SIST EN 15179:2008

(Main)Railway applications - Braking - Requirements for the brake system of coaches

Railway applications - Braking - Requirements for the brake system of coaches

This standard defines basic requirements for the braking of passenger coaches in trains hauled by

locomotives as described in EN 14198, using UIC air brakes (RIC traffic) operating on routes of the European

railways and their infrastructure systems.

This standard covers:

.all new vehicle designs of the passenger coach type of construction (day coaches, restaurant cars,

sleeper coaches, driving trailers, baggage cars, etc.);

.all new constructions of existing vehicle types;

.other vehicles (e.g. motorail vehicles) that may also be included in passenger trains;

.all major overhauls of the above-mentioned vehicles if they involve redesigning or extensive alteration to

the brake system of the vehicle concerned.

The vehicles meet the following technical criteria:

.inclusion in trains in accordance with EN 14198 in regular railway operation is possible (coupling

capacity);

.the maximum speed is between 100 km/h and 200 km/h;

.the lower vehicle limitations of UIC 505-1 (WIs 00256150/151/152) are adhered to.

Bahnanwendungen - Bremsen - Anforderungen für die Bremsausrüstung von Reisezugwagen

Diese Europäische Norm legt grundsätzliche Anforderungen für die Bremsung von Reisezugwagen in nach

EN 14198 definierten lokbespannten Zügen mit UIC-Druckluftbremsen (RIC-Verkehr) fest, die auf den Strecken der europäischen Eisenbahnen und ihren Infrastruktursystemen verkehren.

Anhang E beschreibt Reisezugwagen, die ausschließlich innerhalb des Vereinigten Königreiches verkehren.

Diese Europäische Norm gilt für:

- alle neu zu konstruierenden Fahrzeuge der Reisezugwagenbauart (Sitzwagen, Speisewagen, Schlafwagen, Steuerwagen, Gepäckwagen, Liegewagen;

- alle zeitversetzten Nachbauten von vorhandenen Fahrzeugbauarten;

- sonstige Fahrzeuge (z. B. Autotransportwagen), die auch in Reisezügen mitgeführt werden können;

- alle größeren Grundüberholungen der o. g. Fahrzeuge, wenn diese Neukonstruktion oder umfassende Änderung der Bremsanlage ) des betreffenden Fahrzeuges einschließt.

Die Fahrzeuge entsprechen folgenden technischen Kriterien:

- eine Einstellung in Züge nach EN 14198 ist im regulären Bahnbetrieb möglich (Kuppelbarkeit);

- die Höchstgeschwindigkeit beträgt größer/gleich 100 km/h bis 200 km/h;

- die untere Fahrzeugbegrenzung nach prEN 15273-1, prEN 15273-2, prEN 15273-3 wird eingehalten.

Applications ferroviaires - Freinage - Exigences concernant le systeme de freinage des voitures voyageurs

Cette norme définit les exigences fondamentales pour le freinage des voitures à voyageurs dans les trains tractés par locomotive conformes à l'EN 14198 avec des freins pneumatiques UIC (transport RIC), roulant sur les réseaux européens et leurs systèmes d'infrastructure.

L’Annexe E décrit les voitures pour voyageurs qui circulent à l’intérieur du Royaume-Uni.

Cette norme est applicable à :

tous les véhicules nouvellement construits du type de construction de voitures à voyageurs (voitures à places assises, voitures-restaurants, voitures-lits, remorques à cabine de conduite, fourgons à bagages, voitures-couchettes) ;

l'ensemble des améliorations différées des types de véhicules existants ;

les autres véhicules (par exemple les wagons porte-autos) qui peuvent également être tractés dans les trains de voyageurs ;

toutes les grandes révisions des véhicules précités, si elles incluent une ré-étude ou des modifications conséquentes du système de freinage ).

Les véhicules correspondent aux critères techniques suivants :

le remaniement de composition des trains selon l’EN 14198 est possible sur une simple voie (sécabilité) ;

la vitesse maximale est supérieure/égale à 100 km/h jusqu'à 200 km/h ;

le gabarit inférieur du véhicule selon les prEN 15273-1, prEN 15273-2, prEN 15273-3 est maintenu.

Železniške naprave - Zavore - Zahteve za zavorne sisteme potniških vagonov

General Information

- Status

- Published

- Publication Date

- 02-Mar-2008

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 22-Feb-2008

- Due Date

- 28-Apr-2008

- Completion Date

- 03-Mar-2008

Overview

EN 15179:2007 - Railway applications: Braking - Requirements for the brake system of coaches is a European standard published by CEN that specifies basic braking requirements for passenger coaches using UIC air brakes (RIC traffic). It applies to new coach designs, new constructions of existing types, other vehicles used in passenger trains (e.g., motorail vehicles), and major overhauls that redesign or extensively alter the brake system. The standard targets coaches designed for operation on European railway infrastructure with a maximum speed between 100 km/h and 200 km/h and meeting coupling and vehicle gauge limitations.

Key topics and technical requirements

EN 15179 defines functional and performance criteria for coach brake systems. Major technical topics include:

- Brake control and basic principles - automatic train brake concepts, brake release devices, and load-proportional control.

- Components of the basic system - UIC-compatible valves, distributors, brake hoses and end cocks, and electro-pneumatic options (EBO).

- Additional braking devices - disc brakes, tread brakes, magnetic or auxiliary brakes where applicable.

- Thermal capacity - principles for disc and tread brake heat management and related design considerations.

- Brake performance - prescribed brake positions, performance targets and test-related requirements for service and emergency braking.

- Other components and requirements - parking brake, end-of-coach component layout, brake inscriptions/marks, maintenance accessibility and fault-finding provisions.

- Special cases and annexes - multi-section coaches, driving trailers, and a normative annex covering UK internal traffic requirements.

Practical applications and users

EN 15179 is used to ensure interoperable, safe braking on passenger coaches across European networks. Typical users and applications:

- Rolling stock designers and manufacturers - to design and validate compliant coach brake systems for tendered projects and new builds.

- Railway operators and maintenance organizations - for refurbishment, major overhauls and maintenance planning that affect brake systems.

- Infrastructure managers and interoperability assessors - to verify compatibility of coach braking with network requirements and EN 14198 coupling rules.

- Procurement and certification bodies - to define minimum brake specifications in Europe-wide tenders and conformity assessments.

Related standards

EN 15179 references and complements other standards and UIC leaflets, including:

- EN 14198 - Requirements for the brake system of trains hauled by a locomotive

- EN 14478 - Braking vocabulary

- EN 14535 series - Brake discs for rolling stock

- EN 14601 - End cocks for brake and reservoir pipes

- Relevant UIC leaflets (e.g., UIC 541 series on brakes)

- Additional EN / prEN documents on gauges, brake pads, relay valves and wheel slip prevention

Using EN 15179 helps deliver consistent, interoperable brake system designs for passenger coaches, improving safety, maintainability and cross-border operability on European railways.

Frequently Asked Questions

SIST EN 15179:2008 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Braking - Requirements for the brake system of coaches". This standard covers: This standard defines basic requirements for the braking of passenger coaches in trains hauled by locomotives as described in EN 14198, using UIC air brakes (RIC traffic) operating on routes of the European railways and their infrastructure systems. This standard covers: .all new vehicle designs of the passenger coach type of construction (day coaches, restaurant cars, sleeper coaches, driving trailers, baggage cars, etc.); .all new constructions of existing vehicle types; .other vehicles (e.g. motorail vehicles) that may also be included in passenger trains; .all major overhauls of the above-mentioned vehicles if they involve redesigning or extensive alteration to the brake system of the vehicle concerned. The vehicles meet the following technical criteria: .inclusion in trains in accordance with EN 14198 in regular railway operation is possible (coupling capacity); .the maximum speed is between 100 km/h and 200 km/h; .the lower vehicle limitations of UIC 505-1 (WIs 00256150/151/152) are adhered to.

