SIST EN 17138:2019

(Main)Conservation of cultural heritage - Methods and materials for cleaning porous inorganic materials

Conservation of cultural heritage - Methods and materials for cleaning porous inorganic materials

This document provides the guidelines for the choice of the operational cleaning technical specifications in order to optimize the cleaning operation. The fundamental requirements for each specific cleaning method are given as to adapt cleaning works for single specific cases.

The objective of cleaning may consist of removal of any combination of unwanted materials, such as: degraded protective coatings, surface or near-surface materials, which constitute a present or future threat to conservation, materials which prevent legibility of the object or are disfiguring by nature, deposits which are judged to be incompatible to the historical nature of the object.

Erhaltung des kulturellen Erbes - Verfahren und Materialien für die Reinigung von porösen inorganischen Materialien

Dieses Dokument stellt die Leitlinien zur Auswahl der technischen Reinigungsmerkmale bereit, um das Reinigungsverfahren zu optimieren. Die grundlegenden Anforderungen für jedes spezifische Reinigungs-verfahren werden vermittelt, um die Reinigungsarbeiten an spezifische Einzelfälle anpassen zu können.

Die Zielsetzung der Reinigung kann die Entfernung von allen Kombinationen unerwünschter Materialien sein, wie beispielsweise: zersetzten Schutzbeschichtungen, Oberflächen- oder oberflächennahen Materialien, die eine gegenwärtige oder zukünftige Bedrohung für die Konservierung darstellen, Materialien, die eine Lesbarkeit des Objekts verhindern oder ihrer Art nach entstellend sind, Ablagerungen, die als unvereinbar mit dem historischen Wesen des Objekts einzustufen sind.

Conservation du patrimoine culturel - Méthodes et produits de nettoyage des matériaux inorganiques poreux

Le présent document formule des lignes directrices quant au choix des spécifications techniques de nettoyage opérationnel en vue d'optimiser l'opération de nettoyage. Les exigences fondamentales de chaque méthode de nettoyage spécifique sont décrites de manière à permettre l'adaptation des travaux de nettoyage à chaque cas particulier.

Le nettoyage peut avoir pour vocation d'éliminer toute combinaison de matériaux indésirables, par exemple : revêtements de protection dégradés ; matériaux de surface ou proches de la surface qui constituent ou constitueront une menace pour la conservation du bien ; matériaux qui altèrent la lisibilité du bien ou qui sont de nature à le défigurer ; dépôts jugés incompatibles avec la nature historique du bien.

Ohranjanje kulturne dediščine - Metode in materiali za čiščenje poroznih anorganskih materialov

Ta evropski standard zagotavlja smernice za izbiro tehničnih specifikacij operativnega čiščenja, s katerimi se optimizira postopek čiščenja. Za prilagoditev čiščenja v posameznih posebnih primerih so podane temeljne zahteve za vsako metodo čiščenja posebej.

Namen čiščenja je lahko odstranitev kakršne koli kombinacije neželenih materialov, kot so: površinski materiali ali materiali blizu površine, ki predstavljajo sedanjo ali prihodnjo nevarnost za ohranjanje, materiali, ki preprečujejo berljivost predmeta ali pa so po naravi deformirani, ostanki, ki so nezdružljivi z zgodovinsko naravo predmeta.

General Information

- Status

- Published

- Public Enquiry End Date

- 13-Sep-2017

- Publication Date

- 08-Jan-2019

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 03-Jan-2019

- Due Date

- 10-Mar-2019

- Completion Date

- 09-Jan-2019

Overview

SIST EN 17138:2019 - "Conservation of cultural heritage - Methods and materials for cleaning porous inorganic materials" - is a CEN-based guidance standard for selection, testing and application of cleaning techniques on porous inorganic heritage substrates (natural stone, brick, mortar, plaster, ceramics, concrete). The standard frames cleaning as an irreversible conservation action and provides a systematic approach to optimize cleaning operations while minimizing harm to cultural property.

Key topics and technical requirements

- Scope and objectives: Defines when cleaning is appropriate (removal of degraded coatings, harmful deposits, disfiguring materials or substances that hinder legibility).

- Decision framework: Emphasises the balance of selectivity, effectiveness and controllability; cleaning must remove unwanted materials without increasing future deterioration.

- Requirements affecting cleaning choices:

- Avoid adverse chemical reactions or permanent residues.

- Prevent physical/mechanical damage (erosion, loss of cohesion, micro-cracks).

- Respect original surface finishes and historic additions.

- Manage health, safety and waste (consult safety data sheets).

- Preliminary investigation: Mandatory preliminary survey, substrate identification and characterisation of unwanted materials; use of specimens and trial cleaning areas to evaluate effectiveness and risk.

- Structured method descriptions: Each cleaning technique is described with: description, technical specifications, adjustable variables, advantages/disadvantages and indicative applications.

