SIST EN 50626-1:2023

(Main)Conduit systems buried underground for the protection and management of insulated electrical cables or communication cables - Part 1: General requirements

Conduit systems buried underground for the protection and management of insulated electrical cables or communication cables - Part 1: General requirements

This document specifies requirements and tests for conduit systems with circular cross section buried underground for the protection and management of insulated conductors and/or power cables or communication cables installed individually or installed as a part of an assembly where the cable is installed by pulling or pushing.

This document does not include requirements for leak-tightness according to EN ISO 13259 and performance time.

NOTE 1 EN 50626 2 specifies requirements and tests for performance time and leak-tightness for solid wall conduit systems made of PE, PP and PVC-U buried underground where the cables are installed by blowing or floating or conduits are installed by trenchless methods.

NOTE 2 It is the responsibility of the purchaser or specifier to take into account any relevant national regulations and installation practices or codes when selecting the products to be installed, based on the characteristics specified in this document.

Erdverlegte Elektroinstallationsrohrsysteme für den Schutz und die Führung isolierter elektrischer Kabel oder Fernmeldekabel – Teil 1: Allgemeine Anforderungen

Systèmes de conduits enterrés dans le sol pour la protection et la gestion des câbles électriques isolés ou des câbles de communication - Partie 1: Exigences générales

Le présent document spécifie les exigences et les essais applicables aux systèmes de conduits de section circulaire enterrés dans le sol pour la protection et le rangement des conducteurs isolés et/ou des câbles d’alimentation ou des câbles de communication installés individuellement ou installés comme éléments d’un assemblage dont le câble est mis en place par tirage ou insertion.

Le présent document n’inclut pas d’exigences relatives à l’étanchéité conformes à l’EN ISO 13259 et à la durée d’utilisation.

NOTE 1 L’EN 50626 2 spécifie les exigences et les essais relatifs à la durée d’utilisation et à l’étanchéité des systèmes de conduits à paroi pleine en PE, PP et PVC-U enterrés dans le sol dont les câbles sont installés par soufflage ou flottage ou dont les conduits sont installés par des méthodes sans tranchées.

NOTE 2 Il est de la responsabilité de l’acheteur ou du prescripteur de prendre en compte tous les règlements nationaux appropriés et les pratiques ou les codes d'installation lors du choix des produits à installer, en fonction des caractéristiques spécifiées dans le présent document.

Podzemni kanalski sistem za zaščito in upravljanje izoliranih električnih ali komunikacijskih kablov - 1. del: Splošne zahteve

Ta evropski standard določa splošne zahteve in preskuse za podzemne kanalske sisteme za zaščito in upravljanje izoliranih vodnikov in/ali napajalnih ali komunikacijskih kablov.

Ta evropski standard se uporablja samo za vode s krožnim prečnim prerezom.

Zahteve, ki so opisane v tem standardu, veljajo za vse vodnike,

– ki so nameščeni posamično ali kot del sestava;

– če se kabel vgrajuje z vlečenjem ali potiskanjem.

Standard prEN 50626-2 določa posebne zahteve in preskuse, ki so potrebni za posebne načine uporabe.

OPOMBA: Primeri posebnih načinov uporabe zajemajo posebne tehnike vgradnje cevi, med alternativnimi tehnikami za namestitev kablov pa je vgradnja brez izkopa.

General Information

- Status

- Published

- Public Enquiry End Date

- 17-Sep-2020

- Publication Date

- 17-Aug-2023

- Technical Committee

- I11 - Imaginarni 11

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 27-Jul-2023

- Due Date

- 01-Oct-2023

- Completion Date

- 18-Aug-2023

Relations

- Effective Date

- 01-Sep-2023

Overview - EN 50626-1:2023 (Conduit systems buried underground)

EN 50626-1:2023 is a European (CLC/CENELEC) standard that specifies general requirements and type tests for circular cross‑section conduit systems buried underground used to protect and manage insulated electrical cables and communication cables. It covers conduit and fittings intended for cable installation by pulling or pushing and defines mechanical, fire and environmental performance criteria. This part does not cover leak‑tightness or specified performance time (see EN 50626‑2 and EN ISO 13259 for those aspects).

