SIST EN 14898:2006+A1:2007

(Main)Water conditioning equipment inside buildings - Active media filters - Requirements for performance, safety and testing

Water conditioning equipment inside buildings - Active media filters - Requirements for performance, safety and testing

This European Standard specifies requirements relating to the construction, performance and methods of testing for active media filters for drinking water installations inside buildings, with a maximum working pressure of at least 1 000 kPa and a maximum working temperature of less than 30 °C. It only concerns units, which are permanently connected to the mains supply at the point of entry or point of use.

This standard applies only to filter systems comprising a housing and filter media tested together.

It includes capsule type units where both the element and its outer housing are disposable.

NOTE Products intended for use in water supply systems are to comply, when existing, with national regulations and testing arrangements that ensure fitness for contact with drinking water. The Member States relevant regulators and the EC Commission agreed on the principle of a future unique European Acceptance Scheme (EAS) which would provide a common testing and approval arrangement at European level.

If and when the EAS is adopted, European Standards on products will be amended by the addition of an Annex Z/EAS under Mandate M/136 which will contain formal references to the testing, certification and product marking requirements of the EAS. Until the EAS comes into force, the current national regulations remain applicable.

Anlagen zur Behandlung von Trinkwasser innerhalb von Gebäuden - Filter mit aktiven Substanzen - Anforderungen an Ausführung, Sicherheit und Prüfung

Diese Europäische Norm legt Anforderungen an die Konstruktion, Leistung und Prüfverfahren für Filter mit aktiven Substanzen für Trinkwasser-Installationen in Gebäuden mit einem maximalen Arbeitsdruck von mindestens 1 000 kPa und einer maximalen Arbeitstemperatur von höchstens 30 °C fest. Sie gilt nur für Einheiten, die fest mit der Hausinstallation am Eintrittspunkt oder an der Verbrauchsstelle verbunden sind.

Diese Norm gilt nur für Filtersysteme, die ein Gehäuse und eine Filterkartusche aufweisen, die zusammen geprüft werden.

Sie beinhaltet Kapselfilter-Systeme, bei denen die Filterkartusche und das Außengehäuse entsorgt werden können.

ANMERKUNG Produkte für die Verwendung in Wasserversorgungssystemen, soweit vorhanden, erfüllen die nationalen Bestimmungen und Prüfanforderungen, die ihre Eignung für den Kontakt mit Trinkwasser bestätigen. Die für die Mitgliedstaaten zuständigen Behörden und die EU-Kommission haben sich auf die Prinzipien eines zukünftigen einheitlichen Europäischen Zulassungssystems (EAS) geeinigt, welches eine gemeinsame Prüf- und Zulassungsregelung auf europäischer Basis bietet.

Falls und sobald EAS eingeführt ist, werden die Europäischen Produktnormen um einen Anhang Z/EAS unter dem Mandat M/136 ergänzt, in welchem formale Verweise auf die Anforderungen für die Prüfung, die Zertifizierung und die Produktkennzeichnung im Rahmen des EAS gegeben werden. Bis das EAS in Kraft gesetzt ist, bleiben die derzeitigen nationalen Vorschriften anwendbar.

Appareils de traitement d'eau a l'intérieur des bâtiments - Filtres a substance active - Exigences de performance, de sécurité et essais

La présente Norme européenne prescrit les exigences relatives à la construction, aux performances et aux méthodes d’essai des filtres à média actifs destinés aux installations d’eau potable à l’intérieur des bâtiments, avec une pression de service maximale de 1 000 kPa et une température de service maximale de 30 C. Elle concerne uniquement les unités qui sont raccordées en permanence au réseau public, que ce soit au point d’entrée ou au point d’utilisation.

La présente norme ne s’applique qu’aux systèmes de filtres comportant un logement et un média filtrant qui sont soumis à l’essai ensemble.

Il s’agit notamment de filtres monocorps, où l’élément et son logement sont tous deux jetables.

