SIST EN 15436-2:2015

(Main)Road service area maintenance equipment - Part 2: Performance assessment

Road service area maintenance equipment - Part 2: Performance assessment

This European Standard specifies the accuracy of the performance measurement system of road service area maintenance equipment described in the scope of CEN/TC 337 and used for:

- grass-cutting and brush-cutting;

- mechanical plant-cutting.

This equipment is mounted on self-propelled carrying vehicles and is designed to cut and shred grass, brushwood, trees, saplings and bushes in road service areas.

This European Standard does not cover the collection and transportation of shredded grass.

Straßenbetriebsdienstausstattung - Teil 2: Leistungsbewertung

Dieses Dokument legt die Genauigkeiten der Messsysteme zur Messung der Leistungsfähigkeit von Straßenbetriebsdienstausstattung fest, wie diese im Anwendungsbereich von CEN/TC 337 beschrieben werden, mit denen folgende Tätigkeiten ausgeführt werden:

- Mäharbeiten und die Gestrüppentfernung;

- mechanisches Schneiden von Pflanzen.

Die vorgenannten Geräte sind auf Trägerfahrzeugen mit Eigenantrieb montiert und sind einerseits dafür bestimmt, Gras zu mähen und Gestrüpp abzutrennen und zu zerkleinern, und andererseits Bäume oder junge, unbeschnittene Bäume und Sträucher in Straßenrandbereichen zu schneiden.

Das vorliegende Dokument behandelt nicht die Aufnahme und den Transport des Grases.

Matériel d'entretien des dépendances routières - Partie 2: Evaluation des performances

Oprema za vzdrževanje cest - 2. del: Ocenjevanje delovanja

Ta evropski standard določa natančnost sistema za merjenje delovanja opreme za vzdrževanje cest, opisane v standardu CEN/TC 337 in ki se uporablja za:

– košnjo trave in podrasti;

– mehansko odstranjevanje rastlin.

Ta oprema je nameščena na nosilna vozila z lastnim pogonom in je zasnovana za košnjo in drobljenju trave, podrasti, dreves, mladik in grmičevja ob cestah.

Ta evropski standard ne zajema pobiranja in odvoza pokošene trave.

General Information

- Status

- Published

- Public Enquiry End Date

- 04-Feb-2015

- Publication Date

- 28-Jul-2015

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 09-Jul-2015

- Due Date

- 13-Sep-2015

- Completion Date

- 29-Jul-2015

Relations

- Replaces

SIST EN 15436-2:2008 - Road service area maintenance equipment - Part 2: Performance assessment - Effective Date

- 01-Sep-2015

Overview

EN 15436-2:2015 is the CEN European Standard that specifies test methods and measurement accuracies for the performance assessment of road service area maintenance equipment. It applies to machinery mounted on self‑propelled carrying vehicles and designed for:

- grass‑cutting and brush‑cutting (articulated‑arm grass cutters / brushcutters and in‑line flail mowers), and

- mechanical plant‑cutting (trees, saplings, bushes).

This Part 2 standard focuses on how to measure and report the technical performance of new production machines (head of series). It does not cover collection or transportation of shredded material.

Key topics and technical requirements

EN 15436-2 defines measurement procedures, required accuracies and reporting formats for core performance domains:

- Cutting specifications - measurement of cutting width and cutting height for different head types. Example: cutting width is measured to an accuracy of ±0.01 m.

- Kinematic properties - ranges and articulation metrics (horizontal/vertical ranges, embankment and ditch reach, offsets, clearance and rotation angles) for articulated arms and in‑line mowers.

- Weights and dimensions - transport dimensions (height, width, length) and total machine weight checks.

- Power and drive checks - protocols and calculations to determine power delivered to cutting tools for machines driven by:

- PTO shafts (mechanical/hydraulic transmission),

- carrying‑vehicle hydraulics. Annex D provides a normative test protocol for power measurement at the tool.

- Performance characteristics - definitions and methods to determine maximum continuous and instantaneous power, cutting tool speed, torque, circumferential speed and kinetic energy.

