SIST EN 152:2012

(Main)Wood preservatives - Determination of the protective effectiveness of a preservative treatment against blue stain in wood in service - Laboratory method

Wood preservatives - Determination of the protective effectiveness of a preservative treatment against blue stain in wood in service - Laboratory method

This European Standard specifies a method which is only suitable for testing preparations and systems which are intended to prevent the occurrence of blue stain fungi in wood in service. It is not suitable for assessing the temporary preventive effectiveness of anti-stain preservatives on round wood or on freshly cut wood. The method is not intended for the determination of the fungicidal properties of the surface coating applied to the wood after the priming coat. This European Standard lays down a method for determining the effectiveness of a preparation applied by e.g. brushing, spraying, spraying tunnel, dipping or vacuum and pressure treatments resulting in an equivalent retention of product in preventing the development of blue stain fungi in wood in service. It is also applicable where a primer paint is used in conjunction with the preservative system.This method is applicable to the following types of preparations or systems: Type A: fungicidal preparations with or without pigment, used in conjunction with unspecified varnishes or paint coatings;or Type B: fungicidal preparations with or without pigment, used in conjunction with specified varnishes or paint coatings;or Type C: fungicidal preparations with or without pigment, used without subsequent varnish or paint coating (e.g. stains).

Holzschutzmittel - Bestimmung der vorbeugenden Wirksamkeit einer Schutzbehandlung von verarbeitetem Holz gegen Blaüepilze - Laboratoriumsverfahren

Diese Europäische Norm legt ein Verfahren fest, das nur zur Prüfung von Schutzmitteln und Systemen

geeignet ist, die einen Bläuepilzbefall an verarbeitetem Holz verhindern sollen. Sie ist dagegen nicht zur

Beurteilung der temporären vorbeugenden Wirksamkeit von bläuewidrigen Holzschutzmitteln auf Rundholz

oder auf frisch eingeschnittenem Holz geeignet. Das Verfahren ist nicht zur Bestimmung der fungiziden

Eigenschaften der im Anschluss an eine Grundierung auf die Holzoberfläche aufgebrachten Oberflächenbeschichtung

vorgesehen.

Diese Europäische Norm legt ein Verfahren für die Bestimmung der Wirksamkeit eines Schutzmittels zur

Schutzbehandlung von verarbeitetem Holz gegen Bläupilze fest, das z. B. durch Streichen, Sprühen, mit dem

Sprühtunnel-, Kurztauchverfahren oder durch Vakuum- und Druckbehandlungen aufgebracht wird, mit denen

eine gleichwertige Schutzmittelaufnahme erzielt wird. Es kann auch für eine Erstbeschichtung (primer paint)

angewendet werden, die in Verbindung mit einem Holzschutzsystem eingesetzt wird1).

Dieses Verfahren ist für die folgenden Typen der Schutzmittel und Systeme geeignet:

- Typ A: fungizide Schutzmittel mit oder ohne Pigment, die in Verbindung mit beliebigen Lack- oder Farbbeschichtungen

angewendet werden;

oder

- Typ B: fungizide Schutzmittel mit oder ohne Pigment, die in Verbindung mit bestimmten Lack- oder Farbbeschichtungen

angewendet werden;

oder

- Typ C: fungizide Schutzmittel mit oder ohne Pigment, die ohne anschließenden Lack-, Farb- oder andere

Beschichtungen angewendet werden.

ANMERKUNG Es ist auch möglich, die Wirksamkeit zur Vermeidung der Bläue beim Einsatz eines kombinierten

Schutzsystems zu prüfen, das die Anwendung eines Schutzmittels durch ein Tränkverfahren und anschließende

Anwendung eines anderen Schutzmittels durch ein Verfahren der Oberflächenbehandlung umfasst.

Produits de préservation du bois - Détermination de l'efficacité préventive d'un traitement de protection du bois mis en œuvre contre le bleuissement fongique - Méthode de laboratoire

La présente Norme européenne spécifie une méthode d'essai qui n'est adaptée qu'aux préparations et

systèmes destinés à prévenir l'apparition du bleuissement fongique dans le bois mis en oeuvre. Elle n'est pas

adaptée à l'évaluation de l'efficacité préventive temporaire de produits de préservation appliqués sur des bois

ronds ou des bois fraîchement débités contre les agents de discoloration. La méthode n'est pas destinée à

déterminer les propriétés fongicides d'une couche de finition appliquée après application d’un produit

d’impression (primaire) sur le bois.

