SIST EN 1459-1:2018+A1:2020

(Main)Rough-terrain trucks - Safety requirements and verification - Part 1: Variable-reach trucks

Rough-terrain trucks - Safety requirements and verification - Part 1: Variable-reach trucks

This European Standard specifies the safety requirements of self-propelled variable-reach rough-terrain trucks (hereafter referred to as trucks), intended to handle loads, equipped with a telescopic lifting means (pivoted boom), on which a load handling device (e.g. carriage and fork arms) is fitted.

For the purpose of this standard, rough-terrain variable-reach trucks are designed to transport, lift and place loads and can be driven on unimproved terrain.

Fork arms are considered to be part of the truck. Trucks can also be equipped with a variety of attachments (e.g. bale spikes, mowers, sweepers).

This European Standard deals with all the significant hazards, hazardous situations and events relevant to the trucks when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A).

This European Standard does not apply to:

- slewing variable reach rough terrain trucks covered by EN 1459-2;

- industrial variable reach trucks covered by EN ISO 3691-2;

- lorry-mounted variable reach trucks;

- variable reach trucks fitted with tilting or elevating operator position;

- mobile cranes covered by EN 13000;

- machines designed primarily for earth moving, even if their buckets and blades are replaced with forks (see EN 474 series);

- trucks designed primarily with variable length load suspension elements (e.g. chain, ropes) from which the load may swing freely in all directions;

- trucks fitted with personnel/work platforms, designed to move persons to elevated working positions;

- trucks designed primarily for container handling;

- trucks on tracks;

- trucks with articulated chassis;

- attachments (covered by prEN 1459-5).

This European Standard does not address hazards linked to:

- hybrid power systems;

- gas power system;

- gasoline engine system;

- battery power system;

- tractor specific devices (e.g. PTO).

This European Standard does not address hazards which may occur:

a) when handling suspended loads which may swing freely (additional requirements are given in prEN 1459-4 (in preparation));

b) when using trucks on public roads;

c) when operating in potentially explosive atmospheres;

d) when operating underground;

e) when towing trailers;

f) when fitted with a personnel work platform (additional requirements are given in EN 1459-3);

g) when using cruise-control.

This European Standard does not provide a method of calculation for fatigue and strength of material.

This document is not applicable to trucks manufactured before the date of its publication.

Geländegängige Stapler - Sicherheitstechnische Anforderungen und Verifizierung - Teil 1: Stapler mit veränderlicher Reichweite

Diese Europäische Norm legt die sicherheitstechnischen Anforderungen an kraftbetriebene geländegängige Stapler mit veränderlicher Reichweite (nachfolgend als Stapler bezeichnet) fest, welche zur Handhabung von Lasten vorgesehen sind, ausgestattet mit einer teleskopierbaren Hebevorrichtung (drehbarer Hubarm), an der eine Lastaufnahmeeinrichtung (z. B. Gabelträger und Gabelzinken) angebracht ist.

Zum Zwecke dieser Norm werden geländegängige Stapler mit veränderlicher Reichweite als Fahrzeuge ausgeführt, welche Lasten transportieren, heben und absetzen, sowie auf unbefestigten Untergründen fahren können.

Gabelzinken gelten als Teile des Staplers. Stapler können auch mit einer Vielzahl Zusatzeinrichtungen (z. B. Ballenspieße, Mäher, Räumgeräten) ausgestattet sein.

Diese Europäische Norm behandelt die für die Stapler zutreffenden signifikanten Gefährdungen, Gefährdungssituationen und -ereignisse, wenn die Stapler bestimmungsgemäß und unter Bedingungen, die vom Hersteller als Fehlanwendung vernünftigerweise vorhersehbar sind, verwendet werden (siehe Anhang A).

Diese Europäische Norm gilt nicht für:

- schwenkbare geländegängige Stapler mit veränderlicher Reichweite, die in EN 1459 2 behandelt werden;

- Flurförderzeuge mit veränderlicher Reichweite, die in EN ISO 3691 2 behandelt werden;

- Mitnehmstapler mit veränderlicher Reichweite;

- Stapler mit veränderlicher Reichweite, die mit neigbarem oder hebbarem Bedienerplatz ausgestattet sind;

- Mobilkräne, die in EN 13000 behandelt werden;

- Maschinen, die in erster Linie für Erdbewegungen ausgelegt sind, auch wenn deren Schaufeln und Planierschilde durch Gabelzinken ersetzt wurden (siehe Normenreihe EN 474);

- Stapler, die in erster Linie mit Lastaufnahmeelementen veränderlicher Länge (z. B. Kette, Seile) ausgestattet sind, bei denen die Last in alle Richtungen frei pendeln kann;

- Stapler mit Arbeitsbühnen, die dafür ausgelegt sind, Personen zu höher gelegenen Arbeitspositionen zu heben;

- Stapler, die in erster Linie für die Handhabung von Containern ausgelegt sind;

- schienengebunde Stapler;

- Stapler mit Knicklenkung;

- !Zusatzeinrichtungen".

Diese Europäische Norm befasst sich nicht mit Gefährdungen in Verbindung mit:

- hybridbetriebenen Systemen;

- gasbetriebenen Systemen;

- benzinbetriebenen Systemen;

- batteriebetriebenen Systemen;

- traktorspezifischen Vorrichtungen (z. B. PTO).

Diese Europäische Norm befasst sich nicht mit Gefährdungen, die vorkommen können:

a) durch Befördern hängender Lasten, die frei pendeln können (zusätzliche Anforderungen sind in prEN 1459 4 angegeben (in Vorbereitung));

b) durch Benutzung von Staplern auf öffentlichen Straßen;

c) beim Betrieb in explosionsfähigen Atmosphären;

d) beim Betrieb unter Tage;

e) beim Schleppen von Anhängern;

f) beim Anbringen einer Arbeitsbühne (zusätzliche Anforderungen sind in EN 1459 3 gegeben);

g) bei Verwendung der Geschwindigkeitsregelung.

