SIST EN 16351:2021

(Main)Timber structures - Cross laminated timber - Requirements

Timber structures - Cross laminated timber - Requirements

This document sets out provisions regarding the performance of characteristics of the following Types of cross laminated timber for use in buildings and bridges:

- Type 1: Straight or curved cross laminated timber comprising only timber layers but no large finger joints;

- Type 2: Straight cross laminated timber comprising only timber layers and large finger joints;

- Type 3: Straight cross laminated timber comprising timber and wood-based panel layers but no large finger joints.

This document covers cross laminated timber of all three Types of cross laminated timber:

- manufactured according to this document, which sets up provisions for:

- boundary conditions during manufacture of cross laminated timber;

- moisture content and temperature of timber to be bonded;

- production of finger joints and bonds between layers;

- to be used in service class 1 or 2 according to EN 1995-1-1;

- made of coniferous species and poplar listed in this document;

- which may be made of layers made of different species;

- bonded with phenolic or aminoplastic or moisture curing one-component polyurethane or emulsion polymer isocyanate adhesives of adhesive Type I according to the respective standard;

- made of timber laminations having a nominal width between 40 mm (including) and 300 mm (including);

- built up of at least three orthogonally bonded layers (at least two of them timber layers);

- which may have, depending on the number of layers, adjacent layers bonded parallel to the grain;

- made of timber layers which are made of strength graded timber according to EN 14081-1;

-made of timber layers having nominal thicknesses between 6 mm (including) and 47 mm (including);

- made of timber layers which may comprise edge bonds;

- having nominal overall thicknesses up to 500 mm.

Additional provisions of this document apply for straight cross laminated timber comprising only timber layers and comprising large finger joints (Type 2):

- made from cross laminated timber pieces having the same cross-section and layup;

- made from cross laminated timber pieces having nominal cross-sectional thicknesses from 51 mm (including) up to 345 mm (including) and nominal minimum thicknesses of the outer layers not less than 17 mm (including);

- made from cross laminated timber pieces solely comprising timber layers;

- made from plane cross laminated timber pieces;

- with parallel x-axes of the jointed components;

- with large finger joints having a finger length of at least 45 mm and fingers which are visible at the two narrow sides of the components;

- having large finger joints bonded with phenolic or aminoplastic or moisture curing one-component polyurethane adhesives of adhesive Type I according to the respective standard.

Additional provisions of this document apply for straight cross laminated timber comprising timber and wood-based panel layers but no large finger joints (Type 3):

- made of structural wood-based panels specified in this document;

- made of one panel per layer and;

- having thicknesses between 6 mm (including) and 45 mm (including).

This document applies to cross laminated timber untreated or treated against biological attack.

This document does not cover:

- cross laminated timber treated with fire retardants;

- cross laminated timber which is produced from re-used timber or wood-based panels comprising re-used timber.

It also lays down procedures for assessment and verification of constancy of performance (AVPC) of cross laminated timber.

Holzbauwerke - Brettsperrholz - Anforderungen

In diesem Dokument werden die Bestimmungen hinsichtlich der Leistungsmerkmale der folgenden Arten von Brettsperrholz festgelegt, die in Gebäuden und Brücken verwendet werden:

— Typ 1: ebenes oder gekrümmtes Brettsperrholz, das nur Brettlagen, aber keine Universal-Keilzinken-verbindungen umfasst;

— Typ 2: ebenes Brettsperrholz, das nur Brettlagen und Universal-Keilzinkenverbindungen umfasst;

— Typ 3: ebenes Brettsperrholz, das Bretter und Holzwerkstofflagen, aber keine Universal-Keilzinken-verbindungen umfasst.

Dieses Dokument gilt für alle drei Arten von Brettsperrholz:

— das nach diesem Dokument hergestellt wurde, das folgende Bestimmungen festlegt:

— Randbedingungen bei der Herstellung von Brettsperrholz;

— Feuchtegehalt und Temperatur der zu verklebenden Bretter;

— Herstellung von Keilzinkenverbindungen und Klebverbindungen zwischen Lagen;

— das in der Nutzungsklasse 1 oder 2 nach EN 1995 1 1 angewendet wird;

— das aus Pappel oder Nadelholzarten besteht, die in diesem Dokument aufgeführt sind;

— das aus Lagen bestehen darf, die aus verschiedenen Holzarten hergestellt sind;

— das mit Phenoplast und Aminoplast-Klebstoffen oder einem feuchtigkeitsvernetzenden Einkomponenten-Klebstoff auf Polyurethanbasis oder Emulsion-Polymer-Isocyanat-Klebstoffen vom Typ I nach der jeweiligen Norm verklebt ist;

— das aus Brettlamellen mit Nennbreiten von 40 mm (einschließlich) bis 300 mm (einschließlich) besteht;

— das aus mindestens drei rechtwinklig zueinander verklebten Lagen (mindestens zwei Lagen sind Brettlagen) besteht;

— bei dem je nach Anzahl der Lagen aneinandergrenzende Lagen parallel zur Faser verklebt werden dürfen;

— das aus Lagen aus Vollholz (Bretter oder Bohlen, im Folgenden als Bretter bezeichnet) besteht, das entsprechend EN 14081 1 nach Festigkeit sortiert ist;

— das aus Brettlagen mit Nenndicken von 6 mm (einschließlich) bis 47 mm (einschließlich) besteht;

— das aus Brettlagen mit oder ohne Schmalseitenverklebung besteht;

— das Gesamt-Nenndicken von bis zu 500 mm hat.

Zusätzliche Bestimmungen dieses Dokuments gelten für ebenes Brettsperrholz, das nur Brettlagen und Universal-Keilzinkenverbindungen (Typ 2) enthält:

— das aus Brettsperrholzstücken mit gleichem Querschnitt und Aufbau besteht;

— das aus Brettsperrholzstücken mit Querschnitts-Nenndicken von 51 mm (einschließlich) bis 345 mm (einschließlich) besteht, wobei die Mindest-Nenndicken der äußeren Lagen mindestens 17 mm (einschließlich) betragen;

— das aus Brettsperrholzstücken besteht, die ausschließlich Brettlagen enthalten;

— das aus ebenen Brettsperrholzstücken besteht;

— mit parallelen x-Achsen der verbundenen Bauteile;

— das große Keilzinkenverbindungen mit einer Keilzinkenlänge von mindestens 45 mm enthält, wobei die Keilzinken an den beiden Schmalseiten der Komponenten sichtbar sind;

— das große Keilzinkenverbindungen enthält, die mit Phenoplast oder Aminoplast-Klebstoffen oder einem feuchtigkeitsvernetzenden Einkomponenten-Klebstoff auf Polyurethanbasis vom Typ I nach der jeweiligen Norm verklebt sind.