Key topics and technical requirements

- Scope and definitions: Terminology for conduits (plain, corrugated, combined), fittings, metallic/non‑metallic/composite systems, rigid vs. pliable conduits.

- Classification: Mechanical properties (resistance to compression, impact and bending), resistance to external influences, and flame propagation behaviour (non‑flame propagating vs. flame propagating).

- Mechanical tests: Type tests including compression test, impact test, and bending test to verify mechanical strength and installation durability.

- Fire hazard and reaction to fire: Requirements and referenced glow‑wire and small‑flame test methods (see EN 60695 series).

- Ingress protection and environmental resistance: Degree of protection against solids and water (IP code / IEC 60529 references), and corrosion resistance for metallic or composite components.

- Marking, documentation and dimensions: Requirements for product identification, technical documentation and dimensional tolerances.

- Material and construction rules: Guidance on plain, corrugated and combined conduit constructions and methods for determining material thickness (normative annexes).

- Test conditions: Type test rules, sample sizes and test sequencing; national conditions may apply (Annex B).

Practical applications and users

This standard is intended for:

- Cable management product manufacturers designing conduits and fittings for buried installation.

- Specifiers, purchasers and procurement teams selecting conduit systems for civil, utility and telecom projects.

- Installation engineers and contractors who need to ensure components meet mechanical and environmental requirements for underground use.

- Testing laboratories and notified bodies performing type testing and conformity checks.

- Regulators and standards committees aligning national rules with CENELEC requirements.

Note: Purchasers/specifiers must also consider relevant national regulations and installation codes when selecting products.

Related standards and references

- EN 50626‑2 (performance time and leak‑tight solid wall conduits)

- EN ISO 13259 (leak‑tightness tests)

- IEC/EN 60529 (IP code for ingress protection)

- EN 60695‑2‑11, EN 60695‑11‑2 (fire test methods)

- ISO 2768 (general tolerances)

- Supersedes: EN 61386‑24:2010

Keywords: EN 50626-1:2023, conduit systems buried underground, insulated electrical cables, communication cables, conduit fittings, compression test, impact test, bending test, ingress protection, fire hazard.

Frequently Asked Questions

SIST EN 50626-1:2023 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Conduit systems buried underground for the protection and management of insulated electrical cables or communication cables - Part 1: General requirements". This standard covers: This document specifies requirements and tests for conduit systems with circular cross section buried underground for the protection and management of insulated conductors and/or power cables or communication cables installed individually or installed as a part of an assembly where the cable is installed by pulling or pushing. This document does not include requirements for leak-tightness according to EN ISO 13259 and performance time. NOTE 1 EN 50626 2 specifies requirements and tests for performance time and leak-tightness for solid wall conduit systems made of PE, PP and PVC-U buried underground where the cables are installed by blowing or floating or conduits are installed by trenchless methods. NOTE 2 It is the responsibility of the purchaser or specifier to take into account any relevant national regulations and installation practices or codes when selecting the products to be installed, based on the characteristics specified in this document.

This document specifies requirements and tests for conduit systems with circular cross section buried underground for the protection and management of insulated conductors and/or power cables or communication cables installed individually or installed as a part of an assembly where the cable is installed by pulling or pushing. This document does not include requirements for leak-tightness according to EN ISO 13259 and performance time. NOTE 1 EN 50626 2 specifies requirements and tests for performance time and leak-tightness for solid wall conduit systems made of PE, PP and PVC-U buried underground where the cables are installed by blowing or floating or conduits are installed by trenchless methods. NOTE 2 It is the responsibility of the purchaser or specifier to take into account any relevant national regulations and installation practices or codes when selecting the products to be installed, based on the characteristics specified in this document.