Diese Europäische Norm stellt keine Verfahren zur Berechnung von Werkstoffermüdung und festigkeit zur Verfügung.

Dieses Dokument gilt nicht für Stapler, die vor Veröffentlichung dieser EN hergestellt wurden.

Chariots tout-terrain - Prescriptions de sécurité et vérification - Partie 1 : Chariots à portée variable

La présente Norme européenne spécifie les prescriptions de sécurité des chariots tout-terrain automoteurs à portée variable (ci-après désignés « chariots »), destinés à manutentionner des charges, équipés de moyens de levage télescopiques (flèche relevable), sur lesquels un dispositif porte-charge est monté (par exemple, un tablier porte-équipement et des bras de fourche).

Pour les besoins de la présente norme, les chariots tout-terrain à portée variable sont conçus pour transporter, soulever et placer des charges, et peuvent être conduits sur des sols non aménagés.

Les bras de fourche sont considérés comme partie du chariot. Les chariots peuvent être également équipés d'une grande variété d'accessoires (par exemple, fourche à ballots, faucheuse, balayeuse).

La présente Norme européenne traite de tous les phénomènes dangereux significatifs, des situations et évènements dangereux pertinents pour les chariots lorsqu'ils sont utilisés comme prévu et dans les conditions de mauvaise utilisation qui sont raisonnablement prévisibles par le fabricant (voir Annexe A).

La présente Norme européenne ne s'applique pas :

- aux chariots tout-terrain à portée variable rotatifs couverts par l'EN 1459 2 ;

- aux chariots industriels à portée variable traités dans l'EN ISO 3691 2 ;

- aux chariots à portée variable embarqués sur porteurs routiers ;

- aux chariots à portée variable avec poste de conduite inclinable ou élevable ;

- aux grues mobiles couvertes par l'EN 13000 ;

- aux machines conçues principalement pour le terrassement, même si leurs godets et leurs lames sont remplacés par des fourches (voir la série de normes EN 474) ;

- aux chariots conçus principalement avec des éléments de suspension de la charge à longueur variable (tels que chaînes, câbles) et permettant à la charge d'osciller librement dans toutes les directions ;

- aux chariots équipés de plates-formes de travail pour le personnel, conçues pour déplacer les personnes vers des positions de travail surélevées ;

- aux chariots conçus principalement pour la manutention de conteneurs ;

- aux chariots sur chenilles ;

- aux chariots à châssis articulé ;

- aux accessoires.

La présente Norme européenne ne traite pas des phénomènes dangereux liés aux :

- systèmes à source d'énergie hybride ;

- système à source d'énergie gaz ;

- système à moteur à essence ;

- système alimentés par batteries ;

- dispositifs spécifiques aux tracteurs (par exemple, PTO).

La présente Norme européenne ne traite pas des phénomènes dangereux pouvant apparaître :

a) lors de la manutention de charges suspendues qui peuvent se balancer librement (les prescriptions supplémentaires sont données dans le prEN 1459-4 (en cours d’élaboration)) ;

b) lors de l'utilisation des chariots sur les voies publiques ;

c) lors d’une utilisation en atmosphères explosibles ;

d) lors de travaux souterrains ;

e) lors de la traction de remorques ;

f) lorsque les chariots sont équipés d’une plate-forme de personnel/travail (des prescriptions supplémentaires sont données dans l’EN 1459-3) ;

g) lors de l'utilisation d'un régulateur de vitesse.

La présente Norme européenne ne fournit pas de méthode de calcul de la fatigue et de la résistance du matériau.

Le présent document n'est pas applicable aux chariots fabriqués avant la date de sa publication.

Vozila za talni transport - Terenska vozila - Varnostne zahteve in preverjanje - 1. del: Vozila z mehanizmom za dviganje s spremenljivim dosegom

General Information

- Status

- Withdrawn

- Publication Date

- 08-Jun-2020

- Withdrawal Date

- 08-Sep-2025

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 08-Sep-2025

- Due Date

- 01-Oct-2025

- Completion Date

- 09-Sep-2025

Relations

- Effective Date

- 04-May-2022

- Effective Date

- 13-Nov-2019

- Effective Date

- 13-Nov-2019

Frequently Asked Questions

SIST EN 1459-1:2018+A1:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Rough-terrain trucks - Safety requirements and verification - Part 1: Variable-reach trucks". This standard covers: This European Standard specifies the safety requirements of self-propelled variable-reach rough-terrain trucks (hereafter referred to as trucks), intended to handle loads, equipped with a telescopic lifting means (pivoted boom), on which a load handling device (e.g. carriage and fork arms) is fitted. For the purpose of this standard, rough-terrain variable-reach trucks are designed to transport, lift and place loads and can be driven on unimproved terrain. Fork arms are considered to be part of the truck. Trucks can also be equipped with a variety of attachments (e.g. bale spikes, mowers, sweepers). This European Standard deals with all the significant hazards, hazardous situations and events relevant to the trucks when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A). This European Standard does not apply to: - slewing variable reach rough terrain trucks covered by EN 1459-2; - industrial variable reach trucks covered by EN ISO 3691-2; - lorry-mounted variable reach trucks; - variable reach trucks fitted with tilting or elevating operator position; - mobile cranes covered by EN 13000; - machines designed primarily for earth moving, even if their buckets and blades are replaced with forks (see EN 474 series); - trucks designed primarily with variable length load suspension elements (e.g. chain, ropes) from which the load may swing freely in all directions; - trucks fitted with personnel/work platforms, designed to move persons to elevated working positions; - trucks designed primarily for container handling; - trucks on tracks; - trucks with articulated chassis; - attachments (covered by prEN 1459-5). This European Standard does not address hazards linked to: - hybrid power systems; - gas power system; - gasoline engine system; - battery power system; - tractor specific devices (e.g. PTO). This European Standard does not address hazards which may occur: a) when handling suspended loads which may swing freely (additional requirements are given in prEN 1459-4 (in preparation)); b) when using trucks on public roads; c) when operating in potentially explosive atmospheres; d) when operating underground; e) when towing trailers; f) when fitted with a personnel work platform (additional requirements are given in EN 1459-3); g) when using cruise-control. This European Standard does not provide a method of calculation for fatigue and strength of material. This document is not applicable to trucks manufactured before the date of its publication.