Zusätzliche Bestimmungen dieses Dokuments gelten für ebenes Brettsperrholz, das Bretter und Holzwerk-stofflagen, aber keine Universal‑Keilzinkenverbindungen (Typ 3) enthält:

— das aus den in diesem Dokument festgelegten Holzwerkstoffen für tragende Zwecke besteht;

— das aus einer Platte je Lage besteht und;

— mit Dicken zwischen 6 mm (einschließlich) und 45 mm (einschließlich).

Dieses Dokument gilt für Brettsperrholz, das unbehandelt ist oder gegen biologischen Befall behandelt wurde.

Dieses Dokument gilt nicht für:

— mit Feuerschutzmittel behandeltes Brettsperrholz;

— Brettsperrholz, das aus Altholz oder aus Holzwerkstoffen besteht, die Altholz enthalten.

Darüber hinaus legt die Norm auch Verfahren zur Bewertung und Überprüfung der Leistungsbeständigkeit (AVCP) von Brettsperrholz fest.

Structures en bois - Bois lamellé croisé - Exigences

Le présent document établit les dispositions relatives à la performance des caractéristiques pour les types suivants de bois lamellé croisé, destinés à être utilisés dans les bâtiments et les ponts :

- Type 1 : bois lamellé croisé, droit ou courbe, constitué uniquement de couches de bois et sans aboutage à entures multiples de grandes dimensions ;

- Type 2 : bois lamellé croisé droit, constitué uniquement de couches de bois et comprenant des aboutages à entures multiples de grandes dimensions ;

- Type 3 : bois lamellé croisé droit, constitué de couches de bois et de couches en panneaux à base de bois, sans aboutage à entures multiples de grandes dimensions.

Le présent document couvre le bois lamellé croisé appartenant à l'ensemble des trois types de bois lamellé croisé :

- fabriqué conformément au présent document, qui établit les dispositions pour :

- les conditions limites pendant la fabrication du bois lamellé croisé ;

- la teneur en humidité et la température du bois à coller ;

- la production des aboutages à entures multiples et du collage entre les couches ;

- destiné à être utilisé en classe de service 1 ou 2 conformément à l'EN 1995-1-1 ;

- constitué des essences de bois de résineux et de peuplier énumérées dans le présent document ;

- qui peut être constitué de couches composées de différentes essences ;

- collé avec des adhésifs de nature phénolique ou aminoplaste ou des adhésifs polyuréthane monocomposants durcissant à l'humidité ou des adhésifs à base d'isocyanate et de polymère en émulsion de Type I conformément à la norme correspondante ;

- constitué de lamelles de bois avec une largeur nominale comprise entre 40 mm (inclus) et 300 mm (inclus) ;

- constitué d'au moins trois couches collées orthogonalement (au moins deux d'entre elles étant des couches de bois) ;

- pouvant comporter, en fonction du nombre de couches, des couches contigües collées parallèlement au fil ;

- comportant des couches de bois constituées de bois classé pour sa résistance conformément à l'EN 14081-1 ;

- constitué de couches de bois avec une épaisseur nominale comprise entre 6 mm (inclus) et 47 mm (inclus) ;

- constitué de couches de bois pouvant comporter des collages sur chant ;

- ayant des épaisseurs totales nominales inférieures ou égales à 500 mm.

[...]

Lesene konstrukcije - Križno lamelirani les - Zahteve

General Information

- Status

- Published

- Public Enquiry End Date

- 14-Jan-2019

- Publication Date

- 18-May-2021

- Technical Committee

- KON.005 - Timber structures

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 24-Feb-2021

- Due Date

- 01-May-2021

- Completion Date

- 19-May-2021

Relations

- Effective Date

- 01-Jul-2021

Overview

SIST EN 16351:2021 - Timber structures - Cross laminated timber (CLT) - Requirements - is the European product standard that specifies performance, production and conformity requirements for CLT used in buildings and bridges. It defines three CLT Types (straight/curved timber-only, timber-only with large finger joints, and timber plus wood‑based panels) and sets rules for manufacture, material selection, bonding and factory control. The standard also establishes procedures for Assessment and Verification of Constancy of Performance (AVCP).

Key technical topics and requirements

- CLT Types covered

- Type 1: Straight or curved, timber layers only, no large finger joints

- Type 2: Straight, timber layers only, includes large finger joints

- Type 3: Straight, timber + wood-based panel layers, no large finger joints

- Materials and grading

- Coniferous species and poplar allowed; layers may be of different species

- Timber laminations must be strength‑graded in accordance with EN 14081-1

- Geometrical limits

- Lamination nominal width: 40 mm to 300 mm

- Lamination nominal thickness: 6 mm to 47 mm

- Overall nominal thickness: up to 500 mm

- Built up of at least three orthogonally bonded layers (minimum two timber layers)

- Adhesives and bonding

- Permitted adhesives: phenolic, aminoplastic, moisture‑curing one‑component polyurethane, or emulsion polymer isocyanate adhesives - adhesive Type I per relevant adhesive standards

- Bonding strength, delamination, edge bonds and large finger joint bonding are specified and tested (see normative annexes)

- Type‑specific provisions

- Type 2 (large finger joints): finger length ≥ 45 mm, visible on narrow sides; pieces with consistent cross‑section and layup; piece thickness ranges and outer layer minima specified

- Type 3 (panels): structural panels specified, one panel per layer, panel thickness 6–45 mm

- Service & treatments

- For service classes 1 or 2 (EN 1995‑1‑1)

- Applies to CLT untreated or treated against biological attack; excludes CLT treated with fire retardants or made from reused timber/panels

- Conformity & testing

- AVCP, Type testing, and Factory Production Control (FPC) requirements are included; normative annexes provide test methods (delamination, shear, moisture, strength/stiffness, adhesive application, minimum production provisions).

Practical applications and users

- Designed for manufacturers of CLT, structural engineers, architects, and certification bodies who need to ensure product compliance for structural use in buildings and bridges.

- Useful for quality assurance, specifying CLT properties in procurement documents, and ensuring compatibility with Eurocode design rules.

- Relevant to timber fabricators planning jointing methods (finger joints), adhesive selection, and factory production control systems.

