SIST-TS CEN/TS 1459-8:2019

(Main)Rough-terrain trucks - Safety requirements and verification - Part 8: Variable-reach tractors

Rough-terrain trucks - Safety requirements and verification - Part 8: Variable-reach tractors

This document specifies requirements related to permanent mounted equipment for rough-terrain variable-reach tractors (here-after referred to as “RTVR tractors”) and additional requirements for the combination.

This document does not apply to:

- machines designed primarily for earth moving, even if their buckets and blades are replaced with forks (see EN 474 series);

- attachments.

This document does not address hazards which may occur

a) when handling suspended loads which may swing freely;

b) when using RTVR tractors on public roads;

c) when operating in potentially explosive atmospheres;

d) when operating underground;

e) when towing trailers;

f) when fitted with a personnel work platform (additional requirements are given in EN 1459-3);

g) when using cruise-control.

This document does not provide a method of calculation for fatigue and strength of material.

This document is not applicable to RTVR tractors manufactured before the date of its publication.

Geländegängige Flurförderzeuge - Sicherheitsanforderungen und Verifizierung - Teil 8: Traktoren mit veränderlicher Reichweite

Chariots tout-terrain - Prescriptions de sécurité et vérification - Partie 8 : Tracteurs à portée variable

La présente Spécification technique spécifie les prescriptions relatives aux équipements montés en permanence pour les tracteurs tout-terrain à portée variable (ci-après désignés « tracteurs RTVR ») ainsi que des prescriptions supplémentaires pour l'ensemble combiné.

La présente Norme européenne ne s'applique pas :

- aux machines conçues principalement pour le terrassement, même si leurs godets et leurs lames sont remplacés par des fourches (voir la série EN 474) ;

- aux accessoires.

La présente Spécification technique ne traite pas des phénomènes dangereux qui peuvent apparaître :

a) lors de la manutention de charges suspendues qui peuvent se balancer librement ;

b) lors de l'utilisation des tracteurs RTVR sur les voies publiques ;

c) lors d’une utilisation en atmosphères explosibles ;

d) lors de travaux souterrains ;

e) lors de la traction de remorques ;

f) lorsqu’ils sont équipés d’une plateforme de personnel/travail (des prescriptions supplémentaires sont données dans l’EN 1459 3) ;

g) lors de l'utilisation d'un régulateur de vitesse.

La présente Spécification technique ne fournit pas de méthode de calcul de la fatigue et de la résistance du matériau.

Le présent document n'est pas applicable aux tracteurs RTVR fabriqués avant la date de sa publication.

Vozila za talni transport - Terenska vozila - Varnostne zahteve in preverjanje - 8. del: Traktorji z mehanizmom s spremenljivim dosegom

Ta tehnična specifikacija določa zahteve v zvezi s trajno nameščeno opremo za traktorje z mehanizmom s spremenljivim dosegom za talni transport (v nadaljevanju traktorji »RTVR«) in dodatne zahteve za kombinacijo.

Ta evropski standard se ne uporablja za:

– stroje, ki so primarno zasnovani za zemeljska dela , tudi če imajo namesto žlic in rezil vilice (glej skupino standardov EN 474);

– priključke.

Ta tehnična specifikacija ne obravnava nevarnosti, ki se lahko pojavijo:

a) pri ravnanju z visečimi tovori, ki lahko prosto nihajo;

b) pri uporabi traktorjev RTVR na javnih cestah;

c) pri upravljanju vozil v potencialno eksplozivnih atmosferah;

d) pri upravljanju pod zemljo;

e) pri vleki prikolic;

f) pri vozilih, opremljenih s ploščadmi za osebje/delovnimi ploščadmi (dodatne zahteve so podane v standardu EN 1459 3);

g) pri uporabi tempomata.

Ta tehnična specifikacija ne zagotavlja metode za izračun utrujenosti in trdnosti materiala.

Ta dokument se ne uporablja za traktorje RTVR, izdelane pred datumom njegove objave.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Mar-2018

- Publication Date

- 13-Jan-2019

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 25-Sep-2018

- Due Date

- 30-Nov-2018

- Completion Date

- 14-Jan-2019

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Dec-2022

Overview

CEN/TS 1459-8:2018 - Rough-terrain trucks - Safety requirements and verification - Part 8: Variable-reach tractors - is a CEN Technical Specification that defines safety requirements and verification procedures for permanently mounted equipment on rough-terrain variable-reach tractors (RTVR tractors). Intended for RTVR tractors homologated under Regulation 167/2013, this TS clarifies how the Machinery Directive 2006/42/EC applies to permanently mounted equipment and supports CE marking, Declaration of Conformity (DOC) and Certificate of Conformity (COC).

Note: CEN/TS 1459-8 does not apply to attachments, machines primarily for earth moving, or hazards related to suspended swinging loads, public-road use, explosive atmospheres, underground operation, towing trailers, personnel work platforms, cruise control or fatigue/strength calculation. It is not retroactive to machines manufactured before publication.