This European Standard specifies the safety requirements of self-propelled variable-reach rough-terrain trucks (hereafter referred to as trucks), intended to handle loads, equipped with a telescopic lifting means (pivoted boom), on which a load handling device (e.g. carriage and fork arms) is fitted. For the purpose of this standard, rough-terrain variable-reach trucks are designed to transport, lift and place loads and can be driven on unimproved terrain. Fork arms are considered to be part of the truck. Trucks can also be equipped with a variety of attachments (e.g. bale spikes, mowers, sweepers). This European Standard deals with all the significant hazards, hazardous situations and events relevant to the trucks when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A). This European Standard does not apply to: - slewing variable reach rough terrain trucks covered by EN 1459-2; - industrial variable reach trucks covered by EN ISO 3691-2; - lorry-mounted variable reach trucks; - variable reach trucks fitted with tilting or elevating operator position; - mobile cranes covered by EN 13000; - machines designed primarily for earth moving, even if their buckets and blades are replaced with forks (see EN 474 series); - trucks designed primarily with variable length load suspension elements (e.g. chain, ropes) from which the load may swing freely in all directions; - trucks fitted with personnel/work platforms, designed to move persons to elevated working positions; - trucks designed primarily for container handling; - trucks on tracks; - trucks with articulated chassis; - attachments (covered by prEN 1459-5). This European Standard does not address hazards linked to: - hybrid power systems; - gas power system; - gasoline engine system; - battery power system; - tractor specific devices (e.g. PTO). This European Standard does not address hazards which may occur: a) when handling suspended loads which may swing freely (additional requirements are given in prEN 1459-4 (in preparation)); b) when using trucks on public roads; c) when operating in potentially explosive atmospheres; d) when operating underground; e) when towing trailers; f) when fitted with a personnel work platform (additional requirements are given in EN 1459-3); g) when using cruise-control. This European Standard does not provide a method of calculation for fatigue and strength of material. This document is not applicable to trucks manufactured before the date of its publication.

SIST EN 1459-1:2018+A1:2020 is classified under the following ICS (International Classification for Standards) categories: 53.060 - Industrial trucks. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1459-1:2018+A1:2020 has the following relationships with other standards: It is inter standard links to SIST EN 1459-1:2025, SIST EN 1459-1:2018/kprA1:2019, SIST EN 1459-1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1459-1:2018+A1:2020 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 1459-1:2018+A1:2020 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2020

Vozila za talni transport - Terenska vozila - Varnostne zahteve in preverjanje - 1.

del: Vozila z mehanizmom za dviganje s spremenljivim dosegom

Rough-terrain trucks - Safety requirements and verification - Part 1: Variable-reach

trucks

Geländegängige Stapler - Sicherheitstechnische Anforderungen und Verifizierung - Teil

1: Stapler mit veränderlicher Reichweite

Chariots tout-terrain - Prescriptions de sécurité et vérification - Partie 1 : Chariots à

portée variable

Ta slovenski standard je istoveten z: EN 1459-1:2017+A1:2020

ICS:

53.060 Industrijski tovornjaki Industrial trucks

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1459-1:2017+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2020

EUROPÄISCHE NORM

ICS 53.060 Supersedes EN 1459-1:2017

English Version

Rough-terrain trucks - Safety requirements and

verification - Part 1: Variable-reach trucks

Chariots tout-terrain - Prescriptions de sécurité et Geländegängige Stapler - Sicherheitstechnische

vérification - Partie 1 : Chariots à portée variable Anforderungen und Verifizierung - Teil 1: Stapler mit

veränderlicher Reichweite

This European Standard was approved by CEN on 1 May 2017 and includes Amendment 1 approved by CEN on 25 November

2019.

This European Standard was corrected and reissued by the CEN-CENELEC Magagement Centre on 11 March 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1459-1:2017+A1:2020 E

worldwide for CEN national Members.

