SIST EN 1794-2:2025

(Main)Road traffic noise reducing devices - Non-acoustic performance - Part 2: Methods of determination of the general safety and environmental characteristics

Road traffic noise reducing devices - Non-acoustic performance - Part 2: Methods of determination of the general safety and environmental characteristics

This document specifies methods and criteria for assessing the general safety and environmental performance of road traffic noise reducing devices under typical roadside conditions. Appropriate test methods are provided where these are necessary. The treatment of each topic is covered separately in Annexes A to F.

Lärmschutzvorrichtungen an Straßen - Nichtakustische Eigenschaften - Teil 2: Methoden zur Bestimmung der allgemeinen Sicherheits- und Umwelteigenschaften

Dieses Dokument legt Verfahren und Kriterien zur Bewertung von Lärmschutzvorrichtungen an Straßen hinsichtlich der Sicherheit und des Umweltschutzes im Allgemeinen unter für den Straßenrand typischen Bedingungen fest. Sofern erforderlich, sind geeignete Prüfverfahren angegeben. Diese Aspekte werden in Anhang A bis Anhang F einzeln behandelt.

Dispositifs de réduction du bruit du trafic routier - Performances non acoustiques - Partie 2 : Méthodes de détermination des caractéristiques générales de sécurité et des caractéristiques environnementales

Le présent document spécifie les méthodes et les critères d’évaluation de la sécurité générale ainsi que des performances relatives à l’environnement des dispositifs de réduction du bruit du trafic routier dans des conditions classiques d’installation en bordure de route. Des méthodes d’essai appropriées sont données chaque fois que cela est nécessaire. Chaque sujet est traité séparément dans les Annexes A à F.

Protihrupne ovire za cestni promet - Neakustične lastnosti - 2. del: Metode ugotavljanja splošnih značilnosti glede varnosti in okolja

Ta dokument določa metode in merila za ocenjevanje splošnih značilnosti protihrupnih ovir za cestni promet glede varnosti in okolja v običajnih pogojih ob cesti. Ustrezne preskusne metode so na voljo, kjer je to potrebno. Vsaka tema je ločeno obravnavana v dodatkih od A do G.

General Information

- Status

- Published

- Public Enquiry End Date

- 27-Feb-2022

- Publication Date

- 09-Dec-2024

- Technical Committee

- OCE - Road equipment

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 11-Nov-2024

- Due Date

- 16-Jan-2025

- Completion Date

- 10-Dec-2024

Relations

- Effective Date

- 01-Jan-2025

Overview

EN 1794-2:2024 - published by CEN - specifies methods of determination of the general safety and environmental characteristics of road traffic noise reducing devices under typical roadside conditions. It covers the non-acoustic performance requirements and provides appropriate test methods and reporting requirements. EN 1794-2:2024 supersedes the 2020 edition and forms Part 2 of the EN 1794 series (Part 1 covers mechanical and stability characteristics).

Key topics and technical requirements

This standard treats each non-acoustic topic separately (Annexes A–F) and requires documented test evidence and a structured test report. Main technical topics include:

- Fire safety (Annex A): methods to assess safety in the case of brushwood/vegetation fires near barriers and recommendations for firebreaks where materials are flammable.

- Resistance to dynamic loads (Annex B): test methods to evaluate the risk of falling debris and secondary safety when panels are struck or loaded dynamically.

- Environmental protection (Annex C): identification of constituent materials and their breakdown products (leachates, emissions) to assess environmental impact.

- Access for maintenance and emergency exits (Annex D): requirements and performance checks for doors or escape routes integrated into noise-reducing devices.

- Light reflection (Annex E): standardized reflectivity tests to ensure devices do not prejudice road safety through glare or inappropriate reflections.

- Transparency (Annex F, informative): methodology for static and dynamic transparency assessment of transparent elements (visual access, obstruction angles, calculation uncertainty).

Also referenced are related normative documents, e.g. EN 1794-1:2024 (mechanical performance) and EN ISO 2813:2014 for gloss/reflectivity measurement.

Required test-report contents are specified (standard reference, full description of tested element, sampling method, test place/date, methods and results, and a performance summary).

Practical applications

EN 1794-2:2024 is used to:

- Specify non-acoustic performance requirements when procuring or specifying noise barriers, claddings, covers, and added devices.

- Design and verify barrier systems so they do not introduce fire, environmental, visibility or maintenance hazards.

- Provide objective test evidence for product certification, compliance checks, and risk assessments.

- Inform mitigation choices (material selection, firebreaks, transparent panel design, anti-reflective finishes).