- Presentation of results - informative annexes provide standardized result formats for different machine types.

The standard also cross‑references EN 15436‑1:2008 (Terminology) and forms part of the EN 15436 series (Parts 1–4).

Practical applications and users

EN 15436-2:2015 is used by:

- Manufacturers and R&D teams to validate machine performance and demonstrate compliance during design and production validation.

- Test laboratories and inspection bodies to carry out repeatable, accredited performance testing.

- Public agencies and road authorities for procurement specifications, acceptance testing and performance verification of roadside maintenance fleets.

- OEMs and component suppliers to size powertrains and verify hydraulic/PTO interfaces.

- Certification and conformity assessors preparing reports tied to delivery acceptance (see EN 15436‑4).

Using this standard ensures consistent, comparable performance data for equipment used in roadside vegetation management, vegetation clearance and safety maintenance.

Related standards

- EN 15436-1:2008 - Terminology (normative reference)

- EN 15436-3 - Classification (part of the series)

- EN 15436-4 - Delivery acceptance of machines by users

Keywords: EN 15436-2:2015, road service area maintenance equipment, performance assessment, grass-cutting, brush-cutting, mechanical plant-cutting, articulated-arm, in-line flail mower, CEN standard.

Frequently Asked Questions

SIST EN 15436-2:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Road service area maintenance equipment - Part 2: Performance assessment". This standard covers: This European Standard specifies the accuracy of the performance measurement system of road service area maintenance equipment described in the scope of CEN/TC 337 and used for: - grass-cutting and brush-cutting; - mechanical plant-cutting. This equipment is mounted on self-propelled carrying vehicles and is designed to cut and shred grass, brushwood, trees, saplings and bushes in road service areas. This European Standard does not cover the collection and transportation of shredded grass.

This European Standard specifies the accuracy of the performance measurement system of road service area maintenance equipment described in the scope of CEN/TC 337 and used for: - grass-cutting and brush-cutting; - mechanical plant-cutting. This equipment is mounted on self-propelled carrying vehicles and is designed to cut and shred grass, brushwood, trees, saplings and bushes in road service areas. This European Standard does not cover the collection and transportation of shredded grass.

SIST EN 15436-2:2015 is classified under the following ICS (International Classification for Standards) categories: 43.160 - Special purpose vehicles. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15436-2:2015 has the following relationships with other standards: It is inter standard links to SIST EN 15436-2:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15436-2:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Oprema za vzdrževanje cest - 2. del: Ocenjevanje delovanjaStraßenbetriebsdienstausstattung - Teil 2: LeistungsbewertungMatériel d'entretien des dépendances routières - Partie 2: Evaluation des performancesRoad service area maintenance equipment - Part 2: Performance assessment43.160Vozila za posebne nameneSpecial purpose vehiclesICS:Ta slovenski standard je istoveten z:EN 15436-2:2015SIST EN 15436-2:2015en,fr,de01-september-2015SIST EN 15436-2:2015SLOVENSKI

STANDARDSIST EN 15436-2:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15436-2

July 2015 ICS 43.160 Supersedes EN 15436-2:2008English Version

Road service area maintenance equipment - Part 2: Performance assessment

Matériel d'entretien des dépendances routières - Partie 2: Evaluation des performances

Straßenbetriebsdienstausstattung - Teil 2: Leistungsbewertung This European Standard was approved by CEN on 14 May 2015.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2015 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15436-2:2015 ESIST EN 15436-2:2015