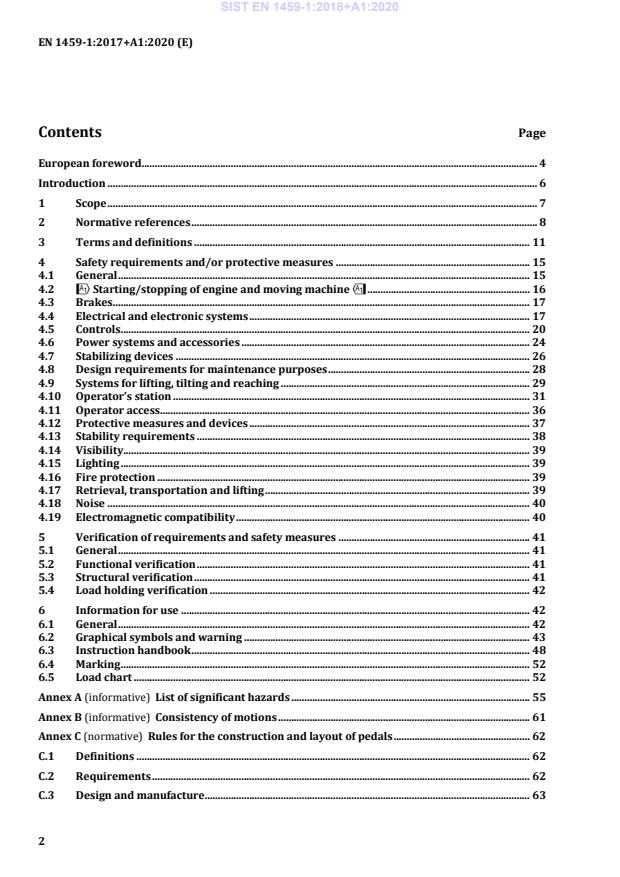

Contents Page

European foreword . 4

Introduction . 6

1 Scope . 7

2 Normative references . 8

3 Terms and definitions . 11

4 Safety requirements and/or protective measures . 15

4.1 General . 15

4.2 !Starting/stopping of engine and moving machine" . 16

4.3 Brakes. 17

4.4 Electrical and electronic systems . 17

4.5 Controls . 20

4.6 Power systems and accessories . 24

4.7 Stabilizing devices . 26

4.8 Design requirements for maintenance purposes . 28

4.9 Systems for lifting, tilting and reaching . 29

4.10 Operator’s station . 31

4.11 Operator access. 36

4.12 Protective measures and devices . 37

4.13 Stability requirements . 38

4.14 Visibility. 39

4.15 Lighting . 39

4.16 Fire protection . 39

4.17 Retrieval, transportation and lifting . 39

4.18 Noise . 40

4.19 Electromagnetic compatibility . 40

5 Verification of requirements and safety measures . 41

5.1 General . 41

5.2 Functional verification . 41

5.3 Structural verification . 41

5.4 Load holding verification . 42

6 Information for use . 42

6.1 General . 42

6.2 Graphical symbols and warning . 43

6.3 Instruction handbook . 48

6.4 Marking . 52

6.5 Load chart . 52

Annex A (informative) List of significant hazards . 55

Annex B (informative) Consistency of motions . 61

Annex C (normative) Rules for the construction and layout of pedals . 62

C.1 Definitions . 62

C.2 Requirements . 62

C.3 Design and manufacture . 63

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 65

Bibliography . 69

European foreword

This document (EN 1459-1:2017+A1:2020) has been prepared by Technical Committee CEN/TC 150

“Industrial Trucks - Safety”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2020 and conflicting national standards shall

be withdrawn at the latest by February 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes !EN 1459-1:2017".

This document includes Amendment 1, approved by CEN on 2019-11-25.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

!Together with EN ISO 3691-2:2016 and prEN 16307-2:2017, EN 1459-1:2017 superseded

EN 1459:1998+A3:2012.

In comparison with the previous edition EN 1459:1998+A3:2012, the following significant changes

have been made:

— industrial variable-reach trucks have been removed from the scope and are dealt with in

EN ISO 3691-2 and EN 16307-2;

— annexes giving stability tests requirements have been removed; this standard refers to the

ISO 22915 series for stability tests;

— LPG-engine powered trucks have been removed from the scope;

— performance level requirements for safety functions have been added in a table;

— ergonomic requirements have been added;

— format and requirements have been influenced by the equivalent ISO standard in order to prepare

the global relevance.

The most significant changes introduced by Amendment 1 FprEN 1459-1:2019 leading to the new

version EN 1459-1:2017+A1:2020 of edition EN 1459-1:2017 are:

— different conditions for the test to determine if the truck can still be controlled in case of failure of

the hydraulic steering;

— incorporation in this standard of the relevant requirements applicable to electric circuits, instead of

referencing to EN 1175-2:1998+A1:2010;

— exclusion of some requirements of EN ISO 4413:2010, which were not relevant or applicable to

trucks;

— other minor changes, mainly editorial clarifications of existing requirements."

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directives, see informative Annex ZA, which is an integral part of this

document.

EN 1459 consists of the following parts, under the general title Rough-terrain trucks — Safety

requirements and verification:

— Part 1: Variable-reach trucks

— Part 2: Slewing variable-reach trucks

— Part 3: Interface between the variable-reach truck and the work platform

— Part 4: Additional requirements for variable-reach trucks handling suspended loads (in preparation)

— Part 5: Additional requirements for attachments and attachment interface

— Part 6: Application of EN ISO 13849-1 to slewing and non-slewing variable-reach rough-terrain

trucks (Technical Report)

— Part 7: Test method and determination of noise emission (in preparation)

— Part 8: Variable-reach tractors (Technical Specification)

NOTE Part 7 will be developed in line with the development of the revision of the Outdoor noise directive.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

This European Standard covers general safety requirements and the means for verification of these

requirements for rough-terrain variable-reach trucks.

All quantities are in SI units, and this includes metric units.

Considering the technical improvements to the previous version of EN 1459, a transition period of

12 months is permitted after the date of publication, such that manufacturers can develop their

products sufficiently to meet the requirements of this European Standard.

This document is a type C standard as stated in EN ISO 12100.

This document is of relevance, in particular, for the following stakeholder groups representing the

market players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance etc.)

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events

are covered are indicated in the Scope of this document.

When provisions of this type C standard are different from those which are stated in type A or B

standards, the provisions of this type C standard take precedence over the provisions of the other

standards, for machines that have been designed and built according to the provisions of this type C

standard.