La présente Norme européenne établit une méthode de détermination de l'efficacité d'une préparation

appliquée, par exemple, par brossage, aspersion, aspersion sous tunnel, trempage ou traitements sous vide

et sous pression, donnant des rétentions de produit équivalentes, dans la prévention du développement du

bleuissement fongique dans le bois mis en oeuvre. Elle est également applicable lorsqu'une couche

d'impression (primaire) est employée en corrélation avec un système de préservation1).

Cette méthode est applicable aux types suivants de préparations ou de systèmes :

- type A : préparations fongicides avec ou sans pigment, utilisées avec des couches de vernis ou de

peinture non spécifiés ;

ou

- type B : préparations fongicides avec ou sans pigment, utilisées avec des couches de vernis ou de

peinture spécifiés ;

ou

- type C : préparations fongicides avec ou sans pigment, utilisées sans couche ultérieure de vernis ou de

peinture (par exemple, teintures).

NOTE Il est également possible de déterminer l'efficacité préventive contre le bleuissement d'un bois mis en oeuvre

d'un système mixte de préservation qui prévoit l'application d'une préparation au moyen d'une technique de traitement par

imprégnation, suivie de l'application ultérieure d'une autre préparation par une méthode de traitement superficielle.

Zaščitna sredstva za les - Ugotavljanje preventivne učinkovitosti zaščitnega sredstva proti glivam modrivkam - Laboratorijska metoda

Ta evropski standard določa metodo, ki je ustrezna le za preskušanje pripravkov in sistemov za preprečevanje gliv modrivk v uporabljenem lesu. Ni primeren za ocenjevanje začasne preventivne učinkovitosti zaščitnih sredstev proti glivam na okroglem ali sveže posekanem lesu. Metoda ni namenjena za ugotavljanje fungicidnih lastnosti površinskega premaza, ki se na les nanese po osnovnem premazu.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Mar-2010

- Publication Date

- 16-Jan-2012

- Technical Committee

- LLZ - Les, lesni izdelki in zaščita lesa

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 02-Dec-2011

- Due Date

- 06-Feb-2012

- Completion Date

- 17-Jan-2012

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-Jun-2012

- Effective Date

- 01-Jun-2012

- Effective Date

- 01-Jun-2012

Overview - EN 152:2011 (CEN)

EN 152:2011 is the CEN laboratory method for assessing the protective effectiveness of wood preservatives against blue stain fungi in wood in service. The standard specifies a laboratory test combined with pre‑conditioning (natural or artificial weathering) and applies to preservative systems intended to prevent disfigurement of timber (for example, external decorative timber and joinery). It is not intended for freshly cut or round wood anti‑stain tests nor to evaluate the fungicidal properties of surface coatings applied after the priming coat.

Key topics and technical requirements

- Scope and applicability

- Tests preparations applied by brushing, spraying (including spraying tunnels), dipping, or vacuum/pressure treatments.

- Applicable to three system types: Type A (used with unspecified varnishes/paints), Type B (used with specified varnishes/paints), Type C (used without subsequent coatings).

- Test principle

- Pre‑condition treated specimens (natural or artificial weathering or other specified methods) then expose to a mixed spore suspension of blue stain fungi to observe infection development into treated faces.

- Biological test organisms

- Mixed culture of Aureobasidium pullulans and Sydowia polyspora (spore suspension preparation detailed in Annex B).

- Materials and coatings

- Requirements for nutrient media and guidance on coating materials and primers (see normative Annex A).

- Specimen preparation and treatment

- Standardised timber species, specimen sizes and treatment protocols are defined to ensure repeatable assessment.

- Test conditions and assessment

- Controlled laboratory fungal exposure, assessment criteria and reporting formats; pre‑conditioning can include artificial weathering cycles (Annex F).

- Safety and quality

- Environmental, health and safety precautions for chemical/biological labs provided (Annex H).

Practical applications - who uses EN 152:2011

- Wood preservative manufacturers - to validate product performance against blue stain for marketing and compliance.

- Independent test laboratories - to perform standardized laboratory assessments for clients.

- Coating and paint manufacturers - to evaluate compatibility of primers and topcoats with preservative systems.

- Specifiers and architects - to select treatments for external joinery and decorative timber where staining is a concern.

- Regulatory bodies and procurement - to set requirements or acceptance criteria for treated wood.