- Categories of cleaning methods:

- Water cleaning (including nebulous spray, low-pressure spray, steam, aqueous poultices)

- Mechanical cleaning (abrasive, microblasting, peeling systems)

- Chemical cleaning (acids/alkalis, chelating agents, surfactants, biocides)

- Physical cleaning (laser cleaning, cryogenic/dry-ice methods, ion exchange, biocleaning)

- Informative annexes: Practical guidance on poultices, abrasive materials, solvent solubility, alkaline/acid compounds, chelating agents and surfactants.

Practical applications and users

SIST EN 17138:2019 is intended as a reference for professionals involved in conservation and heritage management:

- Conservators / restorers

- Conservation scientists

- Architects and surveyors working on historic fabric

- Curators and heritage managers

- Government bodies and cultural heritage agencies

Use cases include planning and specifying cleaning interventions on historic buildings, monuments, archaeological materials and movable objects with porous inorganic components. The standard supports safe, documented, and reversible-aware cleaning strategies and provides criteria for tender documents, trial protocols and post-treatment monitoring.

Related standards

- EN 15898 (Conservation terminology and principles)

- EN 16302 (Sampling and specimens)

- EN 15801 (Definitions for porous inorganic materials)

Keywords: conservation of cultural heritage, cleaning porous inorganic materials, SIST EN 17138:2019, stone cleaning, laser cleaning, aqueous poultices, trial cleaning areas, conservation standards.

Frequently Asked Questions

SIST EN 17138:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Conservation of cultural heritage - Methods and materials for cleaning porous inorganic materials". This standard covers: This document provides the guidelines for the choice of the operational cleaning technical specifications in order to optimize the cleaning operation. The fundamental requirements for each specific cleaning method are given as to adapt cleaning works for single specific cases. The objective of cleaning may consist of removal of any combination of unwanted materials, such as: degraded protective coatings, surface or near-surface materials, which constitute a present or future threat to conservation, materials which prevent legibility of the object or are disfiguring by nature, deposits which are judged to be incompatible to the historical nature of the object.

This document provides the guidelines for the choice of the operational cleaning technical specifications in order to optimize the cleaning operation. The fundamental requirements for each specific cleaning method are given as to adapt cleaning works for single specific cases. The objective of cleaning may consist of removal of any combination of unwanted materials, such as: degraded protective coatings, surface or near-surface materials, which constitute a present or future threat to conservation, materials which prevent legibility of the object or are disfiguring by nature, deposits which are judged to be incompatible to the historical nature of the object.

SIST EN 17138:2019 is classified under the following ICS (International Classification for Standards) categories: 97.195 - Items of art and handicrafts. Cultural property and heritage. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17138:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.RUR]QLKErhaltung des kulturellen Erbes - Verfahren und Materialien für die Reinigung von porösen inorganischen MaterialienConservation du patrimoine culturel - Méthodes et produits de nettoyage des matériaux inorganiques poreuxConservation of cultural heritage - Methods and materials for cleaning porous inorganic materials97.195GHGLãþLQDItems of art and handicrafts. Cultural property and heritageICS:Ta slovenski standard je istoveten z:EN 17138:2018SIST EN 17138:2019en,fr,de01-marec-2019SIST EN 17138:2019SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 17138

December

t r s z ICS

{ yä s { w English Version

Conservation of Cultural Heritage æ Methods and materials for cleaning porous inorganic materials Conservation du patrimoine culturel æ Méthodes et produits de nettoyage des matériaux inorganiques poreux

Erhaltung des kulturellen Erbes æ Verfahren und Materialien für die Reinigung von porösen anorganischen Materialien This European Standard was approved by CEN on

t { July

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s y s u zã t r s z ESIST EN 17138:2019