SIST EN 50626-1:2023 is classified under the following ICS (International Classification for Standards) categories: 29.120.10 - Conduits for electrical purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 50626-1:2023 has the following relationships with other standards: It is inter standard links to SIST EN 61386-24:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 50626-1:2023 is associated with the following European legislation: EU Directives/Regulations: 2006/95/EC, 2014/35/EU; Standardization Mandates: M/490, M/511. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 50626-1:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2023

Podzemni kanalski sistem za zaščito in upravljanje izoliranih električnih ali

komunikacijskih kablov - 1. del: Splošne zahteve

Conduit systems buried underground for the protection and management of insulated

electrical cables or communication cables - Part 1: General requirements

Erdverlegte Elektroinstallationsrohrsysteme für den Schutz und die Führung isolierter

elektrischer Kabel oder Fernmeldekabel – Teil 1: Allgemeine Anforderungen

Systèmes de conduits enterrés dans le sol pour la protection et la gestion des câbles

électriques isolés ou des câbles de communication - Partie 1: Exigences générales

Ta slovenski standard je istoveten z: EN 50626-1:2023

ICS:

29.120.10 Inštalacijske cevi za Conduits for electrical

električne namene purposes

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD EN 50626-1

NORME EUROPÉENNE

EUROPÄISCHE NORM July 2023

ICS 29.120.10 Supersedes EN 61386-24:2010

English Version

Conduit systems buried underground for the protection and

management of insulated electrical cables or communication

cables - Part 1: General requirements

Systèmes de conduits enterrés dans le sol pour la Erdverlegte Elektroinstallationsrohrsysteme für den Schutz

protection et la gestion des câbles électriques isolés ou des und die Führung isolierter elektrischer Kabel oder

câbles de communication - Partie 1: Exigences générales Fernmeldekabel - Teil 1: Allgemeine Anforderungen

This European Standard was approved by CENELEC on 2021-10-25. CENELEC members are bound to comply with the CEN/CENELEC

Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC

Management Centre or to any CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the

same status as the official versions.

CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the

Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Türkiye and the United Kingdom.

European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique

Europäisches Komitee für Elektrotechnische Normung

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CENELEC All rights of exploitation in any form and by any means reserved worldwide for CENELEC Members.