Key Topics and Requirements

This Technical Specification builds on EN 1459-1 and covers practical safety and verification topics for variable-reach tractors, including:

- Safety requirements and protective measures for permanently mounted equipment

- Starting/moving and braking systems requirements and verification

- Electrical and electronic systems, including functional safety and EMC considerations

- Controls and operator interface - layout, signals, pedals and consistency of motions

- Power systems, hydraulics and stabilizing devices

- Systems for lifting, tilting and reaching and load-holding verification

- Stability requirements and additional stability tests (see referenced ISO stability standards)

- Operator’s station, access, visibility and lighting

- Information for use: instruction handbook, markings, load charts and warning signals

- Verification procedures: functional verification, structural checks and load tests

The TS includes annexes on significant hazards, consistency of motions and pedal design rules.

Applications and Who Uses It

CEN/TS 1459-8 is essential for:

- Manufacturers and designers of RTVR tractors and permanently mounted telescopic handlers - to design compliant equipment

- Certification bodies and test laboratories - to verify conformity with safety and verification procedures

- Fleet owners, rental companies and safety managers - to understand operator information, load charts and safe operation limits

- Compliance teams ensuring CE marking and alignment with Tractor Regulation 167/2013 and the Machinery Directive

Use cases include design validation, conformity assessment of permanently mounted equipment, preparing instruction handbooks, and performing stability/load verification tests.

Related Standards

Relevant references and related standards include:

- EN 1459 series (Parts 1–7)

- EN 15000, ISO 22915-14 (stability verification)

- EN ISO 12100, EN ISO 13849-1, EN ISO 4413 (risk, functional safety, hydraulics)

- Various ISO standards for operator environment, symbols, alarms and enclosure protection

For manufacturers and safety professionals working with rough-terrain variable-reach tractors, CEN/TS 1459-8 is a practical guide to meeting European safety and verification expectations for permanently mounted equipment.

Frequently Asked Questions

SIST-TS CEN/TS 1459-8:2019 is a technical specification published by the Slovenian Institute for Standardization (SIST). Its full title is "Rough-terrain trucks - Safety requirements and verification - Part 8: Variable-reach tractors". This standard covers: This document specifies requirements related to permanent mounted equipment for rough-terrain variable-reach tractors (here-after referred to as “RTVR tractors”) and additional requirements for the combination. This document does not apply to: - machines designed primarily for earth moving, even if their buckets and blades are replaced with forks (see EN 474 series); - attachments. This document does not address hazards which may occur a) when handling suspended loads which may swing freely; b) when using RTVR tractors on public roads; c) when operating in potentially explosive atmospheres; d) when operating underground; e) when towing trailers; f) when fitted with a personnel work platform (additional requirements are given in EN 1459-3); g) when using cruise-control. This document does not provide a method of calculation for fatigue and strength of material. This document is not applicable to RTVR tractors manufactured before the date of its publication.

This document specifies requirements related to permanent mounted equipment for rough-terrain variable-reach tractors (here-after referred to as “RTVR tractors”) and additional requirements for the combination. This document does not apply to: - machines designed primarily for earth moving, even if their buckets and blades are replaced with forks (see EN 474 series); - attachments. This document does not address hazards which may occur a) when handling suspended loads which may swing freely; b) when using RTVR tractors on public roads; c) when operating in potentially explosive atmospheres; d) when operating underground; e) when towing trailers; f) when fitted with a personnel work platform (additional requirements are given in EN 1459-3); g) when using cruise-control. This document does not provide a method of calculation for fatigue and strength of material. This document is not applicable to RTVR tractors manufactured before the date of its publication.

SIST-TS CEN/TS 1459-8:2019 is classified under the following ICS (International Classification for Standards) categories: 53.060 - Industrial trucks. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST-TS CEN/TS 1459-8:2019 has the following relationships with other standards: It is inter standard links to oSIST prEN 17968:2025, oSIST prEN 17968:2025, oSIST prEN 17968:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST-TS CEN/TS 1459-8:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2019

Vozila za talni transport - Terenska vozila - Varnostne zahteve in preverjanje - 8.

del: Traktorji z mehanizmom s spremenljivim dosegom

Rough-terrain trucks - Safety requirements and verification - Part 8: Variable-reach

tractors

Geländegängige Flurförderzeuge - Sicherheitsanforderungen und Verifizierung - Teil 8:

Traktoren mit veränderlicher Reichweite

Chariots tout-terrain - Prescriptions de sécurité et vérification - Partie 8 : Tracteurs à

portée variable

Ta slovenski standard je istoveten z: CEN/TS 1459-8:2018

ICS:

53.060 Industrijski tovornjaki Industrial trucks

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TS 1459-8

TECHNICAL SPECIFICATION

SPÉCIFICATION TECHNIQUE

September 2018

TECHNISCHE SPEZIFIKATION

ICS 53.060

English Version

Rough-terrain trucks - Safety requirements and

verification - Part 8: Variable-reach tractors

Chariots tout-terrain - Prescriptions de sécurité et Geländegängige Flurförderzeuge -

vérification - Partie 8 : Tracteurs à portée variable Sicherheitsanforderungen und Verifizierung - Teil 8:

Traktoren mit veränderlicher Reichweite

This Technical Specification (CEN/TS) was approved by CEN on 6 May 2018 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to

submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS

available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in

parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2018 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 1459-8:2018 E

worldwide for CEN national Members.

