oSIST IEC 60079-0:2018

Explosive atmospheres - Part 0: Equipment - General requirements

Explosive atmospheres - Part 0: Equipment - General requirements

IEC 60079-0:2017 specifies the general requirements for construction, testing and marking of Ex Equipment and Ex Components intended for use in explosive atmospheres. The standard atmospheric conditions (relating to the explosion characteristics of the atmosphere) under which it may be assumed that Ex Equipment can be operated are:

-temperature –20 °C to +60 °C;

-pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar); and

-air with normal oxygen content, typically 21 % v/v.

This part of IEC 60079 and other standards supplementing this standard specify additional test requirements for Ex Equipment operating outside the standard temperature range, but further additional consideration and additional testing may be required for Ex Equipment operating outside the standard atmospheric pressure range and standard oxygen content. Such additional testing may be particularly relevant with respect to Types of Protection that depend on quenching of a flame such as ‘flameproof enclosures “d”’ (IEC 60079-1) or limitation of energy, ‘intrinsic safety “i”’ (IEC 60079-11). This seventh edition cancels and replaces the sixth edition, published in 2011. This edition constitutes a technical revision. Refer to the Foreword of the document for a complete listing of the technical changes between edition 7.0 and the previous edition of the document.

Keywords: Ex Equipment and Ex Components intended for use in explosive atmospheres

The contents of the interpretation sheet 1 of April 2019, of the interpretation sheet 2 of June 2019 and the corrigendum 1 of January 2020 have been included in this copy.

Explosionsgefährdete Bereiche - Teil 0: Betriebsmittel - Allgemeine Anforderungen

Atmosphères explosives - Partie 0: Matériel - Exigences générales

IEC 60079-0:2017 spécifie les exigences générales de construction, d'essais et de marquage de l’appareil Ex et des Composants Ex destinés à être utilisés dans des atmosphères explosives. Les conditions atmosphériques normales (relatives aux caractéristiques d’explosion de l’atmosphère) dans lesquelles, par hypothèse l’appareil Ex peut être utilisé, sont les suivantes:

-température de –20 °C à +60 °C;

-pression de 80 kPa (0,8 bar) à 110 kPa (1,1 bar); et

-air avec teneur normale en oxygène, typiquement 21 % v/v.

La présente partie de la norme IEC 60079 et les autres normes qui la complètent spécifient des exigences d’essai supplémentaires pour les appareils Ex fonctionnant hors de la plage normale de températures, une attention supplémentaire ultérieure et des essais complémentaires pouvant toutefois être exigés pour les appareils Ex fonctionnant hors de la plage normale de pressions atmosphériques et de la teneur normale en oxygène. De tels essais complémentaires peuvent se révéler pertinents, notamment pour les modes de protection qui dépendent de l’extinction d’une flamme, tels qu’une «enveloppe antidéflagrante «d»» (IEC 60079-1), ou de la limitation de l’énergie, tels que la «sécurité intrinsèque «i»» (IEC 60079-11). Reportez-vous à l'avant-propos du document pour une liste complète des modifications techniques entre l'édition 7.0 et édition précédente du document.

Mots-clés: l’appareil Ex et des Composants Ex destinés à être utilisés dans des atmosphères explosives.

Le contenu de la feuille d'interprétation 1 d'avril 2019, la feuille d'interprétation 2 de juin 2019 et le corrigendum 1 de janvier 2020 a été pris en considération dans cet exemplaire.

Eksplozivne atmosfere - 0. del: Oprema - Splošne zahteve

General Information

- Status

- Not Published

- Public Enquiry End Date

- 29-Apr-2018

- Technical Committee

- EXP - Product for explosive atmospheres

- Current Stage

- 98 - Abandoned project (Adopted Project)

- Start Date

- 20-Jul-2021

- Due Date

- 25-Jul-2021

- Completion Date

- 20-Jul-2021

Overview

IEC 60079-0:2017 - Explosive atmospheres - Part 0: Equipment - General requirements - sets the baseline general requirements for the construction, testing and marking of Ex Equipment and Ex Components intended for use in explosive atmospheres. This seventh edition (replacing the 2011 edition) is a technical revision and incorporates interpretation sheets (April 2019, June 2019) and Corrigendum 1 (January 2020). The standard defines the standard atmospheric conditions under which Ex equipment is assumed operable:

- Temperature: −20 °C to +60 °C

- Pressure: 80 kPa to 110 kPa (0.8–1.1 bar)

- Air: normal oxygen content (typically 21 % v/v)

IEC 60079-0 also explains when additional testing or special considerations are required for operation outside these ranges, particularly for Types of Protection that rely on flame quenching (e.g., flameproof “d”) or energy limitation (intrinsic safety “i”).

Key Topics

The standard covers technical subjects that are essential for designers, manufacturers and certifying bodies:

- Equipment grouping (Group I, II, III) and selection for specific atmospheres

- Temperature classification and maximum surface temperatures, including measurement and limitation

- Material requirements for non‑metallic and metallic enclosures, and resistance to UV, thermal ageing and electrostatic charge

- Mechanical design: strength, fasteners, interlocks, bushings and entries (cable glands, blanking elements)

- Connection facilities: earthing/bonding, creepage/clearance and secure electrical connections

- Supplementary requirements for electric machines, switchgear, luminaires, plugs, batteries and handlights

- Ex Components: mounting, marking and certification requirements

- Testing and verification: type tests, thermal and impact tests, small component ignition tests and IP protection tests

- Documentation and marking requirements to demonstrate compliance

Applications

IEC 60079-0 is the foundational reference for designing and assessing equipment for hazardous areas and explosive atmospheres. Practical uses include:

- Development and certification of hazardous‑area electrical and electronic equipment

- Product design decisions for enclosures, materials and sealing to prevent ignition sources

- Test laboratory procedures and conformity assessment for Ex marking and type testing

- Specification and procurement of equipment for industry sectors such as oil & gas, mining, chemical processing, and grain handling

- Guidance on additional testing when equipment is intended to operate outside standard temperature, pressure or oxygen ranges

Who uses this standard

- Equipment designers and manufacturers of Ex Equipment and Ex Components

- Certification bodies and test laboratories performing type tests and assessments

- System integrators, facility engineers and maintenance teams specifying and installing hazardous‑area equipment

- Regulatory and compliance professionals aligning products with national and international hazardous‑area requirements

Related standards

IEC 60079-0 is the general part of the IEC 60079 series and is used together with specific Type of Protection standards such as IEC 60079-1 (flameproof “d”) and IEC 60079-11 (intrinsic safety “i”) for more detailed test and construction requirements.

IEC 60079-0:2017 RLV - Explosive atmospheres - Part 0: Equipment - General requirements Released:12/13/2017 Isbn:9782832252048

IEC 60079-0:2017 - Explosive atmospheres - Part 0: Equipment - General requirements

Frequently Asked Questions

oSIST IEC 60079-0:2018 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Explosive atmospheres - Part 0: Equipment - General requirements". This standard covers: IEC 60079-0:2017 specifies the general requirements for construction, testing and marking of Ex Equipment and Ex Components intended for use in explosive atmospheres. The standard atmospheric conditions (relating to the explosion characteristics of the atmosphere) under which it may be assumed that Ex Equipment can be operated are: -temperature –20 °C to +60 °C; -pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar); and -air with normal oxygen content, typically 21 % v/v. This part of IEC 60079 and other standards supplementing this standard specify additional test requirements for Ex Equipment operating outside the standard temperature range, but further additional consideration and additional testing may be required for Ex Equipment operating outside the standard atmospheric pressure range and standard oxygen content. Such additional testing may be particularly relevant with respect to Types of Protection that depend on quenching of a flame such as ‘flameproof enclosures “d”’ (IEC 60079-1) or limitation of energy, ‘intrinsic safety “i”’ (IEC 60079-11). This seventh edition cancels and replaces the sixth edition, published in 2011. This edition constitutes a technical revision. Refer to the Foreword of the document for a complete listing of the technical changes between edition 7.0 and the previous edition of the document. Keywords: Ex Equipment and Ex Components intended for use in explosive atmospheres The contents of the interpretation sheet 1 of April 2019, of the interpretation sheet 2 of June 2019 and the corrigendum 1 of January 2020 have been included in this copy.