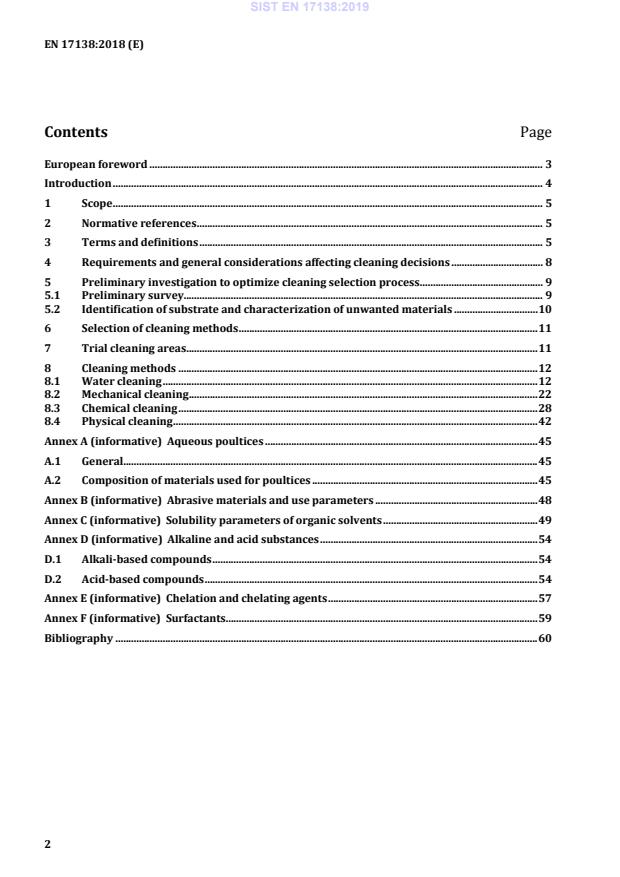

Contents Page European foreword . 3 Introduction . 4 1 Scope . 5 2 Normative references . 5 3 Terms and definitions . 5 4 Requirements and general considerations affecting cleaning decisions . 8 5 Preliminary investigation to optimize cleaning selection process . 9 5.1 Preliminary survey. 9 5.2 Identification of substrate and characterization of unwanted materials . 10 6 Selection of cleaning methods . 11 7 Trial cleaning areas . 11 8 Cleaning methods . 12 8.1 Water cleaning . 12 8.2 Mechanical cleaning . 22 8.3 Chemical cleaning . 28 8.4 Physical cleaning . 42 Annex A (informative)

Aqueous poultices . 45 A.1 General. 45 A.2 Composition of materials used for poultices . 45 Annex B (informative)

Abrasive materials and use parameters . 48 Annex C (informative)

Solubility parameters of organic solvents . 49 Annex D (informative)

Alkaline and acid substances . 54 D.1 Alkali-based compounds . 54 D.2 Acid-based compounds . 54 Annex E (informative)

Chelation and chelating agents . 57 Annex F (informative)

Surfactants. 59 Bibliography . 60 SIST EN 17138:2019

European foreword This document (EN 17138:2018) has been prepared by Technical Committee CEN/TC 346 “Conservation of Cultural Heritage”, the secretariat of which is held by UNI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by June 2019, and conflicting national standards shall be withdrawn at the latest by June 2019. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN shall not be held responsible for identifying any or all such patent rights. This document calls for the use of substances and/or procedures that can be injurious to health if adequate precautions are not taken. It is recommended to read the relevant safety data sheets on the occupational and health hazards of the main chemical constituents of the products before using them. It refers only to technical suitability and this not absolves the user from legal obligations relating to health and safety at any stage. The manufacturer should also provide safety data sheets. According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 17138:2019

Introduction Cleaning is the removal of unwanted material from an object surface or near-surface. The surface of an object is cleaned either for conservation and/or maintenance or to improve legibility. A cultural heritage object is irreplaceable and while cleaning is undertaken for object conservation; its effects are irreversible. Failure to consider and address the technical problems which can arise during cleaning may cause irrevocable damage to an object. Cultural Heritage should be cleaned using the least disruptive/invasive procedure possible in order to best preserve it. Furthermore, an inadequate or inappropriate intervention may cause, or increase, future deterioration processes or eliminate materials which are undocumented or which would allow a greater understanding of the history of the object. Materials to be removed may include alteration products of the constituent materials, air particulate pollutants, dust, salt efflorescence; partially or totally soluble encrustations; layers of intentionally applied materials that are either inappropriate or no longer functional; biofilms; lichens; mosses. Cleaning, as a part of the conservation plan, is based on the definition of which materials are to be removed and which materials to be preserved. In order to fulfil this task, the appropriate balance should be found among the following requirements: selectivity, effectiveness and controllability. Before cleaning is carried out, it should be evaluated in terms of effectiveness and potential damage (harmfulness) by the use of trial areas. Evaluation should be continued during the cleaning operations and over the longer terms to monitor the effects of cleaning. This framework document describes the cleaning systems providing a list of technical specifications useful for their selection, evaluation and optimization to allow proper and systematic evaluation. Cleaning methods will be described according to a common structure: a) description; b) technical specifications (factors that define the system to be used); c) variables (factors that end users can adjust, control or change to optimize the process according to surface condition, the type and thickness of material to be removed, etc.); d) advantages; e) disadvantages; f) examples of applications (indicative situations in which the cleaning methods have been found to be effective). This standard presents the methodology and requirements for cleaning particularly applicable to natural stone, ceramics, plaster, mortars and concrete. The presence of sensitive components, which may include certain stone lithologies or paint or other decorations on porous inorganic surfaces, for example, will preclude the use of some of the methods outlined in this document. The example applications given in the standard are indicative of practice and are not exhaustive. The standard is intended to serve as guidance for all conservation professionals (architects, surveyors, conservators/restorers, conservation scientists, curators, etc.) involved in the conservation of objects. The standard is intended as a reference for organizations including government bodies and cultural heritage agencies, with a duty to preserve items of cultural heritage. SIST EN 17138:2019

1 Scope This document provides the guidelines for the choice of the operational cleaning technical specifications in order to optimize the cleaning operation. The fundamental requirements for each specific cleaning method are given as to adapt cleaning works for single specific cases. The objective of cleaning may consist of removal of any combination of unwanted materials, such as: degraded protective coatings, surface or near-surface materials, which constitute a present or future threat to conservation, materials which prevent legibility of the object or are disfiguring by nature, deposits which are judged to be incompatible to the historical nature of the object. 2 Normative references There are no normative references in this document. 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. ISO and IEC maintain terminological databases for use in standardization at the following addresses:

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp 3.1 porous inorganic material material including natural stones, e.g. sandstone, limestone, marble, granite, gneiss, gypsum as well as artificial materials, such as mortar, plaster, brick, ceramics, concrete and others [SOURCE: EN 15801:2009, 3.1, modified] 3.2 object single manifestation of tangible cultural heritage Note 1 to entry: The term object is used in this standard for cultural heritage, both immovable and movable. In specific professional contexts, other terms are used: e.g. artefact, cultural property, item, ensemble, site, building fabric. [SOURCE: EN 15898:2011, 3.1.3] 3.3 specimen part considered representative of the material constituting an object Note 1 to entry: The specimen can have different origins and can be taken from: — materials similar to those constituting the object under study (e.g. stone quarries); — specifically prepared comparative materials e.g. reference materials; — available materials from the object. Note 2 to entry: The number and dimension of the specimens can be different depending on constraints encountered in sampling the required amount of material. [SOURCE: EN 16302:2013, 3.3] SIST EN 17138:2019

3.4 cleaning removal of unwanted material from an object Note 1 to entry: The criteria for something being “unwanted” can be stated, e.g. potentially damaging, obscuring detail, diminishes aesthetic value, etc. [SOURCE: EN 15898:2011, 3.5.3] 3.5 water cleaning cleaning including a series of different systems using water in liquid or vapour phase 3.6 nebulous spray intermittent mist spray development of low-pressure water washing, characterised by a mist spray entering in contact with the object surface 3.7 water spray at low pressure spray based on the use of water at low pressure 3.8 abrasive cleaning cleaning including all techniques that physically abrade the object surface to remove unwanted materials 3.9 dry grit blasting sandblasting dry blasting process delivering a stream of abrasive particles, under pressure, toward the object surface 3.10 microblasting microsandblasting dry blasting process delivering a thin stream of fine abrasive particles, under pressure, toward the object surface 3.11 wet grit blasting hydro sandblasting blowing of a mixture of water and grit toward the object surface 3.12 peeling system cleaning method consisting of the application of a film forming product which can be peeled off to remove adhered particulate materials 3.13 steam cleaning cleaning method where water vapour is used SIST EN 17138:2019

3.14 aqueous poultices packs absorbent materials (non-reactive packs) mixed with water to form a paste which is applied to the object surface 3.15 biocide substance able to kill micro-organisms, animals or plants colonizing porous substrates 3.16 biocleaning cleaning using non-pathogenic micro-organisms to remove undesired substances (sulfates, nitrates, organic matter, etc.) from a surface 3.17 chelating agents organic substances forming coordinate bonds with metal ions and producing a stable structure 3.18 cryogenic cleaning dry ice-blasting in a pressurized air stream and directed onto the object surface 3.19 ion exchange resins polymers (essentially) which contain ionic groups linked to their macromolecules by a weak bond and consequently have the ability to inter-exchange these groups with the ions present in the surrounding medium 3.20 laser cleaning cleaning consisting in the removal of the unwanted surface materials from a substrate by using laser irradiation 3.21 surfactant substance which lowers the surface tension of the medium in which it is dissolved, and/or the interfacial tension with other phases, and, accordingly, is positively adsorbed at the liquid/vapour and/or at other interfaces 3.22 toxic substances and preparations which, if they are inhaled or taken internally or if they penetrate the skin, may involve serious, acute or chronic health risks and even death Note 1 to entry: See Directive 67/548/EEC. 3.23 toxicity degree to which a substance is toxic SIST EN 17138:2019

4 Requirements and general considerations affecting cleaning decisions Cleaning should not be carried out unless necessary and when done it should be at the minimum level deemed effective. The cleaning treatment should effectively remove both unwanted materials from the surface and/or in the bulk of the substrate (effectiveness) and should not increase the likelihood of future deterioration (harmfulness). Therefore, to be a “conservation treatment” a cleaning method has to meet the following criteria: a) it should not raise the possibility that reactive chemical compounds have adverse reactions with the materials to be conserved, either immediately or in the future; b) it should not leave permanent or non volatile residues on or inside the object which might be harmful or have the capacity to change the morphology or the colour of the surface (for example efflorescences, stains, halos) either immediately or in the future; c) it should not cause physical - mechanical damage to the object (including erosion, loss of cohesion, detachment or formation of micro-cracks, increase of porosity); d) it should respect the original surface and finishes, and any subsequent additions with artistic or historic value (painting, patination, etc.) and/or original tool marks of the surface; e) it should maintain or, if possible, restore a level of surface topography comparable to that of the original surface; f) it should not be carried out in such way that it endangers the health of building occupants or workers; therefore the possible toxicity of the products shall be taken into account; as well as the possible toxicity of waste requiring removal to appropriate storage sites; g) it should minimize the risk of damage to any personal or public property; h) it should require that due consideration is taken on the practicalities of treatment in order to minimize potential problems with efficiency and application. As no building, no environment, no object, no deterioration history is necessarily identical it is anticipated that solutions will differ. A number of different decay features may occur on an object which necessitates deployment of various methods. Each conservation project should be considered carefully, taking into account previous experience with the object (or similar objects) and available materials and methods which might be useful but should not be assumed to apply fully in every case. Some deposits are not fully removable from surfaces without causing excessive damage. In this case, residual or uneven marks may remain and do not necessarily indicate poor quality cleaning. Methods which allow careful control and evaluation and which may be readily halted by the operator are favoured. The efficacy of each method should be evaluated for each specific situation. Preliminary laboratory tests are intended to define the potential danger as well as the likely effectiveness of the method for each type and condition of porous materials. Special attention should be paid to the chemical and physical nature of the product used, for the cleaning process, the methodology and the duration of the application. Methods and products which are harmless in some cases, may cause damage on other materials or on the same material if applied incorrectly. SIST EN 17138:2019