Related standards

- EN 927-6 (artificial weathering with fluorescent UV lamps)

- EN ISO 3696 (laboratory water quality)

- EN 335 (use classes for wood)

- EN 73 (evaporative ageing alternative for certain use classes)

- EN 1001-1 / EN 1001-2 (terms and sampling)

EN 152:2011 provides a practical, harmonised laboratory framework to evaluate preservative systems against blue stain, enabling manufacturers, laboratories and specifiers to demonstrate and compare protective performance under controlled pre‑conditioning and fungal exposure.

Frequently Asked Questions

SIST EN 152:2012 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Wood preservatives - Determination of the protective effectiveness of a preservative treatment against blue stain in wood in service - Laboratory method". This standard covers: This European Standard specifies a method which is only suitable for testing preparations and systems which are intended to prevent the occurrence of blue stain fungi in wood in service. It is not suitable for assessing the temporary preventive effectiveness of anti-stain preservatives on round wood or on freshly cut wood. The method is not intended for the determination of the fungicidal properties of the surface coating applied to the wood after the priming coat. This European Standard lays down a method for determining the effectiveness of a preparation applied by e.g. brushing, spraying, spraying tunnel, dipping or vacuum and pressure treatments resulting in an equivalent retention of product in preventing the development of blue stain fungi in wood in service. It is also applicable where a primer paint is used in conjunction with the preservative system.This method is applicable to the following types of preparations or systems: Type A: fungicidal preparations with or without pigment, used in conjunction with unspecified varnishes or paint coatings;or Type B: fungicidal preparations with or without pigment, used in conjunction with specified varnishes or paint coatings;or Type C: fungicidal preparations with or without pigment, used without subsequent varnish or paint coating (e.g. stains).

This European Standard specifies a method which is only suitable for testing preparations and systems which are intended to prevent the occurrence of blue stain fungi in wood in service. It is not suitable for assessing the temporary preventive effectiveness of anti-stain preservatives on round wood or on freshly cut wood. The method is not intended for the determination of the fungicidal properties of the surface coating applied to the wood after the priming coat. This European Standard lays down a method for determining the effectiveness of a preparation applied by e.g. brushing, spraying, spraying tunnel, dipping or vacuum and pressure treatments resulting in an equivalent retention of product in preventing the development of blue stain fungi in wood in service. It is also applicable where a primer paint is used in conjunction with the preservative system.This method is applicable to the following types of preparations or systems: Type A: fungicidal preparations with or without pigment, used in conjunction with unspecified varnishes or paint coatings;or Type B: fungicidal preparations with or without pigment, used in conjunction with specified varnishes or paint coatings;or Type C: fungicidal preparations with or without pigment, used without subsequent varnish or paint coating (e.g. stains).

SIST EN 152:2012 is classified under the following ICS (International Classification for Standards) categories: 71.100.50 - Wood-protecting chemicals. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 152:2012 has the following relationships with other standards: It is inter standard links to SIST EN 152-2:1996, SIST EN 152-1:1996, SIST EN 152-2:1996/AC1:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 152:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 152:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Holzschutzmittel - Bestimmung der vorbeugenden Wirksamkeit einer Schutzbehandlung von verarbeitetem Holz gegen Blaüepilze - LaboratoriumsverfahrenProduits de préservation du bois - Détermination de l'efficacité préventive d'un traitement de protection du bois mis en œuvre contre le bleuissement fongique - Méthode de laboratoireWood preservatives - Determination of the protective effectiveness of a preservative treatment against blue stain in wood in service - Laboratory method71.100.50Wood-protecting chemicalsICS:Ta slovenski standard je istoveten z:EN 152:2011SIST EN 152:2012en,fr,de01-februar-2012SIST EN 152:2012SLOVENSKI

STANDARDSIST EN 152-2:1996/AC1:2002SIST EN 152-2:1996SIST EN 152-1:19961DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 152

November 2011 ICS 71.100.50 Supersedes EN 152-1:1988, EN 152-2:1988English Version

Wood preservatives - Determination of the protective effectiveness of a preservative treatment against blue stain in wood in service - Laboratory method

Produits de préservation du bois - Détermination de l'efficacité préventive d'un traitement de protection du bois mis en œuvre contre le bleuissement fongique - Méthode de laboratoire