IEC 60079-0:2017 specifies the general requirements for construction, testing and marking of Ex Equipment and Ex Components intended for use in explosive atmospheres. The standard atmospheric conditions (relating to the explosion characteristics of the atmosphere) under which it may be assumed that Ex Equipment can be operated are: -temperature –20 °C to +60 °C; -pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar); and -air with normal oxygen content, typically 21 % v/v. This part of IEC 60079 and other standards supplementing this standard specify additional test requirements for Ex Equipment operating outside the standard temperature range, but further additional consideration and additional testing may be required for Ex Equipment operating outside the standard atmospheric pressure range and standard oxygen content. Such additional testing may be particularly relevant with respect to Types of Protection that depend on quenching of a flame such as ‘flameproof enclosures “d”’ (IEC 60079-1) or limitation of energy, ‘intrinsic safety “i”’ (IEC 60079-11). This seventh edition cancels and replaces the sixth edition, published in 2011. This edition constitutes a technical revision. Refer to the Foreword of the document for a complete listing of the technical changes between edition 7.0 and the previous edition of the document. Keywords: Ex Equipment and Ex Components intended for use in explosive atmospheres The contents of the interpretation sheet 1 of April 2019, of the interpretation sheet 2 of June 2019 and the corrigendum 1 of January 2020 have been included in this copy.

oSIST IEC 60079-0:2018 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST IEC 60079-0:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60079-0 ®

Edition 7.0 2017-12

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Explosive atmospheres –

Part 0: Equipment – General requirements

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60079-0 ®

Edition 7.0 2017-12

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Explosive atmospheres –

Part 0: Equipment – General requirements

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.260.20 ISBN 978-2-8322-5204-8

IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

IEC 60079-0

Edition 7.0 2017-12

EXPLOSIVE ATMOSPHERES –

Part 0: Equipment – General requirements

INTERPRETATION SHEET 1

This interpretation sheet has been prepared by IEC technical committee 31: Equipment for

explosive atmospheres.

The text of this interpretation sheet is based on the following documents:

DISH Report on voting

31/1455/DISH 31/1464/RVDISH

Full information on the voting for the approval of this interpretation sheet can be found in the

report on voting indicated in the above table.

___________

Interpretation sheet of Subclause 16.6 of IEC 60079-0:2017

The TC31/CAG requested (Resolution 2 of 2018-04-19) that WG22 prepare an interpretation

sheet based on IECEx Decision Sheet DS2018/002 addressing the assignment of entry point

and branching point temperatures of electrical rotating machines.

Details of interpretation:

requirements

Interpretation of Subclause 16.6: Temperature at branching point and entry point:

Question: Subclause 16.6 of IEC 60079-0:2017 states “When the temperature under rated

conditions is higher than 70 °C at the entry point or 80 °C at the branching point of the

conductors, information shall be marked on the equipment exterior to provide guidance to the

user on the proper selection of cable and cable gland or conductors in conduit.”

ICS 29.260.20

– 2 – IEC 60079-0:2017/ISH1:2019

IEC 2019

It is not normal practice for electrical rotating machines to be tested with the cable entry

devices and cables that might be used in an actual installation, but with the cables available

at the manufacturer’s test area. In many cases, there will be no formal entry device as the

cables will enter via the space reserved for fixing of a gland plate.

How shall the relevant entry point and branching point temperatures be determined?

Interpretation: The use of the maximum internal air space temperature to represent the

maximum service temperature of terminal box gaskets and seals, the cable branching point

temperature, and the entry point temperature reflects the normal practice of testing electrical

rotating machines without prior knowledge of the actual glands and cables to be used for

installation. The production of heat from the electrical rotating machine connections is

generally insignificant with respect to the production of heat from the machine windings and

core.

Further amplification:

1) The entry point of the cable where the temperature is measured should be sealed so far

as possible to ensure that there is minimum air-circulation which can reduce the measured

temperature.

2) This is not intended to apply to any gasket between the terminal box and the frame of the

electrical rotating machine, where higher temperatures may be recorded, but only to the

gasket between the terminal box and its lid.

Although written in the context of electrical rotating machines, there may be other types of

equipment where an equivalent approach is applicable

IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

IEC 60079-0

Edition 7.0 2017-12

EXPLOSIVE ATMOSPHERES –

Part 0: Equipment – General requirements

INTERPRETATION SHEET 2

This interpretation sheet has been prepared by IEC technical committee 31: Equipment for

explosive atmospheres.

The text of this interpretation sheet is based on the following documents:

DISH Report on voting

31/1469/DISH 31/1486/RVDISH

Full information on the voting for the approval of this interpretation sheet can be found in the

report on voting indicated in the above table.

___________

Question:

How shall marking be shown for equipment covered by both the electrical and non-electrical

standards (IEC 60079 and ISO 80079 series)?

Answer:

Equipment which includes both an electrical part and a non-electrical part shall have

combined marking. For example:

Ex db h IIA T4 Gb

Ex h tb IIIC T135 °C Db

ICS 29.260.20

– 2 – IEC 60079-0:2017/ISH2:2019

IEC 2019

It will be clearer for the user that the combined risk of the electrical part and the non-electrical

part, covered by a single certificate, has been assessed for the complete equipment, stating

one EPL, one equipment Group and one temperature class for Gas and the same for Dust

(but showing a maximum surface temperature instead of a temperature class). It is also noted

that Ex Components are not marked with either a temperature class (Group II) or a maximum

surface temperature (Group III).

For equipment where separate certificates have been prepared, with one for the electrical

parts, and one for the non-electrical parts, it is appropriate to have separate electrical and

non-electrical marking strings, each with its own associated certificate number.

NOTE Additional guidance on the marking of assemblies is given in IEC TS 60079-46.