This standard defines basic requirements for the braking of passenger coaches in trains hauled by locomotives as described in EN 14198, using UIC air brakes (RIC traffic) operating on routes of the European railways and their infrastructure systems. This standard covers: .all new vehicle designs of the passenger coach type of construction (day coaches, restaurant cars, sleeper coaches, driving trailers, baggage cars, etc.); .all new constructions of existing vehicle types; .other vehicles (e.g. motorail vehicles) that may also be included in passenger trains; .all major overhauls of the above-mentioned vehicles if they involve redesigning or extensive alteration to the brake system of the vehicle concerned. The vehicles meet the following technical criteria: .inclusion in trains in accordance with EN 14198 in regular railway operation is possible (coupling capacity); .the maximum speed is between 100 km/h and 200 km/h; .the lower vehicle limitations of UIC 505-1 (WIs 00256150/151/152) are adhered to.

SIST EN 15179:2008 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15179:2008 is associated with the following European legislation: EU Directives/Regulations: 2007-01-6194, 2011-01-2104, 93/38/EEC; Standardization Mandates: M/024. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15179:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Železniške naprave - Zavore - Zahteve za zavorne sisteme potniških vagonovBahnanwendungen - Bremsen - Anforderungen für die Bremsausrüstung von ReisezugwagenApplications ferroviaires - Freinage - Exigences concernant le systeme de freinage des voitures voyageursRailway applications - Braking - Requirements for the brake system of coaches45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 15179:2007SIST EN 15179:2008en,fr,de01-maj-2005SIST EN 15179:2008SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15179September 2007ICS 45.060.20 English VersionRailway applications - Braking - Requirements for the brakesystem of coachesApplications ferroviaires - Freinage - Exigences concernantle système de freinage des voitures voyageursBahnanwendungen - Bremsen - Anforderungen für dieBremsausrüstung von ReisezugwagenThis European Standard was approved by CEN on 3 August 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15179:2007: ESIST EN 15179:2008

Brake system of vehicles with UIC air brake.23 Annex B (normative)

Common train configurations.25 Annex C (informative)

Drainage devices, valves.26 Annex D (informative)

Equipment fitted at driving positions in driving trailers.30 Annex E (normative)

Requirements for internal traffic in the United Kingdom.32 E.1 General.32 E.2 Normative references.32 E.3 Brake systems other than those covered by the requirements of UIC.32 E.4 Functions at train level.33 E.5 Functions at vehicle level.33 E.5.1 Brake command and control.33 E.5.2 Brake force application system.34 E.6 Braking performance.34 SIST EN 15179:2008

Functional representation of the EBO system of the DB.36 F.1 Introduction.36 F.2 Design of the emergency brake override in conjunction with electro-pneumatic brake control.36 F.2.1 Electro-pneumatic brake control (ep).36 F.2.2 Emergency brake override (EBO).36 F.3 Transmission systems for information and control commands in the DB system.37 Annex G (informative)

Emergency brake handles.40 Annex H (informative)

Basic arrangement of the brake system and arrangement of the brake pipes.41 Bibliography.47

Before this time, brake engineering regulations only existed as internal railway documents in the form of UIC leaflets.

Agreements based on these govern the conditions for vehicle transfers between the individual railways. The relationship between the infrastructures and the minimum brake engineering requirements on trains and their individual vehicles is defined in EN 14198.This covers mainly generic vehicle regulations that should be assigned to individual vehicles by corresponding specifications.

With this European Standard, all suppliers will in future be able to offer in a Europe-wide tender invitation passenger coaches that have a defined basic brake engineering system and meet the minimum brake engineering requirements, taking into account the vehicle types SIST EN 15179:2008

1 Scope This European Standard defines basic requirements for the braking of passenger coaches in trains hauled by locomotives as described in EN 14198, using UIC air brakes (RIC traffic) operating on routes of the European railways and their infrastructure systems. Normative Annex E is provided for passenger coaches limited to internal use in the UK. This European Standard covers:

all new vehicle designs of the passenger coach type of construction (day coaches, restaurant cars, sleeper coaches, driving trailers, baggage cars, couchette coaches); ¾ all new constructions of existing vehicle types; ¾ other vehicles (e.g. motorail vehicles) that may also be included in passenger trains; ¾ all major overhauls of the above-mentioned vehicles if they involve redesigning or extensive alteration to the brake system1 of the vehicle concerned. The vehicles meet the following technical criteria: ¾ inclusion in trains in accordance with EN 14198 in regular railway operation is possible (coupling capacity); ¾ the maximum speed is between 100 km/h and 200 km/h; ¾ the lower vehicle limitations of prEN 15273-1, prEN 15273-2, prEN 15273-3

are adhered to.

2 Normative references The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any amendments) applies. EN 286-3, Simple unfired pressure vessels designed to contain air or nitrogen — Part 3: Steel pressure vessels designed for air braking equipment and auxiliary pneumatic equipment for railway rolling stock EN 286-4, Simple unfired pressure vessels designed to contain air or nitrogen — Part 4: Aluminium alloy pressure vessels designed for air braking equipment and auxiliary pneumatic equipment for railway rolling stock

EN 10220, Seamless and welded steel tubes — Dimensions and masses per unit length EN 10305-4, Steel tubes for precision applications — Technical delivery conditions — Part 4:

Seamless cold drawn tubes for hydraulic and pneumatic power systems EN 10305-6, Steel tubes for precision applications — Technical delivery conditions — Part 6: Welded cold drawn tubes for hydraulic and pneumatic power systems

1 or alterations to the vehicle weight also. SIST EN 15179:2008

EN 14478:2005, Railway applications — Braking — Generic vocabulary EN 14535-1, Railway applications — Brake disks for railway rolling stock — Part 1: Brake discs pressed or shrunk onto the axle or drive shaft, dimensions and quality requirements

EN 14601, Railway applications — Straight and angled end cocks for brake pipe and main reservoir pipe

prEN 15220-1, Railway applications — Brake indicators —

Part 1: Pneumatic operation brake indicators prEN 15273-2, Railway applications — Gauges — Part 2:

Rolling stock gauge

prEN 15273-3, Railway applications — Gauges — Part 3: Obstacle gauge

prEN 15327-1, Railway applications — Passenger

alarm subsystem — Part 1: General

requirements and passenger interface

for the passenger emergency brake

system prEN 15328, Railway applications — Braking — Brake pads prEN 15355,

Railway applications — Braking — Distributor valves prEN 15595, Railway applications — Braking — Wheel slip prevention equipment prEN 15611, Railway applications — Braking — Relay valves prEN 15612, Railway applications — Braking — Brake pipe accelerator valve EN 50125-1, Railway applications — Environmental conditions for equipment — Part 1:

Equipment on board rolling stock

prEN 14535-22, Railway applications — Brake discs for railway rolling stock — Part 2: Brake discs mounted onto the wheel rim, wheel web or wheel hub, dimensions and quality requirements UIC 541-1:20033, Brakes — Regulations concerning the construction of the various brake components UIC 541-3:1984, Brakes — Disc brakes and their application —- General conditions for the approval of brake pads UIC 541-5, Brakes — Electro-pneumatic brake (ep-brake) — Electro-pneumatic emergency brake override (EBO) UIC 541-06, Brakes — Regulations concerning the construction of the various brake components — Magnetic brakes UIC 544-1, Brakes — Braking power UIC 545:2003, Brakes — Inscriptions, marks and signs UIC 546, Brakes — High-power brakes for passenger trains UIC 550, Power supply installations for passenger stock

2 To be published.

3 Available from: UIC Direction Générale, 16 rue Jean Rey, F-75015 Paris. SIST EN 15179:2008

passenger coach vehicle without its own traction unit, for conveying people and comprising

a body; ¾ running gear (e.g. 2 bogies); ¾ specific connectors at coach ends (coupling capacity); ¾ brake installation; ¾ service installations for passengers (air conditioning, catering, luggage transport

etc.); ¾ a driving cab if the vehicle is a driving trailer. Passenger coaches may also comprise two or more bodies with associated running gear (modules) forming a functional unit.

The connectors (connections) between the modules may be individually designed.

The end connectors of the functional unit should be suitable for the interchange conditions.

