SIST EN IEC 62512:2021/A11:2021

(Amendment)Electric clothes washer-dryers for household use - Methods for measuring the performance

Electric clothes washer-dryers for household use - Methods for measuring the performance

IEC 62512:2012 provides a globally applicable and agreed method to test the washing and drying function of washer-dryers. Although this standard is based on IEC 61121:2012 on tumble dryers and IEC 60456:2010 on clothes washers, it specifies the conditions needed to test the combined function of washing and drying. The main elements of this standard are: - the definition of the loads to be tested in continuous and interrupted operation cycles; - the method for testing automatic and not automatic operation of the drying cycles; - the way to handle the load for interrupted operation cycles; - the correction to be applied to test results for continuous and interrupted operation cycles.

Elektrische Wasch-Trockner für den Hausgebrauch - Prüfverfahren zur Bestimmung der Gebrauchseigenschaften

Lavantes-séchantes électriques à usage domestique - Méthodes de mesure de l’aptitude à la fonction

Ajouter le second alinéa du Domaine d'application après ce qui suit:

"Le présent document donne un mode opératoire de mesure pour les règlements de l'UE relatifs à

l'écoconception et à l'étiquetage énergétique sur les lavantes-séchantes combinées à usage

domestique dans leur fonction combinée de lavage et de séchage des textiles."

Remplacer la Note dans le domaine d'application par:

"NOTE Les lavantes-séchantes à usage commun dans les immeubles ou dans les laveries automatiques sont

également incluses dans le domaine d'application du présent document. Il ne s'applique pas aux lavantes

séchantes utilisées dans les blanchisseries."

Električni pralno-sušilni stroji za uporabo v gospodinjstvu - Metode za merjenje funkcionalnosti - Dopolnilo A11

General Information

- Status

- Published

- Publication Date

- 11-Jan-2021

- Technical Committee

- FGA - Consumer information related to household electrical appliances

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 07-Jan-2021

- Due Date

- 14-Mar-2021

- Completion Date

- 12-Jan-2021

Relations

- Effective Date

- 01-Feb-2021

Overview

EN IEC 62512:2020/A11:2020 - titled Electric clothes washer-dryers for household use - Methods for measuring the performance - is a CLC/CENELEC amendment to IEC 62512:2012 that defines standardized test methods for combined washer‑dryers. It provides a globally applicable, harmonized procedure to measure washing and drying performance (including combined wash‑and‑dry cycles) and to generate repeatable data for energy labelling and ecodesign compliance in the EU.

Key topics and technical requirements

- Scope and purpose: Measurement procedures for washer‑dryers (household and communal use), specifically covering combined wash‑and‑dry performance for regulatory testing.

- Test cycles defined: Continuous, segmented and interrupted operation cycles; definitions for complete operation cycle, drying cycle and wash‑and‑dry cycles (e.g., eco 40‑60).

- Load definitions and handling: Definition of full and half test loads, treatment types (treatment full / treatment half), and handling procedures for interrupted/segmented cycles.

- Drying operation: Methods for testing automatic and non‑automatic drying programmes and the determination of final moisture content.

- Multi‑drum requirements: Specific clauses for multi‑drum washer‑dryers and multi‑drum mode, including combined rated capacity, combined programme time and combined cycle time for simultaneous programme testing.

- Data corrections and reporting: Corrections applied to test results for continuous and interrupted cycles; Annex B provides suggested reporting forms and mandatory data to be reported.

- Regulatory alignment: Annex ZA (normative) and informative Annexes ZZA/ZZB relate the standard to EU energy labelling (Commission Delegated Regulation (EU) 2019/2014) and ecodesign (Commission Regulation (EU) 2019/2023) requirements.

- Instrumentation and references: Includes required test conditions, materials and instrumentation and incorporates relevant normative references (e.g., EN IEC 60704‑2‑16).

Applications - who uses this standard

- Manufacturers: to verify declared washing/drying capacities and to prepare compliant technical documentation for CE marking, energy labels and ecodesign.

- Test laboratories: for repeatable performance measurement, certification testing and producing comparable efficiency and moisture‑content metrics.

- Regulators and conformity assessors: to assess compliance with EU energy labelling and ecodesign requirements.

- Product designers & R&D teams: to benchmark performance, optimize programmes (eco 40‑60, wash and dry cycles) and evaluate multi‑drum designs.

Related standards

- IEC 62512:2012 (base international standard)

- IEC 61121:2012 (tumble dryer methods)

- IEC 60456:2010 (washing machine test methods)

- EN IEC 60704‑2‑16 (acoustical noise - washer‑dryers)

- CLC/TS 50677, CLC/TS 50707 (rinsing effectiveness, maximum internal temperature)

For certification or regulatory use, consult the full text of EN IEC 62512:2020/A11:2020 and associated annexes to ensure correct test set‑up, reporting and alignment with EU energy labelling and ecodesign obligations.

Frequently Asked Questions

SIST EN IEC 62512:2021/A11:2021 is a amendment published by the Slovenian Institute for Standardization (SIST). Its full title is "Electric clothes washer-dryers for household use - Methods for measuring the performance". This standard covers: IEC 62512:2012 provides a globally applicable and agreed method to test the washing and drying function of washer-dryers. Although this standard is based on IEC 61121:2012 on tumble dryers and IEC 60456:2010 on clothes washers, it specifies the conditions needed to test the combined function of washing and drying. The main elements of this standard are: - the definition of the loads to be tested in continuous and interrupted operation cycles; - the method for testing automatic and not automatic operation of the drying cycles; - the way to handle the load for interrupted operation cycles; - the correction to be applied to test results for continuous and interrupted operation cycles.