– 2 – IEC 60079-0:2017 RLV IEC 2017

CONTENTS

FOREWORD . 9

1 Scope . 16

2 Normative references . 18

3 Terms and definitions . 21

4 Equipment grouping . 21

4.1 General . 39

4.2 Group I . 39

4.3 Group II . 40

4.4 Group III . 40

4.5 Equipment for a particular explosive gas atmosphere . 40

5 Temperatures . 40

5.1 Environmental influences . 40

5.1.1 Ambient temperature . 40

5.1.2 External source of heating or cooling . 41

5.2 Service temperature . 41

5.3 Maximum surface temperature . 42

5.3.1 Determination of maximum surface temperature . 42

5.3.2 Limitation of maximum surface temperature . 42

5.3.3 Small component temperature for Group I or Group II electrical

equipment. 42

5.3.4 Component temperature of smooth surfaces for Group I or Group II

electrical equipment . 44

6 Requirements for all electrical equipment . 45

6.1 General . 45

6.2 Mechanical strength of equipment . 45

6.3 Opening times . 45

6.4 Circulating currents in enclosures (e.g. of large electrical machines) . 46

6.5 Gasket retention . 46

6.6 Electromagnetic and ultrasonic energy radiating equipment . 46

6.6.1 General . 46

6.6.2 Radio frequency sources . 46

6.6.3 Ultrasonic sources . 47

6.6.4 Lasers, luminaires, and other non-divergent continuous wave optical

sources. 47

7 Non-metallic enclosures and non-metallic parts of enclosures . 47

7.1 General . 48

7.1.1 Applicability . 48

7.1.2 Specification of materials . 49

7.2 Thermal endurance . 50

7.2.1 Tests for thermal endurance . 50

7.2.2 Material selection . 50

7.2.3 Alternative qualification of elastomeric sealing O-rings . 50

7.3 Resistance to ultraviolet light . 51

7.4 Electrostatic charges on external non-metallic materials . 51

7.4.1 Applicability . 51

7.4.2 Avoidance of a build-up of electrostatic charge on for Group I

or Group II electrical equipment . 51

7.4.3 Avoidance of a build-up of electrostatic charge on equipment for Group

III . 54

7.5 Accessible metal Attached external conductive parts . 55

8 Metallic enclosures and metallic parts of enclosures . 55

8.1 Material composition . 55

8.2 Group I . 56

8.3 Group II . 56

8.4 Group III . 56

8.5 Copper Alloys . 57

9 Fasteners . 57

9.1 General . 57

9.2 Special fasteners . 57

9.3 Holes for special fasteners . 57

9.3.1 Thread engagement . 57

9.3.2 Tolerance and clearance . 58

9.4 Hexagon socket set screws . 59

10 Interlocking devices . 59

11 Bushings . 59

12 Materials used for cementing (Reserved for future use) . 59

13 Ex Components . 59

13.1 General . 60

13.2 Mounting . 60

13.3 Internal mounting . 60

13.4 External mounting . 60

13.5 Ex Component certificate . 60

14 Connection facilities and termination compartments . 61

14.1 General . 61

14.2 Termination compartment .

14.2 Type of protection . 61

14.3 Creepage and clearance . 61

15 Connection facilities for earthing or bonding conductors . 61

15.1 Equipment requiring earthing or bonding . 61

15.1.1 Internal earthing . 61

15.1.2 External bonding. 61

15.2 Equipment not requiring earthing . 62

15.3 Size of protective earthing conductor connection . 62

15.4 Size of equipotential bonding conductor connection . 62

15.5 Protection against corrosion . 62

15.6 Secureness of electrical connections . 62

15.7 Internal earth continuity plate . 62

16 Entries into enclosures . 63

16.1 General . 63

16.2 Identification of entries . 63

16.3 Cable glands . 63

16.4 Blanking elements. 64

16.5 Thread adapters . 64

– 4 – IEC 60079-0:2017 RLV IEC 2017

16.6 Temperature at branching point and entry point . 64

16.7 Electrostatic charges of cable sheaths . 64

17 Supplementary requirements for rotating electric machines . 65

17.1 General . 65

17.2 Ventilation. 65

17.2.1 Ventilation openings . 65

17.2.2 Materials for external fans . 66

17.2.3 Cooling fans of rotating electric machines . 66

17.2.4 Auxiliary motor cooling fans . 66

17.2.5 Room ventilating fans . 67

17.3 Bearings . 67

18 Supplementary requirements for switchgear . 68

18.1 Flammable dielectric . 68

18.2 Disconnectors . 68

18.3 Group I – Provisions for locking . 69

18.4 Doors and covers . 69

19 Supplementary requirements for fuses Reserved for future use . 69

20 Supplementary requirements for external plugs, socket outlets and connectors for

field wiring connection . 69

20.1 General . 69

20.2 Explosive gas atmospheres . 70

20.3 Explosive dust atmospheres . 70

20.4 Energized plugs . 70

21 Supplementary requirements for luminaires . 70

21.1 General . 70

21.2 Covers for luminaires of EPL Mb, EPL Gb, or EPL Db . 70

21.3 Covers for luminaires of EPL Gc or EPL Dc . 71

21.4 Sodium lamps . 71

22 Supplementary requirements for caplights and handlights . 71

22.1 Group I caplights . 71

22.2 Group II and Group III caplights and handlights . 72

23 Equipment incorporating cells and batteries . 72

23.1 General . 72

23.2 Interconnection of cells to form batteries . 72

23.3 Cell types . 72

23.4 Cells in a battery . 75

23.5 Ratings of batteries . 76

23.6 Interchangeability . 76

23.7 Charging of primary batteries . 76

23.8 Leakage . 76

23.9 Connections . 76

23.10 Orientation . 76

23.11 Replacement of cells or batteries . 76

23.12 Replaceable battery pack . 76

24 Documentation . 77

25 Compliance of prototype or sample with documents . 77

26 Type tests . 77

26.1 General . 77

26.2 Test configuration . 77

26.3 Tests in explosive test mixtures . 77

26.4 Tests of enclosures . 77

26.4.1 Order of tests . 77

26.4.2 Resistance to impact . 79

26.4.3 Drop test . 81

26.4.4 Acceptance criteria . 82

26.4.5 Degree of protection (IP) by enclosures . 82

26.5 Thermal tests . 83

26.5.1 Temperature measurement . 83

26.5.2 Thermal shock test . 85

26.5.3 Small component ignition test (Group I and Group II) . 85

26.6 Torque test for bushings . 86

26.6.1 Test procedure . 86

26.6.2 Acceptance criteria . 87

26.7 Non-metallic enclosures or non-metallic parts of enclosures . 87

26.7.1 General . 87

26.7.2 Test temperatures . 87

26.8 Thermal endurance to heat . 87

26.9 Thermal endurance to cold . 89

26.10 Resistance to UV light . 89

26.10.1 Test procedure General . 89

26.10.2 Light exposure . 89

26.10.3 Acceptance criteria . 89

26.11 Resistance to chemical agents for Group I electrical equipment . 90

26.12 Earth continuity . 90

26.13 Surface resistance test of parts of enclosures of non-metallic materials . 91

26.14 Measurement of capacitance . 92

26.14.1 General . 92

26.14.2 Test procedure . 92

26.15 Verification of ratings of ventilating fans . 93

26.16 Alternative qualification of elastomeric sealing O-rings . 93

26.17 Transferred charge test . 94

26.17.1 Test equipment . 94

26.17.2 Test sample . 94

26.17.3 Test procedure . 95

27 Routine tests . 96

28 Manufacturer's responsibility . 96

28.1 Conformity with the documentation . 96

28.2 Certificate . 96

28.3 Responsibility for marking . 96

29 Marking . 96

29.1 Applicability . 96

29.2 Location . 97

29.3 General . 97

29.4 Ex marking for explosive gas atmospheres . 97

29.5 Ex marking for explosive dust atmospheres . 100

29.6 Combined types (or levels) of protection . 103

– 6 – IEC 60079-0:2017 RLV IEC 2017

29.7 Multiple types of protection . 103

29.8 Ga equipment using two independent Gb types (or levels) of protection . 103

29.9 Boundary wall . 103

29.10 Ex Components . 104

29.11 Small Ex Equipment and small Ex Components . 104

29.12 Extremely small Ex Equipment and extremely small Ex Components . 104

29.13 Alternate marking of equipment protection levels (EPLs) .

29.13.1 Alternate marking of type of protection for explosive gas

atmospheres .

29.13.2 Alternate marking of type of protection for explosive dust

atmospheres .