Who should use this standard

- Road authorities and highway asset owners

- Barrier and acoustic product manufacturers and designers

- Civil and traffic engineers specifying roadside installations

- Test laboratories and certification bodies

- Environmental and safety assessors involved in infrastructure projects

Related standards

- EN 1794-1:2024 - Non-acoustic performance, Part 1: mechanical and stability characteristics

- EN ISO 2813:2014 - Paints and varnishes: determination of gloss (used for reflectivity tests)

Keywords: EN 1794-2:2024, road traffic noise reducing devices, noise barriers, non-acoustic performance, test methods, safety, environmental characteristics, transparency, reflectivity, CEN.

Frequently Asked Questions

SIST EN 1794-2:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Road traffic noise reducing devices - Non-acoustic performance - Part 2: Methods of determination of the general safety and environmental characteristics". This standard covers: This document specifies methods and criteria for assessing the general safety and environmental performance of road traffic noise reducing devices under typical roadside conditions. Appropriate test methods are provided where these are necessary. The treatment of each topic is covered separately in Annexes A to F.

This document specifies methods and criteria for assessing the general safety and environmental performance of road traffic noise reducing devices under typical roadside conditions. Appropriate test methods are provided where these are necessary. The treatment of each topic is covered separately in Annexes A to F.

SIST EN 1794-2:2025 is classified under the following ICS (International Classification for Standards) categories: 13.020.99 - Other standards related to environmental protection; 17.140.30 - Noise emitted by means of transport; 93.080.30 - Road equipment and installations. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1794-2:2025 has the following relationships with other standards: It is inter standard links to SIST EN 1794-2:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1794-2:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2025

Nadomešča:

SIST EN 1794-2:2020

Protihrupne ovire za cestni promet - Neakustične lastnosti - 2. del: Metode

ugotavljanja splošnih značilnosti glede varnosti in okolja

Road traffic noise reducing devices - Non-acoustic performance - Part 2: Methods of

determination of the general safety and environmental characteristics

Lärmschutzvorrichtungen an Straßen - Nichtakustische Eigenschaften - Teil 2: Methoden

zur Bestimmung der allgemeinen Sicherheits- und Umwelteigenschaften

Dispositifs de réduction du bruit du trafic routier - Performances non acoustiques - Partie

2 : Méthodes de détermination des caractéristiques générales de sécurité et des

caractéristiques environnementales

Ta slovenski standard je istoveten z: EN 1794-2:2024

ICS:

13.020.99 Drugi standardi v zvezi z Other standards related to

varstvom okolja environmental protection

17.140.30 Emisija hrupa transportnih Noise emitted by means of

sredstev transport

93.080.30 Cestna oprema in pomožne Road equipment and

naprave installations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1794-2

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2024

EUROPÄISCHE NORM

ICS 93.080.30 Supersedes EN 1794-2:2020

English Version

Road traffic noise reducing devices - Non-acoustic

performance - Part 2: Methods of determination of the

general safety and environmental characteristics

Dispositifs de réduction du bruit du trafic routier - Lärmschutzvorrichtungen an Straßen - Nichtakustische

Performances non acoustiques - Partie 2 : Méthodes de Eigenschaften - Teil 2: Methoden zur Bestimmung der

détermination des caractéristiques générales de allgemeinen Sicherheits- und Umweltmerkmale

sécurité et des caractéristiques environnementales

This European Standard was approved by CEN on 12 August 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1794-2:2024 E

worldwide for CEN national Members.