IEC 62512:2012 provides a globally applicable and agreed method to test the washing and drying function of washer-dryers. Although this standard is based on IEC 61121:2012 on tumble dryers and IEC 60456:2010 on clothes washers, it specifies the conditions needed to test the combined function of washing and drying. The main elements of this standard are: - the definition of the loads to be tested in continuous and interrupted operation cycles; - the method for testing automatic and not automatic operation of the drying cycles; - the way to handle the load for interrupted operation cycles; - the correction to be applied to test results for continuous and interrupted operation cycles.

SIST EN IEC 62512:2021/A11:2021 is classified under the following ICS (International Classification for Standards) categories: 97.060 - Laundry appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN IEC 62512:2021/A11:2021 has the following relationships with other standards: It is inter standard links to SIST EN IEC 62512:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN IEC 62512:2021/A11:2021 is associated with the following European legislation: EU Directives/Regulations: 2009/125/EC, 2017/1369, 2019/2014, 2019/2023; Standardization Mandates: M/495, M/566. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN IEC 62512:2021/A11:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2021

Električni pralno-sušilni stroji za uporabo v gospodinjstvu - Metode za merjenje

funkcionalnosti - Dopolnilo A11

Electric clothes washer-dryers for household use - Methods for measuring the

performance

Elektrische Wasch-Trockner für den Hausgebrauch - Prüfverfahren zur Bestimmung der

Gebrauchseigenschaften

Lavantes-séchantes électriques à usage domestique - Méthodes de mesure de l’aptitude

à la fonction

Ta slovenski standard je istoveten z: EN IEC 62512:2020/A11:2020

ICS:

97.060 Aparati za nego perila Laundry appliances

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD EN IEC 62512:2020/A11

NORME EUROPÉENNE

EUROPÄISCHE NORM

December 2020

ICS 97.060

English Version

Electric clothes washer-dryers for household use - Methods for

measuring the performance

Lavantes-séchantes électriques à usage domestique - Elektrische Wasch-Trockner für den Hausgebrauch -

Méthodes de mesure de l'aptitude à la fonction Prüfverfahren zur Bestimmung der

Gebrauchseigenschaften

This amendment A11 modifies the European Standard EN IEC 62512:2020; it was approved by CENELEC on 2020-10-21. CENELEC

members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this amendment the

status of a national standard without any alteration.

Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC

Management Centre or to any CENELEC member.

This amendment exists in three official versions (English, French, German). A version in any other language made by translation under the

responsibility of a CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the same status as

the official versions.

CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the

Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique

Europäisches Komitee für Elektrotechnische Normung

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CENELEC All rights of exploitation in any form and by any means reserved worldwide for CENELEC Members.

Ref. No. EN IEC 62512:2020/A11:2020 E

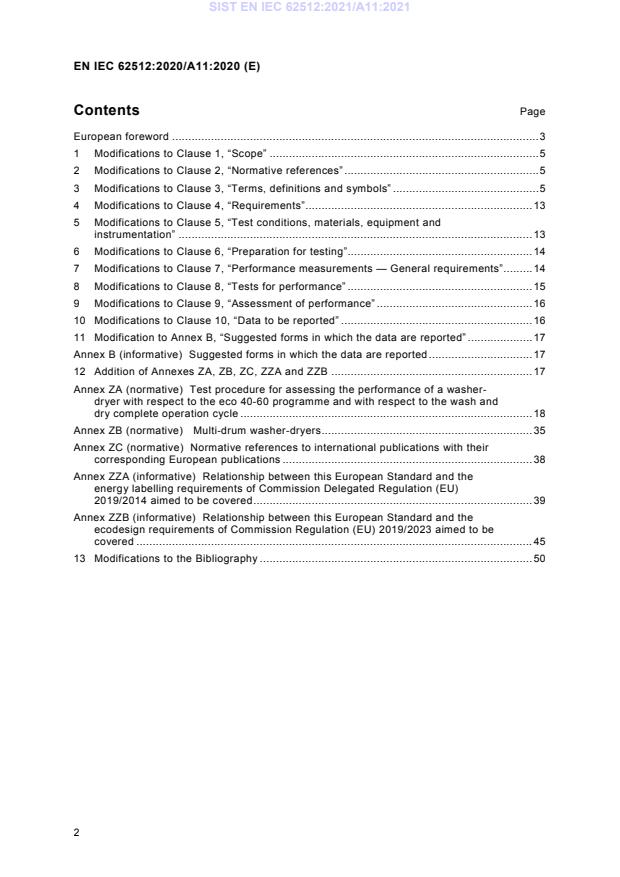

Contents Page

European foreword . 3

1 Modifications to Clause 1, “Scope” . 5

2 Modifications to Clause 2, “Normative references” . 5

3 Modifications to Clause 3, “Terms, definitions and symbols” . 5

4 Modifications to Clause 4, “Requirements”. 13

5 Modifications to Clause 5, “Test conditions, materials, equipment and

instrumentation” . 13

6 Modifications to Clause 6, “Preparation for testing”. 14

7 Modifications to Clause 7, “Performance measurements — General requirements” . 14

8 Modifications to Clause 8, “Tests for performance” . 15

9 Modifications to Clause 9, “Assessment of performance” . 16

10 Modifications to Clause 10, “Data to be reported” . 16

11 Modification to Annex B, “Suggested forms in which the data are reported” . 17

Annex B (informative) Suggested forms in which the data are reported . 17

12 Addition of Annexes ZA, ZB, ZC, ZZA and ZZB . 17

Annex ZA (normative) Test procedure for assessing the performance of a washer-

dryer with respect to the eco 40-60 programme and with respect to the wash and

dry complete operation cycle . 18

Annex ZB (normative) Multi-drum washer-dryers . 35

Annex ZC (normative) Normative references to international publications with their

corresponding European publications . 38

Annex ZZA (informative) Relationship between this European Standard and the

energy labelling requirements of Commission Delegated Regulation (EU)

2019/2014 aimed to be covered . 39

Annex ZZB (informative) Relationship between this European Standard and the

ecodesign requirements of Commission Regulation (EU) 2019/2023 aimed to be

covered . 45

13 Modifications to the Bibliography . 50

European foreword

This document (EN IEC 62512:2020/A11:2020) consists of the text of IEC 62512:2012 prepared by

IEC/SD 59, "Home laundry appliances", together with the common modifications prepared by CLC/TC

59X "Performance of household and similar electrical appliances".