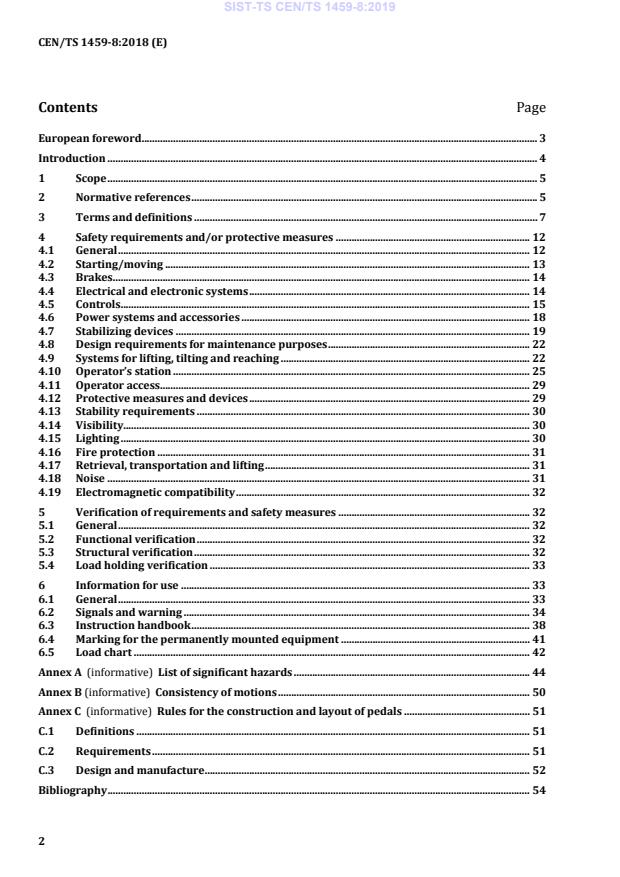

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 7

4 Safety requirements and/or protective measures . 12

4.1 General . 12

4.2 Starting/moving . 13

4.3 Brakes. 14

4.4 Electrical and electronic systems . 14

4.5 Controls . 15

4.6 Power systems and accessories . 18

4.7 Stabilizing devices . 19

4.8 Design requirements for maintenance purposes . 22

4.9 Systems for lifting, tilting and reaching . 22

4.10 Operator’s station . 25

4.11 Operator access. 29

4.12 Protective measures and devices . 29

4.13 Stability requirements . 30

4.14 Visibility. 30

4.15 Lighting . 30

4.16 Fire protection . 31

4.17 Retrieval, transportation and lifting . 31

4.18 Noise . 31

4.19 Electromagnetic compatibility . 32

5 Verification of requirements and safety measures . 32

5.1 General . 32

5.2 Functional verification . 32

5.3 Structural verification . 32

5.4 Load holding verification . 33

6 Information for use . 33

6.1 General . 33

6.2 Signals and warning . 34

6.3 Instruction handbook . 38

6.4 Marking for the permanently mounted equipment . 41

6.5 Load chart . 42

Annex A (informative) List of significant hazards . 44

Annex B (informative) Consistency of motions . 50

Annex C (informative) Rules for the construction and layout of pedals . 51

C.1 Definitions . 51

C.2 Requirements . 51

C.3 Design and manufacture . 52

Bibliography . 54

European foreword

This document (CEN/TS 1459-8:2018) has been prepared by Technical Committee CEN/TC 150

“Industrial trucks - Safety”, the secretariat of which is held by BSI.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

EN 1459 consists of the following parts, under the general title Rough-terrain trucks - Safety

requirements and verification:

— Part 1: Variable-reach trucks

— Part 2: Slewing variable-reach trucks

— Part 3: Interface between the variable-reach truck and the work platform

— Part 4: Additional requirements for variable-reach trucks handling suspended loads

— Part 5: Additional requirements for attachments and attachment interface

— Part 6: Application of EN ISO 13849-1 to slewing and non-slewing variable-reach rough-terrain trucks

(Technical Report)

— Part 7: Test method and determination of noise emission (in preparation) for variable-reach trucks

— Part 8: Variable-reach tractors (Technical Specification)

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

This document is applicable to rough-terrain variable-reach trucks homologated as tractors according

to 167/2013, called rough-terrain variable-reach tractors (RTVR tractors).

This document is also intended to highlight and explain the requirements of the Machinery Directive

2006/42/EC applicable to the permanently mounted equipment on a RTVR tractor.

It is based on EN 1459-1:2017.

The two following regulations apply to those RTVR tractors with permanently mounted equipment:

Tractor regulation 167/2013

Machinery directive 2006/42/CE for the permanently mounted equipment.

As a consequence, the two following documents accompany each piece of equipment:

— COC certificate of conformity

— DOC declaration of conformity for permanently mounted equipment

The permanently mounted equipment bears the CE marking.

All quantities are in SI units, and this includes metric units.

This document is a type C standard as stated in EN ISO 12100.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document.

When provisions of this type C standard are different from those which are stated in type A or B

standards, the provisions of this type C standard take precedence over the provisions of the other

standards, for machines that have been designed and built according to the provisions of this type C

standard.