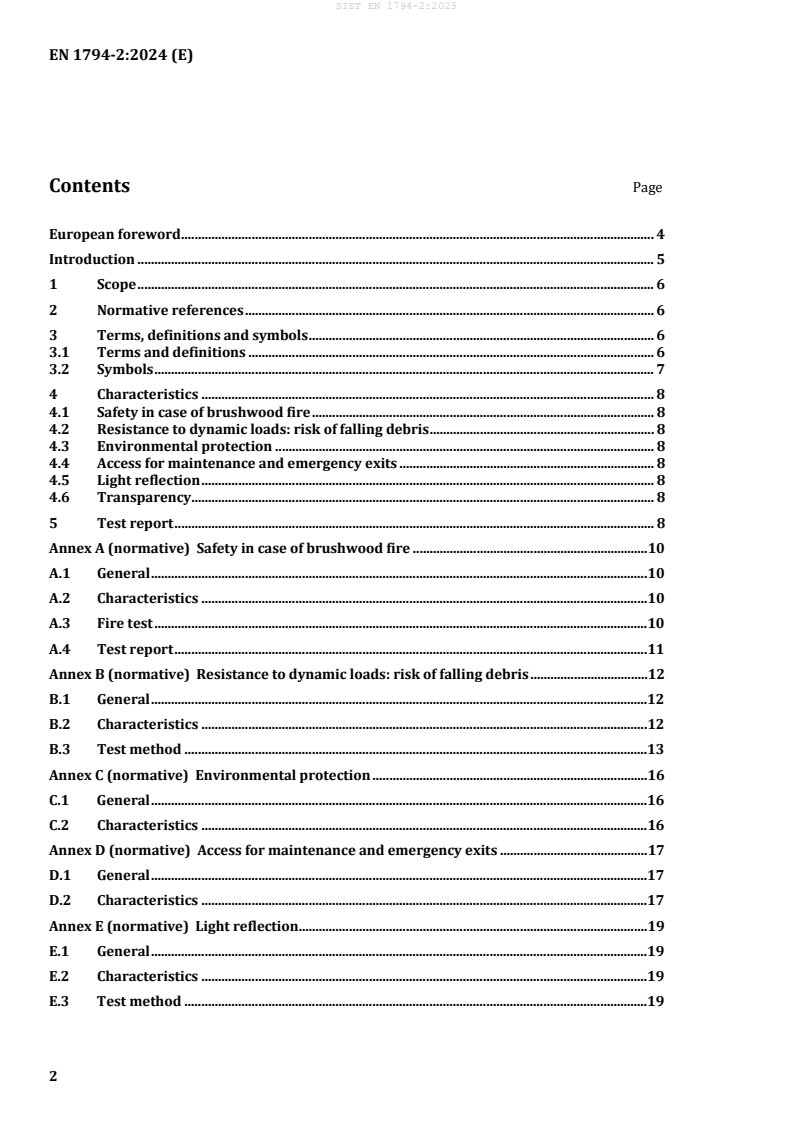

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and symbols . 6

3.1 Terms and definitions . 6

3.2 Symbols . 7

4 Characteristics . 8

4.1 Safety in case of brushwood fire . 8

4.2 Resistance to dynamic loads: risk of falling debris . 8

4.3 Environmental protection . 8

4.4 Access for maintenance and emergency exits . 8

4.5 Light reflection . 8

4.6 Transparency . 8

5 Test report . 8

Annex A (normative) Safety in case of brushwood fire .10

A.1 General .10

A.2 Characteristics .10

A.3 Fire test .10

A.4 Test report .11

Annex B (normative) Resistance to dynamic loads: risk of falling debris .12

B.1 General .12

B.2 Characteristics .12

B.3 Test method .13

Annex C (normative) Environmental protection .16

C.1 General .16

C.2 Characteristics .16

Annex D (normative) Access for maintenance and emergency exits .17

D.1 General .17

D.2 Characteristics .17

Annex E (normative) Light reflection.19

E.1 General .19

E.2 Characteristics .19

E.3 Test method .19

E.4 Test report . 21

Annex F (informative) Transparency . 22

F.1 General . 22

F.2 Definition of transparency . 22

F.3 Static transparency . 23

F.4 Dynamic transparency . 24

F.5 Methodology . 24

F.6 Uncertainty in calculation of effective transparency . 28

Bibliography . 30

European foreword

This document (EN 1794-2:2024) has been prepared by Technical Committee CEN/TC 226 “Road

equipment”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2025, and conflicting national standards shall be

withdrawn at the latest by April 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1794-2:2020.

— The annexes were renumbered. Annex A now includes the safety in case of brushwood fire.

This document is part of the EN 1794 series, which consists of the following parts under the general title

“Road traffic noise reducing devices — Non-acoustic performance”:

— Part 1: Methods of determination of the mechanical and stability characteristics;

— Part 2: Methods of determination of the general safety and environmental characteristics.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

While performing their primary function, road traffic noise reducing devices should not pose hazards to

road users or other people in the vicinity or to the environment at large. Noise reducing devices should

not reflect light in such a way as to prejudice road safety. They should be made from materials which do

not emit noxious fumes or leachates as the result of natural or industrial processes, or as the result of fire.

Noise reducing devices should allow a means of escape by road users and access by operatives in the

event of an emergency or for maintenance.