The following dates are fixed:

• latest date by which this document has to be (dop) 2021-07-21

implemented at national level by publication of

an identical national standard or by

endorsement

• latest date by which the national standards (dow) 2023-10-21

conflicting with this document have to be

withdrawn

This document supersedes EN 50229:2015.

Significant technical differences are:

a the definition of the loads to be tested in continuous, segmented and interrupted operation cycles;

b the method for testing automatic and not automatic operation of the drying cycles;

c the way to handle the load for interrupted operation cycles;

d the correction to be applied to test results for continuous and interrupted operation cycles;

e the definition of a procedure for a segmented operation cycle to simulate a continuous wash and

dry cycle, if the machine does not offer those programme setting;

f the test procedure for the performance measurements for multi-drum washer dryers according to

EU energy label regulation.

This document also specifies, as far as necessary, the test method for household washing machines in

accordance with the COMMISSION DELEGATED REGULATION (EU) 2019/2014 of 11 March 2019

supplementing Regulation 2017/1369 of the European Parliament and of the Council with regard to

energy labelling of household washing machines and household washer-dryers and repealing

Commission Regulation (EU) No 1061/2010 and Commission Directive 96/60/EC and in accordance

with the COMMISSION REGULATION (EU) 2019/2023 of 1 October 2019 laying down ecodesign

requirements for household washing machines and household washer-dryers pursuant to Directive

2009/125/EC of the European Parliament and of the Council, amending Commission Regulation (EC)

No 1275/2008 and repealing Commission regulation (EU) No 1015/2010.

Clauses, notes, tables, figures and annexes which are additional to those in IEC 62512:2012 are

prefixed “Z”.

Annex ZA sets out the procedure to be applied for testing according to Commission Regulations with

regard to energy labelling and ecodesign and provides all necessary links to all relevant clauses of this

document.

This document has been prepared in view of the upcoming Standardization Request which will be given

to CENELEC by the European Commission and the European Free Trade Association and supports

Commission Delegated Regulation (EU) 2019/2014 and Commission Regulation (EU) 2019/2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CENELEC shall not be held responsible for identifying any or all such patent rights.

Classified as Internal

For the relationship with Commission Delegated Regulation (EU) 2019/2014 and Commission

Regulation (EU) 2019/2023 informative Annex ZZA and Annex ZZB will be published following the

adoption of the Standardization Request.

Endorsement notice

The text of the International Standard IEC 62512:2012 was approved by CENELEC as a European

Standard with agreed common modifications.

1 Modifications to Clause 1, “Scope”

Add after the second paragraph of the Scope the following:

"This document provides a measurement procedure for EU regulations on ecodesign and energy

labelling on household combined washer-dryers in their function to wash and dry textiles"

Replace the Note in the Scope with:

"NOTE Washer-dryers for communal use in blocks of flats or in launderettes are also included within the scope

of this document. It does not apply to washer-dryers for commercial laundries."

2 Modifications to Clause 2, “Normative references”

In Clause 2, delete IEC 60704-2-4 and IEC 60704-2-6.

Add the following standards:

"EN IEC 60704-2-16:2019 + A11:2020, Household and similar electrical appliances — Test code for the

determination of airborne acoustical noise — Part 2-16: Particular requirements for washer-dryers

EN 60335-2-7:2010, Household and similar electrical appliances — Safety — Part 2-7: Particular

requirements for washing machines

CLC/TS 50677, Clothes washing machines and washer-dryers for household and similar use — Method

for the determination of rinsing effectiveness by measurement of the surfactant content at textile

materials

CLC/TS 50707:2020, Clothes washing machines and washer-dryers for household and similar use —

Method for the determination of the maximum temperature inside the load"

3 Modifications to Clause 3, “Terms, definitions and symbols”

Add table before 3.1.1

Table 3.1 – Reference table for terms and definition in alphabetical order

sub-clause

terms and definition

automatic drying 3.1.9

combined cycle time 3.1.Z10

combined programme time 3.1.Z9

combined rated capacity 3.1.Z8

complete operation cycle 3.1.4

continuous operation cycle 3.1.5

drying cycle 3.1.8

eco 40-60 3.1.Z11

end of programme 3.1.10

final moisture content 3.1.Z2

Classified as Internal

sub-clause

terms and definition

full load 3.1.Z13

half load 3.1.Z14

interrupted operation cycle 3.1.6

multi-drum mode washer-dryer 3.1.Z5

multi-drum washer-dryer 3.1.Z4

part A 3.1.Z15

part B 3.1.Z16

3.1.2

rated drying capacity

rated washing capacity 3.1.1

rated washing-drying capacity 3.1.3

segmented operation cycle 3.1.Z3

simultaneous cycle 3.1.Z7

simultaneous programme 3.1.Z6

treatment 3.1.Z17

treatment full 3.1.Z18

treatment half 3.1.Z19

wash and dry cycle 3.1.Z12

3.1.Z1

washer-dryer

washing cycle 3.1.7

In Clause 3, replace the terms 3.1.1, 3.1.2, 3.1.3, 3.1.5 and 3.1.8 with the following:

3.1.1

rated washing capacity

maximum mass of conditioned textiles which the manufacturer declares can be treated in one complete

washing cycle; for multi-drum mode washer-dryers the rated washing capacities are for each

individual drum

Note 1 to entry: For different textile types, the rated washing capacity of a multi-drum washer-dryer is usually

different.

