pressure

R Design value of the resistance

d

Characteristic value of the resistance

R

k

T Temperature

V Volume

V Coefficient of variation

x

3.2.2 Latin lowercase symbols

f Characteristic foil stress in the considered direction in the framework of the SLS verification

E

f Design membrane stress in the considered direction

Ed

f Characteristic ( = 5 % fractile) elastic limit of a foil in the framework of the SLS verification

el23

determined from in a uniaxial short-term tensile test at T = 23 °C

f Characteristic ( = 5 % fractile) tensile strength of a membrane or connection in a uniaxial

k23

short-term tensile test at T = 23 °C

f Stress limit of a foil in the framework of the SLS verification

str23

f Characteristic tensile strength of a foil or a foil connection in the framework of the SLS

R

verification

f Design tensile strength of a membrane or a membrane connection

Rd

f Characteristic tensile strength of a foil or a foil connection related to the specific SLS design

R,mod

situation

f Design tensile strength of a foil or a foil connection related to the specific design situation

Rd,mod

f Characteristic ( = 5 % fractile) tensile strength of a foil in a uniaxial short-term tensile test at

u23

T = 23 °C

f Characteristic ( = 5 % fractile) tensile strength of a foil connection in a uniaxial short-term

uw23

tensile test at T = 23 °C

k Modification factor taking into account separate specific effects influencing the membrane

properties in specific design situations

3.2.3 Greek lowercase symbols

ß Reliability index

Irreversible strain

ε

irr

residual strain after a relaxation time

ε

res

strain when elongation has stopped in a creep test

ε

sat

γ Shear angle

γ Partial factor for a material property

m

γ Partial factor for a material property, also accounting for model uncertainties and

M

dimensional variations

γ Partial factor for material

M0

γ Partial factor for connections

M1

γ Partial factor for material in the SLS verification

M,ser

Partial factor associated with the uncertainty of the resistance model

γ

Rd

ν Poisson’s ratio

φ Spreading angle in a cable pocket

3.2.4 Abbreviations

CC Consequence class

Cl. Clause

D Dimension

EXC Execution class

EPDM Ethylene propylene diene (monomer) rubber

ETFE Ethylene-tetrafluoroethylene

FEP Fluorinated Ethylene Propylene

PES Polyester

PET Polyethylene terephthalate

PFA Tetrafluoroethylene perfluoroalkoxy vinyl ether copolymer

PP Polypropylene

PTFE Polytetrafluoroethylene

PVC Polyvinylchlor

...