NOTE Les produits destinés à l’usage dans les systèmes d’alimentation en eau doivent être conformes aux réglementations nationales et aux dispositions d'essais existant éventuellement pour assurer qu’ils sont aptes au contact avec l'eau potable. Les réglementeurs respectifs des États membres et la Commission CE ont convenu du principe d'un futur système européen d’homologation (European Acceptance Scheme = EAS) unique, qui fournirait à l’échelon européen un cadre commun d’essai et d’agrément.

Quand l'EAS sera adopté, s’il l’est, les normes européennes de produits seront amendées par l’ajout d'une Annexe ZA/EAS selon le Mandat M/136, qui contiendra des références formelles aux exigences de l’EAS en matière d’essais, de certification et de marquage du produit de l'EAS. En attendant l’entrée en vigueur de l’AES, les réglementations nationales actuelles demeurent en vigueur.

Oprema, ki se uporablja za pripravo pitne vode v stavbah - Filtri z aktivnimi snovmi - Zahteve za delovanje, varnost in preskušanje

General Information

- Status

- Published

- Publication Date

- 02-Jul-2007

- Technical Committee

- IOVO - Water supply and waste water engineering

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 22-Jun-2007

- Due Date

- 27-Aug-2007

- Completion Date

- 03-Jul-2007

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-Sep-2007

Overview

EN 14898:2006+A1:2007 is a CEN European Standard for water conditioning equipment inside buildings, specifically addressing active media filters used on drinking water installations. The standard defines requirements for construction, performance, safety and testing of filters that are permanently connected to the mains at the point of entry or point of use. It applies to filter systems where the housing and filter media are tested together, including disposable capsule-type units. Key limits in scope: maximum working pressure of at least 1 000 kPa and maximum working temperature below 30 °C.

Key topics and technical requirements

The standard sets out clear, testable requirements and methods in areas including:

- Materials of construction and suitability for contact with drinking water

- Working conditions: temperature, flow and pressure limits

- Filter housing and cartridge design: cartridge replacement, end connections, and capsule units

- Safety features: backflow prevention and structural pressure strength

- Cartridge exchange indicators (time, throughput, or other methods)

- Performance requirements and testing:

- Static and dynamic pressure tests for housings and cartridges

- Pressure drop characterization across the filter

- Substance reduction performance (chlorine reduction, organic chemical reduction, odour/flavour and inorganic reduction)

- Test methods and acceptance criteria: standardized procedures for sampling, analytical methods and expression of results

- Technical documentation, marking, labelling and packaging for traceability and user information

The standard also notes the need to comply with existing national regulations for materials in contact with drinking water and references a potential future European Acceptance Scheme (EAS) for harmonized certification.

Applications and who uses it

EN 14898 is used by a range of stakeholders involved in the design, manufacture, testing and procurement of in-building water treatment devices:

- Filter manufacturers developing active media filters and capsule units

- Test laboratories that perform performance and safety testing to validate manufacturer claims

- Product certifiers and regulators assessing compliance with European and national drinking water requirements

- Plumbing engineers, specifiers and building contractors selecting point-of-entry or point-of-use filtration systems

- Water utilities and facility managers evaluating solutions for taste, odour or specific contaminant reduction

Practical benefits include demonstrated safety under pressure, validated contaminant reduction performance, standardized labelling and reliable cartridge replacement guidance.

Related standards

Standards referenced in EN 14898 include (selection):

- EN 1717 (backflow protection)

- Product standards for filter media: EN 12903, EN 12915-1, EN 13752, EN 13753

- Laboratory and analytical methods: EN ISO 3696, EN ISO 7027, EN ISO 7393-1

Keywords: EN 14898, active media filters, water conditioning equipment, drinking water filtration, filter performance testing, pressure test, chlorine reduction, CEN standard.