1 Scope

This European Standard specifies the safety requirements of self-propelled variable-reach rough-

terrain trucks (hereafter referred to as trucks), intended to handle loads, equipped with a telescopic

lifting means (pivoted boom), on which a load handling device (e.g. carriage and fork arms) is fitted.

For the purpose of this standard, rough-terrain variable-reach trucks are designed to transport, lift and

place loads and can be driven on unimproved terrain.

Fork arms are considered to be part of the truck. Trucks can also be equipped with a variety of

attachments (e.g. bale spikes, mowers, sweepers).

This European Standard deals with all the significant hazards, hazardous situations and events relevant

to the trucks when they are used as intended and under conditions of misuse which are reasonably

foreseeable by the manufacturer (see Annex A).

This European Standard does not apply to:

— slewing variable reach rough terrain trucks covered by EN 1459-2;

— industrial variable reach trucks covered by EN ISO 3691-2;

— lorry-mounted variable reach trucks;

— variable reach trucks fitted with tilting or elevating operator position;

— mobile cranes covered by EN 13000;

— machines designed primarily for earth moving, even if their buckets and blades are replaced with

forks (see EN 474 series);

— trucks designed primarily with variable length load suspension elements (e.g. chain, ropes) from

which the load may swing freely in all directions;

— trucks fitted with personnel work platforms, designed to move persons to elevated working

positions;

— trucks designed primarily for container handling;

— trucks on tracks;

— trucks with articulated chassis;

— !attachments".

This European Standard does not address hazards linked to:

— hybrid power systems;

— gas power system;

— gasoline engine system;

— battery power system;

— tractor specific devices (e.g. PTO).

This European Standard does not address hazards which may occur:

a) when handling suspended loads which may swing freely (additional requirements are given in

prEN 1459-4 (in preparation));

b) when using trucks on public roads;

c) when operating in potentially explosive atmospheres;

d) when operating underground;

e) when towing trailers;

f) when fitted with a personnel work platform (additional requirements are given in EN 1459-3);

g) when using cruise-control.

This European Standard does not provide a method of calculation for fatigue and strength of material.

This document is not applicable to trucks manufactured before the date of its publication.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

!deleted text"

prEN 1459-5:2017, Rough-terrain trucks - Safety requirements and verification - Part 5: Attachments and

attachment interface

EN 12053:2001+A1:2008, Safety of industrial trucks - Test methods for measuring noise emissions

EN 12895:2015, Industrial trucks - Electromagnetic compatibility

EN 13059:2002+A1:2008, Safety of industrial trucks - Test methods for measuring vibration

EN 13309:2010, Construction machinery - Electromagnetic compatibility of machines with internal power

supply

EN 15000:2008, Safety of industrial trucks - Self propelled variable reach trucks - Specification,

performance and test requirements for longitudinal load moment indicators and longitudinal load

moment limiters

EN 15830:2012, Rough-terrain variable reach trucks - Visibility - Test methods and verification

1)

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 62061:2005, Safety of machinery - Functional safety of safety-related electrical, electronic and

programmable electronic control systems (IEC 62061:2005)

1) This European Standard is impacted by the amendments EN 60529:1991/A1:2000 and

EN 60529:1991/A2:2013.

EN ISO 2860:2008, Earth-moving machinery - Minimum access dimensions (ISO 2860:1992)

EN ISO 2867:2011, Earth-moving machinery - Access systems (ISO 2867:2011)

EN ISO 3449:2008, Earth-moving machinery - Falling-object protective structures - Laboratory tests and

performance requirements (ISO 3449:2005)

EN ISO 3457:2008, Earth-moving machinery - Guards - Definitions and requirements (ISO 3457:2003)

EN ISO 3471:2008, Earth-moving machinery - Roll-over protective structures - Laboratory tests and

performance requirements (ISO 3471:2008)

EN ISO 4413:2010, Hydraulic fluid power - General rules and safety requirements for systems and their

components (ISO 4413:2010)

EN ISO 5353:1998, Earth-moving machinery, and tractors and machinery for agriculture and forestry -

Seat index point (ISO 5353:1995)

EN ISO 6682:2008, Earth-moving machinery - Zones of comfort and reach for controls (ISO 6682:1986,

including Amd 1:1989)

EN ISO 6683:2008, Earth-moving machinery - Seat belts and seat belt anchorages - Performance

requirements and tests (ISO 6683:2005)

EN ISO 7096:2008, Earth-moving machinery - Laboratory evaluation of operator seat vibration (ISO

7096:2000)

EN ISO 11688-1:2009, Acoustics - Recommended practice for the design of low-noise machinery and

equipment - Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2015, Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13850:2015, Safety of machinery - Emergency stop function - Principles for design (ISO

13850:2015)

EN ISO 13857:2008, Safety of machinery - Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2008)

!ISO 2328:2011, Fork-lift trucks — Hook-on type fork arms and fork arm carriages — Mounting

dimensions"

ISO 2330:2002, Fork-lift trucks - Fork arms - Technical characteristics and testing

ISO 3795:1989, Road vehicles, and tractors and machinery for agriculture and forestry - Determination of

burning behaviour of interior materials

ISO 5053-1:2015, Industrial trucks - Terminology and classification - Part 1: Types of industrial trucks

ISO 6011:2003, Earth-moving machinery - Visual display of machine operation

ISO 6016:2008, Earth-moving machinery - Methods of measuring the masses of whole machines, their

equipment and components

ISO 6292:2008, Powered industrial trucks and tractors - Brake performance and component strength

ISO 7000:2014, Graphical symbols for use on equipment - Registered symbols

ISO 9533:2010, Earth-moving machinery - Machine-mounted audible travel alarms and forward horns -