Ref. No. EN 50626-1:2023 E

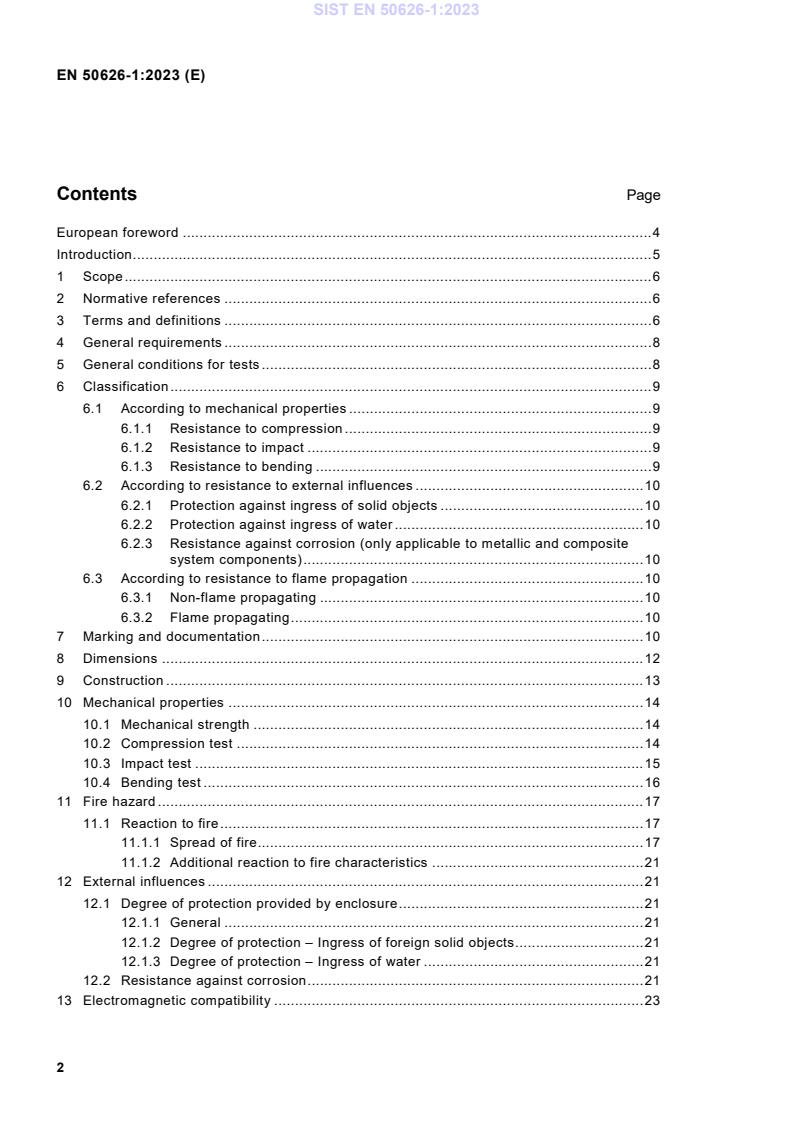

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General requirements . 8

5 General conditions for tests . 8

6 Classification . 9

6.1 According to mechanical properties . 9

6.1.1 Resistance to compression . 9

6.1.2 Resistance to impact . 9

6.1.3 Resistance to bending . 9

6.2 According to resistance to external influences . 10

6.2.1 Protection against ingress of solid objects . 10

6.2.2 Protection against ingress of water . 10

6.2.3 Resistance against corrosion (only applicable to metallic and composite

system components) . 10

6.3 According to resistance to flame propagation . 10

6.3.1 Non-flame propagating . 10

6.3.2 Flame propagating . 10

7 Marking and documentation . 10

8 Dimensions . 12

9 Construction . 13

10 Mechanical properties . 14

10.1 Mechanical strength . 14

10.2 Compression test . 14

10.3 Impact test . 15

10.4 Bending test . 16

11 Fire hazard . 17

11.1 Reaction to fire . 17

11.1.1 Spread of fire . 17

11.1.2 Additional reaction to fire characteristics . 21

12 External influences . 21

12.1 Degree of protection provided by enclosure . 21

12.1.1 General . 21

12.1.2 Degree of protection – Ingress of foreign solid objects . 21

12.1.3 Degree of protection – Ingress of water . 21

12.2 Resistance against corrosion . 21

13 Electromagnetic compatibility . 23

Annex A (normative) Determination of material thickness . 24

A.1 Material thickness of plain conduit . 24

A.2 Material thickness of corrugated conduit . 24

A.3 Material thickness of combined plain conduit and corrugated conduit . 25

A.4 Material thickness of plain conduit, with an intermediate corrugated layer . 25

Annex B (normative) Special national conditions . 26

Annex ZZ (informative) Relationship between this European standard and the safety

objectives of Directive 2014/35/EU [2014 OJ L96] aimed to be covered . 27

Bibliography . 28

European foreword

This document (EN 50626-1:2023) has been prepared by CLC/TC 213, “Cable management systems”.

The following dates are fixed:

• latest date by which this document has to be (dop) 2024-01-21

implemented at national level by publication of

an identical national standard or by

endorsement

• latest date by which the national standards (dow) 2026-07-21

conflicting with this document have to be

withdrawn

This document supersedes EN 61386-24:2010 and all of its amendments and corrigenda (if any).

— the scope has been modified for clarity and relationship with EN 50626-2;

— normative references have been updated;

— new definitions have been introduced;

— changes to general conditions for tests;

— changes to classifications;

— changes to tests for marking;

— changes to figure numbers;

— Clause 11 has been deleted and subsequent clauses renumbered;

— Clause 12 and Clause 13 have been replaced by new Clause 11.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CENELEC shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a Standardization Request given to CENELEC by the European

Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s)

/ Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZZ, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national committee. A complete

listing of these bodies can be found on the CENELEC website.