1 Scope

This document specifies requirements related to permanent mounted equipment for rough-terrain

variable-reach tractors (here-after referred to as “RTVR tractors”) and additional requirements for the

combination.

This document does not apply to:

— machines designed primarily for earth moving, even if their buckets and blades are replaced with

forks (see EN 474 series);

— attachments.

This document does not address hazards which may occur

a) when handling suspended loads which may swing freely;

b) when using RTVR tractors on public roads;

c) when operating in potentially explosive atmospheres;

d) when operating underground;

e) when towing trailers;

f) when fitted with a personnel work platform (additional requirements are given in EN 1459-3);

g) when using cruise-control.

This document does not provide a method of calculation for fatigue and strength of material.

This document is not applicable to RTVR tractors manufactured before the date of its publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1175-2:1998+A1:2010, Safety of industrial trucks - Electrical requirements - Part 2: General

requirements of internal combustion engine powered trucks

EN 1459-5, Rough-terrain trucks - Safety requirements and verification - Part 5: Attachments and

attachment interface

EN 15000:2008, Safety of industrial trucks - Self propelled variable reach trucks - Specification,

performance and test requirements for longitudinal load moment indicators and longitudinal load

moment limiters

EN 15830:2012, Rough-terrain variable reach trucks - Visibility - Test methods and verification

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

Under preparation. Stage at time of publication: prEN 1459-5:2018.

EN 62061, Safety of machinery - Functional safety of safety-related electrical, electronic and

programmable electronic control systems (IEC 62061)

EN ISO 3449:2008, Earth-moving machinery - Falling-object protective structures - Laboratory tests and

performance requirements (ISO 3449:2005)

EN ISO 3457, Earth-moving machinery - Guards - Definitions and requirements (ISO 3457)

EN ISO 3471:2008, Earth-moving machinery - Roll-over protective structures - Laboratory tests and

performance requirements (ISO 3471:2008)

EN ISO 4413:2010, Hydraulic fluid power - General rules and safety requirements for systems and their

components (ISO 4413:2010)

EN ISO 5353, Earth-moving machinery, and tractors and machinery for agriculture and forestry - Seat

index point (ISO 5353)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1, Safety of machinery - Safety-related parts of control systems - Part 1: General principles

for design (ISO 13849-1)

EN ISO 13850, Safety of machinery - Emergency stop function - Principles for design (ISO 13850)

EN ISO 13857, Safety of machinery - Safety distances to prevent hazard zones being reached by upper and

lower limbs (ISO 13857)

ISO 5053-1:2015, Industrial trucks — Terminology and classification — Part 1: Types of industrial trucks

ISO 6011:2003, Earth-moving machinery — Visual display of machine operation

ISO 7000, Graphical symbols for use on equipment — Registered symbols

ISO 9533, Earth-moving machinery — Machine-mounted audible travel alarms and forward horns — Test

methods and performance criteria

ISO 10263-2, Earth-moving machinery — Operator enclosure environment — Part 2: Air filter element

test method

ISO 10263-3, Earth-moving machinery — Operator enclosure environment — Part 3: Pressurization test

method

ISO 10263-4, Earth-moving machinery — Operator enclosure environment — Part 4: Heating, ventilating

and air conditioning (HVAC) test method and performance

ISO 13333, Earth-moving machinery — Dumper body support and operator's cab tilt support devices

ISO 15817:2012, Earth-moving machinery — Safety requirements for remote operator control systems

This European Standard is impacted by the amendments EN 60529:1991/A1:2000 and EN 60529:1991/A2:2013.

ISO 15818, Earth-moving machinery - Lifting and tying-down attachment points - Performance

requirements

ISO 15870, Powered industrial trucks — Safety signs and hazard pictorials — General principles

ISO 16528-1, Boilers and pressure vessels — Part 1: Performance requirements

ISO 16528-2, Boilers and pressure vessels — Part 2: Procedures for fulfilling the requirements of ISO

16528-1

ISO 21507, Earth-moving machinery — Performance requirements for non-metallic fuel tanks

ISO 22915-10, Industrial trucks — Verification of stability — Part 10: Additional stability test for trucks

operating in the special condition of stacking with load laterally displaced by powered devices

ISO 22915-14, Industrial trucks — Verification of stability — Part 14: Rough-terrain variable-reach

trucks

ISO 22915-20, Industrial trucks — Verification of stability — Part 20: Additional stability test for trucks

operating in the special condition of offset load, offset by utilization

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010,

ISO 5053-1:2015 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

rough-terrain variable-reach tractor

RTVR tractor

tractor with a permanently mounted telescopic material handler non-slewing or having a slewing

movement of not more than 5° either side of the longitudinal axis of the tractors used for stacking loads

with or without stabilizers

a)

b)

Figure 1 — Rough-terrain variable-reach tractor

3.2

compact rough terrain variable reach tractor

RTVR tractor having

— a maximum height in normal travel mode of 2 150 mm and:

— a maximum operating mass of 6 000 kg;

and/or

— a maximum width in normal travel mode of 1 850 mm

Note 1 to entry: These dimensions do not include equipment such as working lights, mirrors, etc.