Test methods and performance criteria

ISO 10263-2:2009, Earth-moving machinery - Operator enclosure environment - Part 2: Air filter element

test method

ISO 10263-3:2009, Earth-moving machinery - Operator enclosure environment - Part 3: Pressurization

test method

ISO 10263-4:2009, Earth-moving machinery - Operator enclosure environment - Part 4: Heating,

ventilating and air conditioning (HVAC) test method and performance

ISO 11112:1995+A1:2001, Earth-moving machinery - Operator’s seat - Dimensions and requirements

ISO 12508:1994, Earth-moving machinery - Operator station and maintenance areas - Bluntness of edges

ISO 12509:2004, Earth-moving machinery - Lighting, signalling and marking lights, and reflex-reflector

devices

!ISO 13284:2003, Fork-lift trucks — Fork-arm extensions and telescopic fork arms — Technical

characteristics and strength requirements"

ISO 13333:1994, Earth-moving machinery - Dumper body support and operator’s cab tilt support devices

ISO 15817:2012, Earth-moving machinery - Safety requirements for remote operator control systems

ISO 15818:2017, Earth-moving machinery - Lifting and tying-down attachment points - Performance

requirements

ISO 15870:2000, Powered industrial trucks - Safety signs and hazard pictorials - General principles

ISO 16528-1:2007, Boilers and pressure vessels - Part 1: Performance requirements

ISO 16528-2:2007, Boilers and pressure vessels - Part 2: Procedures for fulfilling the requirements of ISO

16528-1

ISO 21507:2010, Earth-moving machinery - Performance requirements for non-metallic fuel tanks

ISO 22915-10:2008, Industrial trucks - Verification of stability - Part 10: Additional stability test for trucks

operating in the special condition of stacking with load laterally displaced by powered devices

ISO 22915-14:2010, Industrial trucks - Verification of stability - Part 14: Rough-terrain variable-reach

trucks

ISO 22915-20:2008, Industrial trucks - Verification of stability - Part 20: Additional stability test for trucks

operating in the special condition of offset load, offset by utilization

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010,

ISO 5053-1:2015 and the following apply.

3.1

rough-terrain variable-reach truck

variable-reach truck intended primarily for operation on unimproved natural terrain and on the

disturbed terrain of, for example, construction site

[SOURCE: ISO 5053-1:2015, 2.21]

3.2

variable-reach truck

lift truck fitted with one or more articulated arms, telescopic or not, non-slewing or having a slewing

movement of not more than 5° either side of the longitudinal axis of the truck used for stacking loads

[SOURCE: ISO 5053-1:2015, 2.20]

Note 1 to entry: See Figure 1.

Figure 1 — Variable-reach truck

3.3

compact truck

truck having a maximum height in normal travel mode of 2 150 mm and:

— a maximum operating mass of 6 000 kg;

and/or

— a maximum width in normal travel mode of 1 850 mm

Note 1 to entry: These dimensions do not include equipment such as working lights, mirrors, etc.

3.4

actual capacity

Q

maximum load, established by the manufacturer based on components strength and truck stability, that

the truck can carry, lift and stack to a specified height, at a specified standard load centre distance and

reach, in normal operating conditions

Note 1 to entry: The actual capacity depends on the configuration of the truck in terms of such variables as:

— lift height;

— reach of the boom;

— standard load centre distance;

— load handling device (fork arms or attachment fitted);

— stabilizing devices.

Note 2 to entry: This actual capacity defines the load handling ability of the particular truck as equipped.

Additional actual capacity ratings with removable attachments may also be established where permitted by the

appropriate stability test or by calculation verified by empirical data.

3.5

rated capacity

Q1

maximum load permitted by the manufacturer at the standard load centre distance (D) that the truck is

capable of lifting and transporting on fork arms in normal conditions with the boom fully retracted

3.6

reach

d

distance between two vertical parallel planes, one plane tangent to the front of the outside diameter of

the front tyres, the other plane described by the vertical projection of the centre-of-gravity of the load

to the ground

Note 1 to entry: The centre-of-gravity of the load (G) is defined in Table 1.

Note 2 to entry: See Figure 2 for examples of reach.

Note 3 to entry: For practical matters, d can be measured referring to point g, being g the vertical projection of

the centre-of-gravity (G) of the load onto the plane of the top surface of the fork arms.

Key

d reach

D standard load centre distance

G centre of gravity of the load

g the vertical projection of the centre-of-gravity (G) of the load onto the plane of the top surface of the fork

arms

H height of the load

Q actual capacity

Q1 rated capacity

Q2 actual capacity at maximum height or elevation

Q3 actual capacity at maximum reach

Figure 2 — Parameters for the designation of the actual capacity of the truck with fork

3.7

lift height

H

vertical distance between the upper face of the fork arms and the ground

Note 1 to entry: See Figure 2.

3.8

standard load centre distance

D

distance from the centre of gravity (G) of the load measured horizontally back to the front of the fork

shanks and vertically down to the upper faces of the fork arms, as specified in Table 1

Note 1 to entry: See Figure 2, for example.

Note 2 to entry: Typical standard load centre distances are given in Table 1. Trucks may be rated for special

applications with load centres related to those applications which may be different from those listed in Table 1.