Introduction

CENELEC TC 213 is responsible for the development of the EN 50626 series, which consists of two separate

parts, both covering different products/applications.

This document covers requirements and tests for conduit systems buried underground for the protection and

management of insulated conductors and/or power cables or communication cables.

EN 50626-2 covers requirements and tests for conduit systems buried underground for the protection and

management of insulated conductors and/or power cables or communication cables having a specified

performance time and which are leak-tight solid wall conduit systems and manufactured in PE, PP and PVC-U.

A conduit system buried underground that conforms to this document is deemed to be safe for use.

This is a European Standard for cable management products used for electro-technical purposes. It relates to

the Council Directives on the approximation of laws, regulations and administrative provisions of the Member

States relating to Low Voltage Directive 2014/35/EU through consideration of the essential requirements of this

directive.

This document is supported by separate standards to which references are made.

1 Scope

This document specifies requirements and tests for conduit systems with circular cross section buried

underground for the protection and management of insulated conductors and/or power cables or communication

cables installed individually or installed as a part of an assembly where the cable is installed by pulling or

pushing.

This document does not include requirements for leak-tightness according to EN ISO 13259 and performance

time.

NOTE 1 EN 50626-2 specifies requirements and tests for performance time and leak-tightness for solid wall conduit

systems made of PE, PP and PVC-U buried underground where the cables are installed by blowing or floating or conduits

are installed by trenchless methods.

NOTE 2 It is the responsibility of the purchaser or specifier to take into account any relevant national regulations and

installation practices or codes when selecting the products to be installed, based on the characteristics specified in this

document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references, the

latest edition of the referenced document (including any amendments) applies.

Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 60529:1991,

EN 60695-2-11:2014, Fire hazard testing - Part 2-11: Glowing/hot-wire based test methods - Glow-wire

flammability test method for end-products (GWEPT) (IEC 60695-2-11:2014)

EN 60695-11-2:2017, Fire hazard testing - Part 11-2: Test flames - 1 kW nominal pre-mixed flame - Apparatus,

confirmatory test arrangement and guidance (IEC 60695-11-2:2013)

ISO 2768-1:1989, General tolerances — Part 1: Tolerances for linear and angular dimensions without individual

tolerance indications

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

conduit system

cable management system consisting of conduits and conduit fittings for the protection and management of

insulated conductors and/or cables in electrical or communication installations, allowing them to be drawn in

and/or replaced, but not to be inserted laterally

___________

As impacted by EN 60529:1991/A1:2000 and EN 60529:1991/A2:2013.

3.2

conduit

part of conduit system of circular cross-section for insulated conductors and/or cables in electrical or

communication installations, allowing them to be drawn in and/or replaced

3.3

conduit fitting

device designed to join components of a conduit system, or for them to change direction

3.4

terminating conduit fitting

conduit fitting that terminates a conduit system

3.5

metallic conduit and/or conduit fitting

conduit or conduit fitting which consists of metal only

3.6

non-metallic conduit and/or conduit fitting

conduit or conduit fitting which consists uniquely of non-metallic material and which has no metallic components

whatsoever

3.7

composite conduit and/or conduit fitting

conduit or conduit fitting comprising both metallic and non-metallic materials

3.8

non-flame propagating conduit and/or conduit fitting

conduit or conduit fitting which is liable to catch fire as a result of an applied flame, but in which the flame does

not propagate, and which extinguishes itself within a limited time after the flame is removed

3.9

plain conduit

conduit in which the profile is even in the longitudinal section

Note 1 to entry: The intermediate layer of a plain conduit can be corrugated.

Note 2 to entry: A typical example is shown in Figures A.1 and A.4.

3.10

corrugated conduit

conduit in which the profile is corrugated in the longitudinal section

Note 1 to entry: Both annular and helical corrugated conduits are permissible.