3.3

actual capacity

Q

maximum load, established by the manufacturer based on components strength and RTVR tractor

stability, that the RTVR tractor can carry, lift and stack to a specified height, at a specified standard load

centre distance and reach, in normal operating conditions

Note 1 to entry: The actual capacity depends on the configuration of the RTVR tractor in terms of such variables

as:

— lift height;

— reach of the boom;

— standard load centre distance;

— load handling device (fork arms or attachment fitted);

— stabilizing devices.

Note 2 to entry: This actual capacity defines the load handling ability of the particular RTVR tractor as

equipped. Additional actual capacity ratings with removable attachments may also be established where

permitted by the appropriate stability test or by calculation verified by empirical data.

3.4

rated capacity of RTVR tractor

Q1

maximum load permitted by the manufacturer at the standard load centre distance (D) that the RTVR

tractor is capable of lifting and transporting on fork arms in normal conditions with the boom fully

retracted

3.5

reach

d

distance between two vertical parallel planes, one plane tangent to the front of the outside diameter of

the front tyres, the other plane described by the vertical projection of the centre-of-gravity of the load

to the ground

Note 1 to entry: The centre-of-gravity of the load (G) is defined in Table 1.

Note 2 to entry: See Figure 2 for examples of reach.

Note 3 to entry: For practical matters, d can be measured referring to point g, being g the vertical projection of

the centre-of-gravity (G) of the load onto the plane of the top surface of the fork arms.

Key

d reach

D standard load centre distance

G centre of gravity of the load

g vertical projection of the centre-of-gravity (G) of the load onto the plane of the top surface of the fork arms

H lift height

Q actual capacity

Q1 rated capacity

Q2 rated capacity at maximum height or elevation

Q3 rated capacity at maximum reach

Figure 2 — Parameters for the designation of the actual capacity of the RTVR tractor with fork

3.6

lift height

H

vertical distance between the upper face of the fork arms and the ground

Note 1 to entry: See Figure 2.

3.7

standard load centre distance

D

distance from the centre of gravity (G) of the load measured horizontally back to the front of the fork

shanks and vertically down to the upper faces of the fork arms, as specified in Table 1

Note 1 to entry: See Figure 2, for example.

Note 2 to entry: Typical standard load centre distances are given in Table 1.

Table 1 — Typical standard load centre distance

Rated capacity Q in kg Standard load centre distance D in mm

400 500 600 900 1 200

0 < 1 000 X

≥ 1 000 < 5 000 X

≥ 5 000 ≤ 10 000 X

> 10 000 < 20 000 X X X

≥ 20 000 < 25 000 X X

≥ 25 000 X

RTVR tractors may be rated for special applications with load centres related to those applications which may be

different from those listed in Table 1.

3.8

axle oscillation lock

mechanism designed to prevent oscillation of an axle to improve RTVR tractor stability

3.9

stabilising device

extendable and/or pivoting mechanical support used to improve stability of a RTVR tractor when

stationary

3.10

lateral levelling

changing the lateral inclination angle between the chassis and the ground to ensure the boom operates

in a vertical plane even when the RTVR tractor is positioned on a side slope

3.11

fork

device comprising two or more solid fork arms, each consisting of a shank (vertical portion) and blade,

which is hook- or shaft-mounted, fitted on the carriage and usually adjusted manually

3.12

boom

pivoting support member that permits horizontal and vertical positioning of the load or attachment

3.13

crab steering mode

steering mode where all wheels of the RTVR tractor steer in the same direction

3.14

normal operating position

position specified by the manufacturer in which the operator is able to control the RTVR tractor

operations, including load handling functions

Note 1 to entry: Other positions may be necessary if it is not possible to control all the functions of the RTVR

tractor from a single position.

[SOURCE: ISO 10896-1:2012, 3.16, 3.16, modified – Truck was replaced with RTVR tractor]

3.15

quick coupler

device fitted at the end of the boom to mount interchangeable attachments to facilitate quick

interchange of attachment

Note 1 to entry: Quick coupler was previously called attachment bracket in EN 1459-1.

3.16

boom float

control mode that uses gravity to allow an attachment at the end of the boom to follow a contour (e.g.

the ground)

3.17

maximum working pressure

maximum pressure in the hydraulic circuit during normal operation

Note 1 to entry: Source ISO 10972-3:2003, 3.2, modified.

3.18

level ground

ground with a gradient of (0 ± 2)%

3.19

permanently mounted equipment

PME

part of the RTVR tractor not covered by the tractor regulation, intended to handle loads, equipped with

a telescopic lifting means (pivoted boom) not intended to be removed during normal use, on which a

load handling device (e.g., carriage and fork arms) is fitted

Note 1 to entry: PME includes for example: boom, control of the boom, stabilizer, lighting.

4 Safety requirements and/or protective measures

4.1 General

4.1.1 Introduction

RTVR tractors shall comply with the safety requirements and/or protective measures of this clause. In

addition, the RTVR tractor shall be designed according to the principles of EN ISO 12100 for relevant

but not significant hazards, which are not dealt with by this standard.

4.1.2 Sharp edges and acute angles

Not covered by this document.

