SIST EN 13906-2:2014

(Main)Cylindrical helical springs made from round wire and bar - Calculation and design - Part 2: Extension springs

Cylindrical helical springs made from round wire and bar - Calculation and design - Part 2: Extension springs

This European Standard specifies the calculation and design of cold and hot coiled helical extension springs made from round wire and bar with values according to Table 1, loaded in the direction of the spring axis and operating at normal ambient temperatures.

NOTE In cases of substantially higher or lower working temperature, it is advisable to seek the manufacturer’s advice.

Zylindrische Schraubenfedern aus runden Drähten und Stäben - Berechnung und Konstruktion - Teil 2: Zugfedern

Diese Europäische Norm gilt für die Berechnung und Konstruktion von kalt und warmgeformten Schraubenzug¬federn aus runden Drähten und Stäben, die in Richtung der Federachse auf Zug belastet sind und die bei üblicher Umgebungstemperatur mit Werten nach Tabelle 1 arbeiten.

Ressorts hélicoïdaux cylindriques fabriqués à partir de fils ronds et de barres - Calcul et conception - Partie 2: Ressorts de traction

La présente Norme européenne, spécifie le calcul et la conception des ressorts de traction hélicoïdaux cylindriques enroulés à froid et à chaud fabriqués à partir de fils ronds et de barres, ayant les valeurs du Tableau 1, pour lesquels la sollicitation est appliquée dans la direction de l’axe du ressort et travaillant à température ambiante normale.

NOTE Pour des températures de service substantiellement supérieures ou inférieures, il est recommandé de demander conseil au fabricant.

Vijačne valjaste vzmeti iz okrogle žice in palic - Izračun in načrtovanje - 2. del: Natezne vzmeti

Ta evropski standard določa izračun in načrtovanje hladno in toplo oblikovanih valjastih nateznih vzmeti, izdelanih iz okrogle žice in palic, z vrednostmi, skladnimi s preglednico 1, in z glavno obremenitvijo v smeri osi vzmeti, ki se uporablja pri normalnih temperaturah okolja.

General Information

- Status

- Published

- Publication Date

- 11-Dec-2013

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 04-Dec-2013

- Due Date

- 08-Feb-2014

- Completion Date

- 12-Dec-2013

Relations

- Effective Date

- 01-Jan-2014

Overview

EN 13906-2:2013 is the CEN European Standard that covers the calculation and design of cylindrical helical extension springs made from round wire and bar. It applies to cold- and hot-coiled extension springs used under normal ambient temperatures and defines dimensional, material and calculation principles to ensure reliable spring performance in axial (extension) loading. NOTE: for substantially higher or lower working temperatures, manufacturer advice is recommended.

Key topics

- Scope limits: Cold-coiled springs - wire/bar diameter d ≤ 20 mm; hot-coiled springs - d ≥ 10 mm. Number of active coils n ≥ 3. Spring index (w): cold 4 ≤ w ≤ 20; hot 4 ≤ w ≤ 12.

- Types of loading: definitions and design treatment for static, quasi-static and dynamic loading; dynamic fatigue guidance (service-life categories including infinite life at high cycle counts).

- Calculation formulae: consistent methods for spring force, deflection (stroke), spring rate, spring work, and selection of nominal wire/bar diameter and coil counts.

- Torsional stress and fatigue: uncorrected and corrected torsional stresses using a stress correction factor k (dependent on spring index); permissible torsional stress values are given separately for cold and hot coiled springs and for static vs dynamic conditions.

- Initial tension (F0): definition and design impact. Cold-coiled extension springs may be manufactured with initial tension; hot-coiled springs typically cannot and will have gaps between coils after heat treatment.

- Materials and properties: recommended material property values at ambient temperature (examples: spring steels E ≈ 206 000 N/mm², G ≈ 78 500–81 500 N/mm²; stainless grades range from E ≈ 175 000–200 000 N/mm²). See standard Table 3 for detailed values.

- Supplementary content: normative references, symbols and units, informative annex on types of spring ends, and bibliography.

Applications

- Design and specification of extension springs for mechanical assemblies, automotive components, consumer goods, industrial valves, actuators and retention systems.

- Used by spring designers, mechanical engineers, manufacturers, test engineers, procurement and quality managers to calculate safe loads, deflections, fatigue life and to set manufacturing tolerances.