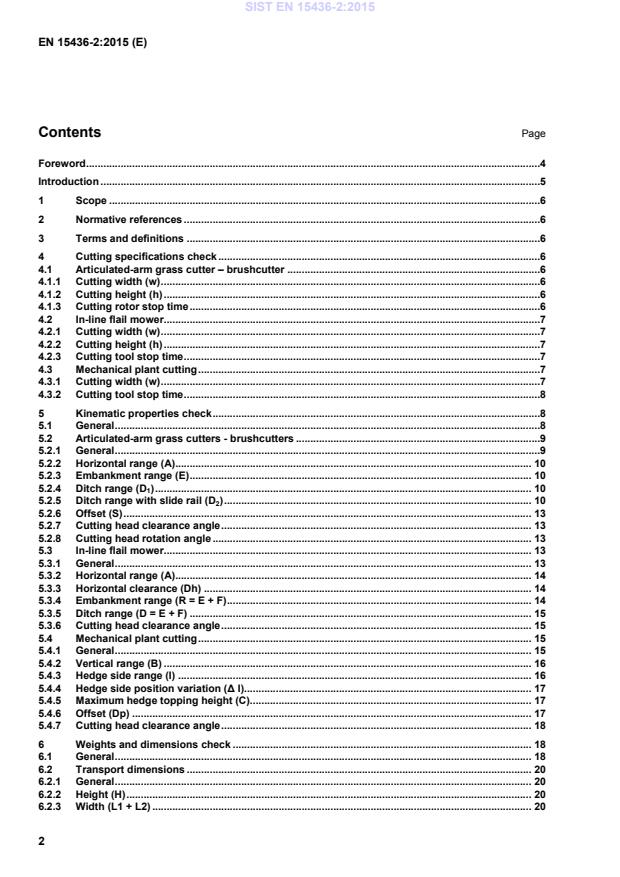

Presentation of results – Articulated-arm grass cutters – Brush cutters . 29 Annex B (informative)

Presentation of results – In-line flail mowers . 32 Annex C (informative)

Presentation of results – Mechanical plant cutting . 34 Annex D (normative)

Tests with movable arms . 37 Bibliography . 38

Key 1 saw blade 2 cutting width w 3 reciprocating cutter bar 4 fixed 5 mobile Figure 1 — Cutting width (w) 4.3.2 Cutting tool stop time The cutting tool stop time is measured automatically, from the time the stop command is sent to the moment when the rotation speed is measured as being equal to 0. The cutting rotor stop time is measured with an accuracy of ± 0,5 s and expressed in seconds (s). A distinction is made between the value of the stop times for open hydraulic circuits and for closed hydraulic circuits. 5 Kinematic properties check 5.1 General In their design structure, all these machines have the same constituent elements, i.e. a frame, articulated arms and a tool. Whatever the shape and size of the components and any accessories that may be used, there is always an articulation between the frame and the primary arm. The articulation which is very close to the frame is used to define three reference planes for the machine. The kinematic properties of the different machines are then defined with respect to these reference planes. See the definitions according to EN 15436-1:2008, 5.1 to 5.6. Given that the height, in relation to the ground plane of the primary arm–frame articulation changes the geometry of certain operating positions significantly, the horizontal reference plane of the machine is positioned at a height ZP from the ground specified by the manufacturer. This height can vary. SIST EN 15436-2:2015

Key 1 mid-plane 2 lvrp 3 hrp 4 ground plane Figure 2 — Kinematic properties SIST EN 15436-2:2015

Key 1 mid-plane Figure 3 — Method of measurement when Zp ≤ 0,9 m

Key 1 cylinder 2 primary arm axis Ef

overall dimensions given by the manufacturer or measured on the machine, including the 1/2 width of the primary arm + possibly the width of the cylinder, etc. (See Figure 3.) Figure 4 — Method of measurement when Zp ≤ 0,9 m SIST EN 15436-2:2015

Key 1 mid-plane Figure 5 — Method of measurement when Zp > 0,9 m D2 is given by D'g +

w' D'2 is given by the formula: [][][]220222g22''DABDLAB+−−++= where []()1pfpp120,92'LAZEZHL=−++− []()1ppp121,52,12'LBXXHL=−−+− and ()()221pfp0,91,5'LZEX=−++− For machines with multiple arms, Arms 2 and 3 shall be fully extended. SIST EN 15436-2:2015

EN 15436-1:2008, 6.29. The measurement system accuracy of the offset S is ± 0,01 m. 5.2.7 Cutting head clearance angle The cutting head clearance angle is defined in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...