In case of well-consolidated materials, cleaning is usually the first operation to be carried out. Where objects are in an advanced state of decay or naturally lack of cohesion, pre-consolidation of the material and protection of the surface with a sheet of Japanese paper prior to cleaning should be considered. It should be noted that such a treatment may influence the eventual choice of the cleaning method, and it may become more difficult to eliminate any biodeteriogens, for example cyanobacteria, algae, lichens and mosses and others unwanted materials deeply penetrated within the substrate. Original paint/decorations should always be retained. In the case of carved surfaces, or any other surfaces of any particular historical and/or artistic importance, scales and fragments of the original surface should be retained in situ, wherever possible, and not deliberately removed. It should be noted also that the end result of cleaning will depend both on the knowledge and capacity of the conservator/restorer, the effectiveness of the materials and methods adopted. 5 Preliminary investigation to optimize cleaning selection process 5.1 Preliminary survey 5.1.1 A preliminary survey should be carried out according to EN 16095 and EN 16096, particularly taking into account the following items: a) historical information of previous conservation intervention (cleaning/treatment); b) description of the nature of the constituent materials and their location on the object by visual inspection, which may include additional investigations where finishes may be present; c) description and mapping of the different forms of deterioration by visual inspection; d) description and localization of the effects of previous cleaning operations and other interventions if they are detectable by visual inspection; e) study of environmental context. A full understanding of the context of the site should be obtained to identify and minimize any environmental decay factors, which may arise from the cleaning process; f) identification of potential test areas; g) background information on susceptibility of substrates as a preliminary guidance for the selection of cleaning methods; h) search for evidence for former paint layers. 5.1.2 Records should be kept of all operations on object of significance including: a) photographs of the object showing its condition and appearance before cleaning is carried out; b) drawings of the different materials constituting the cultural heritage object; c) drawings of unwanted materials location, thickness and nature; and current condition of the object. Specific phenomena should be characterised and a description given with the images to provide an ongoing record. This may be done with reference to an existing visual glossary which should be stated. When non-invasive methods are not available or are unable to provide the necessary information, samples for laboratory analyses should be taken, where possible. These samples are required in order SIST EN 17138:2019

to accurately identify the materials and the deterioration products and consequently to select the most appropriate cleaning method. 5.2 Identification of substrate and characterization of unwanted materials 5.2.1 Following preliminary survey, objects to be cleaned should be inspected closely and analysis/tests should be carried out using the following procedure: a) each constituting material should be identified in sufficient detail so that cleaning can proceed while minimizing risk to the object. The knowledge of the chemical, mineralogical and structural characteristics of the material constituting the object and the properties of the substrate close to the external surface, are important. This is a more accurate assessment of item 5.1.1 b); b) the condition of the object and associated materials should be assessed and mapped (digital record), as well as the nature and effects of previous treatment operations, (see 5.1.1 c) and d); c) the extent, nature, thickness and distribution of materials to be removed should be identified. The layer of unwanted materials and the altered surface of substrate should be distinguished from each other at the investigation stage, so that the level of cleaning can be selected; d) the presence of surface working and or intentional stratification such as finishing, painting and polychrome layers should be identified; e) assessment, by means of preliminary laboratory tests, of the effectiveness and harmfulness over the immediate and long term perspectives of the cleaning products and procedures to be used on similar materials. 5.2.2 Unwanted materials on object surfaces can vary from a few microns to some millimetres in thickness and cleaning can involve removal of one or more of the following materials, reported as the more common examples: a) atmospheric particulates, often bound together as well as to the object surface and composed either of calcium sulfate, calcium carbonate or silica, depending on the substrate; b) biofilms composed by heterotrophic bacteria, cyanobacteria, algae, fungi, lichens; c) mortar splashes and runs; d) encrustations of calcium carbonate; e) efflorescent salts; f) bird droppings; g) paint and graffiti; h) bird repellent gel; i) oils, grease and waxes; j) stains; k) soiling or earth encrustations on archaeological items; SIST EN 17138:2019