Frequently Asked Questions

SIST EN 14898:2006+A1:2007 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Water conditioning equipment inside buildings - Active media filters - Requirements for performance, safety and testing". This standard covers: This European Standard specifies requirements relating to the construction, performance and methods of testing for active media filters for drinking water installations inside buildings, with a maximum working pressure of at least 1 000 kPa and a maximum working temperature of less than 30 °C. It only concerns units, which are permanently connected to the mains supply at the point of entry or point of use. This standard applies only to filter systems comprising a housing and filter media tested together. It includes capsule type units where both the element and its outer housing are disposable. NOTE Products intended for use in water supply systems are to comply, when existing, with national regulations and testing arrangements that ensure fitness for contact with drinking water. The Member States relevant regulators and the EC Commission agreed on the principle of a future unique European Acceptance Scheme (EAS) which would provide a common testing and approval arrangement at European level. If and when the EAS is adopted, European Standards on products will be amended by the addition of an Annex Z/EAS under Mandate M/136 which will contain formal references to the testing, certification and product marking requirements of the EAS. Until the EAS comes into force, the current national regulations remain applicable.

This European Standard specifies requirements relating to the construction, performance and methods of testing for active media filters for drinking water installations inside buildings, with a maximum working pressure of at least 1 000 kPa and a maximum working temperature of less than 30 °C. It only concerns units, which are permanently connected to the mains supply at the point of entry or point of use. This standard applies only to filter systems comprising a housing and filter media tested together. It includes capsule type units where both the element and its outer housing are disposable. NOTE Products intended for use in water supply systems are to comply, when existing, with national regulations and testing arrangements that ensure fitness for contact with drinking water. The Member States relevant regulators and the EC Commission agreed on the principle of a future unique European Acceptance Scheme (EAS) which would provide a common testing and approval arrangement at European level. If and when the EAS is adopted, European Standards on products will be amended by the addition of an Annex Z/EAS under Mandate M/136 which will contain formal references to the testing, certification and product marking requirements of the EAS. Until the EAS comes into force, the current national regulations remain applicable.

SIST EN 14898:2006+A1:2007 is classified under the following ICS (International Classification for Standards) categories: 13.060.20 - Drinking water; 91.140.60 - Water supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14898:2006+A1:2007 has the following relationships with other standards: It is inter standard links to SIST EN 14898:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14898:2006+A1:2007 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC, 98/83/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14898:2006+A1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