Holzschutzmittel - Bestimmung der vorbeugenden Wirksamkeit einer Schutzbehandlung von verarbeitetem Holz gegen Blaüepilze - Laboratoriumsverfahren This European Standard was approved by CEN on 24 September 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 152:2011: ESIST EN 152:2012

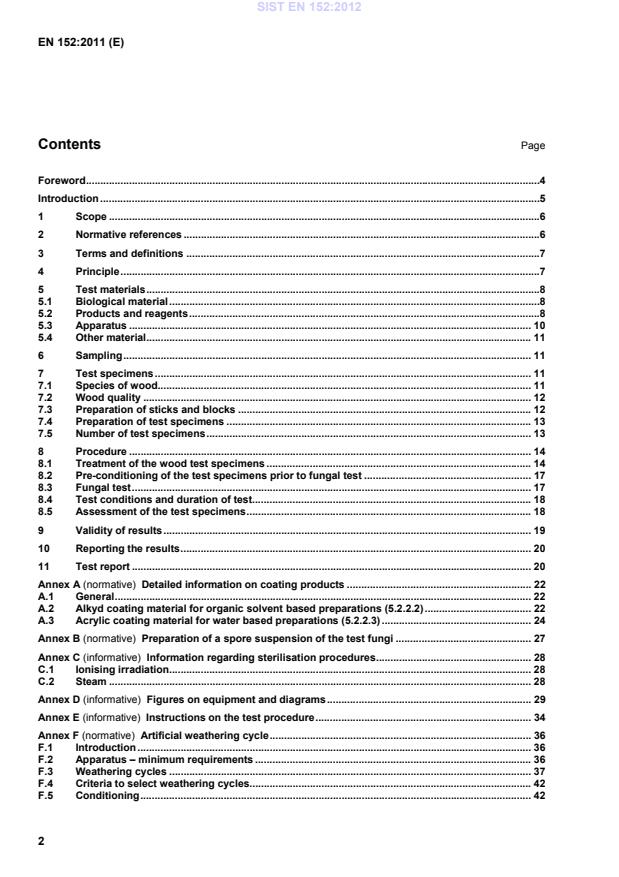

Detailed information on coating products . 22A.1 General . 22A.2 Alkyd coating material for organic solvent based preparations (5.2.2.2) . 22A.3 Acrylic coating material for water based preparations (5.2.2.3) . 24Annex B (normative)

Preparation of a spore suspension of the test fungi . 27Annex C (informative)

Information regarding sterilisation procedures . 28C.1 Ionising irradiation. 28C.2 Steam . 28Annex D (informative)

Figures on equipment and diagrams . 29Annex E (informative)

Instructions on the test procedure . 34Annex F (normative)

Artificial weathering cycle . 36F.1 Introduction . 36F.2 Apparatus – minimum requirements . 36F.3 Weathering cycles . 37F.4 Criteria to select weathering cycles. 42F.5 Conditioning . 42SIST EN 152:2012

Example of a test report . 43Annex H (informative)

Environmental, health and safety precautions within chemical/biological laboratory . 44Bibliography . 45 SIST EN 152:2012

This European Standard lays down a method for determining the effectiveness of a preparation applied by e.g. brushing, spraying, spraying tunnel, dipping or vacuum and pressure treatments resulting in an equivalent retention of product in preventing the development of blue stain fungi in wood in service. It is also applicable where a primer paint is used in conjunction with the preservative system1). This method is applicable to the following types of preparations or systems:

type A: fungicidal preparations with or without pigment, used in conjunction with unspecified varnishes or paint coatings; or type B: fungicidal preparations with or without pigment, used in conjunction with specified varnishes or paint coatings; or type C: fungicidal preparations with or without pigment, used without any subsequent paint, varnish or other coating. NOTE It is also possible to test the effectiveness in preventing blue stain in service of a combined protective system which involves the application of one preparation by a penetrating treatment technique followed by a subsequent application of a different preparation by a superficial treatment method. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 927-6:2006, Paints and varnishes — Coating materials and coating systems for exterior wood — Part 6: Exposure of wood coatings to artificial weathering using fluorescent UV lamps and water EN ISO 3696, Water for analytical laboratory use — Specification and test methods (ISO 3696:1987)

1) The method may also be used for first coat (primer) paints required to give protection during storage of components on-site (see Annex E). These are tested as for preparations of type C. SIST EN 152:2012