3.1.2

rated drying capacity

maximum mass of conditioned textiles which the manufacturer declares can be treated in one complete

drying cycle; for multi-drum mode washer-dryers the rated drying capacities are for each individual

drum

Note 1 to entry: For different textile types, the rated drying capacity of a multi-drum washer-dryer is usually

different.

3.1.3

rated washing-drying capacity

maximum mass of conditioned textiles which the manufacturer declares can be treated in one

continuous operation cycle; for multi-drum mode washer-dryers the rated washing-drying

capacities are for each individual drum

Note 1 to entry: For different textile types, the rated washing-drying capacity of a multi-drum washer-dryer is

usually different.

3.1.5

continuous operation cycle

complete operation cycle without interruption of the process or additional action by an operator

3.1.8

drying cycle

complete drying process, as defined by the required programme, consisting of a series of different

operations (heat, spin, cool down, .)

In Clause 3, add the following items:

3.1.Z1

washer-dryer

washing machine which, in addition to the functions of an automatic washing machine, in the same drum

includes a means for drying the textiles by heating and tumbling

3.1.Z2

final moisture content

moisture content of a base load at the end of a drying cycle

3.1.Z3

segmented operation cycle

interrupted operation cycle where the whole load remains in the drum after the washing cycle and is

used for the drying cycle

3.1.Z4

multi-drum washer-dryer

washer-dryer equipped with more than one drum whether in separate units or in the same casing

offering the washing and drying function for all of these drums

3.1.Z5

multi-drum mode washer-dryer

program where some or all of the drums are operated simultaneously in the washing and drying cycle

Note Z1 to entry: A washer-dryer with more than one drum for the treatment of the textiles, where drums cannot

be operated simultaneously is not regarded as having a multi-drum mode. In this case each drum shall be tested

separately.

Note Z2 to entry: A washer-dryer with more than one drum for the treatment of the textiles where multi-drum

mode is only available for the washing cycle but not for the drying cycle is not regarded as a multi-drum washer-

dryer. Only the washer cycle is regarded and evaluated as a multi-drum appliance while for the wash and dry

cycle, this appliance is regarded as a single drum unit.

Note Z3 to entry: This definition may apply only for specific programmes. In this case only, these programmes

can be tested in multi-drum mode.

Classified as Internal

3.1.Z6

simultaneous programme

series of operations which are pre-defined within the multi-drum washer-dryer and which are declared

by the manufacturer as suitable for washing and drying certain textile types in two or more drums at the

same time

3.1.Z7

simultaneous cycle

complete wash and dry cycle, started at the same time for two or more drums, as defined by the

programme selected, consisting of a series of operations (wash, rinse, spin, etc.) and including any

operations that occur after the completion of the programme

Note Z1 to entry: Examples of operations that could occur after the completion of the programme are pumping,

monitoring and anti-creasing (where applicable).

3.1.Z8

combined rated capacity

sum of rated capacities of all drums suitable for running a simultaneous programme

3.1.Z9

combined programme time

the time from the simultaneous initiation of the programme for two or more drums (excluding any user

programmed delay) until the end of the simultaneous programme; if the end of programme is not

indicated, the combined programme time is equal to the combined cycle time

3.1.Z10

combined cycle time

time from the simultaneous initiation of the programme for two or more drums (excluding any user

programmed delay) until all activity ceases; activity is considered to have ceased when the power

consumption reverts to a steady state condition that persists indefinitely without user intervention; if

there is no activity after the end of the programme, the combined cycle time is equal to the combined

programme time

Note Z1 to entry: Cycle time includes any activity that could occur after the programme is completed. This could

include any electronic activity or any additional mechanical activity that occurs for a limited period after any end of

programme indicator. Any cyclic event that occurs indefinitely is considered to be steady-state

3.1.Z.11

eco 40-60

name of the programme to be able to clean normally soiled cotton laundry declared to be washable at 40 °C or

60°C, together in the same washing cycle

3.1.Z12

Wash and dry cycle

complete operation cycle consisting of the eco 40-60 programme for the washing cycle, and of a

drying cycle achieving cupboard dry status

3.1.Z13

full load

test load to be used for a test series according to Annex ZA, having a nominal mass that is equal to

the rated washing-drying capacity

3.1.Z14

half load

test load, part A or part B, to be used for a test series according to Annex ZA, having a nominal mass

that is approximately equal to a half of the rated washing-drying capacity

3.1.Z15

part A

one half of the full load

3.1.Z16

part B

remaining part of the full load excluding part A

3.1.Z17

treatment

combination of test load and programme to be used for a test run within a test series

3.1.Z18

treatment full

wash and dry cycle with full load

3.1.Z19

treatment half

wash and dry cycle with half load

In 3.2, replace Table 1 as follows:

Table 3.2 — Symbols for application in this document

Clause

Symbol in

Symbol in this (first

Unit Definition

document appearance)

IEC 62512:2012

C reflectance value after wash and dry for the ZA.6.3

k

test run (equal to C )

z,i

C average sum of the reflectance values for the ZA.5.3

ref

reference machine out of all 5 test runs

C average value for the sum of the reflectance ZA.5.3

z

values for treatment z (z = full, 1/2)

C sum of the average reflectance values (Y- ZA.5.3

z,i

values) of test run i for treatment z (z = full,

1/2)