29.13 Warning markings . 105

29.14 Cells and batteries . 106

29.15 Converter-fed Electrical machines operated with a converter . 106

29.16 Examples of marking . 107

30 Instructions . 107

30.1 General . 111

30.2 Cells and batteries . 112

30.3 Electrical machines . 113

30.4 Ventilating fans . 113

30.5 Cable glands . 114

Annex A (normative) Supplementary requirements for cable glands . 115

A.1 General . 115

A.2 Constructional requirements . 115

A.2.1 Cable sealing . 115

A.2.2 Filling compounds . 116

A.2.3 Clamping . 116

A.2.4 Lead-in of cable . 117

A.2.5 Release by a tool . 117

A.2.6 Fixing . 117

A.2.7 Degree of protection . 117

A.3 Type tests . 117

A.3.1 Tests of clamping of non-armoured and braided cables . 118

A.3.2 Tests of clamping of armoured cables . 121

A.3.3 Type test for resistance to impact . 122

A.3.4 Test for degree of protection (IP) of cable glands . 123

A.4 Marking . 123

A.4.1 Marking of cable glands . 123

A.4.2 Marking Identification of cable-sealing rings . 123

A.5 Instructions . 124

Annex B (normative) Requirements for Ex Components . 125

Annex C (informative) Example of rig for resistance to impact test . 127

Annex D (informative) Motors supplied by Electric machines connected to converters . 129

Annex E (informative) Temperature rise testing evaluation of electric machines . 130

Annex F (informative) Guideline Guidance flowchart for tests of non-metallic

enclosures or non-metallic parts of enclosures (26.4) . 133

Annex G (informative) Guidance flowchart for tests of cable glands . 134

Annex H (informative) Shaft voltages resulting in motor bearing or shaft brush

sparking Discharge energy calculation . 135

H.1 General . 135

H.2 Assessment of the risk of ignition using ignition energy calculation . 135

H.3 Shaft voltage determination for a rotating machine . 136

H.4 Capacitance “C” calculation for a rotating machine . 136

H.5 Energy “E” calculation for a rotating machine . 139

H.6 Assessment using reference curves . 139

Bibliography . 141

Figure 1 – Typical battery examples . 23

Figure 2 – Typical battery compartment . 25

Figure 3 – Typical replaceable battery pack . 25

Figure 4 – Tolerances and clearance for threaded fasteners . 58

Figure 5 – Contact surface under head of fastener with a reduced shank . 59

Figure 6 – Cable gland . 65

Figure 7 – Illustration of entry points and branching points Conduit entry . 65

Figure 8 – Assembly of test sample for earth-continuity test . 91

Figure 9 – Test piece with painted electrodes . 92

Figure 10 – Compression set of an O-ring . 94

Figure A.1 – Illustration of the terms used for cable glands . 116

Figure A.2 – Rounded edge of the point of entry of the flexible cable . 117

Figure A.3 – Example of rig for resistance to impact test . 122

Figure C.1 – Example of rig for resistance to impact test . 128

Figure F.1 – Non-metallic enclosures or non-metallic parts of enclosures . 133

Figure H.1 – Capacitance stored in bearing clearance of sleeve bearing Between

journal and outer bearing housing . 138

Figure H.2 – Air-gap between stator and rotor . 138

Figure H.3 – Typical surfaces that form capacitors from the motor shaft to ground . 139

Figure H.4 – Capacitive ignition curves . 140

Table 1 – Ambient temperatures in service and additional marking . 41

Table 2 – Classification of maximum surface temperatures for Group II electrical

equipment . 42

Table 3 – Assessment of temperature classification according to component size at 40

ºC ambient temperature . 44

Table 4 – Assessment of temperature classification Component surface area ≥ 20 mm . 44

Table 5 – Radio frequency power thresholds Threshold power . 47

Table 6 – Radio frequency energy thresholds Threshold energy . 47

Table 7 – Limitation of surface areas . 53

Table 8 – Maximum diameter or width . 53

Table 9 – Limitation of thickness of non-metallic layer . 53

Table 10 – Maximum acceptable transferred charge . 54

Table 11 – Maximum capacitance of unearthed metal conductive parts . 55

Table 12 – Minimum cross-sectional area of PE conductors . 62

Table 13 – Primary cells . 73

Table 14 – Secondary cells . 74

– 8 – IEC 60079-0:2017 RLV IEC 2017

Table 15 – Tests for resistance to impact . 81

Table 16 – Torque to be applied to the stem of bushing used for connection facilities . 87

Table 17 – Thermal endurance test . 88

Table 18 – Text of warning markings . 105

Table 19 – Example of type-test converter parameters . 113

Table B.1 – Applicability of clauses with which to Ex Components shall comply . 125

Table H.1 – Maximum permitted energy . 136

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHERES –

Part 0: Equipment – General requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

intere

...

IEC 60079-0 ®

Edition 7.0 2017-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 0: Equipment – General requirements

Atmosphères explosives –

Partie 0: Matériel – Exigences générales

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

A bout the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60079-0 ®

Edition 7.0 2017-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 0: Equipment – General requirements

Atmosphères explosives –

Partie 0: Matériel – Exigences générales

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.260.20 ISBN 978-2-8322-5065-5

IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

IEC 60079-0

Edition 7.0 2017-12

EXPLOSIVE ATMOSPHERES –

Part 0: Equipment – General requirements

INTERPRETATION SHEET 1

This interpretation sheet has been prepared by IEC technical committee 31: Equipment for

explosive atmospheres.

The text of this interpretation sheet is based on the following documents:

DISH Report on voting

31/1455/DISH 31/1464/RVDISH

Full information on the voting for the approval of this interpretation sheet can be found in the

report on voting indicated in the above table.

___________

Interpretation sheet of Subclause 16.6 of IEC 60079-0:2017

The TC31/CAG requested (Resolution 2 of 2018-04-19) that WG22 prepare an interpretation

sheet based on IECEx Decision Sheet DS2018/002 addressing the assignment of entry point

and branching point temperatures of electrical rotating machines.

Details of interpretation:

requirements

Interpretation of Subclause 16.6: Temperature at branching point and entry point:

Question: Subclause 16.6 of IEC 60079-0:2017 states “When the temperature under rated

conditions is higher than 70 °C at the entry point or 80 °C at the branching point of the

conductors, information shall be marked on the equipment exterior to provide guidance to the

user on the proper selection of cable and cable gland or conductors in conduit.”

ICS 29.260.20

– 2 – IEC 60079-0:2017/ISH1:2019

IEC 2019

It is not normal practice for electrical rotating machines to be tested with the cable entry

devices and cables that might be used in an actual installation, but with the cables available

at the manufacturer’s test area. In many cases, there will be no formal entry device as the

cables will enter via the space reserved for fixing of a gland plate.

How shall the relevant entry point and branching point temperatures be determined?

Interpretation: The use of the maximum internal air space temperature to represent the

maximum service temperature of terminal box gaskets and seals, the cable branching point

temperature, and the entry point temperature reflects the normal practice of testing electrical

rotating machines without prior knowledge of the actual glands and cables to be used for

installation. The production of heat from the electrical rotating machine connections is

generally insignificant with respect to the production of heat from the machine windings and

core.

Further amplification:

1) The entry point of the cable where the temperature is measured should be sealed so far

as possible to ensure that there is minimum air-circulation which can reduce the measured

temperature.

2) This is not intended to apply to any gasket between the terminal box and the frame of the

electrical rotating machine, where higher temperatures may be recorded, but only to the

gasket between the terminal box and its lid.

Although written in the context of electrical rotating machines, there may be other types of

equipment where an equivalent approach is applicable

IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

IEC 60079-0

Edition 7.0 2017-12

EXPLOSIVE ATMOSPHERES –

Part 0: Equipment – General requirements

INTERPRETATION SHEET 2

This interpretation sheet has been prepared by IEC technical committee 31: Equipment for

explosive atmospheres.

The text of this interpretation sheet is based on the following documents:

DISH Report on voting

31/1469/DISH 31/1486/RVDISH

Full information on the voting for the approval of this interpretation sheet can be found in the

report on voting indicated in the above table.

___________

Question:

How shall marking be shown for equipment covered by both the electrical and non-electrical

standards (IEC 60079 and ISO 80079 series)?

Answer:

Equipment which includes both an electrical part and a non-electrical part shall have

combined marking. For example:

Ex db h IIA T4 Gb

Ex h tb IIIC T135 °C Db

ICS 29.260.20

– 2 – IEC 60079-0:2017/ISH2:2019

IEC 2019

It will be clearer for the user that the combined risk of the electrical part and the non-electrical

part, covered by a single certificate, has been assessed for the complete equipment, stating

one EPL, one equipment Group and one temperature class for Gas and the same for Dust

(but showing a maximum surface temperature instead of a temperature class). It is also noted

that Ex Components are not marked with either a temperature class (Group II) or a maximum

surface temperature (Group III).