Coaches for which special traction units are mandatory (ICE, TGV) are not considered to be passenger coaches

3.2 automatic train brake brake at train level, the action of which is based on the fact that a break in the brake pipe (pipe for control commands) in the two parts of the train automatically leads to application of the brakes

3.3 brake release device device operable from each side of the coach which, when operated, releases the brake

NOTE In UIC distributors, this equalizes the pressure in the control chamber to the value of the pressure in the brake pipe or below 3.4

brake release device operable from each side of the coach which, when operated, releases the brake

3.5 load-proportional brake control device for automatically matching the brake force to the specific vehicle load, whereby the adjustment may be in steps or continuous 3.6 indicating and warning devices devices that show the status of the brake system or sub-systems.

The information is given by windows, position of handles, analogue gauges, digital displays, lamps or buzzers

NOTE For indicating the status in service, a binary indication (on/off) is used. Analogue gauges (dials or digital displays) are for maintenance purposes

3.8 brake hose couplings flexible hose connections at the end of the coach with brake-hose coupling head to UIC 541-1, of different shapes for brake pipe and main reservoir pipe NOTE A European Standard is in preparation for this (WI 00256241) 3.9 auxiliary tread brake tread brake acting generally on one side of the wheels to support the power of the disc brake.

3.10 release time on brake release, the time taken for the brake cylinder pressure to fall in accordance with prEN 15355

3.11 maximum mass sum of the operating load of the coach and the maximum payload

NOTE 1 In contrast to the total mass, it takes into account extreme occupancy

NOTE 2 A European Standard is in preparation for this (WI 00256224).

3.12

laden mass sum of the operating load of the coach and the nominal payload

NOTE A European Standard is in preparation for this (EN 00256224).

3.13

constant mass assumption fictional value for the mass of the passengers in a coach. It is based on 100 % of seats occupied. The mandatory constant mass assumption is specified in UIC 410 for the different types of vehicles

NOTE A European Standard is in preparation for this (WI 00256224).

4 Symbols and abbreviations For the purposes of this European Standard, the following symbols and abbreviations apply in accordance with existing UIC leaflets: BP:

Air brake pipe MRP:

Main reservoir pipe DBV:

Driver's brake valve ED:

Electro-dynamic brake

EP:

Electro-pneumatic brake ep(UIC): Electro-pneumatic brake as specified in UIC 541-5

BA:

Brake pipe accelerator FRA Federal Railway Authority RCOR Railways Construction and Operating Regulations

WSP:

Wheel slide protection HD:

Hydro-dynamic brake

EP/EBO: Electro-pneumatic emergency brake override Mg:

Magnetic track brake RGS Railway Group Standard Wb

Eddy-current brake :

Effective braking power

R:

Air reservoir On/Off:

Brake On/Off controller G, P, R:

Brake positions according to UIC DV:

Distributor valve AL:

Automatic load-proportional brake SO

Top edge of rail SIST EN 15179:2008

The manufacturers shall indicate in the tender where the requirements of the standard are not met. Vehicles as specified in this standard shall totally meet the relevant generic requirements described in

EN 14198 for the train and the resulting requirements for the individual vehicles.

These requirements are defined for the individual vehicle in the clauses:

brake control; ¾ thermal capacity; ¾ brake performance; ¾ other brake components. The specific requirements are allocated in vehicle classes.

The specific brake systems mandatory for the particular vehicle class are contained in Table A.1. Each vehicle class is divided into subclasses for additional brake devices. 5.2 Climatic conditions In general, the requirements of EN 50125-1 apply.

The requirements listed below are minimum requirements.

The temperature class according to EN 50125-1 shall be specified by the Railway Authoritiy.

The functional ability of the brake shall be achieved under the following conditions unless deviations have been agreed for the associated vehicle:

outside temperature – 25 °C to + 40 °C (in sunshine up to + 70 °C); ¾ altitude up to 1 370 m above sea level; ¾ relative humidity up to 100 %; ¾ snowfall, lying snow up to 300 mm above top edge of rail; ¾ rain, ice; ¾ gusts of wind up to 30 m/s The special climatic conditions in tunnels (e.g. Simplon up to 27 °C and 100 % relative humidity in winter also) should be noted. 5.3 Brake control 5.3.1 Basic principles The brake installation for each vehicle shall meet the requirements of the UIC brake system. The basic system arrangement is shown in Figure H.1. SIST EN 15179:2008

The brake control system shall be able to provide the passenger train and goods train brake types and the associated brake positions and have the standardized operating and indicating devices on the coach sides. 5.3.2 Components of the basic system The components described in the following are brake components in the coach that are to be assigned to train level 5 or vehicle level 6 in accordance with Figure H.2. 5.3.2.1 Air brake pipe (BP) and main reservoir pipe (MRP) All vehicles shall be equipped with a continuous air brake pipe (BP) and a continuous main reservoir pipe (MRP) in a bifurcated connection each with an inside diameter of at least 25 mm.

The basic function of the brake system (transmission of braking command and control function, energy supply) shall be possible via the BP alone.

The compressed air in the BP shall not be used for other purposes not related to the brake installation. The compressed air in the MRP can be used for supplying energy to other loads in the vehicle (door operating, toilets, air springs etc.) in addition to supplying energy for the brake installation. The air pipes shall be installed free of water collection pockets and be as straight as possible utilizing large bend radii (minimum dimension for bend radius 5 ´ Da = outside diameter).

The bifurcation shall be achieved by means of a Y-connection.

Filters or other components that would reduce the cross-section of the BP shall not be fitted.

If low points are unavoidable in routing the pipes, easily accessible drainage devices shall be fitted. Free passage through BPs and MRPs shall be capable of being verified by means of a ball test. The diameter of the ball to be used shall be 19 mm.

Steel pipes used shall meet the requirements of EN 10220 or

EN 10305-4 or EN 10305-6.

The number of pipe fittings used shall be kept to a practical minimum and all fittings shall be accessible without having to disassemble other equipment. Connections consisting of threads on the pipes are not permitted. The pipe connections at the coach end shall meet the UIC requirements. A recommended method of fitting is described in 5.3.2.6.

This takes account of the installation space for the end cocks and the space requirement of other pipe connections also for the possible counter-movements of the vehicles to be coupled. 5.3.2.2 Controller Every vehicle shall be equipped with at least one distributor valve which complies with the requirements of

prEN 15355.

The maximum BP volume of 25 l shall be assigned to any distributor valve.

For connection into the coach brake system, the diagram illustrated in Figure H.2 of this European Standard applies.

The controller indicated as item 10 is connected by its large pipe cross-section to the BP and is connected to the E-store (reserve air tank (R-tank) and the devices generating the brake force thus allowing single-pipe operation (operation without MRP). The supply to the energy store is from the BP through the controller.

Every controller shall be equipped with one or more isolation devices that can be operated from both sides of the vehicle.

Operation of these devices shall isolate the controller from the brake pipe and the main reservoir pipe and isolate any other brake related devices (e.g. track brake, etc.) from the main reservoir pipe. The brake cylinders and the auxiliary reservoir shall then be vented, either automatically or manually using another control device that can also be operated from both sides of the vehicle. Free passage of air through the BP and MRP shall be maintained on that vehicle. Every controller shall also be equipped with a device that allows the brake on that vehicle to be released when it is applied (release valve).

Every controller shall be equipped with a mode switch for the selection of brake positions (e.g. G, P, R, R+Mg) that can be operated from both sides of the vehicle.

Test points shall be fitted for the verification of the correct functioning of the controller; at least the output pressure and the load- and speed-dependent pressures, e.g. brake cylinder pressures. 5.3.2.3 Energy store Every controller shall be connected to an energy store so that energy can be fed from this store into the devices generating the brake force when a brake command is given.

The energy store shall be dimensioned so that, when the brake is applied, the available brake power at each point in the train journey and for all track conditions meets the requirements of the UIC brake system. The inexhaustibiity as defined in EN 14198 shall be achieved.

The energy store for pneumatically-operated brake systems shall also be fed from the MRP via filter, pressure-reducing valve, isolating cock and non-return valve.