l) overpaints; m) anti-graffiti coatings; n) previous treatments or reaction products derived from previous treatments. 5.2.3 Records should be kept of previous operations on object of significance including drawings (photographs or analyses) of: a) the different materials constituting cultural heritage object if different from 5.1.1 b); b) the extent, nature, thickness and distribution of materials to be removed and of the condition of the object, if different from 5.1.1 c) and d); c) the surface finishes or tool marks, painting and polychrome layers; d) the sampling location, if applicable. Specifications and other documents that might be required for a cleaning project should be prepared in sufficient detail to give a proper guidance in the preparation of estimates and execution of the work. Copies of all relevant documents should be available to all parties involved, including site personnel responsible for supervision. Documents should be retained to provide background information prior to further assessments or work. Following these surveys the decision on which, if any, cleaning methods are appropriate, should be made. 6 Selection of cleaning methods Following the preliminary survey and the identification of the substrate and unwanted materials (see 5.2) an appropriate cleaning method should be selected among those reported in Clause 8. As a cleaning process may involve multiple applications of one system or several removal systems in situ trials should be carried out on representative areas Efficacy and suitability of the products and procedures (see Clause 7) tested, shall be subject to preliminary evaluation. As a single object can consist of a complex assemblage of features differentiated by their physical and chemical properties, the expertise of a team of professionals, each one specialized in a defined field of knowledge may be required to produce a conservation plan which uses several different products and procedures. 7 Trial cleaning areas The aim of cleaning a trial area should be to determine: — the suitability of the cleaning method for the object, its condition, and the unwanted materials; — the degree of cleaning that can be achieved, and its acceptability. Cleaning processes should be pre-tested on surfaces of the object representative of all those on which cleaning will be performed. If possible, test areas should be located in unobtrusive locations, and in any case should be small in case the decision made after the trials is not to proceed with full scale cleaning. When trialling different cleaning methods those which are (seen as / predicted to be) least aggressive shall be tested first. Progression towards methods which are more aggressive should be made only if necessary. SIST EN 17138:2019

A detailed record should be kept of trial cleaning and the location of trial areas. This should be retained for reference throughout the duration of the cleaning process. Trial cleaning should be observed and assessed by persons responsible for preparing the cleaning specification. Trial areas should be available for inspection by relevant authorities. Trial cleaning should be agreed beforehand, and carried out by trained and experienced specialists conversant in a variety of cleaning systems. When useful, trial areas should be assessed in wet and dry conditions. Full assessment should include: a) potential damage to the object as a result of cleaning; b) colour changes resulting from the cleaning process; c) the general appearance change of the object surface after cleaning; d) the efficacy of the removal of unwanted materials. 8 Cleaning methods 8.1 Water cleaning 8.1.1 General Water cleaning includes a series of different systems using water in liquid or vapour phase. Water can be supplied in different forms as mist of droplets, spray, steam etc. or contained within a gel or poultice medium. The solvent action of water is mainly influenced by temperature and specific surface of the droplets coming into contact with the object surface. In addition to the solvent action a mechanical effect is also present, due to the water contact pressure. If the condition of the surface allows it, the action of the water spray can be augmented by a gentle mechanical action, using, for example, nylon or bristle brushes. Before selection of any one of these methods, the porosity and condition of the material shall be assessed in order to balance the amount of water and duration required. Special consideration should be given to areas where the materials change, for example at mortar joints The conductivity of the water used shall generally be less than 400 µS/cm, a level at which most tap water will be suitable for cleaning. In case of historical building some preliminary works should be considered prior to cleaning such as temporary pointing or filling of any cracks that would let cleaning liquids enter the wall or the building interiors. Glazing and window frames shall be protected with plastic foils and tape. Vulnerable items or materials within the location shall be protected within the cleaning area if applicable. Before cleaning the exterior of a building, the building’s rainwater drainage system shall be inspected to ensure that it is of sufficient capacity, in good condition and free from blockages. Water-based methods shall not be used if there is a risk that outside temperature will fall below 5 during cleaning and until the material is sufficiently dry following cleaning to reduce possibility of frost formation. Water run-off must be managed and contained. SIST EN 17138:2019