For equipment where separate certificates have been prepared, with one for the electrical

parts, and one for the non-electrical parts, it is appropriate to have separate electrical and

non-electrical marking strings, each with its own associated certificate number.

NOTE Additional guidance on the marking of assemblies is given in IEC TS 60079-46.

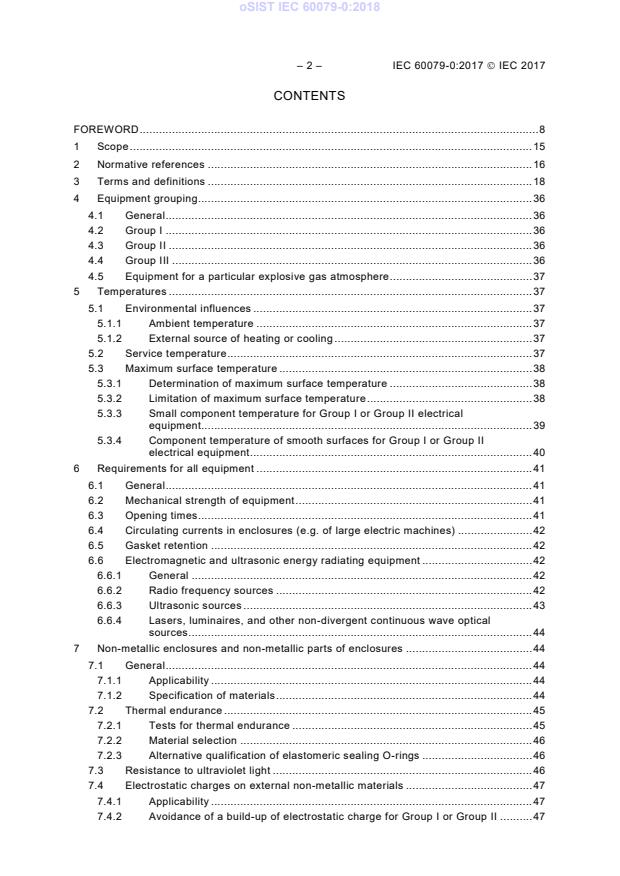

– 2 – IEC 60079-0:2017 IEC 2017

CONTENTS

FOREWORD . 8

1 Scope . 15

2 Normative references . 16

3 Terms and definitions . 18

4 Equipment grouping . 36

4.1 General . 36

4.2 Group I . 36

4.3 Group II . 36

4.4 Group III . 36

4.5 Equipment for a particular explosive gas atmosphere . 37

5 Temperatures . 37

5.1 Environmental influences . 37

5.1.1 Ambient temperature . 37

5.1.2 External source of heating or cooling . 37

5.2 Service temperature . 37

5.3 Maximum surface temperature . 38

5.3.1 Determination of maximum surface temperature . 38

5.3.2 Limitation of maximum surface temperature . 38

5.3.3 Small component temperature for Group I or Group II electrical

equipment. 39

5.3.4 Component temperature of smooth surfaces for Group I or Group II

electrical equipment . 40

6 Requirements for all equipment . 41

6.1 General . 41

6.2 Mechanical strength of equipment . 41

6.3 Opening times . 41

6.4 Circulating currents in enclosures (e.g. of large electric machines) . 42

6.5 Gasket retention . 42

6.6 Electromagnetic and ultrasonic energy radiating equipment . 42

6.6.1 General . 42

6.6.2 Radio frequency sources . 42

6.6.3 Ultrasonic sources . 43

6.6.4 Lasers, luminaires, and other non-divergent continuous wave optical

sources. 44

7 Non-metallic enclosures and non-metallic parts of enclosures . 44

7.1 General . 44

7.1.1 Applicability . 44

7.1.2 Specification of materials . 44

7.2 Thermal endurance . 45

7.2.1 Tests for thermal endurance . 45

7.2.2 Material selection . 46

7.2.3 Alternative qualification of elastomeric sealing O-rings . 46

7.3 Resistance to ultraviolet light . 46

7.4 Electrostatic charges on external non-metallic materials . 47

7.4.1 Applicability . 47

7.4.2 Avoidance of a build-up of electrostatic charge for Group I or Group II . 47

7.4.3 Avoidance of a build-up of electrostatic charge for Group III . 49

7.5 Attached external conductive parts . 50

8 Metallic enclosures and metallic parts of enclosures . 51

8.1 Material composition . 51

8.2 Group I . 51

8.3 Group II . 51

8.4 Group III . 52

8.5 Copper Alloys . 52

9 Fasteners . 52

9.1 General . 52

9.2 Special fasteners . 53

9.3 Holes for special fasteners . 53

9.3.1 Thread engagement . 53

9.3.2 Tolerance and clearance . 53

9.4 Hexagon socket set screws . 54

10 Interlocking devices . 54

11 Bushings . 54

12 (Reserved for future use) . 54

13 Ex Components . 54

13.1 General . 54

13.2 Mounting . 55

13.3 Internal mounting . 55

13.4 External mounting . 55

13.5 Ex Component certificate . 55

14 Connection facilities . 55

14.1 General . 55

14.2 Type of protection . 56

14.3 Creepage and clearance . 56

15 Connection facilities for earthing or bonding conductors . 56

15.1 Equipment requiring earthing or bonding . 56

15.1.1 Internal earthing . 56

15.1.2 External bonding. 56

15.2 Equipment not requiring earthing . 56

15.3 Size of protective earthing conductor connection . 56

15.4 Size of equipotential bonding conductor connection . 57

15.5 Protection against corrosion . 57

15.6 Secureness of electrical connections . 57

15.7 Internal earth continuity plate . 57

16 Entries into enclosures . 57

16.1 General . 57

16.2 Identification of entries . 57

16.3 Cable glands . 58

16.4 Blanking elements. 58

16.5 Thread adapters . 58

16.6 Temperature at branching point and entry point . 59

16.7 Electrostatic charges of cable sheaths . 59

17 Supplementary requirements for electric machines . 60

17.1 General . 60

– 4 – IEC 60079-0:2017 IEC 2017

17.2 Ventilation. 60

17.2.1 Ventilation openings . 60

17.2.2 Materials for external fans . 60

17.2.3 Cooling fans of rotating electric machines . 60

17.2.4 Auxiliary motor cooling fans . 61

17.2.5 Room ventilating fans . 61

17.3 Bearings . 62

18 Supplementary requirements for switchgear . 62

18.1 Flammable dielectric . 62

18.2 Disconnectors . 62

18.3 Group I – Provisions for locking . 63

18.4 Doors and covers . 63

19 Reserved for future use . 63

20 Supplementary requirements for external plugs, socket outlets and connectors for

field wiring connection . 63

20.1 General . 63

20.2 Explosive gas atmospheres . 64

20.3 Explosive dust atmospheres . 64

20.4 Energized plugs . 64

21 Supplementary requirements for luminaires . 64

21.1 General . 64

21.2 Covers for luminaires of EPL Mb, EPL Gb, or EPL Db . 64

21.3 Covers for luminaires of EPL Gc or EPL Dc . 65

21.4 Sodium lamps . 65

22 Supplementary requirements for caplights and handlights . 65

22.1 Group I caplights . 65

22.2 Group II and Group III caplights and handlights . 65

23 Equipment incorporating cells and batteries . 66

23.1 General . 66

23.2 Interconnection of cells to form batteries . 66

23.3 Cell types . 66

23.4 Cells in a battery . 69

23.5 Ratings of batteries . 69

23.6 Interchangeability . 69

23.7 Charging of primary batteries . 69

23.8 Leakage . 69

23.9 Connections . 69

23.10 Orientation . 69

23.11 Replacement of cells or batteries . 69

23.12 Replaceable battery pack . 70

24 Documentation . 70

25 Compliance of prototype or sample with documents . 70

26 Type tests . 70

26.1 General . 70

26.2 Test configuration . 70

26.3 Tests in explosive test mixtures . 70

26.4 Tests of enclosures . 71

26.4.1 Order of tests . 71

26.4.2 Resistance to impact . 73

26.4.3 Drop test . 74

26.4.4 Acceptance criteria . 75

26.4.5 Degree of protection (IP) by enclosures . 75

26.5 Thermal tests . 76

26.5.1 Temperature measurement . 76

26.5.2 Thermal shock test . 78

26.5.3 Small component ignition test (Group I and Group II) . 78

26.6 Torque test for bushings . 79

26.6.1 Test procedure . 79

26.6.2 Acceptance criteria . 80

26.7 Non-metallic enclosures or non-metallic parts of enclosures . 80

26.7.1 General . 80

26.7.2 Test temperatures . 80

26.8 Thermal endurance to heat . 80