NOTE Dealt with in Interior fittingsDelegated Act 2015/208 Annex XIII (interior fittings), and in Delegated

Act 1322/2014 Annex XXIV (protection mechanical hazards)

4.1.3 Stored energy components

Components that store energy and can cause a risk of injury during removal or disassembly, e.g.

hydraulic accumulators and spring-applied brakes, shall be provided with a means to release the energy

before removal or disassembly and shall be marked according to 6.2.8.

Verification by type-test.

4.2 Starting/moving

4.2.1 Unauthorised starting

Not covered by this document.

NOTE Dealt with in Delegated Act 2015/208 Annex XVIII

4.2.2 Stopping system

Not covered by this document.

NOTE Dealt with in Delegated Act 1322/2014 Annex XXIII par. 4

4.2.3 Unintended movement

RTVR tractors shall be fitted with a device that prevents the engine being started while the drive-

system is engaged. When the drive system direction control is in neutral, provisions shall be made to

locate and maintain it in its neutral position. This device shall comply with Table 2.

Verification by functional test.

NOTE Delegated Act 1322/2014 Annex XXIII par. 3 - > equivalent

4.2.4 Uncontrolled motion

Means shall be provided to prevent the RTVR tractor from moving from rest on level ground until the

drive system has been engaged. These means shall comply with Table 2.

Verification by functional test.

4.2.5 Powered travel movement

Means shall be provided to prevent powered travel when the operator is not at the normal operator’s

position. Powered travel shall not occur automatically when the operator returns to the normal

operator’s position without an additional operation, e.g. by requiring resetting the direction control.

Application of the parking brake shall engage transmission in neutral, except on RTVR tractors with

hydro-static transmission.

The release of parking brake shall not engage the transmission automatically

NOTE On RTVR tractors with hydro-static transmission, the transmission system achieves the same objective.

Verification by functional test.

Means to fulfil these requirements shall comply with Table 2.

On starting a reverse movement, an audible alarm complying with the requirements of ISO 9533 shall

be given for at least 1 s.

Verification by measurement.

4.2.6 Non-activation of the parking brake

Means to fulfil this requirement shall comply with Table 2.

NOTE Delegated Act 1322/2014 Annex XXIII Clause 9.1 - > equivalent BUT no PL

Verification by functional test.

4.3 Brakes

4.3.1 General

Not covered by this document

NOTE Dealt with in Delegated Act RVBR 2015/68

4.3.2 Failure of energy supply

Not covered by this document

NOTE Dealt with in Delegated Act RVBR 2015/68

4.4 Electrical and electronic systems

4.4.1 General

Not covered by this document.

Verification by design-check.

NOTE EN 1175-2:1998+A1:2010, 5.1 is identical to Delegated Act 1322/2014 Annex XXVIII section 4, 5.2 is

identical to Delegated Act 2015/208 Annex XXIV

4.4.2 Safety related parts of control systems

Safety related parts of control systems shall comply with PL (see EN ISO 13849-1) or SIL (see

r

EN 62061) according to Table 2.

Verification by design-check.

NOTE Guidance can be taken from the complete risk assessment of safety related parts of control systems for

variable-reach trucks in CEN/TR 1459-6.

4.4.3 Degree of protection

Depending on the location/installation of electrical and electronic components, the following degrees of

protection are required:

a) all components installed exterior to the RTVR tractor or directly exposed to the environment shall

have a minimum degree of protection that corresponds to IP 56 (according to EN 60529:1991);

b) all components installed in the operator's enclosed cab or protected against the environment shall

have a minimum degree of protection that corresponds to IP 43 (according to EN 60529:1991).

Verification by design-check.

4.4.4 Identification of wiring

The RTVR tractor shall comply with EN 1175-2:1998+A1:2010, 5.4.

Verification by visual examination and design-check.

This requirement does not apply to electrical circuits of anti-theft systems, when fitted.

4.4.5 Over-current protective devices

Not covered by this document.

Verification by design-check.

NOTE EN 1175-2:1998+A1:2010, 5.5 is identical to Delegated Act 2015/208 Annex XXIV, Clause 1.1.2

4.4.6 Batteries

Not covered by this document

Verification by design-check.

NOTE Delegated Act 1322/2014 Annex XXVIII is equivalent

4.4.7 Battery disconnection

Not covered by this document.

NOTE EN 1175-2:1998+A1:2010, 5.1.3 is identical to Delegated Act 2015/208 Item 4, Annex XXVIII

For marking, see 6.2.10.

4.5 Controls

4.5.1 General

4.5.1.1 General

Not covered by this document.

NOTE equivalent to Delegated Act 1322/2014 Annex XXIII Paragraph1

a) Means shall be provided to prevent any possibility of actuating controls of powered movement if

the operator is not at an operating position (e.g. protection by door, guard or by locking systems).

b) remote operator controlled systems fitted to RTVR tractors shall comply with the relevant

requirements of ISO 15817:2012 with exception to subclause 4.7 remote control system EMC

testing (see 4.19 of the present document).

Verification by design-check.

4.5.1.2 Multiple operating positions

Only if more than one operating position is fitted, an emergency stop at each operating position shall be

fitted.

Verification by visual examination and design-check.

The use of the controls at one operating position shall preclude the use of the controls at other

operating positions, except the emergency stop, which shall be operable from all operating positions.

Means to fulfil this requirement shall comply with Table 2.