1 Scope

This document specifies methods and criteria for assessing the general safety and environmental

performance of road traffic noise reducing devices under typical roadside conditions. Appropriate test

methods are provided where these are necessary. The treatment of each topic is covered separately in

Annexes A to F.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1794-1:2024, Road traffic noise reducing devices — Non-acoustic performance — Part 1: Mechanical

performance and stability characteristics

EN ISO 2813:2014, Paints and varnishes - Determination of gloss value at 20°, 60° and 85° (ISO 2813:2014)

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

road traffic noise reducing device

RTNRD

device designed to reduce the propagation of traffic noise away from the road environment

Note 1 to entry: RTNRDs can comprise acoustic elements (3.1.2) only, or both structural (3.1.3) and acoustic

elements.

Note 2 to entry: Applications of RTNRDs include noise barriers (3.1.5), claddings (3.1.6), covers (3.1.7) and added

devices (3.1.8).

3.1.2

acoustic element

element whose primary function is to provide the acoustic performance of the device

3.1.3

structural element

element whose primary function is to support or hold in place the parts of the RTNRD

3.1.4

self-supporting acoustic element

acoustic element including its own structural element to support itself

3.1.5

noise barrier

noise-reducing device which obstructs the direct transmission of airborne sound emanating from road

traffic

3.1.6

cladding

noise-reducing device which is attached to a wall or other structure and reduces the amount of sound

reflected

3.1.7

cover

noise-reducing device which either spans or overhangs the road

3.1.8

added device

additional component that influences the acoustic performance of the original noise-reducing device

Note 1 to entry: The added device is acting primarily on the diffracted energy.

3.2 Symbols

For the purposes of this document, the following symbols apply:

ϕ angle at which reflections from the surface of the transparent material obscure

m

the view through the material, in degrees

ϕ angle between the visual axis and the normal to the noise reducing device (see

Figure F.2) in degrees

ϴ angle of incidence

αn angle of transparency (see Figure F.2) in degrees

α angle (see Figure B.1)

ß angle of opacity (see Figure F.2) in degrees

n

η angle of the transparent Elements

µ terms of refractive index

t function of the angle of incidence

θ

K visual acuity factor (see Figure F.1) in degrees

A

k Parameter

L light transmission index (as determined in accordance with EN 410 or

T

EN 2155-5), in percent

’

LT overall transparency for different material thickness t’

L /100 coefficient

T

r radius (see Figure B.1)

S area of opaque features within transparent elements, in square millimetres

O

S total area of transparent elements, including horizontal features, in square

T

millimetres

t/t’ material thickness/ different material thickness

T transparency, in percent

T transparency looking right, in percent

r

T transparency looking left, in percent

l

T dynamic transparency, in percent

D

T static transparency, in percent

S

u estimated uncertainties

i

u sum of the estimated combined uncertainties

T

u the square of the uncertainty in T

T

w weights

i

4 Characteristics

4.1 Safety in case of brushwood fire

The safety in case of brushfire shall be determined in accordance with Annex A.

4.2 Resistance to dynamic loads: risk of falling debris

When secondary safety has to be determined, this shall be done in accordance with Annex B.

4.3 Environmental protection

The constituent materials and their breakdown products shall be identified in accordance with Annex C.

4.4 Access for maintenance and emergency exits

The acoustic and mechanical performances of doors or other means of escape shall be determined in

accordance with Annex D.

4.5 Light reflection

The results of a standard test of reflectivity shall be determined in accordance with Annex E.

4.6 Transparency

The results of a standard test of transparency should be determined in accordance with Annex F.

5 Test report

Every test report shall include the following information:

a) number and year of this document, i.e. EN 1794-2:2024;

b) full description of the element or system tested, including manufacturer(s), part numbers, place and

date of origin;

c) description of the method of sampling, description of the sampling procedure, if the performance is

determined by parts of manufactured elements;

d) place and date of determination, and the name of the responsible person(s);

e) sufficient description of any tests carried out, any results measured, and the conclusions drawn about

the product together with any illustrations or photographs, all as specified in the appropriate annex;

f) A summary of information shall be produced, identifying the aspects and the level of performance

assessed, where appropriate.

Annex A

(normative)

Safety in case of brushwood fire

A.1 General

A road traffic noise reducing device can be exposed to fire arising from dry vegetation or other material

in close proximity. More severe fires from spilt fuel can arise as the result of traffic accidents.

Where a road traffic noise reducing device is in close proximity to property it can also be necessary to

consider the need to ensure that fire is not spread from the highway.

Where flammable systems are used, it is recommended that firebreaks of fire-resistant materials or other

design are incorporated into the road traffic noise reducing device in order to prevent the propagation of

fire. This annex is not applicable to such fire-resistant material.