DL

l g/kg ratio of mass of detergent per kg of load of ZA.6.3

test run

EEI Energy Efficiency Index of a test machine for ZA.5.8

the wash and dry cycle

i - number of test run ZA.4.4

I Washing Efficiency Index for the test series ZA.5.3

W

I Washing Efficiency Index for treatment z ZA.5.3

W,z

(z = full, 1/2)

m0 W0 g mass of the conditioned base load 8.3.3.1

m0c W0c g total conditioned mass of the base load for 9.1

the continuous operation cycle

m W g total conditioned mass of the first partial 8.3.3.2

0p 0p

load p of the base load

m g Mass of detergent used for the test run ZA.6.3

det

Classified as Internal

Clause

Symbol in

Symbol in this (first

Unit Definition

document appearance)

IEC 62512:2012

m g Mass of base load for before the test run ZA.6.3

dry

(without test strips)

m W g mass of the load at the end of the test run 9.1

f f

(either W or W )

fp fc

m W g mass of the load at the end of the test run 9.1

fc fc

for complete operational cycle

m W g mass of the load at the end of the test run 7.3.3.3

fp fp

for partial load

m g mass of the conditioned full load ZA.5.4

full,0

m g mass of the full load at the end of the test ZA.5.4

full,f,i

run i (i = 1, 2, 3)

m W g mean value of the initial mass Annex B

i i

m W g actual initial mass of the first partial load p 8.3.3.2

ip ip

of the base load after the washing cycle

m g mass of the conditioned half load ZA.5.4

part,0

(part = part A, part B)

m g mass of the half load part (part = part A, part ZA.5.4

part,f,i

B) at the end of the test run i (i = 1, 2, 3, 4)

n number of test runs for treatment z (z = full, ZA.5.2

z

1/2)

p

c kPa laboratory supply water pressure cold for the ZA.6.3

test run

p kPa laboratory supply water pressure hot for the ZA.6.3

h

test run

R rinsing effectiveness for the test series

max g/kg ZA.5.9

R

z g/kg average ratio of mass of detergent per kg of ZA.5.9

load for treatment z (z = full, 1/2)

s weighted pooled standard deviation for test ZA.5.2

series

s standard deviation for treatment z (z = full,

z ZA.5.2

1/2)

SCE kWh standard energy consumption ZA.5.8

c

t t min (corrected) programme duration drying Annex B

d d

t t min drying time Annex B

dp dp

t min main wash duration for the test run ZA.6.3

m

t min programme time for the test run ZA.6.3

t

t t min programme duration washing Annex B

w w

t t min (corrected) programme duration of the Annex B

wd wd

complete operation cycle

t

z min average value for the programme time for ZA.5.6

treatment z (z = full, 1/2)

Clause

Symbol in

Symbol in this (first

Unit Definition

document appearance)

IEC 62512:2012

t min programme time of test run i for treatment ZA.5.6

z,i

z (z = full, 1/2)

V L weighted average value for the total water ZA.5.5

consumption for the test series

V L cold water consumption during main wash ZA.6.3

cm

for the test run

V L total cold water consumption for the test run ZA.6.3

ct

V L L (corrected) water consumption drying Annex B

d d

V L hot water consumption during main wash for ZA.6.3

hm

the test run

V L total hot water consumption for the test run ZA.6.3

ht

V L total water consumption (cold + hot) for the ZA.6.3

t

test run

V L L water consumption washing Annex B

w w

V L L (corrected) water consumption of the Annex B

wd wd

complete operation cycle

V L average value for the total water ZA.5.5

z

consumption for treatment z (z = full, 1/2)

V

z,i L total water consumption of test run i for ZA.5.5

treatment z (z = full, 1/2)

W kWh weighted average value for the total energy ZA.5.7

consumption for the test series

W E kWh corrected energy consumption of the drying 9.1

d d

cycle

W

et kWh total electrical energy metered for the test ZA.6.3

run

W kWh calculated total hot water energy determined ZA.6.3

ht

for the test run

W E kWh measured energy consumption 9.1

m m

W

total kWh total electrical energy consumption for the ZA.6.3

test run (equal to W )

z,i

W E kWh corrected energy consumption washing Annex B

w w

W E kWh corrected energy consumption of the Annex B

wd wd

complete operation cycle

W kWh average value for the total energy ZA.5.7

z

consumption for treatment z (z = full, 1/2)

W kWh total energy consumption of test run i for ZA.5.7

z,i

treatment z (z = full, 1/2)

Classified as Internal

Clause

Symbol in

Symbol in this (first

Unit Definition

document appearance)

IEC 62512:2012

the average reflectance value of the 4

x ZA.6.3

i

individual readings for each of the 5 soil

types on a stain test strip

x is the value of test run i for treatment z ZA.5.2

i,z

(z = full, 1/2)

average value for treatment z (z = full, 1/2) ZA.5.2

x

z

z

- treatment z (z = full, 1/2) ZA.5.2

ϑ °C ambient temperature (test room) for the test ZA.6.3

a

run

ϑ °C laboratory supply cold water inlet ZA.6.3

c

temperature for the test run

ϑ °C laboratory supply hot water inlet temperature ZA.6.3

h

for the test run

ϑ Average maximum temperature for the test

max °C ZA.6.3

run

ϑ °C Average maximum temperature of the ZA.6.3

max,z

washing cycle for treatment z (z = full, 1/2)

μ average value for final moisture content for

1/2 % ZA.5.4

treatment half

μ μ % final moisture content 9.1

f f

μ μ % target final moisture content (given as 0 % 8.3.3.1

f0 f0

in EU regulations)

μ % average value for final moisture content for ZA.5.4

full

treatment full

μ % final moisture content for single test run i ZA.5.4

full,i

(i = 1, 2, 3) with full load

μ μ actual initial moisture content of the first

ip ip % 8.3.3.2

partial load p of the base load after the

washing cycle

μ value for the final moisture content for the

% ZA.5.4

test series

μ % final moisture content for single test run i ZA.5.4

part,i

(i = 1, 2, 3, 4) with half load (part = part A,

part B)

4 Modifications to Clause 4, “Requirements”

In Clause 4, replace the entire text as follows:

"4.1 General

The requirements shall be in accordance with Clause 4 of EN 60456:2016+A11:2020 and of

EN 61121:2013+A11:2019 as appropriate.