Table 1 — Typical standard load centre distance

Rated capacity Q in kg Standard load centre distance D in mm

400 500 600 900 1 200

0 < 1 000 X

≥ 1 000 < 5 000 X

≥ 5 000 ≤ 10 000 X

> 10 000 < 20 000 X X X

≥ 20 000 < 25 000 X X

≥ 25 000 X

3.9

axle oscillation lock

mechanism designed to prevent oscillation of an axle to improve truck stability

3.10

stabilising devices

extendable and/or pivoting mechanical supports used to improve stability of a truck when stationary

3.11

lateral levelling

changing the lateral inclination angle between the chassis and the ground to ensure the boom operates

in a vertical plane even when the truck is positioned on a side slope

3.12

forks

device comprising two or more solid fork arms, each consisting of a shank (vertical portion) and blade,

which is hook- or shaft-mounted, fitted on the carriage and usually adjusted manually

3.13

boom

pivoting support member that permits horizontal and vertical positioning of the load or attachment

3.14

crab steering mode

steering mode where all wheels of the truck steer in the same direction

3.15

normal operating position

position specified by the manufacturer in which the operator is able to control the truck operations,

including load handling functions

Note 1 to entry: Other positions may be necessary if it is not possible to control all the functions of the truck

from a single position.

[SOURCE: ISO 10896-1:2012, 3.16]

3.16

attachment bracket

device fitted at the end of the boom to mount interchangeable attachments to facilitate quick

interchange of attachment

3.17

boom float

operating mode that uses gravity to allow an attachment at the end of the boom to follow a contour (e.g.

the ground)

3.18

maximum working pressure

maximum pressure in the hydraulic circuit during normal operation

Note 1 to entry: This definition is derived from ISO 10972-3:2003, 3.2.

3.19

level ground

ground with a gradient of (0 ± 2) %

3.20

operating mass

mass of the truck equipped with forks, unladen, and with the operator (75 kg), full fuel tank and all fluid

systems (i.e. hydraulic oil, transmission oil, engine oil, engine coolant) at the levels specified by the

manufacturer

!3.21

technically permissible maximum operating mass

operating mass without the forks and including the heaviest permitted attachment without load"

4 Safety requirements and/or protective measures

4.1 General

4.1.1 Introduction

Trucks shall comply with the safety requirements and/or protective measures of this clause. In

addition, the truck shall be designed according to the principles of EN ISO 12100 for relevant but not

significant hazards, which are not dealt with by this standard.

4.1.2 Sharp edges and acute angles

Sharp edges and acute angles shall meet the requirements specified in ISO 12508 in areas to which the

operator can be exposed during operation, access, egress and maintenance.

Verification by measurement and/or design check.

4.1.3 Stored energy components

Components that store energy and can cause a risk of injury during removal or disassembly, e.g.

hydraulic accumulators and spring-applied brakes, shall be provided with a means to release the energy

before removal or disassembly and shall be marked according to 6.2.8.

Verification by test and visual examination.

4.2 !Starting/stopping of engine and moving machine"

4.2.1 Unauthorized starting

Trucks shall be designed in a way that they cannot be started without a key, a code, a magnetic card or

other equivalent device.

Verification by design check.

4.2.2 Stopping system

!The normal stop control device shall be clearly identifiable, and clearly visible. If it's not a key it

shall be identified using symbol 1388 of ISO 7000:2014.

Verification by design check."

4.2.3 Unintended movement

Trucks shall be fitted with a device that prevents the engine being started while the drive-system is

engaged. When the drive system direction control is in neutral, provisions shall be made to locate and

maintain it in its neutral position. This device shall comply with Table 2.

NOTE CEN/TR 1459–6 describes the methodology followed to determine the values of PLr listed in Table 2.

Verification by functional test.

4.2.4 Uncontrolled motion

Means shall be provided to prevent the truck from moving from rest on level ground until the drive

system has been engaged. These means shall comply with Table 2.

Verification by functional test.

4.2.5 Powered travel movement

Means shall be provided to prevent powered travel when the operator is not at the normal operator’s

position. Powered travel shall not occur automatically when the operator returns to the normal

operator’s position without an additional operation, e.g. by requiring resetting the direction control.

Application of the parking brake shall engage transmission in neutral, except on trucks with hydro-

static transmission.

The release of parking brake shall not engage the transmission automatically.

NOTE On trucks with hydro-static transmission, the transmission system achieves the same objective.

Verification by functional test.

Means to fulfil these requirements shall comply with Table 2.

On starting a reverse movement, an audible alarm complying with the requirements of ISO 9533 shall

be given for at least 1 s.

Verification by measurement.

4.2.6 Non-activation of the parking brake

!A clear warning (audible and/or visual) shall be activated when the operator is not at the normal

operating position and the parking brake has not been applied. Means to fulfil this requirement shall

comply with Table 2.

Verification by functional test."

4.3 Brakes

4.3.1 General

!Trucks shall be equipped with service brake(s) and parking brake system(s), complying with

ISO 6292:2008. The stopping distance test in ISO 6292:2008, 6.2.1 shall be carried out only with the

truck in the configuration giving the technically permissible maximum operating mass.

Verification by design-check and test.

NOTE In addition, national road regulations apply when trucks are used on roads."

Where electromechanical parking brake system is fitted, the braking device shall be applied

mechanically and released electrically.

Verification by design-check.

Where hydro-mechanical parking brake is fitted, the braking device shall be applied mechanically and

released hydraulically. When the operator manually releases the parking brake from the normal

operating position, it shall not disable the service brakes.

Verification by design-check.

4.3.2 Failure of energy supply

Failure of the energy supply to a brake system shall not result in a total loss of braking. The systems

shall be able to bring the truck to a controlled stop and to hold the truck in a parking position.

Verification by design-check (calculation).

4.3.3 !Holding performance

The service brake shall be capable of holding the laden truck motionless on the maximum slope

permitted by the manufacturer.

Verification by design test."

4.4 Electrical and electronic systems

4.4.1 !General

The truck shall comply with the following requirements.