The energy store for compressed air shall be in accordance with EN 286-3 and EN 286-4. Maintenance aspects are covered by UIC 541-07 or other applicable documents, e.g. DIN 5590 and DIN 5580.

Requirements of the energy stores for electrically-operated brake systems shall be according to UIC 550.

5.3.2.4 Passenger emergency brake and emergency brake override 5.3.2.4.1 Basic principles – system interfaces All passenger vehicles shall be equipped with a passenger emergency brake. The passenger emergency brake is located in the "Decentralized command initiation for automatic application of brakes" block (see EN 14198 and Figure H.1 of this European Standard) and on actuation of an operating element (emergency brake handle according to prEN 15327-1) initiates the triggering of an emergency brake valve and thus the activation of the automatic brake of the train. Automatic application of the brake at train level is initiated.

Activation of the automatic train brake by operation of an emergency brake handle shall also be possible with the vehicle brake isolated. When a passenger emergency brake handle has been operated, it shall be automatically locked in this position. An activated emergency brake becomes ineffective with the actuation by the train crew of the resetting device on the applied emergency brake box or activation of the EBO by the train driver in accordance with the operating regulations of the Railway Authorities. SIST EN 15179:2008

The signal line shall not be capable of being interrupted/blocked.

An exception is the EBO. The requirements of Clause II of UIC 541-1:2003 and prEN 15327-1 shall be met.

The relevant provisions of the national approval authorities shall be met, unless superordinate regulations exist. 5.3.2.4.2 Emergency brake override (EBO) An emergency brake override function shall be provided if mandatory in the vehicle specification.

Equipping with EBO is mandatory for travelling over certain infrastructures (e.g. high-speed tracks, tracks with long tunnels). For details concerning rolling stock used only nationally or in bilateral traffic, see national regulations.

The aim of the EBO is for the applied passenger emergency brake to be overridden through a positive action of the driver in accordance with the operating rules of the relevant railway in order to keep the train in motion or to enable an immediate restart. In order to attain the shortest release time of the brake, all vehicles equipped with the EBO function shall be equipped with an ep assist brake. In order to signal clearly to the driver that the passenger emergency brake has been applied and to enable him to override it quickly, where appropriate, the status shall be clearly indicated by an indicator light or audibly by a horn or announcement in the active cab.

In the vehicle/train section in which the emergency brake has been applied, a red flashing indicator light shall indicate to the crew the emergency brake that has been applied until the emergency brake handle is reset. It shall be possible to test the signal transmission paths for the applied emergency brake and the emergency brake override within the context of the brake test in the train. For trains hauled by locomotives, the EBO systems as specified in UIC 541-5 with control via a separate line as shown in Figure H.4 shall be used. NOTE Other national systems are currently in use and may continue to be used for internal traffic of certain Railway Authorities, e.g. the DB system with control via a UIC 558 line.

A functional description of this system is included in

Annex F for information. 5.3.2.4.3 Operating elements of the passenger emergency brake Vehicles conveying passengers shall have clearly visible and accessible emergency brake handles by means of which emergency braking is possible.

Erroneous activation of the device shall not be possible The passenger shall be able to reach emergency brake handles without having to pass through a door. In the vestibules at the ends of the coaches and in the toilets and washrooms, no emergency brake handles need to be deployed. The technical design of the emergency brake handles is specified in prEN 15327-1. Guidelines as to the location of these components within the vehicle are given in Annex F. 5.3.2.5 Indicator and actuation devices Each vehicle shall be fitted with devices to enable functional testing, monitoring and actuation of the brake installation.

These devices shall also permit testing of the brakes in service (brake test) in accordance with the regulations of the Railway Authorities. These devices shall meet the requirements of the following regulations: ¾ for changeover devices:

UIC 541-1; SIST EN 15179:2008

UIC 541-1; ¾ for brake isolating cocks:

UIC 541-1; ¾ for disk brakes:

prEN 15220-1; ¾ for magnetic track brakes:

UIC 541-06; ¾ for regenerative brakes:

UIC 546. The following general principles apply:

visible and operational from both sides of the vehicle; ¾ clear and unmistakeable indication of the status of the associated brake equipment from both sides of the train. Indicator panels in intermediate positions (split colour panels) are not allowed;

NOTE Sudden and smooth changeover from one indication status to the other: "smooth" is understood to mean

that the changeover period from one indicator status to the other is not to exceed 2 s. Deviation from this is

permitted if the changeover phase is clearly recognized by the tester

¾ clear assignment of the indicator panels to the object principle: a specific indicator panel shall be provided for each distributor/load brake valve. Indicator panels shall be marked only for handbrake or spring-loaded brake;

¾ if more than one signal source supplies an indicator panel, the following priority shall apply; ¾ brake functional; ¾ brake not released; ¾ brake released. If it is not possible to evaluate the information from several signal sources conclusively on one indicator panel, the signal sources shall be separated. The correctness of the match of the colours and symbols with the actual state of the brakes shall be ensured. . 5.3.2.6

Coach connections The arrangement of the brake components at the end of the coach shall be in accordance with EN 14601. Connections shall be arranged as shown in Figures H.3, H.4 and H.5. Figure H.3a shows the arrangement of the communications jumpers in accordance with UIC 568.

These jumpers transmit low-power 24 V electric signals and commands. Figure H.3c shows the layout of the BP and MRP.

The double arrangement of the pipe outlets (bifurcation) is mandatory so that the hose connections cannot be crossed.

The handles (F) for the isolating cocks shall be mounted opposite the drawgear, i.e. left-hand and right-hand types shall be used.

The handle position shown indicates the closed cock position.

Equipping coaches with additional braking devices is regulated according to the subclasses of the coach classes in Table A.1 5.3.3.2 ep-brake

The requirements of UIC 541-5 shall be met.

Figure H.4 illustrates the installation of the UIC ep-control cable. The associated dimensions are given in Table 1. In addition, other ep-brake control systems (e.g. via the UIC-IS line, cores 9 to 12, according to UIC 558) may be agreed upon. Installation of the cables is shown in Figure H.5. Table 1 — Table of dimensions relating to Figure H.4 XX Coupling cable

YY Dummy socket

ZZ Socket A 475 to 660

D

G 475 to 660b B 125 to 375

E

H 125 to 275 C 530 to 600/650a

F

I 535 to 605 L 1440 to 1450

Freely selectable providing all other dimensions specified in Figure H.4 are respected

b 0 to15° a 25° to 35°

a 650 mm allowed for passenger coaches

b The dimension Gmax = 660 mm may be increased by DG if the dimension Imax = 605 mm is reduced by DI simultaneously (DI = 0,75 DG). DGmax 80 mm

5.3.3.3 Magnetic track brake The requirements of UIC 541-06 shall be met. The requirements of this subclause also apply if a different source of energy is required for operating the Mg brake.

NOTE Additional requirements on the Mg brake will be contained in a future European Standard.

5.3.3.4 Brake pipe accelerator The accelerator shall be designed in accordance with prEN 15612.

5.3.3.5 Wheel slide protection Passenger coaches with brake positions R and R+Mg shall be equipped with wheel slide protection according to the requirements of prEN 15595. For passenger coaches with only brake position P, the use of wheel slide protection is recommended. If several brakes act on one axle or wheel, the brakes may be controlled by just one wheel slide protection system or by separate wheel slide protection systems.

In both cases, careful matching is required so that the wheel slide protection function is reliably ensured (i.e. braking distance optimization in the event of unfavourable wheel/rail adhesion conditions, prevention of wheel locking). SIST EN 15179:2008

5.4 Thermal capacity 5.4.1 Principles The following braking modes are to be considered with regard to the operating conditions:

a) braking to a stop Two rapid successive operations from maximum speed at maximum weight on the level with fully functional brake installation without the effect of any adhesion value independent brakes. b) drag braking Requirements from downward runs (drag braking) and failure scenarios (brake faults) shall be taken into account if they are not covered by the most unfavourable agreed operating case. The reference travel section is currently the Gotthard-Süd route between Airolo and Biasca with

vmax = 80 km/h, a mean gradient of i = 21 ‰ and a distance of 46 km. If higher or lower performance requirements for both a) or b) above are necessary or possible, then these performance requirements shall be defined by the lead Railway Authorities in the form of brake load collectives (most unfavourable operating case agreed)

5.4.2 Disc brake The disc brake represents the main component of the mechanical brake installation.

It consists of axle-mounted brake discs in accordance with EN 14535-1 or wheel-mounted brake discs in accordance with prEN 14535-2 and the associated brake actuators. The disc brake shall automatically adjust to compensate for the wear of the brake pad and the brake disc. It shall be possible to incorporate parking/handbrake functions. Brake pads in accordance with prEN 15328 shall be used. The products to be used may be specified by the purchaser. When installing axle-mounted brake discs, the bottom reference line as specified in Figure 4 of

prEN 15273-2:2005 for the smallest possible wheel tread diameter shall not be exceeded.