Related standards (selection)

- EN 14081-1 (strength grading of timber)

- EN 1995‑1‑1 / EN 1995‑1‑2 (Eurocode 5 - timber design and fire design)

- EN 301 / EN 302 (adhesives for load‑bearing timber structures)

- EN 13986, EN 12369 (wood‑based panels and formaldehyde testing)

Keywords: SIST EN 16351:2021, cross laminated timber, CLT requirements, timber structures, adhesives, finger joints, AVCP, factory production control, EN 14081-1.

Frequently Asked Questions

SIST EN 16351:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Timber structures - Cross laminated timber - Requirements". This standard covers: This document sets out provisions regarding the performance of characteristics of the following Types of cross laminated timber for use in buildings and bridges: - Type 1: Straight or curved cross laminated timber comprising only timber layers but no large finger joints; - Type 2: Straight cross laminated timber comprising only timber layers and large finger joints; - Type 3: Straight cross laminated timber comprising timber and wood-based panel layers but no large finger joints. This document covers cross laminated timber of all three Types of cross laminated timber: - manufactured according to this document, which sets up provisions for: - boundary conditions during manufacture of cross laminated timber; - moisture content and temperature of timber to be bonded; - production of finger joints and bonds between layers; - to be used in service class 1 or 2 according to EN 1995-1-1; - made of coniferous species and poplar listed in this document; - which may be made of layers made of different species; - bonded with phenolic or aminoplastic or moisture curing one-component polyurethane or emulsion polymer isocyanate adhesives of adhesive Type I according to the respective standard; - made of timber laminations having a nominal width between 40 mm (including) and 300 mm (including); - built up of at least three orthogonally bonded layers (at least two of them timber layers); - which may have, depending on the number of layers, adjacent layers bonded parallel to the grain; - made of timber layers which are made of strength graded timber according to EN 14081-1; -made of timber layers having nominal thicknesses between 6 mm (including) and 47 mm (including); - made of timber layers which may comprise edge bonds; - having nominal overall thicknesses up to 500 mm. Additional provisions of this document apply for straight cross laminated timber comprising only timber layers and comprising large finger joints (Type 2): - made from cross laminated timber pieces having the same cross-section and layup; - made from cross laminated timber pieces having nominal cross-sectional thicknesses from 51 mm (including) up to 345 mm (including) and nominal minimum thicknesses of the outer layers not less than 17 mm (including); - made from cross laminated timber pieces solely comprising timber layers; - made from plane cross laminated timber pieces; - with parallel x-axes of the jointed components; - with large finger joints having a finger length of at least 45 mm and fingers which are visible at the two narrow sides of the components; - having large finger joints bonded with phenolic or aminoplastic or moisture curing one-component polyurethane adhesives of adhesive Type I according to the respective standard. Additional provisions of this document apply for straight cross laminated timber comprising timber and wood-based panel layers but no large finger joints (Type 3): - made of structural wood-based panels specified in this document; - made of one panel per layer and; - having thicknesses between 6 mm (including) and 45 mm (including). This document applies to cross laminated timber untreated or treated against biological attack. This document does not cover: - cross laminated timber treated with fire retardants; - cross laminated timber which is produced from re-used timber or wood-based panels comprising re-used timber. It also lays down procedures for assessment and verification of constancy of performance (AVPC) of cross laminated timber.

This document sets out provisions regarding the performance of characteristics of the following Types of cross laminated timber for use in buildings and bridges: - Type 1: Straight or curved cross laminated timber comprising only timber layers but no large finger joints; - Type 2: Straight cross laminated timber comprising only timber layers and large finger joints; - Type 3: Straight cross laminated timber comprising timber and wood-based panel layers but no large finger joints. This document covers cross laminated timber of all three Types of cross laminated timber: - manufactured according to this document, which sets up provisions for: - boundary conditions during manufacture of cross laminated timber; - moisture content and temperature of timber to be bonded; - production of finger joints and bonds between layers; - to be used in service class 1 or 2 according to EN 1995-1-1; - made of coniferous species and poplar listed in this document; - which may be made of layers made of different species; - bonded with phenolic or aminoplastic or moisture curing one-component polyurethane or emulsion polymer isocyanate adhesives of adhesive Type I according to the respective standard; - made of timber laminations having a nominal width between 40 mm (including) and 300 mm (including); - built up of at least three orthogonally bonded layers (at least two of them timber layers); - which may have, depending on the number of layers, adjacent layers bonded parallel to the grain; - made of timber layers which are made of strength graded timber according to EN 14081-1; -made of timber layers having nominal thicknesses between 6 mm (including) and 47 mm (including); - made of timber layers which may comprise edge bonds; - having nominal overall thicknesses up to 500 mm. Additional provisions of this document apply for straight cross laminated timber comprising only timber layers and comprising large finger joints (Type 2): - made from cross laminated timber pieces having the same cross-section and layup; - made from cross laminated timber pieces having nominal cross-sectional thicknesses from 51 mm (including) up to 345 mm (including) and nominal minimum thicknesses of the outer layers not less than 17 mm (including); - made from cross laminated timber pieces solely comprising timber layers; - made from plane cross laminated timber pieces; - with parallel x-axes of the jointed components; - with large finger joints having a finger length of at least 45 mm and fingers which are visible at the two narrow sides of the components; - having large finger joints bonded with phenolic or aminoplastic or moisture curing one-component polyurethane adhesives of adhesive Type I according to the respective standard. Additional provisions of this document apply for straight cross laminated timber comprising timber and wood-based panel layers but no large finger joints (Type 3): - made of structural wood-based panels specified in this document; - made of one panel per layer and; - having thicknesses between 6 mm (including) and 45 mm (including). This document applies to cross laminated timber untreated or treated against biological attack. This document does not cover: - cross laminated timber treated with fire retardants; - cross laminated timber which is produced from re-used timber or wood-based panels comprising re-used timber. It also lays down procedures for assessment and verification of constancy of performance (AVPC) of cross laminated timber.