8.1.2 Nebulous spray or intermittent mist spray 8.1.2.1 Description Nebulous spray, also known as intermittent mist spray, is a development of low-pressure water washing which is often considered to be the least aggressive form of cleaning. The system of nebulous sprays is based on the principle of passing water through a very fine mesh or filter to create a mist, which is then passed through fine nozzles. The action of the mist swirling across the surface of the object dampens and softens the dirt layers. The action of the mist also activates mobilization of the dirt particulates and thus breaks the cohesion of the dirt layer and the adhesion to the substrate underneath. The aim of nebulous spray is to apply the lowest amount of water for the minimum duration in order to soften the dirt, thus enabling its removal by scrubbing or other relatively gentle mechanical cleaning. The position of the nozzle with respect to the surface to be cleaned should be carefully controlled to prevent any mechanical action from the water droplets, as cleaning method should only work through the process of solubilisation. To reach this purpose the jet of nebulised water should not directly hit the surface to be cleaned, but should reach the surface as it begins to fall downwards. A number of spray heads or nozzles are mounted on a boom arm in front of the area to be cleaned. These are attached by a hose to the water supply. Placing nozzle heads on booms allows the flexibility to create the mist to facilitate cleaning wherever this is required. Enclosure within a protective waterproof covering aids the cleaning process as it prevents interference from external weather conditions. In order to prevent any migration of contaminated water to lower levels, a proper collection and disposal system for waste water shall be installed. The water shall be nebulised, at the ambient temperature, using hydraulic atomizing nozzles which produce a fine mist-like spray in the form of a hollow cone. The recommended diameter of the orifice is less than 1 mm which is capable of producing droplets with diameters varying from 80 µm to the maximum recommended size of 120 µm. The dimensions and distribution of the droplets can be determined by using appropriate hydro-sensitive papers. Every 15-20 min, the extent of cleaning should be checked to guarantee a homogeneous application appropriate to the specific treatment for the material to be removed. The amount of water may be controlled electronically or by timers, allowing pulse or intermittent spraying, to avoid ever having water running down the object surface. The system should be designed to be highly flexible, directing the spray only where needed. The following are indicative of some methods by which the system can be customized: a) the nozzles from the hose may be grouped or spaced according to condition of the surface and to the severity of the dirt or encrustation being treated and condition of surface; b) flat surfaces require less water than a heavily soiled carved detail, which may require a cluster of nozzles positioned on an articulated hose to the profile of the carving; c) the sprays are also operated on an electronic cut-off system. This is run in conjunction with sensors located below the area being cleaned. When the required amount of water determined by trial areas, has been deposited on the wall, and therefore the sensor, this will switch off the supply of water to the nozzle arms; SIST EN 17138:2019

d) an intermittent spray system, whereby a short period of spraying is followed by an extended period where there is no spray, is used in order to confine the action of the spray to outer layers. The cycle adopted is strongly dependent on the physical characteristics of the object substrate and its condition. 8.1.2.2 Technical specifications a) hydraulic nebulizing nozzles orifice diameter of: 0,4 mm to 0,8 mm b) average droplets diameter: 80 µm to 120 µm 8.1.2.3 Variables Depending on the kind of surface, the variables below listed shall be fixed according to the type and thickness of dirt to remove and according to the surface condition, following tests on trial areas: a) specific conductivity of water (for some applications deionized water less than 50 S/cm is recommended); b) water consumption (l/hour); c) distribution of droplets (visual assessment); d) distance between the nozzle and the surface (cm); e) spatial arrangement (orientation and density of the nozzles-number/m2); f) duration (minutes) of each wetting and drying phase and number of cycles (wet+dry). 8.1.2.4 Advantages a) The impact of the mist on the surface is negligible, reducing the risk of mechanical damage unless the surface is extremely disaggregated. b) Thicker encrustations of soiling which tend to form in protected areas of an object, which are not regularly washed by rain, may be softened by the water and subsequently mechanically removed. c) Encrustations and soiling are softened progressively which allows control over removal reducing the risk of over cleaning. d) Compared to other water-based washing systems, a mist spray uses less water, so avoiding the excess run off to adjacent areas of the surface. e) Removing softened material by brush between spraying cycles may accelerate the cleaning process and has the added advantage of enabling progress to be monitored. f) The water presents fewer hazards to the public and operators, than some other methods. 8.1.2.5 Disadvantages a) This method is not effective for the removal of soiling or staining which is insoluble in water. b) Water cleaning with nebulous spray or intermittent mist spray is not recommended for porous inorganic material with a high water absorption capacity, for weathered surfaces and for a salt rich substrate. Water cleaning methods may exacerbate deterioration when used on badly deteriorated SIST EN 17138:2019

surface and may induce dangerous dissolution/recrystallization cycles when rich salt substrate is present. c) A frequent problem with many limestones and some sandstones is the formation of brown or orange staining caused by naturally occurring iron compounds within the stone being mobilised and carried to the surface. d) The risk of water penetration through defective joints or fractures is still present with the nebulous spray system, illustrating the importance of carrying out a thorough survey externally, and continuous monitoring of the interior as cleaning progresses. Despite the relatively low water volumes, water penetration to the interior of the building may sometimes occur. e) The method cannot be used when water sensitive original materials are present, including wall paintings. 8.1.2.6 Example of applications Its application is particularly useful on building façades where unwanted water-soluble materials are present. This method works well on thin soiling layers which are sensitive to water. Water cleaning by nebulous spray has been historically used extensively for the cleaning of marble and low porosity limestone, as the soiling is generally bound to relatively soluble compounds. In some cases, cleaning may be less efficient on silicaceous stones, such as granite or sandstone, where the soiling is bound to the silicate surface as insoluble compounds. Where the use of more invasive cleaning methods is inevitable, the use of nebulous spray system to pre-soften the dirt may be beneficial. 8.1.3 Water spray at low pressure 8.1.3.1 Description The method is based on the use of a water spray system based on the principle of passing water through nozzles thus creating droplets which impact on the surface of the object. Water at low pressure (0,2 MPa to 0,3 MPa) is used. Fan or cone jet nozzles of 25 degrees minimum should normally be used for low pressure washing (hot or cold water). Water pressure and type of nozzle should be adjusted as applicable to the substrate condition. Rotating nozzles should be used for rinsing inside the recesses of complex surfaces (e.g. carvings). Pressure, angle and nozzle distance from the surface should be carefully controlled. Cleaning should be carried out by wetting and softening (rather than by mechanical action of the water). Pressure cleaning systems which use a medium to high pressure through a mechanical sprayer to remove the unwanted materials from the surfaces of buildings are not considered in this clause. The medium or high pressure washing and hydroblasting (very high pressure washing) are not recommended for cleaning of cultural heritage objects. 8.1.3.2 Technical specifications a) nozzles orifice diameter: 1mm to 2 mm SIST EN 17138:2019