Note 2 to entry: A typical example is shown in Figure A.2

3.11

combined corrugated conduit and plain conduit

conduit in which the internal side is plain and external side is corrugated

Note 1 to entry: A typical example is shown in Figure A.3.

3.12

rigid conduit

conduit which cannot be bent, or which can only be bent with the help of a mechanical aid, with or without

special treatment

3.13

pliable conduit

conduit which can be bent by hand with reasonable force, and which is not intended for frequent flexing

3.14

external influence

factors which could affect the conduit system

Note 1 to entry: Examples of such factors are a presence of water, oil or building materials, low and high temperatures,

and corrosive or polluting substances.

3.15

hygroscopic material

material having the characteristic of enabling attraction or holding water greater than 1,0 % by weight of the

material from the surrounding environment at 23 °C and 50 % relative humidity

3.16

type test

test of one or more conduits or conduit fittings made to a certain design to show that the design meets certain

specifications

4 General requirements

4.1 Conduit and conduit fittings shall be so designed and constructed that in normal use their performance is

reliable and they provide protection to the user or surroundings.

When assembled in accordance with manufacturer's instructions as part of a conduit system, conduits and

conduit fittings shall provide mechanical and, where required, electrical protection of the insulated conductors

and cables contained therein.

4.2 The protective properties of the joint between the conduit and conduit fitting shall not be less than that

declared for the conduit system.

4.3 Conduit and conduit fittings shall withstand the stresses likely to occur during transport, storage,

recommended installation practice and application.

4.4 Compliance is checked by carrying out all specified tests.

5 General conditions for tests

Tests in accordance with this document are type tests. Conduit systems, having the same classification, which

can vary in colour only, shall be the same product type.

Where the conduit entries are part of the detachable or loose type conduit fitting, the detachable conduit fitting

shall be capable of being assembled again, after the test, according to the manufacturer's instructions without

loss of the declared properties according to Clause 6.

When toxic or hazardous processes are used, precautions shall be taken to safeguard the test personnel.

Unless otherwise specified in this document,

— three samples are subjected to the tests, and the requirements are satisfied if the tests are met. If only one

of the samples does not satisfy a test, due to an assembly or a manufacturing defect, that test and any

preceding one which could have influenced the result of the test shall be repeated, and also the tests which

follow shall be carried out in the required sequence on another full set of samples, all of which shall comply

with the requirements;

NOTE 1 If the additional set of samples is not submitted at the same time, a failure of one sample will entail a

rejection. The applicant, when submitting the first set of samples, can also submit an additional set of samples which

can be used, if one sample fails. The testing station will then, without further request, test the additional set of samples

and will reject them only if a further failure occurs.

— the tests shall be carried out within 1 min after conditioning and at an ambient temperature of (20 ± 5) °C;

— each test shall be made on three new samples, which may be taken from one length;

NOTE 2 Certain tests, for instance the checking of dimensions, do not affect a change in the property of the

samples; therefore, these samples are considered as new samples and can be used for further tests.

— samples of conduits and conduit fittings shall be conditioned for at least 24 h, at a temperature of (23 ± 2)

°C. Samples of conduits and conduit fittings made of material with hygroscopic behaviour shall be

conditioned for at least 240 h, at a temperature of (23 ± 2) °C and a relative humidity between 40 % and

60 %;

— the samples for each test shall be in a clean and new condition, with all parts in place and mounted as in

normal use. After checking dimensions in accordance with Clause 8, and unless otherwise specified in the

relevant test, the conduit fittings shall be assembled with the lengths of conduit of the type for which they

are intended, as defined in the relevant test. Due regard shall be taken of the manufacturer's instructions,

especially where force is required in the assembly of the joint.

NOTE 3 Where similarities are claimed, the selection of representative fittings for test purposes can be agreed

between the manufacturer, or responsible vendor, and the testing station.

6 Classification

6.1 According to mechanical properties

6.1.1 Resistance to compression

6.1.1.1 Type 250 (code 250)

NOTE A conduit system according to 6.1.1.1 is intended to be installed with additional precautions as specified in the

relevant national regulations.