SIST EN 16351:2021 is classified under the following ICS (International Classification for Standards) categories: 79.060.10 - Plywood; 91.080.20 - Timber structures. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16351:2021 has the following relationships with other standards: It is inter standard links to SIST EN 16351:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 16351:2021 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/112, M/112_AM1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 16351:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2021

Nadomešča:

SIST EN 16351:2015

Lesene konstrukcije - Križno lamelirani les - Zahteve

Timber structures - Cross laminated timber - Requirements

Holzbauwerke - Brettsperrholz - Anforderungen

Structures en bois - Bois lamellé croisé - Exigences

Ta slovenski standard je istoveten z: EN 16351:2021

ICS:

79.060.10 Vezan les Plywood

91.080.20 Lesene konstrukcije Timber structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16351

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2021

EUROPÄISCHE NORM

ICS 79.060.10 Supersedes EN 16351:2015

English Version

Timber structures - Cross laminated timber -

Requirements

Structures en bois - Bois lamellé croisé - Exigences Holzbauwerke - Brettsperrholz - Anforderungen

This European Standard was approved by CEN on 4 January 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16351:2021 E

worldwide for CEN national Members.

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 7

2 Normative references . 8

3 Terms, definitions and symbols .10

3.1 Terms and definitions .10

3.2 Symbols .16

3.2.1 Main symbols .16

3.2.2 Subscripts .17

4 Characteristics .19

4.1 Modulus of elasticity, bending strength, compressive strength, tensile strength and

shear strength .19

4.1.1 General .19

4.1.2 Geometrical data of cross laminated timber .21

4.1.3 Strength, stiffness and density properties of layers .22

4.1.4 Bending strength of large finger joints .24

4.1.5 Rolling shear strength, compression strength perpendicular to grain and density of

cross laminated timber .24

4.2 Bonding strength .25

4.2.1 General .25

4.2.2 Bonding strength of glue lines between layers .25

4.2.3 Bonding strength of structural edge bonds .26

4.2.4 Bonding strength of large finger joints .26

4.3 Resistance to fire .26

4.4 Reaction to fire .27

4.4.1 General .27

4.4.2 Classification without further testing .27

4.4.3 Classification based on testing .29

4.5 Dimensional stability .30

4.6 Emission of formaldehyde .30

4.7 Durability .31

4.7.1 Durability of bonding strength .31

4.7.2 Durability of other characteristics .32

5 Assessment and Verification of Constancy of Performance (AVCP) .33

5.1 General .33

5.2 Type testing .33

5.2.1 General .33

5.2.2 Test samples, testing and compliance criteria .34

5.2.3 Test reports .41

5.3 Factory production control (FPC) .41

5.3.1 General .41

5.3.2 Provisions .41

5.3.3 Initial inspection of factory and of FPC .51

5.3.4 Continuous surveillance of FPC .51

5.3.5 Procedure for modifications .51

Annex A (normative) Delamination test of glue lines between layers . 52

Annex B (normative) Tests with laminations with or without finger joints . 56

Annex C (normative) Determination of strength, stiffness and density characteristics of

cross laminated timber . 59

Annex D (normative) Measurement of moisture content . 76

Annex E (normative) Adhesive application for finger joints in laminations. 77

Annex F (normative) Minimum production provisions . 78

Annex G (normative) Shear tests. 92

Annex H (normative) Additional test methods and requirements for adhesives of subclass

FJ for use in structural edge bonds . 95

Bibliography . 96

European foreword

This document (EN 16351:2021) has been prepared by Technical Committee CEN/TC 124 “Timber

structures”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2021, and conflicting national standards shall

be withdrawn at the latest by December 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 16351:2015.

The following changes have been made:

— the standard has been adjusted to the latest versions of standards for adhesives;

— the provisions for reaction and resistance to fire have been modified;

— the provisions for gap widths and ratios of lamination width by thickness have been modified;

— missing provisions for factory production control have been added;

— the provisions for determination of strength, stiffness and density characteristics of cross laminated

timber have been modified;

— the standard has been adjusted to the latest templates;

— Annex ZA has been deleted.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

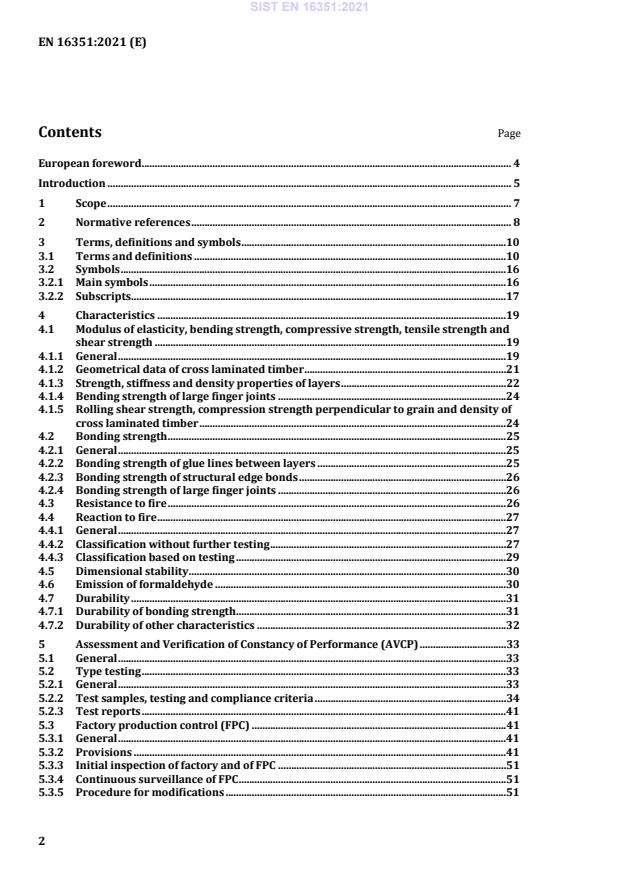

Figure 1 shows the relation of some European Standards on structural timber products.

Key

1 boards 6 glued laminated timber (glulam)

2 is a component for 7 glulam with large finger joints

3 structural finger jointed timber 8 block glued glulam

4 glued laminated products 9 cross laminated timber

5 glued solid timber 10 cross laminated timber with large finger joints

Figure 1 — Relation of some European Standards on structural timber products

Cross laminated timber in accordance with this document and multilayer solid wood panels in

accordance with EN 13353 may have the same layup, but for cross laminated timber the timber is

strength graded according to EN 14081-1 and the adhesives are tested according to the provisions of this

document.

The following standards mentioned in Clause 2, EN 13986, EN 14080, EN 14081-1, EN 14374 and

EN 15497, are harmonized product standards. The applicable version cited in the Official Journal of the

EU are not necessarily the latest published by CEN.

1 Scope

This document sets out provisions regarding the performance of characteristics of the following Types of

cross laminated timber for use in buildings and bridges:

— Type 1: Straight or curved cross laminated timber comprising only timber layers but no large finger

joints;

— Type 2: Straight cross laminated timber comprising only timber layers and large finger joints;

— Type 3: Straight cross laminated timber comprising timber and wood-based panel layers but no large

finger joints.