The following wheelset load/brake disc limit values are recommended for standard cast iron brake discs and organic brake pads in accordance with UIC 541-3 up to 200 km/h:

Axle-mounted brake disc

610 x 110 mm

5,8 t

Axle-mounted brake disc

640 x 110 mm

6,0 t

Wheel-mounted brake disc

610 mm

5,5 t

Limit values deviating from these (e.g. for other friction surfaces or conditions of use) may be agreed upon, in which case, the procedure described in 5.4.1 shall be followed.

The friction materials for the cast iron brake blocks and their geometrical form are defined in prEN 15329 and WI 00256239. 5.4.4 Dynamic brakes Dynamic brakes replace or supplement the friction brake.

They shall be designed as a self-contained subsystem of the coach as electro-dynamic, hydraulic or eddy-current brakes and be controlled via the central brake control pipe.

The brake force characteristic for the same brake requirement (BP pressure step) shall be the same as that resulting from the requirements for the brake control and brake mechanics.

The braking power with blending shall also comply with these requirements. The power required in the different brake positions shall be met in accordance with 5.5.

5.5 Brake performance 5.5.1 General The brake components of passenger train coaches shall be capable of supplying the required braking performances related to the stopping distance. Each brake position corresponds to a specific braking performance range. The brake positions are assigned to the vehicle classes in Annex A. A general overview is given in Annex B.

All wheelsets shall be braked in such a way that the level of wheel/rail adhesion demanded is nominally the same for all wheelsets. The quotient of the brake force relative to the wheel circumference and wheel contact surface force shall be approximately the same for all the wheelsets.

Deviations may be agreed upon. The conditions of UIC 544-1 shall be adhered to regarding adhesion value limits.

The brake force in the individual brake positions is expressed by the braked weight.

The braked weight shall be inscribed on the vehicle. Details are specified in 5.6.3.

If the vehicle classification according to Annex A and Annex B is maintained, it is possible for operational reasons to inscribe a smaller braked weight. The braked weight will be determined according to UIC 544-1.

5.5.2 Brake positions (basic system) 5.5.2.1 Brake position G The requirements of prEN 15355 shall apply.

5.5.2.3 Brake position R The requirements of prEN 15355, prEN 15611 and UIC 546 shall apply.

5.5.3 Brake positions and additional brake system 5.5.3.1 Brake position with brake pipe accelerator The brake pipe accelerator as described in 5.3.3.4 is effective principally in all brake positions.

The efficiency of the brake pipe accelerator shall only be regarded in the brake calculation if the brake is operated in the brake positions R and R+Mg. The braked weight including the brake pipe accelerator is inscribed in red figures on the coach.

5.5.3.2 Brake position with Mg-brake The requirements of UIC 541-06 shall apply. 5.5.3.3 Brake position with ep-assist brake For installed ep-assist brake components, no special brake position is to be provided in passenger coaches. The ep-braking command shall be provided exclusively by the driver’s brake valve in the driving cab. Isolation devices are only provided in the case of defects/malfunctions. The ep-assist brake status according to

UIC 541-5 is detected by the control unit in the driving cab.

5.5.3.4 Brake position with automatic load-proportional braking For automatic load-proportional braking, no additional brake positions exist. Its existence is identified in the brake inscription in accordance with UIC 545.

Automatic load-proportional braking is to be provided if the empty/loaded ratio of the vehicle for the high performance brake in accordance with UIC 546 is more than 1,26 and for the brake pipe accelerator Rrot it exceeds the value 1,14. The technical design is in accordance with prEN 15611 and prEN 15625. 5.6 Other brake components 5.6.1 Parking brake Each coach shall be equipped with a parking brake. The parking brake shall be act on at least half of all the wheelsets, but on at least two of them.

It shall securely hold the empty vehicle on a gradient of 35 ‰. The braked weight is determined according to

UIC 544-1.

An indicator shall be provided so that the application status of the parking brake can be easily determined. Deviations shall be agreed in the specification sheets. The holding effect shall result from a force on the handwheel of 0,5 kN. Where a parking brake is operated by a handwheel, it may be accommodated behind a fl

...

SLOVENSKI STANDARD

01-maj-2008

Železniške naprave - Zavore - Zahteve za zavorne sisteme potniških vagonov

Railway applications - Braking - Requirements for the brake system of coaches

Bahnanwendungen - Bremsen - Anforderungen für die Bremsausrüstung von

Reisezugwagen

Applications ferroviaires - Freinage - Exigences concernant le systeme de freinage des

voitures voyageurs

Ta slovenski standard je istoveten z: EN 15179:2007

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 15179

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2007

ICS 45.060.20

English Version

Railway applications - Braking - Requirements for the brake

system of coaches

Applications ferroviaires - Freinage - Exigences concernant Bahnanwendungen - Bremsen - Anforderungen für die

le système de freinage des voitures voyageurs Bremsausrüstung von Reisezugwagen

This European Standard was approved by CEN on 3 August 2007.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the

official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2007 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15179:2007: E

worldwide for CEN national Members.