A series of blocks of the given timber species are treated with the preparation under test on all faces except the end-grain faces. Subsequently the blocks are cut in the direction of the grain such that two specimens are produced. The treatment differs according to the type of preparation (Annex E, Table E.1) and specifications for its use: Type A

Preparations designed to be used with unspecified varnish or paint coatings are tested using the application rate appropriate to the preparation (Annex E, Table E.2) or as otherwise specified by the supplier followed by the standard test varnish. Type B

Preparations designed to be used with specified varnish or paint coatings are tested using the application rate appropriate to the preparation (Annex E, Table E.2) or as otherwise specified by the supplier followed by a surface coating strictly according to the supplier's specification. Type C Preparations designed to be used without subsequent varnish or paint coatings are tested using the application rate appropriate to the product (Annex E, Table E.2) or as otherwise specified by the supplier but with no subsequent application of coating. Treated test specimens are exposed to pre-conditioning (natural or artificial weathering).

Weathered test specimens are then exposed in the laboratory to the action of a mixed culture of two fungi causing blue stain in service.

NOTE Preparations designed to be used solely in use class 2 (EN 335) may be preconditioned by using the evaporative aging method in EN 73 in place of the natural or artificial weathering procedures in this standard. SIST EN 152:2012

NOTE If desired, spore suspensions of other blue stain fungi of national importance can be used in additional series of tests. The type and extent of the growth of these fungi are to be described in the test report.

5.2 Products and reagents 5.2.1 Nutrient medium A nutrient medium of malt buffered to pH 4,2 shall be used for the preparation of a spore suspension (see 8.3.4) of the test fungi. It shall contain 20 g/l dried malt or an equivalent amount of concentrated malt extract with a nitrogen content of mass fraction of (0,9 ± 0,3) %. The buffer shall be a citrate buffer solution composed of: Citric acid monohydrate, 12,5 g; (analytical reagent grade) 1 mol/l NaOH 120 ml; 0,1 mol/l HCl 390 ml; water to make up 1 000 ml. 5.2.2 Coating material 5.2.2.1 General Tests can be performed for a specific coating material which has been specified by the supplier.

Otherwise a generic coating material can be used as detailed under 5.2.2.2 and 5.2.2.3 below.

2) Maintain the strains on 2 % malt agar and subculture them at intervals not exceeding 6 months. Obtain new cultures if there is evidence of degeneration such as loss of pigmentation or the ability to produce conidia. Cultures can be obtained from Bundesanstalt für Materialforschung und -prüfung, Unter den Eichen 87, 12205 Berlin or from the CABI Bioscience, Bakeham Lane, Egham, Surrey TW20 9TY UK. 3) Identical to strain no. IMI 269 216 of culture deposited at CABI Bioscience, Egham. 4) Identical to strain no. IMI 269 217 of culture deposited at CABI Bioscience, Egham. SIST EN 152:2012

NOTE The water holding capacity of the vermiculite should allow the wood moisture content to stay below 100 % at any time. 5.2.8 Reference product The reference product used shall comply with the composition or equivalent specified in Table 1. SIST EN 152:2012

DCFN = dichlofluanide. b

Example(s) of suitable product(s) available commercially. This information is given for the convenience of users of this EN 152 standard and does not constitute an endorsement by CEN of these products. The product containing dichlofluanide at this concentration shall be applied at 80 g/m² in combination with a varnish coating. If an alternative reference product is used, the concentration chosen should provide a performance equivalent to the specified concentration of DCFN. Evidence of equivalence shall be recorded in the test report.

5.2.9 Fumigant (if necessary) Xylene technical grade. 5.3 Apparatus 5.3.1 Incubation room, with the following climatic conditions: (22 ± 2) °C and (70 ± 5) % relative humidity.

5.3.2 Conditioning room at (20 ± 2) °C and (65 ± 5) % relative humidity. 5.3.3 Saw with blades giving a fine-sawn finish 5.3.4 Weathering site for open air weathering of wood specimens in special racks : weathering racks: frames to take the wood specimens at 45° (see Figure D.5). The frames shall be constructed of inert material (e.g. plastics, aluminium). In the racks the wood test specimens shall be free on all sides and be secured against being dislodged; as a weathering site, any free area without extremes of environmental conditions with regard to humidity, dryness, UV radiation or industrial pollution is suitable. The site shall be free from tall vegetation (max. 0,5 m); erection of the weathering racks, the following are to be observed: they shall at no time be in the shade of trees, houses or other structures; the wood test specimens shall face the direction in which the exposure conditions are expected to be most severe; NOTE In Central Europe and France this is to the South West and in the UK to the South. the wood test specimens shall be placed 1 m to 2 m above the ground . SIST EN 152:2012