This document covers cross laminated timber of all three Types of cross laminated timber:

— manufactured according to this document, which sets up provisions for:

— boundary conditions during manufacture of cross laminated timber;

— moisture content and temperature of timber to be bonded;

— production of finger joints and bonds between layers;

— to be used in service class 1 or 2 according to EN 1995-1-1;

— made of coniferous species and poplar listed in this document;

— which may be made of layers made of different species;

— bonded with phenolic or aminoplastic or moisture curing one-component polyurethane or emulsion

polymer isocyanate adhesives of adhesive Type I according to the respective standard;

— made of timber laminations having a nominal width between 40 mm (including) and 300 mm

(including);

— built up of at least three orthogonally bonded layers (at least two of them timber layers);

— which may have, depending on the number of layers, adjacent layers bonded parallel to the grain;

— made of timber layers which are made of strength graded timber according to EN 14081-1;

— made of timber layers having nominal thicknesses between 6 mm (including) and 47 mm (including);

— made of timber layers which may comprise edge bonds;

— having nominal overall thicknesses up to 500 mm.

Additional provisions of this document apply for straight cross laminated timber comprising only timber

layers and comprising large finger joints (Type 2):

— made from cross laminated timber pieces having the same cross-section and layup;

— made from cross laminated timber pieces having nominal cross-sectional thicknesses from 51 mm

(including) up to 345 mm (including) and nominal minimum thicknesses of the outer layers not less

than 17 mm (including);

— made from cross laminated timber pieces solely comprising timber layers;

— made from plane cross laminated timber pieces;

— with parallel x-axes of the jointed components;

— with large finger joints having a finger length of at least 45 mm and fingers which are visible at the

two narrow sides of the components;

— having large finger joints bonded with phenolic or aminoplastic or moisture curing one-component

polyurethane adhesives of adhesive Type I according to the respective standard.

Additional provisions of this document apply for straight cross laminated timber comprising timber and

wood-based panel layers but no large finger joints (Type 3):

— made of structural wood-based panels specified in this document;

— made of one panel per layer and;

— having thicknesses between 6 mm (including) and 45 mm (including).

This document applies to cross laminated timber untreated or treated against biological attack.

This document does not cover:

— cross laminated timber treated with fire retardants;

— cross laminated timber which is produced from re-used timber or wood-based panels comprising re-

used timber.

It also lays down procedures for assessment and verification of constancy of performance (AVPC) of cross

laminated timber.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 301:2017, Adhesives, phenolic and aminoplastic, for load-bearing timber structures - Classification and

performance requirements

EN 302-1, Adhesives for load-bearing timber structures - Test methods - Part 1: Determination of

longitudinal tensile shear strength

EN 302-2, Adhesives for load-bearing timber structures - Test methods - Part 2: Determination of resistance

to delamination

EN 338, Structural timber - Strength classes

EN 335, Durability of wood and wood-based products - Use classes: definitions, application to solid wood

and wood-based products

EN 350, Durability of wood and wood-based products - Testing and classification of the durability to

biological agents of wood and wood-based materials

EN 351-1, Durability of wood and wood-based products - Preservative-treated solid wood - Part 1:

Classification of preservative penetration and retention

EN 408:2010+A1:2012, Timber structures - Structural timber and glued laminated timber - Determination

of some physical and mechanical properties

EN 717-1, Wood-based panels - Determination of formaldehyde release - Part 1: Formaldehyde emission by

the chamber method

EN 789, Timber structures - Test methods - Determination of mechanical properties of wood based panels

EN 1995-1-1, Eurocode 5: Design of timber structures - Part 1-1: General - Common rules and rules for

buildings

EN 1995-1-2, Eurocode 5: Design of timber structures - Part 1-2: General - Structural fire design

EN 12369-2, Wood-based panels - Characteristic values for structural design - Part 2: Plywood

EN 12369-3, Wood-based panels - Characteristic values for structural design - Part 3: Solid-wood panels

EN 13183-1, Moisture content of a piece of sawn timber - Part 1: Determination by oven dry method

EN 13183-2, Moisture content of a piece of sawn timber - Part 2: Estimation by electrical resistance method

EN 13183-3, Moisture content of a piece of sawn timber - Part 3: Estimation by by capacitance method

EN 13238, Reaction to fire tests for building products - Conditioning procedures and general rules for

selection of substrates

EN 13501-1, Fire classification of construction products and building elements - Part 1: Classification using

data from reaction to fire tests

EN 13501-2, Fire classification of construction products and building elements - Part 2: Classification using

data from fire resistance tests, excluding ventilation services

EN 13823, Reaction to fire tests for building products - Building products excluding floorings exposed to the

thermal attack by a single burning item

EN 13986, Wood-based panels for use in construction - Characteristics, evaluation of conformity and

marking

EN 14081-1, Timber structures - Strength graded structural timber with rectangular cross-section - Part 1:

General requirements

EN 14358, Timber structures - Calculation and verification of characteristic values

EN 14374, Timber structures - Structural laminated veneer lumber - Requirements

EN 15228:2009, Structural timber - Structural timber preservative treated against biological attack

EN 15425:2017, Adhesives - One component polyurethane (PUR) for load-bearing timber structures -

Classification and performance requirements

EN 16254:2013+A1:2016, Adhesives - Emulsion polymerized isocyanate (EPI) for load bearing timber

structures - Classification and performance requirements

EN ISO 9239-1, Reaction to fire tests for floorings - Part 1: Determination of the burning behaviour using a

radiant heat source (ISO 9239-1)

EN ISO 11925-2:2020, Reaction to fire tests - Ignitability of products subjected to direct impingement of

flame - Part 2: Single-flame source test (ISO 11925-2)

3 Terms, definitions and symbols

For the purposes of this document, the following terms, definitions and symbols apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1 Terms and definitions

3.1.1

actual size

measured size of a cross laminated timber at a given moisture content

[SOURCE: EN 14080:2013, 3.1 - modified]

3.1.2

bonding strength

structural effectiveness of adhesives between timber pieces when subjected to stresses

[SOURCE: EN 14080:2013, 3.2]

3.1.3

contact-free application

application without contact between timber and application unit

3.1.4

corrected size

size of a cross laminated timber corrected by calculation from its actual size to its size at the reference

moisture content

[SOURCE: EN 14080:2013, 3.6 - modified]

3.1.5

cross laminated timber

structural timber member composed by at least three face-bonded layers which comprise solid timber

laminations and may comprise wood-based panels, at least one layer orthogonally oriented to the two

adjacent layers

Note 1 to entry: See also Figure 2.