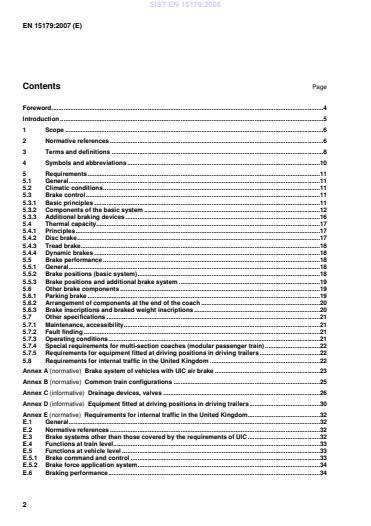

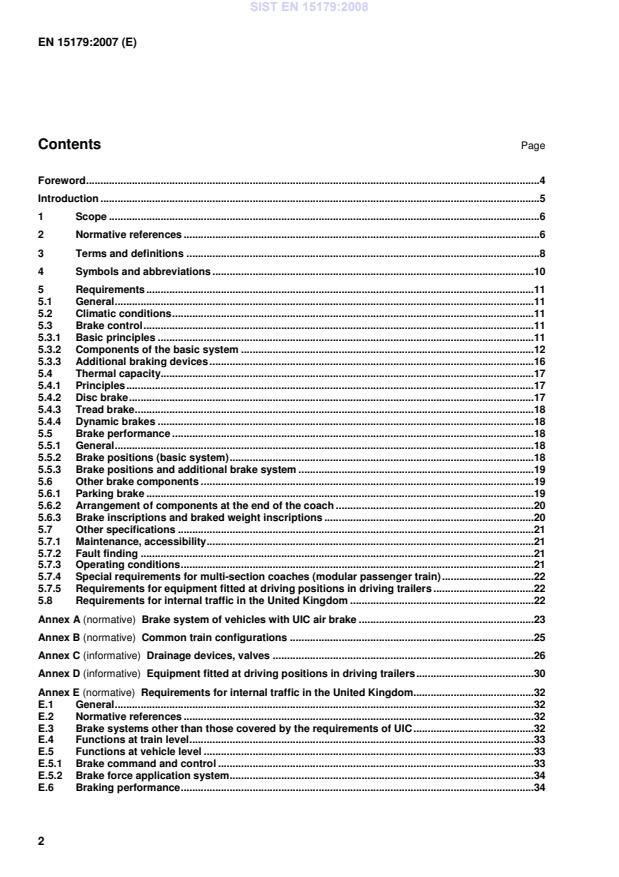

Contents Page

Foreword.4

Introduction .5

1 Scope .6

2 Normative references .6

3 Terms and definitions .8

4 Symbols and abbreviations .10

5 Requirements.11

5.1 General.11

5.2 Climatic conditions.11

5.3 Brake control.11

5.3.1 Basic principles .11

5.3.2 Components of the basic system .12

5.3.3 Additional braking devices .16

5.4 Thermal capacity.17

5.4.1 Principles.17

5.4.2 Disc brake.17

5.4.3 Tread brake.18

5.4.4 Dynamic brakes .18

5.5 Brake performance .18

5.5.1 General.18

5.5.2 Brake positions (basic system).18

5.5.3 Brake positions and additional brake system .19

5.6 Other brake components .19

5.6.1 Parking brake .19

5.6.2 Arrangement of components at the end of the coach .20

5.6.3 Brake inscriptions and braked weight inscriptions .20

5.7 Other specifications .21

5.7.1 Maintenance, accessibility.21

5.7.2 Fault finding .21

5.7.3 Operating conditions.21

5.7.4 Special requirements for multi-section coaches (modular passenger train).22

5.7.5 Requirements for equipment fitted at driving positions in driving trailers .22

5.8 Requirements for internal traffic in the United Kingdom .22

Annex A (normative) Brake system of vehicles with UIC air brake .23

Annex B (normative) Common train configurations .25

Annex C (informative) Drainage devices, valves .26

Annex D (informative) Equipment fitted at driving positions in driving trailers.30

Annex E (normative) Requirements for internal traffic in the United Kingdom.32

E.1 General.32

E.2 Normative references .32

E.3 Brake systems other than those covered by the requirements of UIC.32

E.4 Functions at train level.33

E.5 Functions at vehicle level .33

E.5.1 Brake command and control .33

E.5.2 Brake force application system.34

E.6 Braking performance.34

E.6.1 General .34

E.6.2 Braking performance of trains operating on UK infrastructures .35

Annex F (informative) Functional representation of the EBO system of the DB.36

F.1 Introduction.36

F.2 Design of the emergency brake override in conjunction with electro-pneumatic brake

control.36

F.2.1 Electro-pneumatic brake control (ep).36

F.2.2 Emergency brake override (EBO) .36

F.3 Transmission systems for information and control commands in the DB system.37

Annex G (informative) Emergency brake handles.40

Annex H (informative) Basic arrangement of the brake system and arrangement of the brake

pipes .41

Bibliography.47

Foreword

This document (EN 15179:2007) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by March 2008, and conflicting national standards shall be withdrawn at

the latest by March 2008.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain,

Sweden, Switzerland and the United Kingdom.

Introduction

Currently, in the standard gauge area, there are EU regulations in the form of interoperability directives and

the associated TSI that also contain specifications for the braking of railway vehicles. Before this time, brake

engineering regulations only existed as internal railway documents in the form of UIC leaflets.

Agreements based on these govern the conditions for vehicle transfers between the individual railways. The

relationship between the infrastructures and the minimum brake engineering requirements on trains and their

individual vehicles is defined in EN 14198.This covers mainly generic vehicle regulations that should be

assigned to individual vehicles by corresponding specifications.

With this European Standard, all suppliers will in future be able to offer in a Europe-wide tender invitation

passenger coaches that have a defined basic brake engineering system and meet the minimum brake

engineering requirements, taking into account the vehicle types

1 Scope

This European Standard defines basic requirements for the braking of passenger coaches in trains hauled by

locomotives as described in EN 14198, using UIC air brakes (RIC traffic) operating on routes of the European

railways and their infrastructure systems.

Normative Annex E is provided for passenger coaches limited to internal use in the UK.

This European Standard covers:

all new vehicle designs of the passenger coach type of construction (day coaches, restaurant cars,

sleeper coaches, driving trailers, baggage cars, couchette coaches);

all new constructions of existing vehicle types;

other vehicles (e.g. motorail vehicles) that may also be included in passenger trains;

all major overhauls of the above-mentioned vehicles if they involve redesigning or extensive alteration to

the brake system of the vehicle concerned.

The vehicles meet the following technical criteria:

inclusion in trains in accordance with EN 14198 in regular railway operation is possible (coupling

capacity);

the maximum speed is between 100 km/h and 200 km/h;

the lower vehicle limitations of prEN 15273-1, prEN 15273-2, prEN 15273-3 are adhered to.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 286-3, Simple unfired pressure vessels designed to contain air or nitrogen — Part 3: Steel pressure

vessels designed for air braking equipment and auxiliary pneumatic equipment for railway rolling stock

EN 286-4, Simple unfired pressure vessels designed to contain air or nitrogen — Part 4: Aluminium alloy

pressure vessels designed for air braking equipment and auxiliary pneumatic equipment for railway rolling

stock

EN 10220, Seamless and welded steel tubes — Dimensions and masses per unit length

EN 10305-4, Steel tubes for precision applications — Technical delivery conditions — Part 4: Seamless cold

drawn tubes for hydraulic and pneumatic power systems

EN 10305-6, Steel tubes for precision applications — Technical delivery conditions — Part 6: Welded cold

drawn tubes for hydraulic and pneumatic power systems

or alterations to the vehicle weight also.

EN 14198:2004, Railway applications — Braking — Requirements for the brake system of trains hauled by a

locomotive

EN 14478:2005, Railway applications — Braking — Generic vocabulary

EN 14535-1, Railway applications — Brake disks for railway rolling stock — Part 1: Brake discs pressed or

shrunk onto the axle or drive shaft, dimensions and quality requirements

EN 14601, Railway applications — Straight and angled end cocks for brake pipe and main reservoir pipe

prEN 15220-1, Railway applications — Brake indicators — Part 1: Pneumatic operation brake indicators

prEN 15273-2, Railway applications — Gauges — Part 2: Rolling stock gauge

prEN 15273-3, Railway applications — Gauges — Part 3: Obstacle gauge

prEN 15327-1, Railway applications — Passenger alarm subsystem — Part 1: General requirements and

passenger interface for the passenger emergency brake system

prEN 15328, Railway applications — Braking — Brake pads

prEN 15355, Railway applications — Braking — Distributor valves

prEN 15595, Railway applications — Braking — Wheel slip prevention equipment

prEN 15611, Railway applications — Braking — Relay valves

prEN 15612, Railway applications — Braking — Brake pipe accelerator valve

EN 50125-1, Railway applications — Environmental conditions for equipment — Part 1: Equipment on board

rolling stock

prEN 14535-2 , Railway applications — Brake discs for railway rolling stock — Part 2: Brake discs mounted

onto the wheel rim, wheel web or wheel hub, dimensions and quality requirements

UIC 541-1:2003 , Brakes — Regulations concerning the construction of the various brake components

UIC 541-3:1984, Brakes — Disc brakes and their application —- General conditions for the approval of brake

pads

UIC 541-5, Brakes — Electro-pneumatic brake (ep-brake) — Electro-pneumatic emergency brake override

(EBO)

UIC 541-06, Brakes — Regulations concerning the construction of the various brake components — Magnetic

brakes

UIC 544-1, Brakes — Braking power

UIC 545:2003, Brakes — Inscriptions, marks and signs

UIC 546, Brakes — High-power brakes for passenger trains

UIC 550, Power supply installations for passenger stock

To be published.

Available from: UIC Direction Générale, 16 rue Jean Rey, F-75015 Paris.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 14198:2004, EN 14478:2005 and the

following apply.

3.1

passenger coach

vehicle without its own traction unit, for conveying people and comprising

a body;

running gear (e.g. 2 bogies);

specific connectors at coach ends (coupling capacity);

brake installation;

service installations for passengers (air conditioning, catering, luggage transport etc.);

a driving cab if the vehicle is a driving trailer.