26.9 Thermal endurance to cold . 81

26.10 Resistance to UV light . 81

26.10.1 General . 81

26.10.2 Light exposure . 82

26.10.3 Acceptance criteria . 82

26.11 Resistance to chemical agents for Group I equipment . 82

26.12 Earth continuity . 83

26.13 Surface resistance test of parts of enclosures of non-metallic materials . 84

26.14 Measurement of capacitance . 85

26.14.1 General . 85

26.14.2 Test procedure . 85

26.15 Verification of ratings of ventilating fans . 86

26.16 Alternative qualification of elastomeric sealing O-rings . 86

26.17 Transferred charge test . 86

26.17.1 Test equipment . 86

26.17.2 Test sample . 87

26.17.3 Test procedure . 87

27 Routine tests . 88

28 Manufacturer's responsibility . 88

28.1 Conformity with the documentation . 88

28.2 Certificate . 89

28.3 Responsibility for marking . 89

29 Marking . 89

29.1 Applicability . 89

29.2 Location . 89

29.3 General . 89

29.4 Ex marking for explosive gas atmospheres . 90

29.5 Ex marking for explosive dust atmospheres . 92

29.6 Combined types (or levels) of protection . 95

29.7 Multiple types of protection . 95

29.8 Ga equipment using two independent Gb types (or levels) of protection . 95

29.9 Boundary wall . 95

29.10 Ex Components . 95

29.11 Small Ex Equipment and small Ex Components . 96

– 6 – IEC 60079-0:2017 IEC 2017

29.12 Extremely small Ex Equipment and extremely small Ex Components . 96

29.13 Warning markings . 96

29.14 Cells and batteries . 97

29.15 Electric machines operated with a converter . 97

29.16 Examples of marking . 98

30 Instructions . 101

30.1 General . 101

30.2 Cells and batteries . 102

30.3 Electric machines . 103

30.4 Ventilating fans . 103

30.5 Cable glands . 104

Annex A (normative) Supplementary requirements for cable glands . 105

A.1 General . 105

A.2 Constructional requirements . 105

A.2.1 Cable sealing . 105

A.2.2 Filling compounds . 106

A.2.3 Clamping . 106

A.2.4 Lead-in of cable . 106

A.2.5 Release by a tool . 107

A.2.6 Fixing . 107

A.2.7 Degree of protection . 107

A.3 Type tests . 107

A.3.1 Tests of clamping of non-armoured and braided cables . 107

A.3.2 Tests of clamping of armoured cables . 110

A.3.3 Type test for resistance to impact . 111

A.3.4 Test for degree of protection (IP) of cable glands . 112

A.4 Marking . 113

A.4.1 Marking of cable glands . 113

A.4.2 Identification of cable-sealing rings . 113

A.5 Instructions . 113

Annex B (normative) Requirements for Ex Components . 115

Annex C (informative) Example of rig for resistance to impact test . 118

Annex D (informative) Electric machines connected to converters . 119

Annex E (informative) Temperature evaluation of electric machines . 120

Annex F (informative) Guidance flowchart for tests of non-metallic enclosures or non-

metallic parts of enclosures (26.4) . 123

Annex G (informative) Guidance flowchart for tests of cable glands . 124

Annex H (informative) Shaft voltages resulting in motor bearing or shaft brush

sparking Discharge energy calculation . 125

H.1 General . 125

H.2 Assessment of the risk of ignition using ignition energy calculation . 125

H.3 Shaft voltage determination for a rotating machine . 126

H.4 Capacitance “C” calculation for a rotating machine . 126

H.5 Energy “E” calculation for a rotating machine . 129

H.6 Assessment using reference curves . 129

Bibliography . 131

Figure 1 – Typical battery examples . 20

Figure 2 – Typical battery compartment . 21

Figure 3 – Typical replaceable battery pack . 22

Figure 4 – Tolerances and clearance for threaded fasteners . 53

Figure 5 – Contact surface under head of fastener with a reduced shank . 54

Figure 6 – Cable gland . 59

Figure 7 – Conduit entry . 59

Figure 8 – Assembly of test sample for earth-continuity test . 84

Figure 9 – Test piece with painted electrodes . 85

Figure 10 – Compression set of an O-ring . 86

Figure A.1 – Illustration of the terms used for cable glands . 106

Figure A.2 – Rounded edge of the point of entry of the flexible cable . 107

Figure A.3 – Example of rig for resistance to impact test . 112

Figure C.1 – Example of rig for resistance to impact test . 118

Figure F.1 – Non-metallic enclosures or non-metallic parts of enclosures . 123

Figure H.1 – Capacitance stored in bearing clearance of sleeve bearing Between

journal and outer bearing housing . 128

Figure H.2 – Air-gap between stator and rotor . 128

Figure H.3 – Typical surfaces that form capacitors from the motor shaft to ground . 129

Figure H.4 – Capacitive ignition curves . 130

Table 1 – Ambient temperatures in service and additional marking . 37

Table 2 – Classification of maximum surface temperatures for Group II electrical

equipment . 38

Table 3 – Assessment of temperature classification according to component size . 40

Table 4 – Assessment of temperature classification Component surface area ≥ 20 mm . 40

Table 5 – Threshold power . 43

Table 6 – Threshold energy . 43

Table 7 – Limitation of surface areas . 48

Table 8 – Maximum diameter or width . 49

Table 9 – Limitation of thickness of non-metallic layer . 49

Table 10 – Maximum acceptable transferred charge . 49

Table 11 – Maximum capacitance of unearthed conductive parts . 51

Table 12 – Minimum cross-sectional area of PE conductors . 57

Table 13 – Primary cells . 66

Table 14 – Secondary cells . 68

Table 15 – Tests for resistance to impact .

...

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Eksplozivne atmosfere - 0. del: Oprema - Splošne zahteveExplosionsgefährdete Bereiche - Teil 0: Betriebsmittel - Allgemeine AnforderungenAtmosphères explosives - Partie 0: Matériel - Exigences généralesExplosive atmospheres - Part 0: Equipment - General requirements29.260.20Electrical apparatus for explosive atmospheresICS:Ta slovenski standard je istoveten z:IEC 60079-0 Ed. 7.0oSIST IEC 60079-0:2018en,fr,de01-april-2018oSIST IEC 60079-0:2018SLOVENSKI

STANDARD

IEC 60079-0 Edition 7.0 2017-12 INTERNATIONAL STANDARD NORME INTERNATIONALE Explosive atmospheres –

Part 0: Equipment – General requirements

Atmosphères explosives –

Partie 0: Matériel – Exigences générales INTERNATIONAL ELECTROTECHNICAL COMMISSION COMMISSION ELECTROTECHNIQUE INTERNATIONALE