6.1.1.2 Type 450 (code 450)

NOTE A conduit system according to 6.1.1.2 is intended to be directly buried underground without additional

precautions.

6.1.1.3 Type 750 (code 750)

NOTE A conduit system according to 6.1.1.3 is intended to be directly buried underground without additional

precautions.

6.1.2 Resistance to impact

6.1.2.1 Light (code L)

6.1.2.2 Normal (code N)

6.1.3 Resistance to bending

6.1.3.1 Rigid

6.1.3.2 Pliable

6.2 According to resistance to external influences

6.2.1 Protection against ingress of solid objects

Protection in accordance with EN 60529 to a minimum of IP3X.

6.2.2 Protection against ingress of water

Protection in accordance with EN 60529 to a minimum of IPX0.

6.2.3 Resistance against corrosion (only applicable to metallic and composite system components)

6.2.3.1 Without protection

6.2.3.2 With protection as detailed in Table 4

6.3 According to resistance to flame propagation

6.3.1 Non-flame propagating

6.3.2 Flame propagating

NOTE Conduit systems according to this document are normally flame propagating. Non-flame propagating conduit

systems might be required for some applications.

7 Marking and documentation

7.1 Each conduit shall be marked with the following information as a minimum:

— the manufacturer's or responsible vendor's name or trade mark or identification mark;

— a product identification mark, which may be, for example, the code of this document, a catalogue number,

a symbol or the like, in such a way that it can be identified in the manufacturer’s or responsible vendor’s

literature;

— the code “L” or “N” according to 6.1.2;

— the code “250”, “450” or “750” according to 6.1.1. This code shall be marked immediately after the code” L”

or “N”.

The following requirements apply for products with conduits inside another conduit:

— If the external conduit is marked according to this document, it is not required any marking for the inside

conduits,

— If the external conduit is not marked according to this document, all inside conduits shall be marked

according to this document.

7.1.1 The manufacturer shall be responsible for indicating the compatibility of parts within a conduit system.

NOTE Compatibility comprises mechanical compatibility of parts and also avoidance of galvanic couples within metallic

parts of the system.

7.1.2 The manufacturer shall provide in his literature its classification in accordance with Clause 6 and all

information necessary for the proper and safe transport, storage, installation and use.

7.2 The conduit fitting shall be marked in accordance with 7.1, on the product wherever possible, but, where

this is impractical, then the mark may be on a label attached to the product, or on the smallest supplied package.

7.3 Conduits shall be marked according to 7.1 at regular intervals along their length of preferably 1 m but not

longer than 3 m.

7.4 Compliance with 7.1 and 7.2 is checked by inspection. Compliance with 7.3 is checked by inspection and

measurement.

7.5 The marking shall be durable and clearly legible.

Compliance is checked by inspection, using normal or corrected vision, without additional magnification and by

rubbing the marking for 15 s with a piece of cotton cloth soaked with water and again for 15 s with a piece of

cotton cloth soaked with n-hexane 95 % (Chemical Abstracts Service Registry Number, CAS RN, 110-54-3).

NOTE n-hexane 95 % (Chemical Abstracts Service Registry Number, CAS RN, 110–54–3) is available from a variety

of chemical suppliers as a high pressure liquid chromatography (HPLC) solvent.

When using the liquid specified for the test, precautions as stated in the relative material safety datasheet

provided by the chemical supplier shall be taken to safeguard the laboratory technicians.

Laser marking directly on the product and marking made by moulding, pressing or engraving are not subjected

to this test.

The marking surface to be tested shall be dried before rubbing the marking with n-hexane 95 % solvent.

Rubbing shall commence immediately after soaking the piece of cotton, applying a compression force of (5 ± 1)

N at a rate of about one cycle per second (a cycle comprising a forward and backward movement along the

length of the marking). For markings longer than 20 mm, rubbing can be limited to a part of the marking, over a

path of at least 20 mm length.

The compression force is applied by means of a test piston which is wr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...