Passenger coaches may also comprise two or more bodies with associated running gear (modules) forming a

functional unit. The connectors (connections) between the modules may be individually designed. The end

connectors of the functional unit should be suitable for the interchange conditions. Coaches for which special

traction units are mandatory (ICE, TGV) are not considered to be passenger coaches

3.2

automatic train brake

brake at train level, the action of which is based on the fact that a break in the brake pipe (pipe for control

commands) in the two parts of the train automatically leads to application of the brakes

3.3

brake release device

device operable from each side of the coach which, when operated, releases the brake

NOTE In UIC distributors, this equalizes the pressure in the control chamber to the value of the pressure in the brake

pipe or below

3.4

brake release

device operable from each side of the coach which, when operated, releases the brake

3.5

load-proportional brake

control device for automatically matching the brake force to the specific vehicle load, whereby the adjustment

may be in steps or continuous

3.6

indicating and warning devices

devices that show the status of the brake system or sub-systems. The information is given by windows,

position of handles, analogue gauges, digital displays, lamps or buzzers

NOTE For indicating the status in service, a binary indication (on/off) is used. Analogue gauges (dials or digital

displays) are for maintenance purposes

3.7

end cock

device according to EN 14601

3.8

brake hose couplings

flexible hose connections at the end of the coach with brake-hose coupling head to UIC 541-1, of different

shapes for brake pipe and main reservoir pipe

NOTE A European Standard is in preparation for this (WI 00256241)

3.9

auxiliary tread brake

tread brake acting generally on one side of the wheels to support the power of the disc brake.

3.10

release time

on brake release, the time taken for the brake cylinder pressure to fall in accordance with prEN 15355

3.11

maximum mass

sum of the operating load of the coach and the maximum payload

NOTE 1 In contrast to the total mass, it takes into account extreme occupancy

NOTE 2 A European Standard is in preparation for this (WI 00256224).

3.12

laden mass

sum of the operating load of the coach and the nominal payload

NOTE A European Standard is in preparation for this (EN 00256224).

3.13

constant mass assumption

fictional value for the mass of the passengers in a coach. It is based on 100 % of seats occupied. The

mandatory constant mass assumption is specified in UIC 410 for the different types of vehicles

NOTE A European Standard is in preparation for this (WI 00256224).

4 Symbols and abbreviations

For the purposes of this European Standard, the following symbols and abbreviations apply in accordance

with existing UIC leaflets:

BP: Air brake pipe

MRP: Main reservoir pipe

DBV: Driver's brake valve

ED: Electro-dynamic brake

EP: Electro-pneumatic brake

ep(UIC): Electro-pneumatic brake as specified in UIC 541-5

BA: Brake pipe accelerator

FRA Federal Railway Authority

RCOR Railways Construction and Operating Regulations

WSP: Wheel slide protection

HD: Hydro-dynamic brake

EP/EBO: Electro-pneumatic emergency brake override

Mg: Magnetic track brake

RGS Railway Group Standard

Wb Eddy-current brake

λ: Effective braking power

R: Air reservoir

On/Off: Brake On/Off controller

G, P, R: Brake positions according to UIC

DV: Distributor valve

AL: Automatic load-proportional brake

SO Top edge of rail

5 Requirements

5.1 General

The Railway Authorities shall include this European Standard as part of the requirements for the brake

installation. The manufacturers shall indicate in the tender where the requirements of the standard are not

met.

Vehicles as specified in this standard shall totally meet the relevant generic requirements described in

EN 14198 for the train and the resulting requirements for the individual vehicles.

These requirements are defined for the individual vehicle in the clauses:

brake control;

thermal capacity;

brake performance;

other brake components.

The specific requirements are allocated in vehicle classes. The specific brake systems mandatory for the

particular vehicle class are contained in Table A.1.

Each vehicle class is divided into subclasses for additional brake devices.

5.2 Climatic conditions

In general, the requirements of EN 50125-1 apply. The requirements listed below are minimum requirements.

The temperature class according to EN 50125-1 shall be specified by the Railway Authoritiy.

The functional ability of the brake shall be achieved under the following conditions unless deviations have

been agreed for the associated vehicle:

outside temperature – 25 °C to + 40 °C (in sunshine up to + 70 °C);

altitude up to 1 370 m above sea level;

relative humidity up to 100 %;

snowfall, lying snow up to 300 mm above top edge of rail;

rain, ice;

gusts of wind up to 30 m/s

The special climatic conditions in tunnels (e.g. Simplon up to 27 °C and 100 % relative humidity in winter also)

should be noted.

5.3 Brake control

5.3.1 Basic principles

The brake installation for each vehicle shall meet the requirements of the UIC brake system.

The basic system arrangement is shown in Figure H.1.

If other brake systems are used, the UIC brake system shall be subordinate as a pneumatic back-up brake

(safety level). With the UIC-type brake system, it is allowed to provide electro-pneumatic control support for

the BP.

The functional arrangement of the system is shown in Figure H.2.

The brake control system shall be able to provide the passenger train and goods train brake types and the

associated brake positions and have the standardized operating and indicating devices on the coach sides.

5.3.2 Components of the basic system

The components described in the following are brake components in the coach that are to be assigned to train

level 5 or vehicle level 6 in accordance with Figure H.2.

5.3.2.1 Air brake pipe (BP) and main reservoir pipe (MRP)

All vehicles shall be equipped with a continuous air brake pipe (BP) and a continuous main reservoir pipe

(MRP) in a bifurcated connection each with an inside diameter of at least 25 mm. The basic function of the

brake system (transmission of braking command and control function, energy supply) shall be possible via the

BP alone. The compressed air in the BP shall not be used for other purposes not related to the brake

installation.

The compressed air in the MRP can be used for supplying energy to other loads in the vehicle (door

operating, toilets, air springs etc.) in addition to supplying energy for the brake installation.

The air pipes shall be installed free of water collection pockets and be as straight as possible utilizing large

bend radii (minimum dimension for bend radius 5 × D = outside diameter). The bifurcation shall be achieved

a

by means of a Y-connection. Filters or other components that would reduce the cross-section of the BP shall

not be fitted. If low points are unavoidable in routing the pipes, easily accessible drainage devices shall be

fitted.

Free passage through BPs and MRPs shall be capable of being verified by means of a ball test. The diameter

of the ball to be used shall be 19 mm. Steel pipes used shall meet the requirements of EN 10220 or

EN 10305-4 or EN 10305-6.

The number of pipe fittings used shall be kept to a practical minimum and all fittings shall be accessible

without having to disassemble other equipment.

Connections consisting of threads on the pipes are not permitted.

The pipe connections at the coach end shall meet the UIC requirements. A recommended method of fitting is

described in 5.3.2.6. This takes account of the installation space for the end cocks and the space requirement

of other pipe connections also for the possible counter-movements of the vehicles to be coupled.

5.3.2.2 Controller

Every vehicle shall be equipped with at least one distributor valve which complies with the requirements of

prEN 15355. The maximum BP volume of 25 l shall be assigned to any distributor valve.

For connection into the coach brake system, the diagram illustrated in Figure H.2 of this European Standard

applies.

The controller indicated as item 10 is connected by its large pipe cross-section to the BP and is connected to

the E-store (reserve air tank (R-tank) and the devices generating the brake force thus allowing single-pipe

operation (operation without MRP). The supply to the energy store is from the BP through the controller.

Every controller shall be equipped with an isolation device that can be operated from both sides of the vehicle.

Every controller shall be equipped with one or more isolation devices that can be operated from both sides of

the vehicle. Operation of these devices shall isolate the controller from the brake pipe and the main reservoir

pipe and isolate any other brake related devices (e.g. track brake, etc.) from the main reservoir pipe. The

brake cylinders and the auxiliary reservoir shall then be vented, either automatically or manually using another

control device that can also be operated from both sides of the vehicle. Free passage of air through the BP

and MRP shall be maintained on that vehicle.

Every controller shall also be equipped with a device that allows the brake on that vehicle to be released when

it is applied (release valve).

Every controller shall be equipped with a mode switch for the selection of brake positions (e.g. G, P, R, R+Mg)

that can be operated from both sides of the vehicle.