- Helpful where predictable axial performance and fatigue behaviour are critical (repetitive motion, dynamic loading, long-life applications).

Related standards

- EN 13906-1 (Compression springs) and EN 13906-3 (Torsion springs)

- EN ISO 26909 (Springs - Vocabulary)

- EN 10270-1/2/3 (Steel wire for mechanical springs)

- EN 10089 (Hot-rolled steels for quenched & tempered springs)

- EN 12166 (Copper alloys - Wire)

Keywords: EN 13906-2:2013, extension springs, helical springs, spring calculation and design, cold coiled, hot coiled, torsional stress, initial tension, spring index.

Frequently Asked Questions

SIST EN 13906-2:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Cylindrical helical springs made from round wire and bar - Calculation and design - Part 2: Extension springs". This standard covers: This European Standard specifies the calculation and design of cold and hot coiled helical extension springs made from round wire and bar with values according to Table 1, loaded in the direction of the spring axis and operating at normal ambient temperatures. NOTE In cases of substantially higher or lower working temperature, it is advisable to seek the manufacturer’s advice.

This European Standard specifies the calculation and design of cold and hot coiled helical extension springs made from round wire and bar with values according to Table 1, loaded in the direction of the spring axis and operating at normal ambient temperatures. NOTE In cases of substantially higher or lower working temperature, it is advisable to seek the manufacturer’s advice.

SIST EN 13906-2:2014 is classified under the following ICS (International Classification for Standards) categories: 21.160 - Springs. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13906-2:2014 has the following relationships with other standards: It is inter standard links to SIST EN 13906-2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13906-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zylindrische Schraubenfedern aus runden Drähten und Stäben - Berechnung und Konstruktion - Teil 2: ZugfedernRessorts hélicoïdaux cylindriques fabriqués à partir de fils ronds et de barres - Calcul et conception - Partie 2: Ressorts de tractionCylindrical helical springs made from round wire and bar - Calculation and design - Part 2: Extension springs21.160VzmetiSpringsICS:Ta slovenski standard je istoveten z:EN 13906-2:2013SIST EN 13906-2:2014en,fr,de01-januar-2014SIST EN 13906-2:2014SLOVENSKI

STANDARDSIST EN 13906-2:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13906-2

June 2013 ICS 21.160 Supersedes EN 13906-2:2001English Version

Cylindrical helical springs made from round wire and bar - Calculation and design - Part 2: Extension springs

Ressorts hélicoïdaux cylindriques fabriqués à partir de fils ronds et de barres - Calcul et conception - Partie 2: Ressorts de traction

Zylindrische Schraubenfedern aus runden Drähten und Stäben - Berechnung und Konstruktion - Teil 2: ZugfedernThis European Standard was approved by CEN on 16 May 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13906-2:2013: ESIST EN 13906-2:2014

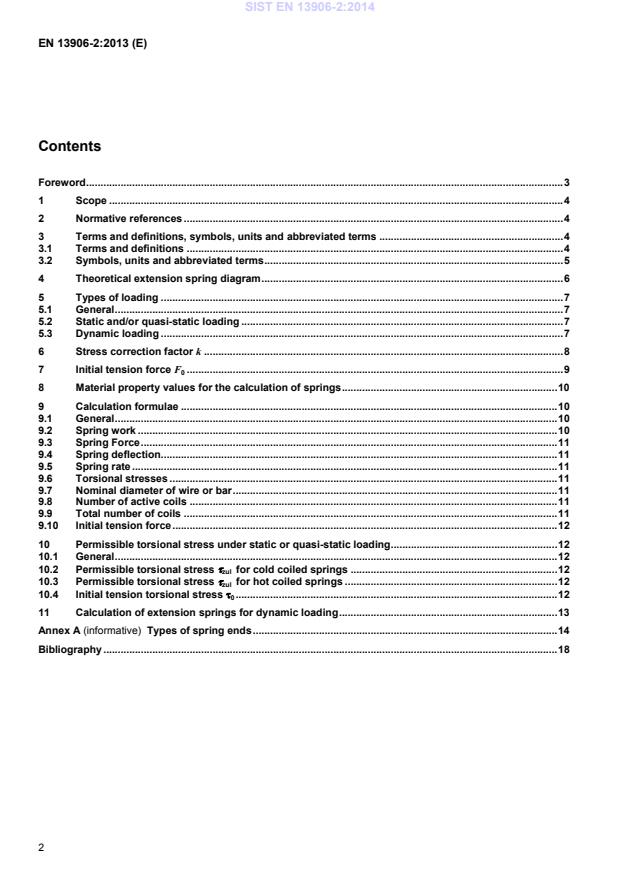

for cold coiled springs . 12 10.3 Permissible torsional stress τzul

for hot coiled springs . 12 10.4 Initial tension torsional stress τ0 . 12 11 Calculation of extension springs for dynamic loading . 13 Annex A (informative)