Verification by functional test.

Emergency stop shall comply with EN ISO 13850.

Verification by design-check.

4.5.1.3 Inadvertent activation

Controls, that can cause a hazard due to inadvertent activation, shall be so arranged, deactivated or

guarded as to minimize this risk. If a deactivation device is used for this purpose, it shall either be self-

acting or acting by compulsory activation of the relevant device and it shall comply with Table 2.

Verification by design-check.

NOTE equivalent to Delegated Act 1322/2014 Annex XXIII Clause 1

4.5.2 Differential locking

If a manual differential lock is fitted, the control shall be so arranged to allow the operator to activate

the disengagement of the differential lock when travelling.

If the RTVR tractor is equipped with a pedal-operated differential lock, depressing the pedal shall lock

the differential.

Verification by type-test.

NOTE clause in addition to Delegated Act 1322/2014 Annex XXIII (which recalls ISO 15077).

4.5.3 Steering controls

4.5.3.1 General

Not covered by this document.

NOTE RVFSR Annex V is equivalent.

4.5.3.2 Steering direction

a) Consistency of steering wheel and the movement of the RVTR tractor when travelling in the

forward direction is not covered by this document.

NOTE Delegated Act 2015/208 Annex V is equivalent.

On RTVR tractors with a crab-steering mode, clockwise rotation of the steering wheel shall move

the RTVR tractor to the right when the RTVR tractor is travelling in the forward direction and to the

left when travelling in the reverse direction.

b) Consistency of single lever (if fitted) and the movement of the RVTR tractor when travelling in the

forward direction is not covered by this document.

NOTE Delegated Act 2015/208 Annex V is practically equivalent (referred to track-laying tractors)

c) On RTVR tractors with reversible control unit or dual controls, the requirements of 4.5.3.2 a) and b)

shall be met when the operator is facing the intended direction of forward travel.

Verification by functional test.

4.5.3.3 Failure of power supply

Not covered by this document.

NOTE Delegated Act 2015/208 Annex V is equivalent or more stringent

4.5.3.4 Strength of components

Not covered by this document.

NOTE is equivalent to Delegated Act 2015/208 Annex V Clause 3.2.2.

4.5.4 Load handling controls

4.5.4.1 General

Controls shall return to neutral when released and stop load movements, except where otherwise

specified in this standard.

Verification by functional-test.

The controls for the load handling functions shall be separated from the driving controls except the

travel direction and/or gear control, which may be separated or not.

Verification by visual examination.

4.5.4.2 Controls with detents or maintained engagement

4.5.4.2.1 General

By exception to 4.5.4.1, the boom float control and the auxiliary hydraulic control(s) (e.g. for concrete

mixers, brooms, augers) may be equipped with a control to maintain engagement of the function. These

controls shall comply with Table 2.

Verification by design-check.

A visual indication that this control is activated shall be provided to the operator.

Verification by visual examination.

The control mode shall:

— be automatically deactivated when the RTVR tractor is switched off and not be automatically

activated when the RTVR tractor is switched on; or

— prevent the RTVR tractor from being restarted until the control mode is deactivated.

Verification by functional test.

4.5.4.2.2 Boom float control

For RTVR tractors equipped with boom float control, protection shall be provided against unintended

lowering of the boom.

Verification by design-check.

In addition to 4.5.4.2.1, the boom float control mode shall be automatically deactivated when the boom

raising/lowering control is operated. Means to fulfil this requirement shall comply with Table 2.

Verification by functional-test.

4.5.5 Multi-function controls

Not covered by this document.

NOTE 1 is equivalent to Delegated Act 1322/2014 Annex XXIII Clause 2

NOTE 2 Guidance for means to fulfil this requirement are given in Table 2.

4.5.6 Stabilizing device control

For RTVR tractors equipped with stabilizing devices:

— each stabilizing device shall be controlled independently;

— the left control shall operate the left stabilizing device, and the right control shall operate the right

stabilizing device; a middle position may operate both stabilizing devices;

Verification by functional test.

— controls for deployment of the stabilizing devices shall be clearly marked (symbols 2074, 2075,

1291, 1536, 0750A, 0746A, 2078, 2080 of ISO 7000);

— controls for retraction of the stabilizing devices shall be clearly marked (symbols 2073, 2076, 1292,

1537, 0751A, 0747A, 2079, 2081 of ISO 7000).

Verification by visual examination.

4.5.7 Sway/levelling control

For RTVR tractors equipped with operator-controlled lateral levelling, operating the control to the left

shall cause the RTVR tractor to sway to the left, and operating the control to the right shall cause the

RTVR tractor to sway to the right.

Verification by functional test.

4.5.8 Axle oscillation

For RTVR tractors equipped with axle oscillation locking, the lock/unlock shall be automatic. Means to

fulfil this requirement shall comply with Table 2. It can be possible to manually lock the axle oscillation

locking.

For RTVR tractors equipped with axle oscillation locking, a visual indication when the axle is locked

shall be provided to the operator

When the axle oscillation locking is manual, lock/unlock control(s) shall be clearly marked (symbols

2872 and 2873 of ISO 7000).

Verification by visual examination.

4.6 Power systems and accessories

4.6.1 Exhaust system

Not covered by this document.