4.4.1.1 Insulation

Any live parts of the battery not connected to the frame shall be insulated.

4.4.1.2 Disconnection

The truck shall be so designed and constructed that the battery can be electrically disconnected with

the aid of an easily accessible device e.g. a switch or connector. Disconnectable battery terminals satisfy

this requirement providing the terminals are accessible without the use of a key or tool.

4.4.1.3 Protection of circuits

Control and auxiliary circuits shall be fuse protected against short circuit conditions and dangerous

excess current. Several auxiliary circuits in parallel, with combined rated current not exceeding 12 A,

may be protected by a single device. Certain circuits may remain connected after batteries

disconnection. In this case, specific maintenance instructions shall be provided.

4.4.1.4 Protection of wiring, conductors and electrical components

All conductors not connected to the truck frame shall be either effectively insulated and where

necessary protected against thermal and mechanical damage or shall be so placed and safeguarded as to

avoid danger when the truck is in its normal operating condition.

4.4.1.5 Cross-sectional area

The cross-sectional area of wiring, circuitry and connectors shall be so selected that during operation of

the truck the temperature does not exceed the temperature rating of insulation used.

4.4.1.6 Specification

Copper conductors external to enclosures (excluding short connections between electric or electronic

components and wires that are an integral part of a proprietary component) shall be:

a) flexible;

b) of cross-sectional area not less than:

1) for control wiring: 0,5 mm ;

2) for signal wiring: 0,3 mm ;

3) for data communication wiring and for conductors of adequately supported copper multicore

cables and wiring harnesses: 0,08 mm ;

c) of cross-sectional area not less than 1,0 mm for single wires not incorporated into a harness or

extending from the harness more than 250 mm.

Conductors of other materials shall be selected and sized to give equivalent performance.

4.4.1.7 Protection of wiring and electrical components against fuel leakage

Wiring and electrical components shall be designed, placed or protected to minimize hazards arising

from leakage from the fuel system, such as contamination and fire.

4.4.1.8 Mechanical protection

Where wiring passes through metal parts of the frame or enclosures, the holes shall be fitted with

insulating bushes/grommets or the wiring protected by some other equivalent means.

4.4.1.9 Wiring that flexes

Wiring that flexes during normal operation of the truck functions shall be relieved of mechanical strain

at their electrical termination.

Verification of requirements specified in 4.4.1 shall be made by design-check."

4.4.2 Safety related parts of control systems

Safety related parts of control systems shall comply with PLr (see EN ISO 13849-1) or SIL (see

EN 62061) according to Table 2.

Verification by design-check.

NOTE The complete risk assessment of safety related parts of control systems for trucks is in CEN/TR 1459–

6.

4.4.3 Degree of protection

Depending on the location/installation of electrical and electronic components, the following degrees of

protection are required:

a) !all components installed exterior to the truck or directly exposed to the environment shall have

a minimum degree of protection that corresponds to IP 54 (according to EN 60529:1991);"

b) all components installed in the operator's enclosed cab or protected against the environment shall

have a minimum degree of protection that corresponds to IP 43 (according to EN 60529:1991).

Verification by design-check.

4.4.4 !Identification of wiring

Wires, cables, terminals, etc. shall be identified by codings in accordance with the electrical diagram

included in the service instructions.

Verification by visual examination and design-check.

This requirement does not apply to electrical circuits of anti-theft systems, when fitted."

4.4.5 !Protection against electric shock

Exposed high tension ignition terminals on trucks shall be protected against direct contact by barriers

or insulated caps.

Verification by design-check."

4.4.6 !Batteries

Batteries shall be restrained to prevent displacement which may give rise to danger. Batteries shall be

positioned in a ventilated location that provides access for maintenance.

Verification by visual examination.

Batteries and/or battery locations shall be designed and built or covered to minimize any hazard to the

operator caused by battery acid or acid vapours in the event of overturning the truck.

Verification by design-check.

For marking, see 6.2.10."

!deleted text"

4.5 Controls

4.5.1 General

4.5.1.1 General

a) The controls (hand levers, joysticks, pedals, switches, etc.) and indicators of the truck and

attachment, shall be designed, constructed and so arranged to be accessed from the normal

operating position in accordance with EN ISO 6682.

Verification by design-check.

b) The controls (hand levers, joysticks, pedals, switches, etc.) and indicators of the truck and

attachment, shall be clearly identified, except where obvious (e.g. accelerator pedal), indelible and

visible in the normal operating position; if appropriate, graphical symbols in accordance with

ISO 7000 shall be used and shall be explained in the information for use (see 6.3). Each symbol shall

be affixed on or in close proximity to the control or indicator to which it applies.

Verification by visual examination.

c) Indicators and movement of the control device shall correspond to the intended effect or common

practice whenever possible.

Verification by test.

NOTE 1 Annex B and ergonomic principals of EN 894–1 give guidance.

d) Pedal operated travel and braking controls shall comply with Annex C.

e) Safety-related parts of control system shall comply with Table 2.

f) Means shall be provided to prevent any possibility of actuating controls of powered movement if

the operator is not at an operating position (e.g. protection by door, guard or by locking systems).

g) remote operator controlled systems (for boom and carriage motion only) fitted to trucks shall

comply with the relevant requirements of ISO 15817:2012 with exception to subclause 4.7 remote

control system EMC testing (see 4.19 of the present standard).

Verification by design-check.

4.5.1.2 Multiple operator’s positions

!Only if more than one operator’s position is fitted, an emergency stop at each operating position

shall be fitted. In case of remote control, compliance with 4.5.1.1 g) is considered to fulfill the

requirement.

Verification by visual examination and design-check.

The use of the controls at one operator’s position shall preclude the use of the controls at other

o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...