5.3.6 Culture vessels with a capacity of 400 cm3 to 600 cm3 and an internal area of base of 90 cm2 to 120 cm2 (see Annex D for an example of a culture vessel). 5.3.7 Sterilisers access to ionising-radiation services (Annex C); autoclave, adjustable at (102 ± 2) °C and (121 ± 1) °C, and, if the autoclave is not adjustable at (102 ± 2) °C , a steaming chamber (Annex C).

5.3.8 Measuring magnifying glass with reading accuracy of 0,1 mm. 5.3.9 Usual laboratory equipment, especially: analytical balance with accuracy 0,01 g. various brushes. abrasive paper, grit size 120 and 180. drying oven, adjustable at (103 ± 2) °C. 5.4 Other material Corrosion resistant nails of length of approx. 30 mm and diameter of approx. 1,5 mm to support wood specimens during weathering (see Figure D.3).

6 Sampling The sample of preservative shall be representative of the product to be tested. Samples shall be stored and handled in accordance with any written recommendations from the supplier. NOTE For the sampling of preservatives from bulk supplies, the procedure given in EN 212 should be used. 7 Test specimens 7.1 Species of wood A species of wood that is very susceptible to blue stain shall be used:

obligatory for every test is Scots pine sapwood (Pinus sylvestris Linnaeus). NOTE Additional tests may be carried out using other species but, if so, this should be stated in the test report. SIST EN 152:2012

Wood from the top of the trunk or the lowest 1 m of the trunk is unsuitable.

Exclusively sapwood shall be used showing a rate of growth of: 2,5 to 8 annual rings per 10 mm.

The proportion of latewood shall be less than 30 %. The wood shall not have been floated, stored in water, heated above 60 °C or treated with chemicals.

Only winter felled trees shall be used which are converted to boards immediately after felling. When requirements of wood quality on the history of the material cannot be verified, the wood batch shall be tested for fungal infection susceptibility using the procedure described in 8.3 on non- weathered specimens and validated according to Clause 9, 1st paragraph. Wood specimens shall be selected at random and they shall represent 1 % of the batch. NOTE

Air drying of the boards is possible but under inappropriate conditions rapid infection with blue stain fungi may occur. Therefore careful kiln drying at temperatures up to 60 °C is preferred.

Storage of derived test specimens shall not normally exceed 3 years from felling of the trees as this might influence the validity of the test. 7.3 Preparation of sticks and blocks Unseasoned wood (sticks) shall be dried carefully to a moisture content of (12 ± 2) %. Prepare sticks of approximately 50 mm × 35 mm cross section with the annual rings forming an angle of (45 ± 15)° with the edges. Number the sticks and mark them at the cross sections to be able to identify the trunk from which they are cut. Plane the sticks to a cross section of 40 mm × 25 mm and round the longitudinal edges with a moulding knife to a radius of curvature of 2 mm.

From these sticks cut blocks free from knots and defects (resin galls etc.) 110 mm long and mark them with the number of the stick in a way that the numbering is detectable after treatment. Smooth the rounded edges and the face except the end grain faces with sandpaper grit size 120 and clean off sanding dust.

Store the blocks in the conditioning room (5.3.2) until use. Take blocks from at least 3 different trees for the test of each preparation.

In Annex D, Figure D.2 detailed drawings are given in relation to the preparation of sticks and blocks.

NOTE 1 If it is recommended that the product under test should be applied by brushing only, it may be suitable to cut the blocks prior to treatment in order to give test specimens described under 7.4.1. NOTE 2 If it is recommended that the product under test should be applied by spraying or dipping, it may be suitable to use only the upper part (representing the face closest to the outer part of the tree) of the treated block in order to give test specimens described under 7.4.1. SIST EN 152:2012

C1 - untreated control test specimens: C1.1 without pre-conditioning 6 control test specimens (2 from each of 3 trees); C1.2 with pre-conditioning (using the same system as for the preparation under test) 3 control test specimens (1 from each of 3 trees). A second set of controls can be included optionally. Where it is desired to test the effectiveness of an active ingredient or of a formulation diluted to different concentrations, the following additional control test specimens can be included.