ICS 29.260.20

ISBN 978-2-8322-5065-5

– 2 – IEC 60079-0:2017 IEC 2017 CONTENTS FOREWORD . 8 1 Scope . 15 2 Normative references . 16 3 Terms and definitions . 18 4 Equipment grouping . 36 4.1 General . 36 4.2 Group I . 36 4.3 Group II . 36 4.4 Group III . 36 4.5 Equipment for a particular explosive gas atmosphere . 37 5 Temperatures . 37 5.1 Environmental influences . 37 5.1.1 Ambient temperature . 37 5.1.2 External source of heating or cooling . 37 5.2 Service temperature . 37 5.3 Maximum surface temperature . 38 5.3.1 Determination of maximum surface temperature . 38 5.3.2 Limitation of maximum surface temperature . 38 5.3.3 Small component temperature for Group I or Group II electrical equipment. 39 5.3.4 Component temperature of smooth surfaces for Group I or Group II electrical equipment . 40 6 Requirements for all equipment . 41 6.1 General . 41 6.2 Mechanical strength of equipment . 41 6.3 Opening times . 41 6.4 Circulating currents in enclosures (e.g. of large electric machines) . 42 6.5 Gasket retention . 42 6.6 Electromagnetic and ultrasonic energy radiating equipment . 42 6.6.1 General . 42 6.6.2 Radio frequency sources . 42 6.6.3 Ultrasonic sources . 43 6.6.4 Lasers, luminaires, and other non-divergent continuous wave optical sources. 44 7 Non-metallic enclosures and non-metallic parts of enclosures . 44 7.1 General . 44 7.1.1 Applicability . 44 7.1.2 Specification of materials . 44 7.2 Thermal endurance . 45 7.2.1 Tests for thermal endurance . 45 7.2.2 Material selection . 46 7.2.3 Alternative qualification of elastomeric sealing O-rings . 46 7.3 Resistance to ultraviolet light . 46 7.4 Electrostatic charges on external non-metallic materials . 47 7.4.1 Applicability . 47 7.4.2 Avoidance of a build-up of electrostatic charge for Group I or Group II . 47 oSIST IEC 60079-0:2018

7.4.3 Avoidance of a build-up of electrostatic charge for Group III . 49 7.5 Attached external conductive parts . 50 8 Metallic enclosures and metallic parts of enclosures . 51 8.1 Material composition . 51 8.2 Group I . 51 8.3 Group II . 51 8.4 Group III . 52 8.5 Copper Alloys . 52 9 Fasteners . 52 9.1 General . 52 9.2 Special fasteners . 53 9.3 Holes for special fasteners . 53 9.3.1 Thread engagement . 53 9.3.2 Tolerance and clearance . 53 9.4 Hexagon socket set screws . 54 10 Interlocking devices . 54 11 Bushings . 54 12 (Reserved for future use) . 54 13 Ex Components . 54 13.1 General . 54 13.2 Mounting . 55 13.3 Internal mounting . 55 13.4 External mounting . 55 13.5 Ex Component certificate . 55 14 Connection facilities . 55 14.1 General . 55 14.2 Type of protection . 56 14.3 Creepage and clearance . 56 15 Connection facilities for earthing or bonding conductors . 56 15.1 Equipment requiring earthing or bonding . 56 15.1.1 Internal earthing . 56 15.1.2 External bonding. 56 15.2 Equipment not requiring earthing . 56 15.3 Size of protective earthing conductor connection . 56 15.4 Size of equipotential bonding conductor connection . 57 15.5 Protection against corrosion . 57 15.6 Secureness of electrical connections . 57 15.7 Internal earth continuity plate . 57 16 Entries into enclosures . 57 16.1 General . 57 16.2 Identification of entries . 57 16.3 Cable glands . 58 16.4 Blanking elements. 58 16.5 Thread adapters . 58 16.6 Temperature at branching point and entry point . 59 16.7 Electrostatic charges of cable sheaths . 59 17 Supplementary requirements for electric machines . 60 17.1 General . 60 oSIST IEC 60079-0:2018

– 4 – IEC 60079-0:2017 IEC 2017 17.2 Ventilation. 60 17.2.1 Ventilation openings . 60 17.2.2 Materials for external fans . 60 17.2.3 Cooling fans of rotating electric machines . 60 17.2.4 Auxiliary motor cooling fans . 61 17.2.5 Room ventilating fans . 61 17.3 Bearings . 62 18 Supplementary requirements for switchgear . 62 18.1 Flammable dielectric . 62 18.2 Disconnectors . 62 18.3 Group I – Provisions for locking . 63 18.4 Doors and covers . 63 19 Reserved for future use . 63 20 Supplementary requirements for external plugs, socket outlets and connectors for field wiring connection . 63 20.1 General . 63 20.2 Explosive gas atmospheres . 64 20.3 Explosive dust atmospheres . 64 20.4 Energized plugs . 64 21 Supplementary requirements for luminaires . 64 21.1 General . 64 21.2 Covers for luminaires of EPL Mb, EPL Gb, or EPL Db . 64 21.3 Covers for luminaires of EPL Gc or EPL Dc . 65 21.4 Sodium lamps . 65 22 Supplementary requirements for caplights and handlights . 65 22.1 Group I caplights . 65 22.2 Group II and Group III caplights and handlights

................................................... 65 23 Equipment incorporating cells and batteries ................................................................... 66 23.1 General ................................................................................................................. 66 23.2 Interconnection of cells to form batteries ............................................................... 66 23.3 Cell types .............................................................................................................. 66 23.4 Cells in a battery ................................................................................................... 69 23.5 Ratings of batteries ............................................................................................... 69 23.6 Interchangeability ................................................................................................. 69 23.7 Charging of primary batteries ................................................................................ 69 23.8 Leakage ................................................................................................................ 69 23.9 Connections .......................................................................................................... 69 23.10 Orientation ............................................................................................................ 69 23.11 Replacement of cells or batteries .......................................................................... 69 23.12 Replaceable battery pack ...................................................................................... 70 24 Documentation .............................................................................................................. 70 25 Compliance of prototype or sample with documents ....................................................... 70 26 Type tests ..................................................................................................................... 70 26.1 General ................................................................................................................. 70 26.2 Test configuration ................................................................................................. 70 26.3 Tests in explosive test mixtures ............................................................................ 70 26.4 Tests of enclosures ............................................................................................... 71 26.4.1 Order of tests ................................................................................................ 71 oSIST IEC 60079-0:2018

26.4.2 Resistance to impact . 73 26.4.3 Drop test . 74 26.4.4 Acceptance criteria . 75 26.4.5 Degree of protection (IP) by enclosures . 75 26.5 Thermal tests . 76 26.5.1 Temperature measurement . 76 26.5.2 Thermal shock test . 78 26.5.3 Small component ignition test (Group I and Group II) . 78 26.6 Torque test for bushings . 79 26.6.1 Test procedure . 79 26.6.2 Acceptance criteria . 80 26.7 Non-metallic enclosures or non-metallic parts of enclosures . 80 26.7.1 General . 80 26.7.2 Test temperatures . 80 26.8 Thermal endurance to heat . 80 26.9 Thermal endurance to cold . 81 26.10 Resistance to UV light . 81 26.10.1 General . 81 26.10.2 Light exposure . 82 26.10.3 Acceptance criteria . 82 26.11 Resistance to chemical agents for Group I equipment . 82 26.12 Earth continuity . 83 26.13 Surface resistance test of parts of enclosures of non-metallic materials . 84 26.14 Measurement of capacitance . 85 26.14.1 General . 85 26.14.2 Test procedure . 85 26.15 Verification of ratings of ventilating fans . 86 26.16 Alternative qualification of elastomeric sealing O-rings . 86 26.17 Transferred charge test . 86 26.17.1 Test equipment . 86 26.17.2 Test sample . 87 26.17.3 Test procedure . 87 27 Routine tests . 88 28 Manufacturer's responsibility . 88 28.1 Conformity with the documentation . 88 28.2 Certificate . 89 28.3 Responsibility for marking . 89 29 Marking . 89 29.1 Applicability . 89 29.2 Location . 89 29.3 General . 89 29.4 Ex marking for explosive gas atmospheres . 90 29.5 Ex marking for explosive dust atmospheres . 92 29.6 Combined types (or levels) of protection . 95 29.7 Multiple types of protection . 95 29.8 Ga equipment using two independent Gb types (or levels) of protection . 95 29.9 Boundary wall . 95 29.10 Ex Components . 95 29.11 Small Ex Equipment and small Ex Components . 96 oSIST IEC 60079-0:2018