4.2 Rated Capacity

The rated washing-drying capacity shall be declared by the manufacturer or supplier as the maximum

mass of cotton textiles, to be washed and dried in a wash and dry cycle without interruption in kg at

0,5 kg intervals given in any user information.

The rated washing-drying capacity for any textile type shall not exceed the maximum mass of dry

laundry, in kg, to be used in the washer-dryer in accordance with 3.1.9 of EN 60335-2-11:2010.

If the rated washing-drying capacity is not declared, it shall be deduced from the volume of the drum

according to EN 61121:2013+A11:2019, Annex E.

If the household washer-dryer does not provide continuous operation cycles, the rated washing-

drying capacity shall be the lowest value between the rated washing capacity and the rated drying

capacity.

If the rated drying capacity in kg at 0,5 kg intervals is not declared, it shall be deduced from the volume

of the drum according to EN 61121:2013 + A11:2019, Annex E.

If the rated washing capacity in kg at 0,5 kg intervals is not declared, it shall be deduced from the

volume of the drum according to EN 60456:2016 + A11:2020 , Annex N.

5 Modifications to Clause 5, “Test conditions, materials, equipment and

instrumentation”

In 5.1, replace the entire text as follows:

"Test conditions, materials, equipment and instrumentation shall be in accordance with Clause 5 of

EN 60456:2016 + A11:2020; however, 5.2.2 and 5.2.3 of the same standard are modified as follows."

In Clause 5, add the following subclauses:

5.2 Water supply

The water supply shall be in accordance with 5.2.2 of EN 60456:2016 + A11:2020.

5.3 Ambient temperature and humidity

Ambient temperature and humidity shall be in accordance with 5.2.3 of EN 61121:2013 + A11:2019.

5.4 Test materials

The specifications for base loads, stain test strips and detergent used for testing washer-dryers shall

be in accordance with 5.3 of EN 60456:2016 + A11:2020.

Classified as Internal

5.5 Equipment

The specification for the reference machine is given in 5.4.2 of EN 60456:2016 + A11:2020. The type

1 reference machine according to Annex D of EN 60456:2016 + A11:2020 shall be used.

Specifications for other specialized test equipment required for washer-dryer testing to this document,

including the spectrophotometer, equipment for conditioning the base load and the iron shall be in

accordance with 5.4.3, 5.4.4 and 5.4.6 of EN 60456:2016 + A11:2020 and in accordance with 5.5 of

EN 61121:2013 + A11:2019. Where these two standards give different values, the smaller value shall

apply.

A checklist of other laboratory equipment which could be required for washer-dryer testing is provided

in 5.4.8 of EN 60456:2016 + A11:2020.

5.6 Instrumentation and accuracy

Instruments used and measurements made according to this document shall comply with the

specifications given in 5.5.2 and 5.5.3 of EN 60456:2016 + A11:2020 and EN 61121:2013 + A11:2019,

5.5, whichever is more precise."

6 Modifications to Clause 6, “Preparation for testing”

At the end of Clause 6, add the following paragraph:

For the test series according to Annex ZA the preparation for testing shall be in accordance with clause

6 of IEC 60456:2010 and with 6.1, 6.3 and 6.4 of IEC 61121:2012

"For the test series according to Annex ZA the load preparation shall be in accordance with ZA.2."

7 Modifications to Clause 7, “Performance measurements — General

requirements”

In Clause 7, add the following:

"The requirements in EN 60456:2016 + A11:2020, Clause 7 related to the combined test series of the

eco 40-60 programme with full load, half load and quarter load according to

EN 60456:2016+A11:2020, Annex ZA is also applicable for the washer-dryer to measure the

performance of the washing program.

For the test series of the wash and dry cycle with full load and half load according to Annex ZA of

this document, the following parameters shall be selected:

The load type shall be cotton.

The following parameters shall be measured for the wash and dry cycle using a test series consisting

of 7 test runs and using two load sizes (full load and half load) as set out in Annex ZA:

— washing performance;

— drying performance;

— programme time;

— energy consumption;

— water consumption;

— rinsing effectiveness;

— temperature inside the load;

— power consumption of low power modes (not related to the test series).

The following parameters shall be measured for the reference washing machine using a test series

consisting of 5 runs as set out in EN 60456:2016 + A11:2020, Clause 8 and using a 5,00 kg cotton test

load as defined for the reference washing machine:

— washing performance;

— water extraction performance;

— spin speed;

— programme time;

— energy consumption;

— water consumption.

The evaluation of these parameters for the washer-dryer is specified in Annex ZA. The evaluation of

these parameters for the reference washing machine is specified in EN 60456:2016 + A11:2020,

Clause 9.

Programmes to be tested for washer-dryers:

If the washer-dryer is offering a continuous wash and dry cycle a combined programme setting of

the eco 40-60 programme shall be used combined with a drying programme setting for cotton load

with the drying target cupboard dry according to manufacturer’s instruction. If the washer-dryer is

offering an automatic drying function, the selected drying programme shall be an automatic program.