Types of spring ends . 14 Bibliography . 18

NOTE In cases of substantially higher or lower working temperature, it is advisable to seek the manufacturer’s advice. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 10270-1, Steel wire for mechanical springs — Part 1: Patented cold drawn unalloyed spring steel wire EN 10270-2, Steel wire for mechanical springs — Part 2: Oil hardened and tempered spring steel wire EN 10270-3, Steel wire for mechanical springs — Part 3: Stainless spring steel wire EN 10089, Hot-rolled steels for quenched and tempered springs — Technical delivery conditions EN 12166, Copper and copper alloys — Wire for general purposes EN ISO 26909:2010, Springs — Vocabulary (ISO 26909:2009) ISO 26910-1, Springs — Shot peening — Part 1: General procedures 3 Terms and definitions, symbols, units and abbreviated terms 3.1 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 26909:2010 and the following apply. 3.1.1 spring mechanical device designed to store energy when deflected and to return the equivalent amount of energy when released [SOURCE: EN ISO 26909:2010, 1.1] 3.1.2 extension spring spring (1.1) that offers resistance to an axial force tending to extend its length, with or without initial tension [SOURCE: EN ISO 26909:2010, 1.3] SIST EN 13906-2:2014

Symbols

Units Terms 2ieDDD+= mm mean diameter of coil De mm outside diameter of the spring Di mm inside diameter of the spring d mm nominal diameter of wire (or bar) E N/mm² (MPa) modulus of elasticity (or Young’s modulus) F0 N initial tension force F N spring force

F1, F2. N spring forces, for the spring lengths L1, L2 . (at ambient temperature of 20 ºC) Fn N maximum permissible spring force for the maximum permissible spring length Ln G N/mm² (MPa) modulus of rigidity

k - stress correction factor (depending on D/d) L mm spring length L0 mm Nominal free length of spring L1, L2. mm spring lengths for the spring forces F1, F2 . LH mm distance from inner radius of loop to spring body LK mm body length when unloaded but subject to initial tension force Ln mm maximum permissible spring length for the spring force Fn m mm hook opening N - Number of cycles up to rupture n - number of active coils nt - total number of coils R N/mm spring rate

Table 2 (2 of 2)

Symbols

Units Terms Rm N/mm² (MPa) minimum value of tensile strength s mm spring deflection

s1, s2 .

mm spring deflections, for the spring forces F1, F2 .

sh mm deflection of spring (stroke) between two positions sn mm spring deflection, for the spring force Fn W Nmm spring work dDw= - spring index ρ kg/dm3 density τ N/mm² (MPa) uncorrected torsional stress (without the influence of the wire curvature being taken into account) τ0 N/mm² (MPa) uncorrected torsional stress, for the initial tension force F0 τ1, τ2 .

N/mm² (MPa) uncorrected torsional stress, for the

spring forces F1, F2 . τk N/mm² (MPa) corrected torsional stress, (according to the correction factor k) τk1, τk2 . N/mm² (MPa) corrected torsional stress, for the

spring forces F1, F2 . τkh N/mm² (MPa) corrected

torsional stress range, for the stroke

sh τkn N/mm² (MPa) corrected torsional stress, for the

spring force Fn τn N/mm² (MPa) uncorrected torsional stress, for the spring force Fn τzul N/mm² (MPa) permissible torsional stress

4 Theoretical extension spring diagram The illustration of the extension spring corresponds to Figure 5.1 from EN ISO 2162-1:1996. The theoretical extension spring diagram is given in Figure 1. SIST EN 13906-2:2014

Key 1

spring deflection 2

spring lengths Figure 1 — Theoretical extension spring diagram 5 Types of loading 5.1 General Before carrying out design calculations, it should be specified

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...