b) water pressure: 0.2 MPa to 0.3 MPa max 8.1.3.3 Variables a) Distance between the water outlet and the surface; b) angle of direction of the nozzle; c) water consumption. 8.1.3.4 Advantages Low cost. Does not require highly specialist equipment. It is effective in removing water soluble dirt from materials of low porosity (e.g. concrete, cement-based renders, some brick type, cast stone etc.). 8.1.3.5 Disadvantages In addition to those reported for 8.1.2.5 a), b), c), d), e), the following have to be taken into account: a) Large amounts of water, higher than that used with the nebulous spray, are potentially hazardous to buildings and proper precautions and supervision should be provided so that water does not enter core material, b) temporary catchments and gutters should be provided to efficiently remove water from the building walls and to avoid over-saturation at lower levels, and dispose of it in an appropriate manner, c) the impact of these techniques on disintegrated surfaces will cause loss of material. 8.1.3.6 Example of applications This technique can only be applied on surfaces in very good condition (e.g. monolithic concrete). 8.1.4 Injection extraction cleaning 8.1.4.1 Description The injection-extraction method is based on a specific vacuum-washing technology. Water is sprayed on the soiled surface through a head which also recovers the dirty water by a suction action. The cleaner nozzle is fitted with a soft bristle brush and protected with a soft plastic joint to be moved over the surface without damaging it. A surfactant in low concentration can be added in order to enhance the wettability. 8.1.4.2 Technical specifications a) Water pressure: 0,2 MPa to ,.0 MPa; b) suction vacuum: 34 kPa ± 4 kPa. 8.1.4.3 Variables a) Water consumption (l/hour); b) surfactant addition (%). SIST EN 17138:2019

8.1.4.4 Advantages Cleaning is based on water effect (dissolution and leaching) but the surface is wetted very slightly and almost instantaneously dried. Specifically designed devices allow the application on a large variety of surface constructions. Tool heads of different widths and shapes are available to allow the application on more or less regular, relatively flat surfaces. The water is confined: the solution and the dirt are vacuumed off into a tank, no waste water runs down the walls and ceilings. The environment does not require any great protection against water, dust, noise; the site can continue to be used (e.g. church, office, stairs…). 8.1.4.5 Disadvantages a) The system is designed to be used on flat surface, so it is extremely difficult to use it on highly contoured surfaces. b) The risk of water penetration through defective joints or fractures is present. c) A frequent problem with many limestones and some sandstones is the possible formation of brown or orange staining caused by naturally occurring iron compounds within the stone being mobilised and carried to the surface. d) The system does not allow sufficient time to soften or dissolve soiling. This method is not recommended for: e) fragile surfaces due to the risk of loss of material; f) removal of soiling or staining which are insoluble in water; g) stone with a high open integral porosity and for weathered surfaces; h) salt rich substrate due to the occurrence of dangerous dissolution/recrystallization cycles. 8.1.4.6 Example of applications The method is suitable to remove loose deposits (e.g. soot deposits) which are frequently present on indoor walls (concrete, brick and stone wall masonry, plaster, etc.). 8.1.5 Steam cleaning 8.1.5.1 Description Most steam cleaning equipment produces a biphasic system where the vapour phase is in a dynamic equilibrium with the liquid phase. The equilibrium is mainly influenced by temperature and pressure. Most steam cleaning equipment produces wet steam, in which there are also a few droplets of hot water. The pressure comes from the steam generation process itself. As the vapour is generated, the pressure inside the container increases; steam at about 150

¹C remains in liquid phase as long as the pressure in the container is above approx. 0,4 MPa. By releasing the pressure when opening the nozzle, the liquid water will vaporize into steam and cool down to the boiling point of water at atmospheric pressure (100

¹C). By doing so, it expands about 1,5 times. This expansion occurs in the nozzle and helps to provide the pressure of the steam. The temperature of the steam tends to drop quickly after the SIST EN 17138:2019

vapour exits the nozzle and some of the vapour will condense into water droplets. Steam cleaning using such equipment is achieved by a combination of steam and the few droplets of hot water. Whilst the temperature in the system is high, the pressure on the surface being cleaned is very gentle and the volume of water is low. The surface is therefore not saturated and will be dry within minutes. There are many different kinds of steam cleaners available on the market and they should be clearly distinguished from hot water washers. The small industrial steam cleaning machines that are used in conservation emit very small quantities of water; typically 2 l to 4 l of w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...