Exactly the same programme setting for the eco 40-60 programme with cotton cupboard dry setting

shall be used for the test runs with full load and half load.

If the washer-dryer is not offering continuous wash and dry cycle a segmented wash and drying

cycle shall be executed. This consists of the eco 40-60 programme and a drying programme for cotton

load with the drying target “cupboard dry” according to manufacturer’s instruction. If the washer-dryer

is offering an automatic drying function, this shall be an automatic program. Exactly the same

programme setting for the eco 40-60 programme and the cotton cupboard dry programme shall be

used for all the test runs with full load and half load.

If the washer-dryer is not offering automatic drying, a timer-controlled programme shall be used for

the drying. The timer setting shall be estimated by pre-test runs to achieve the requested cupboard dry

target.

Selected water hardness shall be hard water; refer to Clause 5.2.2.2 of EN 60456:2016 + A11:2020."

8 Modifications to Clause 8, “Tests for performance”

In 8.2, replace the second paragraph as follows:

"The rinsing effectiveness measurement for the combined test series of the eco 40-60 programme

with full load, half load and quarter load according to Annex ZA of EN 60456:2016 + A11:2020 and

for the test series of the wash and dry cycle with full load and half load according to Annex ZA of

this document shall be done in accordance with ZA.4.9."

In 8.3.3.1, replace the first paragraph as follows:

"The mass of the conditioned base load shall be recorded as m ."

In 8.3.3.1, add after third paragraph:

"For the test series of the wash and dry cycle according to Annex ZA with full load and half load the

base loads shall be dried to a nominal target final moisture content value of 0 %, which is the

thermodynamic equilibrium of the load with the ambient air temperature at 20 ± 2 °C and relative

humidity at 65 ± 5 %."

In 8.3.3.1, add the following after the sixth paragraph:

"For the test series of the wash and dry cycle according to Annex ZA with full load and half load the

invalid test runs shall be identified based on the description in ZA.4.4 only. The final moisture content

shall not be used to identify invalid test runs."

In 8.3.3.1, add at the end of the subclause:

"For the test series of the wash and dry cycle according to Annex ZA with full load and half load, the

procedure for additional time drying cycles in cases where the final moisture content exceeds the

upper limit of the range is not applicable.

The final moisture content from the test runs shall be reported and evaluated without additional time

drying programmes."

In 8.3.3.2, replace the symbol W by m and W by m .

ip ip 0p 0p

Classified as Internal

In 8.3.3.2, add the following at the end of the subclause:

"If the washer-dryer does not offer a continuous wash and dry cycle for the test series with full load

and half load according to Annex ZA, the procedure for the segmented operation cycle set out in

ZA4.12 shall be followed."

In 8.3.3.3, replace the symbol W by m .

fp fp

In 8.3.4, add the following at the end of the subclause:

"For the test according to Annex ZA, the determination of the low power modes shall be made according

to ZA.4.9 of EN 60456:2016 + A11:2020."

9 Modifications to Clause 9, “Assessment of performance”

In 9.1, add the following at the beginning of the subclause:

"For the test series of the wash and dry cycle according to Annex ZA with full load and half load, the

assessment of performance shall be according to ZA.5."

In 9.1 replace all of the symbols as shown in Table 1.

In 9.1, replace the third bullet of step 2 as follows:

— " For the continuous operation cycle and the segmented operation cycle the corrected energy

consumption of the drying cycle W shall be expressed in kWh and calculated as follows (the

d

evaporation energy of the water is considered):

(𝜇𝜇 −𝜇𝜇 )

𝑓𝑓 𝑓𝑓0

𝑊𝑊 =𝑊𝑊 + ×𝑚𝑚 × 0,000628 kWh/g

𝑑𝑑 𝑚𝑚 0𝑐𝑐

100 %

where

0,000628 kWh/g is the evaporation energy of the water;

W is the measured energy consumption;

m

μ is the final moisture content;

f

is the target final moisture content;

μf0

m0 is the total mass of the conditioned base load for the continuous operation

c

cycle and the segmented operation cycle.

NOTE The continuous operation cycle and segmented operation cycle have a higher uncertainty in the

measured values, because different correction formulas are applied in relation to the interrupted operation

cycle. Therefore, these values cannot be compared to an interrupted operation cycle."

In bullets 2, 4 and 6 of step 3 in 9.1, add the phrase: “(in accordance with Clause 9 of EN 60456)” after

“according to 8.3.2”.

In 9.1, modify the first sentence of the last bullet of step 3 as follows:

"Rounding shall only be applied to reported values in Annex B and ZA.6."

In 9.2, replace the entire text with the following:

"Noise emission values shall be measured in accordance with EN 60704-2-16.

For test runs according ZA noise emission values shall be measured in the eco 40-60 programme

using the full rated washing capacity in accordance to EN 60704-2-16."

10 Modifications to Clause 10, “Data to be reported”

In Clause 10, add the following paragraph:

"For the test series for the wash and dry cycle with full load and half load according to Annex ZA,

data to be reported for the test washer-dryer are included in ZA.6. The relevant data for the reference

machine shall be reported according Annex S of EN 60456:2016 + A11:2020."

11 Modification to Annex B, “Suggested forms in which the data are reported”

Annex B

(informative)

Suggested forms in which the data are reported

In Annex B, replace all of the symbols as shown in Table 1.

12 Addition of Annexes ZA, ZB, ZC, ZZA and ZZB

Addition of the following annexes:

NOTE Annex ZA of EN IEC 62512:2020 is deleted and its content added in new Annex ZC in this document.