Key

1 plane of the element 2 wide face 3 narrow faces 4 outer layers

5 inner layers 6 laminations 7 finger joints in lamination 8 large finger joint

9 usually the length 10 usually the width b of a plate or height h of a beam

CL CL

Figure 2 — Cross laminated timber

3.1.6

delamination length

sum of the lengths of delaminations in one glue line measured around the circumference of a test piece

[SOURCE: EN 14080:2013, 3.8 - modified]

3.1.7

edge bond

bond between adjacent laminations within a timber layer

3.1.8

finger angle

inclination α of each side of the fingers of a finger joint

[SOURCE: EN 14080:2013, 3.10]

Note 1 to entry: See Figure 3.

3.1.9

finger joint

interlocking end joint formed by machining a number of similar, tapered, symmetrical fingers in the ends

of timber components using a finger joint cutter and then bonded together

[SOURCE: EN 14080:2013, 3.11]

Note 1 to entry: In this document, the term finger joint is used for finger joints in laminations whereas finger

joints between cross laminated timber are defined as large finger joints (see 3.1.13).

Key

b tip width of the cutter b tip width l finger length l slot base p pitch

cut t j t

α finger angle 1 tip base 2 fingertip 3 finger flank

Figure 3 — Typical profile of a finger joint

3.1.10

finger length

distance l between the finger base and the tip of the finger, measured along the centre line of the finger

j

[SOURCE: EN 14080:2013, 3.12]

Note 1 to entry: See Figure 3.

3.1.11

finished thickness

thickness after machining

[SOURCE: EN 14080:2013, 3.13]

3.1.12

lamination

part of a structural glued timber product consisting of one board or two or more finger-jointed boards

[SOURCE: EN 14080:2013, 3.19 - modified]

3.1.13

large finger joint

finger joint through the full cross-sectional area of two cross laminated timber components

[SOURCE: EN 14080:2013, 3.20 - modified]

Note 1 to entry: See Figure 4.

Figure 4 — Cross laminated timber with large finger joint

3.1.14

layer

courses lying over or under another

3.1.15

layup

cross-sectional arrangement of timber layers which may be assigned to different strength classes

according to EN 338 or different sets of individual values of strength, stiffness and density characteristics

or wood-based panel layers which may be assigned to different strength classes according to EN 12369-2

or EN 12369-3 or different sets of individual values of strength, stiffness and density characteristics

[SOURCE: EN 14080:2013, 3.21 - modified]

3.1.16

maximum delamination length

largest delamination length in any single glue line

[SOURCE: EN 14080:2013, 3.24 - modified]

3.1.17

mean moisture content

mean value of the moisture content of cross laminated timber calculated from at least two measurements

[SOURCE: EN 14080:2013, 3.25 - modified]

Note 1 to entry: See D.2.

3.1.18

minimum mean density

required mean density at reference moisture content, estimated as the weighted mean of the mean

densities of the layers, if necessary

[SOURCE: EN 14080:2013, 3.26]

Note 1 to entry: Minimum mean density is used for the classification of the reaction to fire.

3.1.19

nominal size

size specified at the reference moisture content to which deviations are related

3.1.20

pitch

distance between centres of adjacent fingertips

[SOURCE: EN 14080:2013, 3.27]

Note 1 to entry: See Figure 3.

3.1.21

ratio of resin to hardener

proportion of resin to hardener by mass with the resin set at 100 parts

[SOURCE: EN 14080:2013, 3.28]

3.1.22

reduction factor

ratio ν between tip width b and pitch p

t

[SOURCE: EN 14080:2013, 3.29 - modified]

Note 1 to entry: See Figure 3.

3.1.23

reference moisture content

moisture content of 12 % at which nominal sizes are established

[SOURCE: EN 14080:2013, 3.30]

3.1.24

relative tip gap

ratio e between tip gap l and finger length l

t j

[SOURCE: EN 14080:2013, 3.31 - modified]

Note 1 to entry: See Figure 3.

3.1.25

re-used timber

timber product made from timber which has been used before

3.1.26

rolling shear

shear stress for which both complementary stress components are perpendicular to the grain

3.1.27

solid wood failure

wood failure which is invariably more than two cell layers away from the adhesive layer

3.1.28

straight cross laminated timber

cross laminated timber having a precamber of up to 1 % of the respective span

3.1.29

timber layer

layer made of timber laminations with or without edge bonds

3.1.30

tip gap

distance l between fingertip and slot base in a bonded finger joint

t

[SOURCE: EN 15497:2014, 3.11]

Note 1 to entry: See Figure 3.

3.1.31

tip width

distance b between finger flanks, measured at the tip of the finger

t

[SOURCE: EN 14080:2013, 3.35 - modified]

Note 1 to entry: See Figure 3.

3.1.32

total delamination length

sum of delamination lengths of all glue lines

[SOURCE: EN 14080:2013, 3.36 - modified]

3.1.33

wood-based panels

structural plywood and structural solid wood panels according to EN 13986

and structural LVL according to EN 14374

3.1.34

wood-based panel layer

layer made of one piece of wood-based panel

3.1.35

wood failure percentage

percentage of the solid wood failure area after splitting in relation to the glued area before splitting

[SOURCE: EN 14080:2013, 3.38 - modified]

3.1.36

x-axis

axis parallel to grain of the timber layers or outer layers or veneers of wood-based panel layers

Note 1 to entry: See Figure 2.

3.1.37

z-axis

axis perpendicular to the layers

Note 1 to entry: See Figure 2.