C2 -

control test specimens treated with the product minus active ingredient: C2.1 without pre-conditioning 3 control test specimens (1 from each of 3 trees); C2.2 with pre-conditioning (using the same system as for the preparation under test) 3 control test specimens (1 from each of 3 trees). In selecting the control test specimens note that if more than one preservative is tested, one control test specimen is taken from each tree used for the actual tests (7.3) (hence if only one preservative is being tested at a time, 3 control test specimens (1 from each of 3 trees), are required).

8.1.2 Sealing of the end surfaces Coat the conditioned wood test specimens on their end faces with an appropriate end sealer (5.2.5). Keep them in the conditioning room (5.3.2) until further use.

NOTE To ensure adequate end sealing it can be useful to apply the end sealer and overlap the edges 1 mm to 2 mm, e.g. by using a short dip in the sealer of the cross sections. 8.1.3 Application of test preparation to the wood test specimens 8.1.3.1 Determination of the amount to be applied 8.1.3.1.1 Application by superficial methods excluding dipping The amounts to be applied and the number of applications shall be determined and shall be strictly observed for each parallel test specimen. For the gravimetric control the density of the test product shall be determined and the amount of application should, if necessary, be converted from ml/m² to g/m². The amounts of the preparation under test and the number of coats shall be realistic in relationship to its normally intended method of use (see Annex E, Table E.2). In case no relevant experience is available, the amounts to be applied and the number of coats shall be determined in preliminary trials. Any direction given by the supplier shall be taken into account. 8.1.3.1.2 Application by dipping, vacuum or pressure methods The method of application specified by the supplier shall be followed. In case the effectiveness of an active ingredient or a formulation shall be tested using different concentrations, these shall be specified by the supplier. In case the supplier simply indicates amounts to be applied, preliminary trials shall be made to determine with which concentrations or which times of treatment these amounts may be obtained. The concentrations used and the duration of treatment shall be recorded in the test report. For each treatment block the exact amount of preservative applied shall be indicated.

5) Annex E, Table E.1 gives a key to the sequence of operations with the various different types of product. SIST EN 152:2012

at least 2 cm from each other within a test vessel that can be tightly sealed. During storage turn the test specimens twice a week by 180° so that they rest on their opposite faces. The vessels shall be placed in a well ventilated room. 1)

In the case of blocks treated with water-soluble products To prevent mould growth also place in the vessel small dishes containing xylene (5.2.9) and keep the vessels closed for 2 weeks. During the third week uncover the vessels progressively each day to allow the blocks to dry steadily. From the beginning of the fourth week, leave the vessels completely open. 2)

In the case of blocks treated with water-insoluble products Keep the vessels covered for one week. Open them progressively each day during the second week and leave them open during the third and fourth weeks. SIST EN 152:2012

the product under test minus active ingredient; or

the solvent carrier alone, which ever is appropriate to the product under test.

Treat the validation test specimens with the reference product at 80 g/m² for the product detailed or equivalent (see 5.2.8). 8.1.5 Drying the blocks after treatment In the case of brushed blocks after each preservative coat per face to be coated store all the blocks on a horizontal surface under ambient laboratory conditions. Avoid draughts.

In the case of blocks treated by dipping or vacuum methods dry the treated block according to the requirements of the supplier of the preparation. 8.1.6 Preparation of test specimens After drying (8.1.5) the treated blocks according to 8.1.3.2 are cut longitudinally to produce two test specimens each according to 7.4. Cut the untreated blocks the same way to give untreated test specimens of the same size. 8.1.7 Insertion of nails To support wood test specimens during weathering the introduction of corrosion resistant nails (5.4) is required (see Figure D.3 and Figure D.5 for an example). The fixing procedure shall not have any chemical or biological effect on the wood. Holes of approximately 1,3 mm diameter shall be bored approx. 6 mm into the end surfaces of the test specimens, one in the middle of one end and two in the opposite end at approximately 10 mm from each edge (see Figure D.3). Holes shall be bored parallel to the grain in such a way that cracking or splitting of the wood test specimens is avoided when nails are inserted. Insert into the pre-drilled holes 3 corrosion resistant nails of length of approximately 30 mm and diameter of approx. 1,5 mm (5.4) to a depth of approximately 10 mm. 8.1.8 Coating the wood specimens The application of coatings differs according to the type of preparation (Clause 1):