Classified as Internal

"

Annex ZA

(normative)

Test procedure for assessing the performance of a washer-dryer

with respect to the eco 40-60 programme and with respect to the

wash and dry complete operation cycle

ZA.1 General

ZA.1.1 Intent

The intent of the procedures as set out in this Annex is the determination of performance and related

parameters for

a) Full load, half load and quarter load for the washing cycle of a washer-dryer. Testing of the

washing cycle of the washer-dryer shall be performed according to EN 60456:2016+A11:2020.

b) Full load and half load for the complete operation cycle of a washer-dryer.

ZA.1.2 Complete operation cycle

ZA.1.2.1 Programme setting

The programme setting for the complete operation cycle shall be the wash and dry cycle as

described in chapter 7.

ZA.1.2.2 Treatments

The test series to measure the performance and related parameters of the wash and dry cycle is

defined as a test series of the complete operation cycles consisting of 2 treatments with 7 test runs

in total, as follows:

— treatment full: 3 test runs;

— treatment half: 4 test runs.

The reference washing machine shall be operated in parallel using the defined load size of 5,00 kg

with a test series of 5 test runs using the IEC Cotton 60 °C programme.

NOTE ZA.4.4 describes the parallel operation of the reference washing machine and the test washer-dryer.

ZA.1.2.3 Rounding

Rounding of calculated values shall be handled according to Clause 9.1.

If a value reported in ZA.6 is an intermediate required for use in the calculation of other values, then

rounding shall only apply to the format of the intermediate in ZA.6; the rounding shall not apply prior to

its use in subsequent calculations.

ZA.2 Preparation for testing: Test loads

The requirements for the preparation of the full load and half load used in the test washer-dryer and

the test load used in the reference machine shall be in accordance with Clause 6 of EN 60456:2016

+ A11:2020. All requirements of Clause 6.4 of EN 60456:2016 + A11:2020 are applied to define the full

load for a test series. For the test runs with half load the full load shall be split into two parts. ZA.2

of EN 60456:2016 + A11:2020 defines the splitting of the full load into the two half loads (part A

and part B).

ZA.3 Performance measurements – general requirements: Preparation of the

test machine for a test series

The complete energy label test consists of 2 test series. One is the eco 40-60 programme and the

other is the wash and dry cycle. The preparation of the test washer-dryer following Clause 6.2.1.3 of

EN 60456:2016 + A11:2020 is applicable for both test series regardless which is the first in the

performance test. For the test series of the wash and dry cycle additionally Clause 6.4 of

EN 61121:2013 + A11:2019 shall be applied.

Performance parameters shall be measured for the test machine using two test series consisting of a

total of 17 test runs.

In one combined test series with 3 treatments with 10 test runs, the performance of the eco 40-60

programme with full load, half load and quarter load shall be measured according to ZA.4 of

EN 60456:2016 + A11:2020. The evaluation of these parameters for the test machine is specified in

ZA.5 of EN 60456:2016 + A11:2020. The data to be reported for this test series are specified in ZA.6

of EN 60456:2016 + A11:2020.

In another test series with 2 treatments with 7 test runs the performance of the wash and dry cycle

with full and half of the rated washing-drying capacity shall be measured as set out in ZA.4. The data

to be reported for this test series are specified in ZA.6

For each test series performance parameters shall be measured for the reference washing

machine using a single test series consisting of a total of 5 test runs as set out in Clause 8 of

EN 60456:2016 + A11:2020. The order of test runs for the reference washing machine and for the

test series of the wash and dry cycle is set out in clause ZA.4.4.

The evaluation of these parameters for the reference washing machine is specified in Clause 9 of

EN 60456:2016 + A11:2020.

ZA.4 Procedure for performance tests

ZA.4.1 General

This Clause sets out the additional requirements for the test procedure defined in Clause 8. The

following performance parameters (excluding power consumption in low power modes) shall be

measured using a cotton load in a single test series for the test machine:

— washing performance (see ZA.4.5);

— drying performance (see ZA.4.6);

— energy consumption, water consumption and programme time (see ZA.4.7);

— power consumption of low power modes (see ZA.4.8);

— rinsing effectiveness (see ZA.4.9);

— temperature inside the load (see ZA.4.10).

Classified as Internal

For the assessment of the washing performance the results from the test machine are compared to the

result from the reference machine which is operated in parallel.

ZA.4.2 Test load and loading

The test load composition and the loading sequence shall be in accordance to ZA 4.2 of EN 60456:2016

+ A11:2020.

ZA.4.3 Programmes to be tested on the test washer-dryer

The test runs shall be carried out with a programme selection set out in the amendments to Clause 7

of this document.

The reference programme to be used on the reference machine shall be cotton 60 °C as defined on

the programme memory card labelled EN 60456:2011, IEC 60456 Ed.5 or higher supplied by the

manufacturer of the reference machine.

ZA.4.4 Order of test runs for the test washer-dryer and the reference machine

This procedure applies to the test washer-dryer and the reference machine which shall be run in

parallel as explained below.

The following 7 test runs are required for the test washer-dryer:

— 4 test runs with treatment half;

— 3 test runs with treatment full.

For the reference machine 5 test runs cotton 60 °C (one test per day) with a 5,00 kg test load shall

be carried out.

For the test machine, each part of full load and half load shall be used for 5 runs as follows:

Part A and part B shall be used twice with treatment half as shown in Figure ZA.1. Part A and part B

together (i.e. the complete load) shall be used for 3 test runs with treatment full.

The detailed order of test runs is as follows:

Day 6:

• Test run 11: test washer dryer with treatment half using part A

Test run 1 of the reference machine shall be carried out in parallel to test run 11 of the test

washer dryer.

Day 7:

• Test run 12: test washer dryer with treatment half using part A

Day 8:

• Test run 13: test washer dryer with treatment half using part B

Test run 2 of the reference machine shall be carr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...