3.2 Symbols

3.2.1 Main symbols

A area, in mm ;

A area of wane, in mm (see Figure F.1);

w

A* net sehar area,

a size or distance between support and load introduction or excess length in mm;

a length of the diagonals of wane, in mm (see Figure F.1);

w

a maximum length of the diagonal of wane, in mm (see Figure F.2);

w,max

b width, in mm;

b tip width of the cutter (see Figure 3);

cut

b tip width, in mm (see Figure 3);

t

b gap width, in mm;

gap

d diameter, in mm;

d distance, in mm (see Figure 6);

Delam maximum delamination, in %;

max

Delam total delamination, in %;

tot

e relative tip gap;

E modulus of elasticity, in N/mm ;

E modulus of elasticity related to I , in N/mm ;

local CL,net

(EI) appereant bending stiffness, in N·mm ;

CL,app,net

(EI) bending stiffness of cross laminated timber, in N·mm ;

CL,local,net

(ES) first moment of inertia taking into account the modulus of elasticity of each layer, in N·mm;

CL,ν(r),net

f strength, in N/mm ;

F load, in N;

F ultimate load, in N;

u

G shear modulus, in N/mm ;

(GA) shear stiffness of cross laminated timber, in N;

CL

h height, in mm;

h gauge length, in mm;

I second moment of inertia, in mm ;

I moment of inertia calculated from properties of the layers having its fibres parallel to the

CL,net

span only, in mm ;

k factor;

k moisture deformation factor;

cor,α

k statistical factor;

l span or length, in mm;

l finger length, in mm (see Figure 3);

j

l slot base, in mm (see Figure 3);

t

p pitch, in mm (see Figure 3);

m moment per unit length, in Nmm/mm (see Figure C.1);

n normal force per unit length, in N/mm (see Figure C.1);

r radius of curvature, in mm;

t thickness, in mm;

S Static moment, in mm ;

u moisture content, in %;

w deflection, in mm;

v shear force per unit length, in N/mm (see Figure C.1);

V shear force, in N;

α finger angle, in degree (see Figure 3);

κ shear factor;

ρ density, in kg/m ;

σ stress, in N/mm ;

τ shear stress, in N/mm ;

v reduction factor of a finger joint.

3.2.2 Subscripts

a actual;

app apparent;

bond property related to bonded area;

c compression;

CL property related to cross laminated timber;

cor corrected;

delam property related to delamination;

edge edgewise

global global;

glue line property related to glue line;

i belonging to number i;

j properties of finger joints in laminations;

k characteristic;

l properties of laminations;

lay properties of layers;

lfj properties of large finger joints;

local local;

m bending;

max maximum;

mean mean value;

pl performance level;

r rolling shear;

ref reference;

t tension;

tor,node torsional property linked to a nodal area;

tot total;

v shear;

x global axis in plane of the cross laminated timber and parallel to the fibre direction of the outer

layers, (see Figure 2);

y global axis in plane of the cross laminated timber and orthogonal to the fibre direction of the

outer layers, (see Figure 2);

z global axis perpendicular to the plane of the cross laminated timber, (see Figure 2);

0 local axis parallel to the grain;

15 property determined from 15 test results;

90 local axis perpendicular to the grain (both tangential and radial);

α angle, in degree.

4 Characteristics

4.1 Modulus of elasticity, bending strength, compressive strength, tensile strength and

shear strength

4.1.1 General

Modulus of elasticity, bending strength, compressive strength, tensile strength and shear strength of

cross laminated timber shall be expressed either according to a) or b) or c), see also Figure 5.

Figure 5 — Options for the determination of modulus of elasticity, bending strength, compressive strength, tensile strength and shear

strength

a) geometrical data of cross laminated timber and strength, stiffness and density properties of layers

as:

1) geometrical data of cross laminated timber according to 4.1.2;

2) strength, stiffness and density properties of the layers; as

i) strength, stiffness and density properties of the timber and finger joints according to 4.1.3.1

a); or as

ii) strength, stiffness and density properties of the timber and finger joints determined from

tests according to 4.1.3.1 b) (for Type 1 or 2 only); and

iii) strength, stiffness and density properties of wood-based panel layers according to 4.1.3.2

(for Type 3 only); or as

b) strength, stiffness and density properties of the cross laminated timber as:

1) strength, stiffness and density properties of cross laminated timber apart from large finger joint

properties verified by full scale tests according to Annex C; or

2) rolling shear strength and compression strength perpendicular to the grain of cross laminated

timber may be declared based on tabulated values given in 4.1.5; and

3) strength properties of large finger joints according to 4.1.4 (for Type 2 only) verified by full scale

tests according to Annex C; or as

c) resistances and stiffnesses of cross laminated timber determined by full scale tests according to

Annex C.

Declarations according to method a) and b) can be combined.

4.1.2 Geometrical data of cross laminated timber

4.1.2.1 General

The following geometrical data shall be declared:

a) nominal cross-sectional sizes according to 4.1.2.2;

b) presence of grooves in laminations according to 4.1.2.3;

c) layup as layer thickness according to 4.1.2.4 and layer orientation according to 4.1.2.5;

d) ratio of nominal lamination width to nominal lamination thickness according to 4.1.2.6.

4.1.2.2 Nominal cross-sectional sizes

The nominal cross-sectional sizes of the cross laminated timber shall be declared as single values.

The corrected thickness of the cross-section of the cross laminated timber determined according to F.9

shall not deviate from the nominal thickness by more than ± 2 mm or 2 % of the nominal thickness

whichever is greater.

4.1.2.3 Grooves in laminations

The presence of grooves in laminations shall be expressed as indication "grooves".

4.1.2.4 Layer thickness

The nominal layer thicknesses according F.9 shall be declared as single values in mm.

The corrected thickness of the single layers and laminations within a layer, respectively, determined

according to F.9 shall not deviate from the nominal thickness by more than ± 1 mm.

4.1.2.5 Layer orientation

The layer orientation shall be declared as x for an orientation parallel to the x-axis and y for an orientation

parallel to the y-axis.

The layer orientation shall be expressed in combination with the layer thickness.

EXAMPLE The layer thickness and orientation of a five - layered cross laminated timber with two cross layers

having layer thicknesses of 40 mm could read: 40x-40y-40x-40y-40x.

4.1.2.6 Ratio of nominal lamination width to nominal lamination thickness

For timber layers the ratio of nominal lamination width to nominal lamination thickness width b /t shall

l l

be expressed as single values.

EXAMPLE A declaration could read: b /t ≥ 4.

l l

The nominal width bl of the laminations shall be taken as:

a) the minimum width of the laminations for laminations without grooves; or

b) the minimum spacing between adjacent grooves in laminations; or

c) the minimum distance between grooves and edges of laminations;

whichever is the smallest, disregarding the lamination widths at both ends of the layer width.

The corrected width of a single lamination determined according to F.9 shall not deviate from the nominal

width by more than ± 1 mm.

NOTE For certain ratios of nominal lamination width to nominal lamination thickness, the rolling shear

strength can be determined according to 4.1.5.

4.1.3 Strength, stiffness and density properties of layers

4.1.3.1 Timber layers

Timber shall be strength graded according to EN 14081-1.