NOTE is equivalent to Delegated Act 1322/2014 Article 24 in Annex XXI, and power systems and accessories

are covered by Delegated Act 2015/208 Annex XXIV

4.6.2 Cooling system

The cooling system of the power system shall be designed so as to prevent air flow through the system

from being directed at the operator and passenger position(s) if any, or so that the operator and

passenger position(s) are shielded from air flow through the system.

Verification by design check.

The temperature of the shielding means adjacent to the operator and passenger position(s) shall not

exceed 60 °C.

Verification by measurement.

4.6.3 Tanks and pressure vessels

4.6.3.1 General

Not covered by this document.

NOTE Delegated Act 2015/208 Annex XXV Article 29 is equivalent.

4.6.3.2 Filler openings

Not covered by this document.

NOTE is equivalent to Delegated Act 2015/208 Annex XXV, and Delegated Act 1322/2014 Annex XXVIII Item

1.

4.6.3.3 Fuel tanks

4.6.3.3.1 Metal fuel tanks

Not covered by this document.

NOTE Delegated Act 1322/2014 Annex XXVIII Item 1 gives requirements for metal fuel tanks.

4.6.3.3.2 Non-metallic fuel tanks

If constructed with non-metallic material, the fuel tank shall comply with the requirements in

ISO 21507.

Verification by design check and/or type-test.

4.6.3.4 Pressure vessels

Simple pressure vessels shall comply with ISO 16528-1 and ISO 16528-2.

Verification by design-check and type-test.

4.7 Stabilizing devices

When stabilizing devices are provided

— Stabilizing devices shall be fitted with means, in accordance with Table 2, which keep them in

position in case of hose failure or oil leakage.

Verification by design check.

— A visual indication shall be given to the operator (e.g. light in the dash-board, painted marks visible

from the operator’s position) when each stabilizing device is in the travelling position as defined by

the manufacturer when moving the RTVR tractor. Means to fulfil this requirement shall comply

with Table 2.

Verification by visual examination.

— Each stabilizing device shall be equipped with a footplate that is self-aligning in at least one plane.

Verification by visual examination.

— A visual indication shall be given to the operator (e.g. light in the dash-board, painted marks visible

from the operator’s position) when each stabilizing device is deployed to level and support the

RTVR tractor in conformity with the load chart(s). Means to fulfil this requirement shall comply

with Table 2.

Verification by visual examination.

Table 2 — Safety related parts of control systems

Paragraph of standard PL SIL

r

(EN 62061)

(EN ISO 13849-1)

4.2.3 Unintended movement b 1

4.2.4 Uncontrolled motion b 1

4.2.5 Powered travel movement c 1

Means shall be provided to prevent powered travel when the operator is

not at the normal operator’s position

4.2.5 Powered travel movement b 1

Powered travel shall not occur automatically when the operator returns to

the normal operator’s position without an additional operation, e.g. by

requiring resetting the direction control

4.2.5 Powered travel movement c 1

Application of the parking brake shall apply neutral travel control, except

on RTVR tractors with hydro-static transmission.

4.2.6 Non activation of the parking brake b 1

4.5.1.2 Multiple operating positions c 1

the use of the controls at one operator’s position shall preclude the use of

the controls at other operator’s positions

4.5.1.3 Inadvertent activation b 1

(only when the deactivation device is provided)

4.5.4.2.1 Control with detents b 1

4.5.4.2.2 Boom float control c 1

4.5.5 Multi-function controls – 2nd para b 1

Visual indication shall be provided to inform the operator of the selected

mode(s) of operation

4.5.8 Axle oscillation b 1

For RTVR tractors equipped with axle oscillation locking, the lock/unlock

shall be automatic.

4.7 Stabilizing devices 1st indent b 1

- Stabilizing devices shall be fitted with interlocking devices, e.g. load

holding valves which keep them in position in case of hose failure or oil

leakage

4.7 Stabilizing devices 2nd indent b 1

A visual indication shall be given to the operator (e.g. light in the dash-

board, painted marks visible from the operator’s station) when each

stabilizing device is in the travelling position as defined by the

manufacturer when moving the RTVR tractor.

4.7 Stabilizing devices 4th indent b 1

An indication shall be given to the operator (e.g. sensors, painted marks

visible from the operator’s station) when each stabilizing device is

extended to level and/or support the RTVR tractor in conformity with the

load chart(s).

Verification of Table 2 by design check.

For safety functions that comprise mechanical parts only, no specific performance level is necessary.

4.8 Design requirements for maintenance purposes

4.8.1 General

Not covered by this document

NOTE is equivalent to Delegated Act 2015/208 Annex II.

4.8.2 Boom support device

Where maintenance procedures described in the information for maintenance can only be performed

with the boom in a raised position, the boom shall be mechanically secured with a boom support device

designed to withstand at least 1,5 times the mass of the boom and the carriage with forks.

Verification by design-check.

The boom support device, excluding the attaching parts, shall be red on all machines except where the

machine colour is red, in which case the boom support device shall be yellow.

This boom support device(s) shall be provided with the RTVR tractor and permanently affixed to the

RTVR tractor or be stored in a safe place on the RTVR tractor.

Verification by visu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...