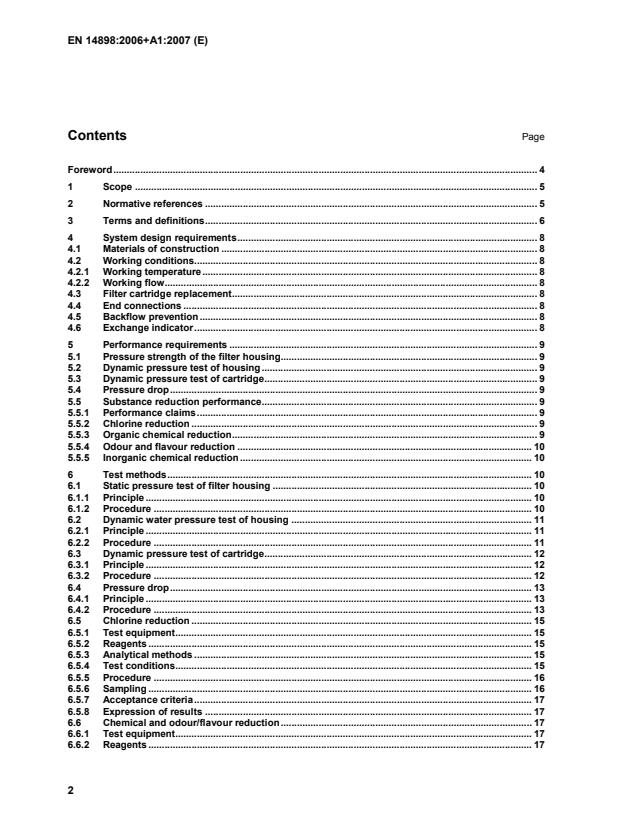

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Water conditioning equipment inside buildings - Active media filters - Requirements for performance, safety and testingOprema, ki se uporablja za pripravo pitne vode v stavbah - Filtri z aktivnimi snovmi - Zahteve za delovanje, varnost in preskušanjeAppareils de traitement d'eau a l'intérieur des bâtiments - Filtres a substance active - Exigences de performance, de sécurité et essaisAnlagen zur Behandlung von Trinkwasser innerhalb von Gebäuden - Filter mit aktiven Substanzen - Anforderungen an Ausführung, Sicherheit und PrüfungTa slovenski standard je istoveten z:EN 14898:2006+A1:2007SIST EN 14898:2006+A1:2007en,fr,de91.140.60Sistemi za oskrbo z vodoWater supply systems13.060.20Pitna vodaDrinking waterICS:SLOVENSKI

STANDARDSIST EN 14898:2006+A1:200701-september-2007

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14898:2006+A1

June 2007 ICS 13.060.20; 91.140.60 SupersedesEN 14898:2006English Version

Water conditioning equipment inside buildings - Active media filters - Requirements for performance, safety and testing

Appareils de traitement d'eau à l'intérieur des bâtiments - Filtres à substance active - Exigences de performance, de sécurité et essais

Anlagen zur Behandlung von Trinkwasser innerhalb von Gebäuden - Filter mit aktiven Substanzen -Anforderungen an Ausführung, Sicherheit und Prüfung This European Standard was approved by CEN on 27 April 2006 and includes Amendment 1 approved by CEN on 10 May 2007.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2007 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14898:2006+A1:2007: E

Example of test rig for substance reduction testing.24 Annex B (informative)

Example test report.25 Annex C (informative)

Substance-specific reduction claims.26 Bibliography.31

any

of the Member States. 2) It should be noted that, while awaiting the adoption of verifiable European criteria, existing national

regulation concerning the use and/or the characteristics of this product remain in force. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

maximum working temperature manufacturer's stipulated maximum water supply temperature above which filter performance and/or structural integrity of the system may be compromised 3.11 minimum reduction rate minimum percentage reduction achieved by a filter with respect to a specified substance, as defined in the performance requirements of this standard 3.12 minimum working pressure manufacturer's stipulated minimum water supply pressure below which filter performance may be compromised 3.13 minimum working temperature manufacturer's stipulated minimum water supply temperature below which filter performance and/or structural integrity of the system may be compromised 3.14 substance-specific rated capacity volume of water, in litres, that the filter is capable of treating to the minimum reduction rate with respect to a specific substance 3.15 unit volume internal empty vessel

volume of the complete system which is in contact with the drinking water 3.16 working flow range manufacturer's stipulated maximum and minimum flow rates outside of which the performance of the filter may be compromised

Determinant

Concentration units

Influent concentration Ci

Effluent percentage reduction Lead µg/l Pb 100 ± 10 90 Copper mg/l Cu 3 ± 0,3 80 Aluminium µg/l Al 600 ± 60 70 Nitrate mg/l NO3 200 ± 20 75a Carbonate hardness mg/l CaCO3 300 ± 30 50 a In the case of nitrate, to check that excessive formation of nitrite is not occurring, filtered water samples shall be analyzed for nitrite as well as nitrate and an additional condition shall be fulfilled: 2003)(NO50)(NOi23C≤+.

NOTE The protocols specified in 6.6 of this standard can be adapted to test the reduction of substances not specifically covered by the performance requirements of this standard (see Annex C). Claims for the reduction of such substances are clearly separated from the claims made of conformity to this standard (see also 7.1). 6 Test methods 6.1 Static pressure test of filter housing 6.1.1 Principle The filter is mounted in a test rig and a water pressure 1.5 times the maximum working pressure is applied for 10 min. The filter is examined for visible evidence of leakage or damage. 6.1.2 Procedure Install the filter in a test rig as shown in Figure 1. The pressure gauge shall be installed at the outlet of the test specimen. It shall be ensured that the pressure at the outlet of the system is at the specified value. Flush with water to purge air from the filter. Increase the water pressure to 1.5 times the maximum working pressure at a minimum rate of 0,1MPa/s. Maintain the pressure for 1020+ min. Examine the filter for visible evidence of leakage or damage.