Test points shall be fitted for the verification of the correct functioning of the controller; at least the output

pressure and the load- and speed-dependent pressures, e.g. brake cylinder pressures.

5.3.2.3 Energy store

Every controller shall be connected to an energy store so that energy can be fed from this store into the

devices generating the brake force when a brake command is given. The energy store shall be dimensioned

so that, when the brake is applied, the available brake power at each point in the train journey and for all track

conditions meets the requirements of the UIC brake system. The inexhaustibiity as defined in EN 14198 shall

be achieved.

The energy store for pneumatically-operated brake systems shall also be fed from the MRP via filter,

pressure-reducing valve, isolating cock and non-return valve.

The energy store for compressed air shall be in accordance with EN 286-3 and EN 286-4. Maintenance

aspects are covered by UIC 541-07 or other applicable documents, e.g. DIN 5590 and DIN 5580.

Requirements of the energy stores for electrically-operated brake systems shall be according to UIC 550.

5.3.2.4 Passenger emergency brake and emergency brake override

5.3.2.4.1 Basic principles – system interfaces

All passenger vehicles shall be equipped with a passenger emergency brake.

The passenger emergency brake is located in the "Decentralized command initiation for automatic application

of brakes" block (see EN 14198 and Figure H.1 of this European Standard) and on actuation of an operating

element (emergency brake handle according to prEN 15327-1) initiates the triggering of an emergency brake

valve and thus the activation of the automatic brake of the train. Automatic application of the brake at train

level is initiated. Activation of the automatic train brake by operation of an emergency brake handle shall also

be possible with the vehicle brake isolated.

When a passenger emergency brake handle has been operated, it shall be automatically locked in this

position.

An activated emergency brake becomes ineffective with the actuation by the train crew of the resetting device

on the applied emergency brake box or activation of the EBO by the train driver in accordance with the

operating regulations of the Railway Authorities.

The signals between the emergency brake handle and the emergency brake valve may be transmitted

pneumatically, electrically or mechanically. The signal line shall not be capable of being interrupted/blocked.

An exception is the EBO.

The requirements of Clause II of UIC 541-1:2003 and prEN 15327-1 shall be met. The relevant provisions of

the national approval authorities shall be met, unless superordinate regulations exist.

5.3.2.4.2 Emergency brake override (EBO)

An emergency brake override function shall be provided if mandatory in the vehicle specification. Equipping

with EBO is mandatory for travelling over certain infrastructures (e.g. high-speed tracks, tracks with long

tunnels). For details concerning rolling stock used only nationally or in bilateral traffic, see national regulations.

The aim of the EBO is for the applied passenger emergency brake to be overridden through a positive action

of the driver in accordance with the operating rules of the relevant railway in order to keep the train in motion

or to enable an immediate restart.

In order to attain the shortest release time of the brake, all vehicles equipped with the EBO function shall be

equipped with an ep assist brake.

In order to signal clearly to the driver that the passenger emergency brake has been applied and to enable

him to override it quickly, where appropriate, the status shall be clearly indicated by an indicator light or

audibly by a horn or announcement in the active cab. In the vehicle/train section in which the emergency

brake has been applied, a red flashing indicator light shall indicate to the crew the emergency brake that has

been applied until the emergency brake handle is reset.

It shall be possible to test the signal transmission paths for the applied emergency brake and the emergency

brake override within the context of the brake test in the train.

For trains hauled by locomotives, the EBO systems as specified in UIC 541-5 with control via a separate line

as shown in Figure H.4 shall be used.

NOTE Other national systems are currently in use and may continue to be used for internal traffic of certain Railway

Authorities, e.g. the DB system with control via a UIC 558 line. A functional description of this system is included in

Annex F for information.

5.3.2.4.3 Operating elements of the passenger emergency brake

Vehicles conveying passengers shall have clearly visible and accessible emergency brake handles by means

of which emergency braking is possible. Erroneous activation of the device shall not be possible

The passenger shall be able to reach emergency brake handles without having to pass through a door. In the

vestibules at the ends of the coaches and in the toilets and washrooms, no emergency brake handles need to

be deployed.

The technical design of the emergency brake handles is specified in prEN 15327-1. Guidelines as to the

location of these components within the vehicle are given in Annex F.

5.3.2.5 Indicator and actuation devices

Each vehicle shall be fitted with devices to enable functional testing, monitoring and actuation of the brake

installation. These devices shall also permit testing of the brakes in service (brake test) in accordance with

the regulations of the Railway Authorities.

These devices shall meet the requirements of the following regulations:

for changeover devices: UIC 541-1;

for quick release valves: UIC 541-1;

for brake isolating cocks: UIC 541-1;

for disk brakes: prEN 15220-1;

for magnetic track brakes: UIC 541-06;

for regenerative brakes: UIC 546.

The following general principles apply:

visible and operational from both sides of the vehicle;

clear and unmistakeable indication of the status of the associated brake equipment from both sides of the

train. Indicator panels in intermediate positions (split colour panels) are not allowed;

NOTE Sudden and smooth changeover from one indication status to the other: "smooth" is understood to mean

that the changeover period from one indicator status to the other is not to exceed 2 s. Deviation from this is

permitted if the changeover phase is clearly recognized by the tester

clear assignment of the indicator panels to the object principle: a specific indicator panel shall be provided

for each distributor/load brake valve. Indicator panels shall be marked only for handbrake or spring-

loaded brake;

if more than one signal source supplies an indicator panel, the following priority shall apply;

brake functional;

brake not released;

brake released.

If it is not possible to evaluate the information from several signal sources conclusively on one indicator panel,

the signal sources shall be separated.

The correctness of the match of the colours and symbols with the actual state of the brakes shall be ensured. .

5.3.2.6 Coach connections

The arrangement of the brake components at the end of the coach shall be in accordance with EN 14601.

Connections shall be arranged as shown in Figures H.3, H.4 and H.5.

Figure H.3a shows the arrangement of the communications jumpers in accordance with UIC 568. These

jumpers transmit low-power 24 V electric signals and commands.

Figure H.3c shows the layout of the BP and MRP. The double arrangement of the pipe outlets (bifurcation) is

mandatory so that the hose connections cannot be crossed.

The handles (F) for the isolating cocks shall be mounted opposite the drawgear, i.e. left-hand and right-hand

types shall be used. The handle position shown indicates the closed cock position.

5.3.3 Additional braking devices

5.3.3.1 General

Equipping coaches with additional braking devices is regulated according to the subclasses of the coach

classes in Table A.1

5.3.3.2 ep-brake

The requirements of UIC 541-5 shall be met. Figure H.4 illustrates the installation of the UIC ep-control cable.

The associated dimensions are given in Table 1.

In addition, other ep-brake control systems (e.g. via the UIC-IS line, cores 9 to 12, according to UIC 558) may

be agreed upon. Installation of the cables is shown in Figure H.5.

Table 1 — Table of dimensions relating to Figure H.4

XX Coupling cable YY Dummy socket ZZ Socket

b

Freely selectable

A 475 to 660 D G 475 to 660

providing all other

B 125 to 375 E H 125 to 275

dimensions

a

specified in

C 530 to 600/650 F I 535 to 605

Figure H.4 are

L 1440 to 1450 0 to15°

β

respected

α 25° to 35° b The dimension G = 660 mm may be

max

increased by ΔG if the dimension I =

max

a 650 mm allowed for

605 mm is reduced by ΔI

passenger coaches

simultaneously (ΔI = 0,75 ΔG).

ΔG 80 mm

max

5.3.3.3 Magnetic track brake

The requirements of UIC 541-06 shall be met.

The requirements of this subclause also apply if a different source of energy is required for operating the Mg

brake.

NOTE Additional requirements on the Mg brake will be contained in a future European Standard.

5.3.3.4 Brake pipe accelerator

The accelerator shall be designed in accordance with prEN 15612.

5.3.3.5 Wheel slide protection

Passenger coaches with brake positions R and R+Mg shall be equipped with wheel slide protection according

to the requirements of prEN 15595.

For passenger coaches with only brake position P, the use of wheel slide protection is recommended.