The timber layers may comprise finger joints. The characteristic tension strength or the characteristic

bending strength of finger joints be determined in accordance with Annex B shall meet Formula (1) or

(2) for strength classes according to EN 338 based on tension tests and Formula (3) for strength classes

based on bending tests.

f ≥ f + 5N /²mm (1)

t, j,k t,0,,lk

f ≥+1, 4 f 8N/ mm² (2)

m, j,k t,0,,lk

f ≥+f 8N /²mm (3)

m, j,k ml,,k

where

f is the characteristic tension strength of the finger joint, in N/mm ;

t,j,k

f is the characteristic bending strength of the finger joint in flatwise bending of the

m,j,k

lamination, in N/mm ;

f is the characteristic tension strength of the timber, in N/mm and;

t,0,l,k

f is the characteristic edge-wise bending strength of the timber, in N/mm .

m,l,k

Each timber layer shall be made of timber laminations of one strength class or one set of individual

strength, stiffness and density values.

The cross laminated timber may be made of layers made from different species. Each timber layer shall

be made of one of the following species:

a) Norway spruce (Picea abies, PCAB);

b) Silver fir (Abies alba, ABAL);

c) Scots pine (Pinus sylvestris, PNSY);

d) Douglas fir (Pseudotsuga menziesii, PSMN);

e) Western hemlock (Tsuga heterophylla, TSHT);

f) Black Pine (Pinus nigra spp., PNNG);

g) European larch (Larix decidua, LADC);

h) Siberian larch (Larix sibirica, LASI);

i) Dahurian larch (Larix gmelinii (Rupr.) Kuzen.);

j) Poplar (Populus spp., POER);

k) Maritime pine (Pinus pinaster, PNPN);

l) Radiata pine (Pinus radiata, PNRD);

m) Sitka spruce (Picea sitchensis, PCST);

n) Southern yellow pine (Pinus palustris, PNPL);

o) Western red cedar (Thuja plicata, THPL);

p) Yellow cedar (Chamaecyparis nootkatensis, CHNT).

Norway spruce and Silver fir may be considered as one species.

Different cultivars of Poplar may be considered as one species.

NOTE 1 Letter codes according to EN 13556, if available, are given after the botanical name.

NOTE 2 EN 1912 does not provide information on all species listed above.

The strength, stiffness and density properties of the timber layers shall:

1) be jointly expressed as the strength class of the timber according to EN 338 or as individual values;

or

2) be determined from full-scale tests according to Annex C with straight cross laminated timber solely

build up from timber laminations of one strength class, having outermost layers with fibres parallel

to span (x-axis), evaluated according to Annex C for cross laminated timber of Type 1 or 2 and the

results jointly expressed:

— as strength class in accordance with EN 338; or as

— individual strength, stiffness and density values.

NOTE 3 Compared to the Euler-Bernoulli beam theory, the beam theory according to Timoshenko takes into

account the influence of the shear deformation on the moment of inertia of the beam.

4.1.3.2 Wood-based panel layers

Wood-based panel layers shall be made of structural plywood or structural solid wood panels according

to EN 13986 or structural LVL according to EN 14374.

Each wood-based panel layer shall be made of one panel.

Wood-based panel layers shall be made of one species listed in 4.1.3.1.

Only wood-based panels which fulfil the provisions for the use in service class 2 or 3 according to

EN 1995-1-1 shall be used.

The material properties of wood-based panel layers shall be taken as the material properties of the wood-

based panels from which they are made of.

The strength, stiffness and density properties of the wood-based panels shall be declared as strength class

according to EN 12369-2 or EN 12369-3 or as single values for plywood and structural solid wood panels

according to EN 13986 or as single values for laminated veneer lumber according to EN 14374.

4.1.4 Bending strength of large finger joints

For straight cross laminated timber comprising timber layers and large finger joints (Type 2), the

characteristic bending strength(s) of the large finger joints f in flatwise or f in edgewise

m,lfj,x/y,k m,edge,lfj,x/y,k

bending shall be tested and declared as single value(s) in accordance with C.2.5 and C.3.4 in the directions

relevant for the intended use.

4.1.5 Rolling shear strength, compression strength perpendicular to grain and density of cross

laminated timber

4.1.5.1 Rolling shear strength of cross laminated timber

For all types of cross laminated timber made from timber having a characteristic bending strength f of

m,l,k

at least 16 N/mm either:

— made of structurally edge bonded timber layers without grooves; or

— made of timber layers, which have a thickness of up to 47 mm (including), which are not structurally

edge bonded and comprise laminations having a ratio of nominal lamination width to nominal

lamination thickness b /t ≥ 4.

l l

The characteristic rolling shear strength f may be declared as f = 1,4 N/mm .

r,k r,k

For other ratios of nominal lamination width to nominal lamination thickness in timber layers without

structural edge bonds having a thickness of up to 47 mm (including) the characteristic rolling shear

strength f may be declared as f = 0,7 N/mm .

r,k r,k

4.1.5.2 Compression strength perpendicular to the grain

The characteristic compression strength perpendicular to the grain of a cross laminated timber may be

declared as f = 3 N/mm .

c,z,k

NOTE The value refers to a volume as defined in C.2.4.

4.2 Bonding strength

4.2.1 General

Bonding strength shall be declared as

a) bonding strength of finger joints in laminations expressed as bending or tension strength of finger

joints in laminations expressed as bending strength of timber according to 4.1.3.1 for all types of

cross laminated timber; and

b) bonding strength of glue lines between layers according to 4.2.2 for all Types; and

c) bonding strength of edge bonds, if any, according to 4.2.3 for all Types; and

d) bonding strength of large finger joints expressed as characteristic bending strength of large finger

joints according to 4.1.4 for Type 2.

4.2.2 Bonding strength of glue lines between layers

The glue line integrity of glue lines between layers shall be tested according to Annex A (delamination

test) and jointly expressed as layer thickness according to 4.1.2.4 and layer orientation according to

4.1.2.5.

The bonding strength of glue lines between layers is proven to be sufficient,

a) if the maximum delamination length of each specimen does not exceed 40 % of the total length of a

single glue line and the total delamination length does not exceed 10 % of the sum of all glue lines;

or

b) if the the minimum wood failure percentage of each split glued area is not less than 50 %, the

minimum wood failure percentage of the sum of all split glued areas shall be not less than 70 %.

Option b) may also be applied, if the maximum delamination length or the total delamination length

exceeds the limits given in a) or if the delamination lengths cannot be estimated due to inadequate surface

quality.

------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...