Key 1 Pressurizing device

4 Pressure gauge 2 Stop valve/ Solenoid valve

5 Test specimen 3 Drain valve Figure 1 – Pressure strength and tightness test rig 6.2 Dynamic water pressure test of housing

6.2.1 Principle The empty filter housing is mounted in a test rig and subjected to 200 000 load cycles with pressure varying from 150 kPa to 1,3 times the maximum working pressure at a frequency of 15 min-1. The filter housing is examined for visible evidence of leakage or damage. 6.2.2 Procedure Position the filter in a suitable test rig (see Figure 1). Apply 200 000 load cycles with the water pressure cycling between 150 kPa and 1,3 times the maximum working pressure, at a frequency of (15 ± 2) min-1

(see Figure 2). The duration of the pressure increase, pressure hold and pressure decrease shall each be (1 ± 0,2) s. The pressure shall be measured at the outlet of the filter. Maintain the water temperature of the system at (20 ± 3)°C. Examine the filter for visible evidence of leakage or damage. The filter used for the test described in 6.2 shall not be used for subsequent testing.

Key X Time, in s Y Pressure, in kPa/100 Figure 2 — Dynamic pressure test of filter housing 6.3 Dynamic pressure test of cartridge 6.3.1 Principle The filter complete with cartridge is mounted in a test rig and subject to 20 000 load cycles with the pressure varying from 150 kPa to 1,3 times the maximum working pressure with a frequency of 6 cycles per minute. The filter cartridge is examined for physical evidence of damage to the cartridge and seals. 6.3.2 Procedure Position the filter with cartridge installed in a test rig (see Figure 1). Apply 20 000 load cycles with the water pressure cycling between 1,3 times the maximum working pressure and 150 kPa. The time for the pressure increase and the pressure hold at 1,3 times maximum working pressure shall each be (2,5 ± 0,2) s. The time for the pressure decrease from 1,3 times the maximum working pressure to 150 kPa and the hold period at 150 kPa shall together be (5 ± 0,2) s (see Figure 3). Maintain the water temperature of the system at (20 ± 3) °C. After the completion of 20 000 load cycles, remove the cartridge and examine it for visible evidence of leakage or damage. The filter used for the test described in 6.3 shall not be used for subsequent testing.

Key X Time, in s Y Pressure, in kPa/100 Figure 3 — Dynamic pressure test of filter cartridge 6.4 Pressure drop 6.4.1 Principle The filter is mounted in a test rig and the differential pressure across the filter is recorded for a number of flow rates in order to generate a pressure drop curve. The test is repeated with the filter cartridge removed. The differential pressure curve across the filter cartridge is calculated by subtracting the curve with the filter removed from that with the cartridge in place. For filters with capsule cartridges, the test with cartridge removed is not applied. For these filters, the pressure drop is provided for the complete system. 6.4.2 Procedure The test rig is shown in Figure 4. Connect the filter in accordance with the manufacturer’s instructions supplied with the filter. Install the filter between two sensors for pressure measurement connected to adequately sized manometers (error limit 2 kPa). Alternatively, a differential pressure gauge may be used. If the appliance to be tested is fitted with a shut-off valve, open it fully. Adjust the flow rate by means of the regulating valve installed downstream of the filter. Maintain the water temperature of the system at (20 ± 3) °C. Measure the differential pressure at a number (e.g. 10) of flow rates in order to generate a pressure drop curve (curve A in Figure 5).

Key

1 Regulating valve 4 Differential pressure gauge 2 Flow meter 4’ Alternatively: two

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...