This annex describes a test for a representative panel of a vertical noise barrier under normal exposure

to brushwood fires at the roadside.

It does not provide information on the results of exposure to more severe conditions, e.g. ignition by

burning spilt fuel. The test should not be used to provide information on the fire safety of claddings used

for tunnels or partial covers over the highway.

A.2 Characteristics

The noise reducing device, after being tested by the method given in A.3, shall be classified as follows:

— class 1: if the panel has been damaged to a greater extent than as defined for classes 2 and 3;

— class 2: if the damaged area above either source is less than 0,06 m2 and extends to no more than

200 mm above the base of the panel, and the panel has not been burnt through to the other side;

— class 3: if there is no damage other than discoloration.

A.3 Fire test

A.2.1 Acoustic elements of at least 2 m long by 1,5 m high shall be tested by exposure to localized

sources of fire at its base next to the front and rear faces independently. Panels shall be free of absorbed

water before testing; in the case of timber components, the moisture content shall be reduced to 18 % by

an approved drying method.

The mass and dimensions of the panel to be tested shall be measured and the panel shall be

photographed. An identical panel shall be examined to determine its construction; the dimensions of its

elements, including wall thickness of hollow sections, shall be measured, and noted on a sketch at 1:20

scale.

A.2.2 Testing shall be carried out in an enclosed fireproof and draught-free chamber having a volume

of at least 150 m .

Fume extraction devices can be installed in or near the ceiling but shall be prevented from fanning any

flames during the test.

The temperature of the chamber, including the floor, before the test begins shall be between 15 °C and

25 °C. The chamber should be fitted with an observation port or window in a suitable position to observe

the panel during the test.

A.2.3 Two identical sources of fire shall be prepared as follows:

a) a rectilinear wire mesh basket 300 mm by 200 mm by 300 mm high shall be made from welded steel

wire mesh, having a square mesh of 3 mm diameter drawn steel wire at 50 mm centres;

b) in addition, three 3 mm diameter wires 300 mm long shall be secured in a vertical position inside the

basket, equally spaced along the central line of the shorter dimension.

The flammable material shall comprise shavings of spruce, 0,2 mm thick by 2 mm wide, and

approximately 50 mm long. The material shall be free from splinters and have a maximum moisture

content of 30 %; it shall be acclimatised at 20 °C and 65 % humidity until its weight is constant.

600 g of shavings shall be lightly pressed down into each basket so that it is just filled.

A.2.4 The test panel shall be supported in a vertical position corresponding to its orientation in use, on

a plinth supporting the full length of the panel. The plinth shall be of masonry or concrete and have a

vertical step to a level of 250 mm above the floor of the chamber. The base of the test panel shall be

completely in contact with the plinth and the face to be tested shall be flush with the edge. The two

sources of fire shall be placed on the floor of the chamber with their longer dimension flush against the

plinth and the face of the test panel. Both sources shall be lit simultaneously, and the time taken for the

test shall start at this point.

A.2.5 The performance of the panel shall be observed during the test and the time at which any

significant change takes place recorded. After the sources of fire and any part of the panel which may

have ignited have burnt out, the panel shall be examined, and the extent of any damage photographed

and measured. The opposite face of the panel shall not be tested until it and the floor of the chamber have

cooled to below 25 °C.

A.4 Test report

A.3.1 The test shall be documented together with time stamps of significant observations for example

maximum intensity of flames, the incidence of any observed changes to the test panel and the number of

samples tested.

The test report shall record the nature and extent of any flames and smoke produced during the test.

A.3.2 Photographs of the test panel before, during and after the test shall be supplied and shall include

an appropriate means of judging scale.

Annex B

(normative)

Resistance to dynamic loads: risk of falling debris

B.1 General

Road traffic noise reducing devices can be mounted on structures or in such a way that if damaged they

could pose a hazard to road users or to others. In particular, even if the road traffic noise reducing device

is protected by the safety system on an elevated structure, there is a possibility of pieces or whole panels

from a noise barrier becoming detached as the result of a violent collision and for the debris to fall,

endangering those below.

Road traffic noise reducing devices which are to be used in a vulnerable position can be required to be

restrained by internal or external linkage between panels and/or elements to prevent them from

becoming detached and falling.

The standard provides some general indications of factors which need to be considered and also provides

a method of establishing the resistance of a product to a severe blow.

NOTE It is principally the responsibility of specifiers to consider the potential consequences of noise barriers

becoming damaged and to provide protection accordingly.

Alternatively, a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...