Type A In the case of preparations intended for use with unspecified coatings, apply three coats of the standard test varnish appropriate to the preparation under test (5.2.2) at intervals of 24 h to the wood test specimens and their corresponding control test specimens (7.5.2) and validation test specimens (7.5.3) including the rounded edges. The quantity applied amounts to approximately 70 ml/m² (waterborne) and 90 ml/m² (solventborne) of each top coat layer:

In the case of preparations intended for use with specified coatings apply these according to the appropriate specification and to the wood test specimens and their corresponding control test specimens (7.5.2) and validation test specimens (7.5.3). During and after coating store the wood test specimens in ambient conditions. Type C If the preparation is designed for use without subsequent coating the test specimens are exposed without further application of varnish: similarly the control test specimens (7.5.2) do not receive an application of varnish contrary to the validation test specimens (7.5.3).

NOTE

Validation test specimens always require a coating as indicated under 5.2.8. 8.2 Pre-conditioning of the test specimens prior to fungal test 8.2.1 Natural weathering Expose the wood test specimens for 26 weeks in the period between 1st March and 31st October.

Commence weathering of the wood test specimens 5 to 7 days after application of the last coating.

Place the treated test specimens and control test specimens (C1.2 and C2.2 - 7.5) for weathering in the rack with the treated side facing upwards and weather them in the open air (5.3.4). Figure D.5. 8.2.2 Artificial weathering Alternatively to the natural weathering procedure an artificial weathering in a device (5.3.5) providing UV-light and spray of demineralised water can be used. The duration of this procedure shall be four weeks. Detailed description of the artificial weathering cycle is given in Annex F. 8.2.3 Storing of control test specimens Control test specimens which are not to be subjected to weathering in the above manner (8.2.1 - 8.2.2) are stored in the conditioning room (5.3.2).

8.3 Fungal test 8.3.1 Preparation of the test specimens Test and control test specimens which are "blue stained" (8.5.2 rating 2) or "strongly blue stained" (8.5.2 rating 3) on the test surface after weathering need not be submitted to the fungal test; note these test specimens in the test report with the extent of blue stain. These test specimens shall be included in the final assessment. SIST EN 152:2012

shorten them equally at both end faces to a final length of 90 mm (Figure D.4); groove them with a saw (5.3.3) to a width of approximately 3 mm and depth 4 mm in the middle of the untreated side parallel to the end surfaces (Figure D.4); wipe lightly on their treated sides with a damp cloth. Condition the test specimens for a minimum of 2 weeks in the conditioning room (5.3.2).

NOTE Wet specimens should be air dried prior to conditioning. 8.3.2 Sterilisation of the test specimens Sterilise the test specimens using the method as given in Annex C. 8.3.3 Preparation of the culture vessels Introduce 200 ml aluminium-iron-magnesium silicate (5.2.7) into the culture vessels (5.3.6) narrow side down in the case of the jars. Level with a spatula. Moisten the surface uniformly with 75 ml water and fit closures loosely before sterilizing for 30 min in the autoclave at (121 ± 1) °C. 8.3.4 Introduction and inoculation of the test specimens NOTE 1 See Annex B for detail on the preparation of the spore suspension. Dip the sterilized test specimens (8.3.2) for 1 s to 2 s in the spore suspension (5.1) and transfer them aseptically to the prepared culture vessels (8.3.3) with their treated sides upwards.

Test specimens treated with different preparations shall be dipped into separate portions of the spore suspension.

Before introducing the test specimens pour 15 ml of spore suspension (5.1) in each culture vessel. Then introduce the test specimens and close the culture vessels. NOTE 2 Care should be taken that the spores remain suspended during inoculation of the test specimens. 8.4 Test conditions and duration of test Store the inoculated culture vessels in the incubation room (5.3.1) in the dark or protected from direct sunlight. Continue the test for 6 weeks from the time of inoculation of the test specimens. 8.5 Assessment of the test specimens 8.5.1 General At the end of the test remove the test specimens from the culture vessels, wash them carefully and clean off all adhering residues of fungus.

0 -

not blue stained: no blue stain can be detected visually on the surface. 1 - insignificantly blue stained: the surface exhibits only individual small blue stained spots none larger than 1,5 mm in width and 4 mm in length, and not more than 5 in number.

2 - blue-stained: the surface is continuously blue stained up to a maximum of one third, or blue stained partially or in streaks up to half the total area. 3 - strongly blue stained: more than one third of the surface is continuously blue stained or more than half is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...