– 6 – IEC 60079-0:2017 IEC 2017 29.12 Extremely small Ex Equipment and extremely small Ex Components . 96 29.13 Warning markings . 96 29.14 Cells and batteries . 97 29.15 Electric machines operated with a converter . 97 29.16 Examples of marking . 98 30 Instructions . 101 30.1 General . 101 30.2 Cells and batteries . 102 30.3 Electric machines . 103 30.4 Ventilating fans . 103 30.5 Cable glands . 104 Annex A (normative)

Supplementary requirements for cable glands . 105 A.1 General . 105 A.2 Constructional requirements . 105 A.2.1 Cable sealing . 105 A.2.2 Filling compounds . 106 A.2.3 Clamping . 106 A.2.4 Lead-in of cable . 106 A.2.5 Release by a tool . 107 A.2.6 Fixing . 107 A.2.7 Degree of protection . 107 A.3 Type tests . 107 A.3.1 Tests of clamping of non-armoured and braided cables . 107 A.3.2 Tests of clamping of armoured cables . 110 A.3.3 Type test for resistance to impact . 111 A.3.4 Test for degree of protection (IP) of cable glands . 112 A.4 Marking . 113 A.4.1 Marking of cable glands . 113 A.4.2 Identification of cable-sealing rings . 113 A.5 Instructions . 113 Annex B (normative)

Requirements for Ex Components . 115 Annex C (informative)

Example of rig for resistance to impact test . 118 Annex D (informative)

Electric machines connected to converters . 119 Annex E (informative)

Temperature evaluation of electric machines . 120 Annex F (informative)

Guidance flowchart for tests of non-metallic enclosures or

non-metallic parts of enclosures (26.4) . 123 Annex G (informative)

Guidance flowchart for tests of cable glands . 124 Annex H (informative)

Shaft voltages resulting in motor bearing or shaft brush sparking Discharge energy calculation . 125 H.1 General . 125 H.2 Assessment of the risk of ignition using ignition energy calculation . 125 H.3 Shaft voltage determination for a rotating machine . 126 H.4 Capacitance “C” calculation for a rotating machine . 126 H.5 Energy “E” calculation for a rotating machine . 129 H.6 Assessment using reference curves . 129 Bibliography . 131

Figure 1 – Typical battery examples . 20 oSIST IEC 60079-0:2018

Figure 2 – Typical battery compartment . 21 Figure 3 – Typical replaceable battery pack . 22 Figure 4 – Tolerances and clearance for threaded fasteners . 53 Figure 5 – Contact surface under head of fastener with a reduced shank . 54 Figure 6 – Cable gland . 59 Figure 7 – Conduit entry . 59 Figure 8 – Assembly of test sample for earth-continuity test . 84 Figure 9 – Test piece with painted electrodes . 85 Figure 10 – Compression set of an O-ring . 86 Figure A.1 – Illustration of the terms used for cable glands . 106 Figure A.2 – Rounded edge of the point of entry of the flexible cable . 107 Figure A.3 – Example of rig for resistance to impact test . 112 Figure C.1 – Example of rig for resistance to impact test . 118 Figure F.1 – Non-metallic enclosures or non-metallic parts of enclosures . 123 Figure H.1 – Capacitance stored in bearing clearance of sleeve bearing Between journal and outer bearing housing . 128 Figure H.2 – Air-gap between stator and rotor . 128 Figure H.3 – Typical surfaces that form capacitors from the motor shaft to ground . 129 Figure H.4 – Capacitive ignition curves . 130

Table 1 – Ambient temperatures in service and additional marking . 37 Table 2 – Classification of maximum surface temperatures

for Group II electrical equipment . 38 Table 3 – Assessment of temperature classification according to component size . 40 Table 4 – Assessment of temperature classification Component surface area ≥ 2M mm2. 40 Table 5 – Threshold power . 43 Table 6 – Threshold energy . 43 Table 7 – Limitation of surface areas . 48 Table 8 – Maximum diameter or width . 49 Table 9 – Limitation of thickness of non-metallic layer . 49 Table 10 – Maximum acceptable transferred charge . 49 Table 11 – Maximum capacitance of unearthed conductive parts . 51 Table 12 – Minimum cross-sectional area of PE conductors . 57 Table 13 – Primary cells . 66 Table 14 – Secondary cells . 68 Table 15 – Tests for resistance to impact . 74 Table 16 – Torque to be applied to the stem of bushing used for connection facilities . 79 Table 17 – Thermal endurance test . 80 Table 18 – Text of warning markings . 97 Table 19 – Example of type-test converter parameters . 103 Table B.1 – Applicability of clauses to Ex Components . 115 Table H.1 – Maximum permitted energy . 126

– 8 – IEC 60079-0:2017 IEC 2017 INTERNATIONAL ELECTROTECHNICAL COMMISSION ____________

EXPLOSIVE ATMOSPHERES –

Part 0: Equipment – General requirements

FOREWORD 1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with may participate in this preparatory work. International, governmental and non-governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for Standardization (ISO) in accordance with conditions determined by agreement between the two organizations. 2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international consensus of opinion on the relevant subjects since each technical committee has representation from all interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any misinterpretation by any end user. 4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications transparently to the maximum extent possible in their national and regional publications. Any divergence between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter. 5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any services carried out by independent certification bodies. 6) All users should ensure that they have the latest edition of this publication. 7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and members of its technical committees and IEC National Committees for any personal injury, property damage or other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is indispensable for the correct application of this publication. 9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent rights. IEC shall not be held responsible for identifying any or all such patent rights. International Standard IEC 60079-0 has been prepared by IEC technical committee 31: Equipment for explosive atmospheres. This seventh edition cancels and replaces the sixth edition, published in 2011. This edition constitutes a technical revision.

The significance of the changes between IEC Standard, IEC 60079-0, Edition 6 (2011) and IEC 60079-0, Edition 7 (2017) are as listed below:

Type Explanation of the significance of the changes Clause Minor and editorial changes Extension Major technical changes Throughout document, “electrical equipment” replaced by “equipment” where appropriate. Multiple X

Scope List of “Type of “Protection” and “Product” standards combined into one list. 1 X

Definitions used in multiple sub-parts added. Definitions harmonized across sub-parts and added to 60079-0 where appropriate. Battery definitions updated 3 X

Clarification of the way that information on process temperature influences can be expressed. 5.1.2 X

Clarification regarding the determination of service temperatures when dust layers are present 5.2 X

Clarification on the need to provide service temperature information for Ex Components in the Schedule of Limitations 5.2 X

Relocation of EPL Da dust layer requirements from IEC 60079-18 & IEC 60079-31 5.3.2.3.1 A1

Clarified that for EPL Db, a maximum specified dust layer of greater than 200 mm is not permitted as thicker layers have no additional effect on maximum surface temperature. b) X

Added for EPL Db, a dust layer in a specified orientation, marked as TL c)

X

Clarified that for EPL Dc, no dust layer tests are required. 5.3.2.3.3 X

Clarified that the “temperature” is the temperature of the air surrounding the component 5.3.3 X

Subdivided section dealing with higher permitted surface temperatures for “smooth” surfaces. Corrected area from 1 000 mm2 to 10 000 mm2. 5.3.4 X

Clarified that the “Ex” requirements of IEC 60079 supplement those of the relevant industrial standards. 6.1 X

Added requirement that where an adhesive is used to secure a gasket, it shall be used within its COT and shall comply with the requirements for cements. 6.5

C1 Requirements relocated to IEC 60079-28 former 6.6.2 A2

Ultrasonic requirements updated based on latest research work 6.6.3

X